Drawers are an integral part of the kitchen interior. Moreover, these days such drawers are beginning to be actively built into other furniture that has nothing to do with storing kitchen utensils - chests of drawers and wardrobes increasingly require the presence of one or another retractable system. Drawers not only save space, but also constructively organize the space from the inside, allowing you to quickly access the things you need. We'll talk about what types of drawer systems exist and how to make a drawer with your own hands below.

How to make a drawer with your own hands

Advantages of drawers

Despite the fact that the advantages of drawers are obvious to most owners, let us briefly dwell on the main ones:

- Thanks to the drawers, access to necessary household items is greatly simplified. The opening overview allows you to immediately cover all the items in the drawer, without forcing you to go deeper into the closet or table;

- convenient design eliminates the need to interrupt all other objects cluttering the foreground in order to get to the thing you are looking for;

- You can appreciate the practicality of drawers in the kitchen, because you no longer have to clink pans and dishes, increasing the risk of them falling out. With a drawer, everything you need is at hand here and now.

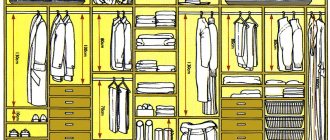

Drawers allow you to arrange items in different ways

Disadvantages of drawers

The disadvantages listed below will relate not so much to the weaknesses of the structure itself, but to the features of its manufacture, which are important to consider before starting work. These features include the following:

- price. It is logical to assume that drawers, due to additional parts, are on average more expensive than drawers for traditional cabinets that do not involve complicated mechanisms. When creating retractable cabinets, it is very important to acquire high-quality fittings, which are not cheap, but provide the drawer with a long life and correct operation;

The quality of the fittings largely determines the quality of the future drawer

- reducing the area of the box. Before you start making a drawer, it is important to be aware of what material you will use. When referring to chipboard, it is important to consider that its thickness will affect the available space, reducing it slightly compared to the expected figures;

- time costs. Drawers require more time to manufacture, especially if you are encountering them for the first time. Even professionals need to spend a lot of effort to create a high-quality structure that can last as long as possible.

Assembling a drawer requires a lot of effort and time, but the result is worth it

DIY drawer

The assembly of the box is largely determined by the individuality of the craftsman who chooses certain tools. That is why all existing instructions will differ from each other in one way or another. Some craftsmen use templates, some do not, some craftsmen work only with clamps, and some consider them a waste of time.

In this regard, the sooner you develop your own manufacturing style, the better it will affect your work.

Available materials

To install the drawer you will need the following tools:

- laminated chipboard (chipboard);

- drill and screwdriver (you can choose one);

- hexagon;

- drill;

- self-tapping screw;

- guides;

- awl;

- measuring square;

- ruler;

- pencil.

Prices for the range of drills

Drill

Step-by-step instruction

Step 1. The first and one of the most important stages in making a box is the correct marking. In order for the parts to connect, the conformation must be located in two places - below and above.

There should be two holes for future screws, as well as markings

The holes should be equidistant from the edges of the side panel

Step 2: Take a 50mm template and make a mark on the top and bottom of the board. It is not recommended to measure less than 50 millimeters, since the fittings can split the chipboard.

When creating a box, you can work without a template, but it greatly simplifies the work

Step 3. Measure half the thickness of the material from which you are assembling the box. For such purposes, it is also convenient to use a template. Repeat this procedure for the top and bottom marks.

The template performs several useful functions at once when making a box

Step 4. To prevent the drill from going away during work, tap a hole at the intersection of the two marks using a screwdriver or any other sharp object.

The hole will be needed for further drilling with a drill.

Step 5. Align the parts of the future box using a template.

Before using the drill, make sure the sides of the box are not warped.

Step 6. Take the drill and press its tip into the indentations already made to fix the tool. While drilling, try to hold the drill straight so that the hole left by it will help the guides fit correctly.

You need to drill the hole gradually so that it comes out neat.

Step 7. Insert the screwdriver into the conformat bit, then insert the conformat itself and position it in place of the hole, smoothly placing it into the recess. If you find that the box has become skewed while placing the conformat, press it out using a hand hexagon and straighten the sides, then clamp it back. To avoid inconvenience, you can use corner clamps, which will immediately give the box the correct angle of inclination.

Insert conformat into the hole made

Step 8. Turn the box over and do the same procedure with the second hole.

Repeat with the second mark

Step 9. Once all other sides of the box have been drilled using the same method, check the diagonals to make sure they match each other.

The side panels folded together should be perpendicular to each other.

Step 10. Screw the bottom to the box, first leveling it. You can use an MDF board (six) as the bottom. If desired, the plate can be coated with enamel.

Fiberboard is often used as a bottom for drawers

Video - How to assemble a drawer

Types of drawer guides

Today the range is represented by the following options:

- roller;

- ball/telescopic;

- metaboxes;

- tandemboxes;

- guides for hidden-mounted drawers.

If you focus on the method of extension, the products can be divided into:

- partial;

- complete.

Ball guides for drawers

The products consist of two rails of the same size, shaped like the letter “P”. They are also called telescopic because the elements move relative to each other. Between the tracks are small steel balls, reminiscent of those found in a bearing. The outer part of the rail is used as a movement limiter. Ball guides for drawers with or without a closer have the following advantages:

- silent movement;

- increasing the permissible load;

- high stability;

- great reliability;

- wide range of products;

- Possibility of use in special furniture.

Guides for kitchen drawers have disadvantages:

- impossibility of fixation in standard furniture;

- requirements for careful care;

- difficulty in choosing colors;

- labor-intensive installation.

Roller guides for drawers

This is the most popular and sought after mechanism. It includes two strips: one is fixed to the box, and the second to the main structure. Roller guides are made of durable sheet metal, with a protective and decorative coating in the form of powder enamel applied to its surface. There are plastic rollers on the edges along which the main elements move. This design can withstand standard operating loads for more than 10 years. Can be installed on cabinets with a load of up to 25 kg.

Roller telescopic guides for drawers have the following advantages:

- affordable cost;

- quick installation;

- trouble-free operation;

- ease of operation.

Among the disadvantages are:

- noise while driving;

- rapid wear;

- over time, deterioration in smoothness;

- incomplete extension.

Tandemboxes

The main feature of this option is retractable ball systems. A tandembox is a special collapsible box that can be made, for example, from chipboard or metal. Thanks to the guides, it extends completely and becomes stronger and easier to use. This retractable mechanism for drawers has the following advantages:

- durability;

- ease of use;

- possibility of self-adjustment;

- smooth running;

- large assortment;

- absence of noise.

Metaboxes

This is an improved version of the roller view. The design has side metal guides. Extension occurs to 3/4 of the length. Drawer guides are made from thin sheet steel of high strength. The height can be increased using roof rails. Smooth closing is ensured by closers. Metaboxes can be painted white, beige, gray and other colors. The rollers are made of plastic. Advantages:

- steel sidewalls;

- reliable bottom made of chipboard;

- suitable for large cabinets and drawers;

- easy adjustment of fasteners.

How to choose a drawer for the kitchen

Choosing a drawer for the kitchen is one of the most important stages of planning a given room, since kitchen utensils are usually the heaviest and require exceptionally high-quality designs. There are several types of boxes of different shapes depending on their purpose and the items that are intended for such boxes, be it:

- cutlery;

- dishes;

- spices;

- conservation;

- bread;

- utensils for cutting food and so on.

Drawers for the kitchen are selected individually, based on the size of the room and the customer’s goals

When choosing drawers for the kitchen, it is advisable to choose full-extension options, because only they allow you to immediately have everything at hand. Otherwise, there are several criteria that you should definitely keep in mind before purchasing a drawer:

- room layout. Before purchasing drawers or making them yourself, it is important to decide on the total number of cabinets and their location. Avoid building drawers at ninety degrees in kitchen corners. For such places it is more convenient to use ordinary shelves that save space;

Drawers can have very different areas and volumes

- degree of workload. Consider the types of items you intend to store in a particular drawer. Despite the fact that some retractable cabinets are very durable, it is not recommended to load them with kitchen utensils to a critical level - you risk sooner or later damaging the mechanisms and rendering the drawer unusable;

- quality of guides. We have already talked about how to choose suitable guides. It is advisable to give preference to those parts that are made of the most durable and thick metal, which is the key to the durability of the structure. If you have the opportunity to check the guides in practice, observe whether they make unnecessary sounds, whether they are distorted horizontally or vertically, etc.;

The quality of the guides is responsible for the strength of the entire retractable system

- box materials. In most hardware stores you will come across boxes made of chipboard or MDF, and occasionally - made of natural wood. Of course, natural wood is the highest quality material, but due to its high cost, not all buyers can afford it. However, if you have wooden boards at home, you can use them as a basis and make your own box. Otherwise, the boxes purchased should not have chips, small cracks or signs of swelling.

Selection of ball guides

To choose the right furniture guides, you need to consider:

- types of device;

- technical characteristics of guides;

- manufacturer, on which the quality of furniture fittings depends.

Types of ball guides

Ball-type guides can be classified according to several criteria:

degree of opening. Partial and full extension systems are available. With limited movement, the viewing angle of the contents is reduced and approximately the distant 5–6 cm of the box is not visible. The full extension system allows you to view the entire contents of the drawer;

Differences in guides according to the degree of opening of drawers

- maintainability. There are cheaper one-piece guides, which in case of breakdown can only be replaced, and detachable structures that are subject to repair, and within the same manufacturer, the interchangeability of component parts;

- installation method. There are standard guides, which are mounted on the side walls of the drawer, and hidden-mounted guides. With this method, the drawer system is installed from the bottom of the drawer, which allows you to hide all the elements and increase the internal space of the cabinet, chest of drawers, cabinets, and so on.

Concealed ball guides

- number of steps. There are single-level and multi-level guides. Depending on this indicator, the maximum load on the box is determined;

- the presence of additional elements. The guides can be equipped with closers that allow the drawer to be closed smoothly, which increases the service life of the furniture and/or with a Push-to-open system - opening the drawer by pressing the front part of the facade.

Push-to-open system principle

What are the best guides? Each user must decide independently, based on the type of furniture (wardrobe, cabinet, chest of drawers, etc.) and the surrounding space.

Selection of technical parameters

After determining the type of guide, you need to select the correct dimensions. Allowed:

- reducing the length of the retractable system relative to the length of the drawer by 10 - 15 mm, but not more than 75% of the indicator (calculation according to the manufacturer’s recommendation). For example, for a drawer 400 mm long, guides 300 - 400 mm long are suitable;

- The width of the guide system is determined according to the required load.

Main dimensions of ball-type guides

Popular manufacturers and their features

The most popular company engaged in the manufacture of various types of retractable systems, including ball guides, is the Austrian company Blum. The main advantages of the manufacturer are:

- use of high quality materials;

- production control at all stages;

- checking accessories before sale;

- application of diagrams for self-installation;

- long service life (manufacturer’s warranty – 15 years).

Among the disadvantages, one can note the high cost of guides and other types of retractable systems.

Furniture fittings from the Austrian company Blum

To reduce the cost of purchasing accessories, you can pay attention to the following companies:

- German company Hettich. The quality of the manufactured accessories is not inferior to the generally recognized leader, but the cost is significantly lower;

- the Polish company GTV, which produces large-sized fittings;

- the Polish company Fgv, whose main specialization is the manufacture of various types of guides and furniture hinges;

- Russian companies Boyard and Firmax. The price of fittings from domestic manufacturers is the lowest, and the quality is at a high level.