When arranging a home interior, the question of organizing a place to store household items, belongings, and small accessories certainly arises. For this purpose, various cabinets, chests of drawers, wardrobes, and shelves are provided. However, such furniture is more suitable for storing large, medium-sized items. It is much more convenient to store various small things in drawers. This article discusses their main advantages and provides detailed manufacturing instructions.

Convenient storage of small parts in drawers

Advantages of drawers

The main task when arranging a home interior is to create a comfortable, functional, practical space. Ordinary cabinets cannot always cope with this task. In standard furniture, part of the space remains empty - you simply cannot reach there with your hand. Things that are in constant use should always be at hand. Drawers will help you store items easily.

Kitchen drawers allow you to place the necessary utensils as compactly and functionally as possible.

Such systems have become simply irreplaceable. They save space, have an attractive appearance, and are easy to assemble yourself. They are very convenient for storing underwear, cosmetics, kitchen utensils, towels, shoe laces, and other small items. Such furniture is needed in any room.

Very convenient drawers for shoes

Drawers for storing jewelry

How to make a kitchen set yourself

Not many people have the creativity to imagine exactly what their kitchen will look like. Usually, for this purpose, they turn to designers who form a design project and provide a finished sketch, created at the request of the customer. But, in the case of creating a kitchen with our own hands, we want to save as much money as possible. In order to estimate the appearance of the furniture, choose the style and design, materials, facades, etc., you can use the online kitchen designer on our website.

3D online kitchen designer

Having entered the required dimensions of the room, you can arrange all the furniture elements, “play” with the size of the cabinets, different fillings and placement. Select different materials, types of finishes, etc. What is important is that you will see the approximate cost of the kitchen when ordering it. Obviously, by making a kitchen set with your own hands, you will spend less.

So, you have decided on the composition of the furniture and household appliances, you know what will be built in and what will stand separately, for example, a refrigerator. We chose facade materials, design and finishing. How to make a kitchen out of all this?

In ours, there are several work options for those who prefer to make a kitchen set themselves:

- If you have extensive experience and knowledge of furniture design, you can independently develop all the drawings and order from us cutting, separate facades, tabletops and buy fittings . All this can be assembled and installed yourself. This option achieves maximum savings.

- If experience and knowledge are not enough, then you can measure the room yourself, visualize the kitchen in the online designer, and see the approximate cost. Our designers will make all the drawings for you according to the selected models and then produce the parts. All you have to do is assemble and install the furniture in your kitchen . Saving 15-20% of the calculation price.

- If the budget does not allow, but you want a high-quality kitchen, then you can divide the order over time into several stages: ordering cabinets, countertops and facades . This way you can pay for the kitchen in installments.

- The last option and the most common is to completely make the kitchen to order . You just tell us your wishes and preferences. Designers will draw up and approve the project, then we will produce all furniture elements, deliver and install.

Kitchen catalog

Whatever option you choose, to make a kitchen set yourself, it is better to contact a company that has experience in the production of kitchen furniture. Managers will suggest all possible options for cooperation and options for maximum savings. In Nizhny Novgorod, we are market leaders in terms of the quantity of furniture produced, we offer various production options and low prices.

Our production

Detailed video about our production

Varieties

Chipboard drawer

Chest of drawers made from furniture board

Spacious drawers are made in different sizes, shapes, and types. It is simply impossible to list all the variety of types developed by furniture technologists. Let's look at the types of such furniture, depending on the two most common classifications, in the table.

| Classification feature | Kinds |

| Case material | Chipboard. Cheap material, easy to process. Elements made from chipboard can last a long time with proper fastening and handling. |

| Furniture panels. Sold ready-made. They are distinguished by high strength and have sufficient density. Panels are more expensive than chipboards and last longer. | |

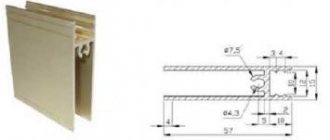

| Guides | Roller. The most popular type. Roller guides are inexpensive, have a reliable mechanism, and a simple design. |

| Telescopic. There are guides with full rollout and incomplete rollout. The first ones are more practical and allow you to fully use the space. These guides are highly reliable. They are able to withstand a lot of weight - about forty kilograms, and are more expensive. | |

| Wooden planks. The most budget-friendly, simple option. Guides of this type can be made on your own from ordinary wood. They can be used to install small drawers. |

Roller guides for partial extension drawers

Full extension telescopic slides

Rails made of slats for drawers

Do-it-yourself features

Making drawers with your own hands is quite simple, following the detailed instructions presented below. Many people will find it easier to purchase ready-made products. However, the required size is not always available.

Making furniture yourself has its own characteristics. First you need to clearly decide on the materials. An excellent option would be to purchase the following elements: chipboard for the sides, fiberboard for the bottom, full roll-out guides. This is an excellent set of materials from which you can build a good-quality box.

The next stage is creating a graphic plan. On a regular piece of paper you need to draw the components of the future product, note their sizes and attachment points. This plan will help complete the assembly as quickly as possible. The most difficult of all of the above is calculating sizes. It is difficult to determine the required dimensions by eye. Incorrectly selected drawer sizes will significantly complicate the assembly and operation process.

Cabinet assembly and finishing

It is better to order cutting of the material in a carpentry shop or in a hardware store where you purchase it; you just need to provide the specialists with sketches and drawings and ask them to number the parts. Assembly is carried out in the following sequence:

- Holes for shelf holders are drilled in the sidewalls. If the doors will cling to hinged hinges, you need to use a router with a tool for removing the holes to select the internal holes for them.

- the sidewalls, roof and bottom are connected;

- guides for drawers (if provided for by the design) and shelf holders are attached to the body;

- a backdrop is mounted or a back strip is attached;

- a false panel is attached to the sidewall, bottom and roof (if available);

- the doors are hung, the hinges are adjusted (first they are attached to the doors, then to the sides);

- if the cabinet is floor-mounted, the base and legs (if available) are mounted;

- if it is wall-mounted, the corners are screwed in for mounting on the wall;

- if the model has a tabletop, the corners are attached under it, and it is installed in place.

It is recommended to first carry out preliminary assembly on wooden dowels, if the product is assembled correctly, without distortions, and the dimensions allow it to be placed (hung) in the designated place, the dowels are coated with glue. You can additionally fasten the parts with Euroscrews. The backdrop is secured with staples using a stapler. Piano hinges are secured with self-tapping screws. At the final stage of assembly, the fittings are installed, the shelves are put in place when the cabinet is hung or put in place.

Calculation of parameters

Drawing for making a retractable furniture drawer

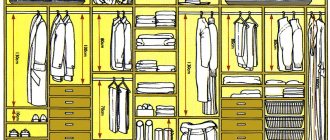

Designing drawers is not difficult. First you need to calculate the required width. It should be 26 mm less than the width of the cabinet body - its internal opening. There should be about thirteen millimeters left on each side to install the guides.

Next you need to find out the length. It will depend on the depth of the cabinet. This parameter is required when selecting guides. They come in different lengths: from 250 to 800 mm. You need to calculate the length of the products in advance, only then buy guides for it. We measure the depth of the cabinet with a regular tape measure. Don’t forget to leave a few tens of millimeters in reserve, depending on the design features of the furniture. Due to the standard dimensions of the guides, sometimes it is necessary to slightly reduce the length of the drawers.

Now is the time to decide on the height of the sides. The dimensions of the sides depend on the furniture design of the cabinet. In the production of furniture products, the rule is that the height of the drawer should be 40-50 mm less than the height of the facade. There are no reasons to deviate from this rule. The space left will provide an opportunity to correct errors and correctly adjust the operation of the finished product.

Kitchen cabinet designs

The cabinet consists of the following parts:

- the upper part (the roof; for a base cabinet it can serve as a countertop);

- lower part (bottom);

- sidewalls (for a base cabinet they usually serve as legs; a base 10-12 cm high can be made between them);

- backdrop (if the cabinet is corner, it consists of 2 parts). Sometimes, instead of a solid backdrop, a screed strip is installed between the sidewalls; a backdrop is not made if the corner floor cabinet is used as a cabinet for a sink;

- shelves.

All these parts form the body, and the cabinet also has a front. Its designs are varied:

- 2 swinging doors (for small narrow cabinets - 1);

- 1 door adjacent to the blind false panel;

- 1 or 2 doors that fold down or up; they require gas lifts and reliable latches;

- the cabinet can be completely open, or there are doors at the bottom and an open niche at the top;

- the drawer(s) can be located above the door or hidden behind it;

- an accordion door is often made in an L-shaped corner cabinet;

- if the corner cabinet is trapezoidal, the facade and sides form obtuse angles;

- In an L-shaped cabinet, the facade consists of 2 parts converging at right angles; its elements can be doors, false panels, drawer fronts.

There is also a model that occupies an intermediate position between the L-shaped and trapezoidal corner cabinet, with a front made of 3 parts. Usually this is not a solid cabinet, but a modular corner set.

The left and right sides are symmetrical with each other, the roof usually completely coincides in size with the bottom, and the tabletop should be somewhat larger and thicker. The height of a base cabinet is usually correlated with the height of the table, sink or stove, and the depth - with the depth of adjacent cabinets. The countertop, which is the lid of the cabinet, usually protrudes beyond the facade, and the internal shelves should be slightly less in depth than the bottom and lid, so as not to interfere with the closing of the doors. If the wall cabinet is located above the sink, stove, table, there should be enough vertical space between them to place tall dishes and perform various operations. This must be taken into account when drawings are drawn up and dimensions are taken.

In a corner trapezoidal cabinet, for ease of access to the contents, rotating round shelves, the so-called carousel shelves, are sometimes made. But their usable area is smaller than that of shelves that follow the shape of the bottom and top.

Therefore, the corner cabinet loses its main advantage, which is that it takes up little space, but has solid internal dimensions. Other options for internal filling are possible, but at home it is best to stick with regular shelves.

Tools, materials

To assemble drawers, you need to prepare the following list of tools and materials:

- drill (sometimes it can be replaced with a screwdriver, but you need a very powerful screwdriver);

- an electric jigsaw (it will allow you to cut chipboard as efficiently as possible, eliminating damage and chips);

- ruler;

- construction corner;

- rag;

- knife;

- pencil;

- roulette;

- nails, screws, fasteners;

- guides;

- the main material for the manufacture of the structure.

When purchasing slats and structural elements for future drawers, you need to take into account several important criteria. The first is strength, high quality. Materials must withstand loads and not lose their qualities after several years of use. The second criterion is resistance to damage. The peculiarity of such boxes is their frequent use. Pulling out the structure can easily cause minor damage. Durable material must withstand small impacts and collisions with the structure of the cabinet.