0

56632

Cabinet or modular furniture is often equipped with drawers, which are designed to store various small items. They can have different sizes, but their main feature is that they can easily be pulled out and pushed back in if necessary. For this purpose, furniture guides are used, which can be presented in several types. They differ in the installation method and operating principle. Their main task is to ensure smooth and quiet use of the drawers. At the same time, they must be reliable to guarantee long service life and ease of use of the furniture.

Main types of drawer guides

The action of drawer guides is due to the movement of specially made metal guides using balls or rollers.

Ball guides, like roller guides, consist of two parts. One of them is attached to the box, the other to the side wall.

Depending on the type of movement, they are divided into two types: roller guides and ball guides.

Roller guides.

Ball guides.

Ball guides

Ball systems allow the drawer to extend completely and can support heavy weights. Some designs can withstand about 60 kilograms. Ball guides can be installed in any plane.

There are many varieties of ball guides; they differ mainly in height, as well as in the degree of extension and the presence of a closer.

Compared to roller guides, ball guides have their advantages:

- Ability to regulate the system in 2 directions;

- Silent drawer movement;

- Duration of operation;

- Carrying out work under heavy load;

- Possibility of full extension.

Today, furniture is often equipped with roller and ball guides.

Despite all the positive aspects, such guides are more expensive than roller guides. But if there is a need to install guides in structures where heavy objects will be stored, then you should give preference to ball systems.

Ball guides have many different modifications, with different designs, sizes, fastening methods, and degrees of extension.

Which guides are best for drawers?

Roller guides are the most popular. They have the following advantages:

- They are easy to install and do not require numerous drillings for fastenings.

- Provides smooth movement.

- They do not require lubricating pastes or other compounds.

- They are distinguished by affordable prices and high quality.

They are easy to install, since there is no need to drill numerous holes for fasteners.

Ball guides can withstand heavy loads, have a smoother ride, and can be equipped with closers and dampers. They vary in degree of extension and size of structures. Even large items can be stored in such boxes.

If new guides are selected to replace broken ones, then it is better to install a similar system.

The minimum thickness of metal fittings must be at least 1.2 mm.

Modern tandem boxes are quite specific in terms of installation, so in this case they most often resort to the help of specialists.

Due to the complexity of the design and ease of use, the cost of such products is considered quite high.

Roller guides

Drawer extension in this type of guides is only possible incompletely, but their cost is several times lower than that of ball-type ones. Roller guides create noise when opening the drawer; to eliminate this effect, rubber-coated rollers should be used.

Roller guides can withstand dynamic loads of up to 25 kg.

The load that the roller guides can withstand is 25 kg. When choosing roller guides, it is important to take into account their thickness: in order for them to serve for a long time, it should be from 1.2 mm.

Roller guides are partial extension guides.

Types of guides or how to make the right choice

As you know, one of the main types of furniture fittings are retractable systems or guides. They are widely used in kitchens, wardrobes, chests of drawers, bedside tables and other furniture.

Main types of guides:

• roller guides;

• sidewalls with roller guides or metaboxes;

• ball or telescopic guides;

• concealed mounting ball guides;

• tandemboxes

In addition, according to the method of extension, all guides are divided into partial and full extension systems. In the first case, the drawer extends to a limited distance, and in the second, the drawer extends along the entire length of the guides, which is undoubtedly much more convenient. Accordingly, full extension systems have a more complex design and are more expensive. To make the right choice, consider the advantages and disadvantages of these retractable systems.

Roller guides

- This is the most inexpensive type of retractable systems. The drawer is pulled out using rollers. The load-bearing part is attached to the side of the furniture, and the second part of the guides is attached with self-tapping screws to the bottom of the drawer. Roller guides for full and partial extension differ in price by about 4-5 times. To choose the right quality roller guides, you need to pay attention to the thickness of the metal. It should be noted that when installing drawers longer than 50 cm, it is better not to use this type of guides. This fitting is practically not suitable for large drawers. The bearing capacity of these guides is up to 10 kg. They are quite noisy in operation and are not durable.

Sidewalls with roller guides or metaboxes (metal boxes)

is a system with metal sidewalls on roller guides. The side of the box here is the supporting part of the metabox. The metabox roller system is much more reliable than the previous one; the rollers are made of especially durable plastic. The thickness of high-quality guides should be at least 1.0 mm. Load-bearing capacity of metaboxes is up to 20 kg. As an improved version of roller guides, metaboxes are successfully used in the manufacture of inexpensive furniture for kitchens and offices.

Ball guides (telescopic)

– this is the most reliable type of middle-class extension systems. In this case, the drawer is pulled out using steel ball bearings. They are virtually silent in operation and can withstand much greater loads than the most powerful roller systems. The bearing capacity of these guides is up to 40-60 kg. In cases where boxes are made to store heavy objects, only ball guides should be used. Although ball guides are about 2-3 times more expensive than roller guides, they are reliable, have an aesthetic appearance and are easier to install.

Concealed ball guides

is a modern take on ball guides in furniture. They are attached to the bottom of the box so they are not visible. For comfortable and silent closing, shock absorbers - closers - were developed. The built-in closer mechanism has a spring mechanism and oil shock absorbers, which allow the drawer to close smoothly and silently.

Tandemboxes

is a full extension system in which the bottom and back wall are made of chipboard, and the metal or glass sides have a tubular rail. This is a high-quality and modern hidden-mount sliding system with an automatic closer, thanks to which even heavily loaded tall drawers glide as if weightless. The load-bearing capacity of tandem boxes reaches 50 kg. The cost of tandemboxes is noticeably higher than metaboxes, but they can withstand a weight that is 2-3 times greater than the capabilities of metaboxes. And if they are equipped with an electric drive with sensors for touch or movement, you just need to touch the front of the drawer without any effort, and it will open silently and smoothly.

In all the variety of furniture fittings, choosing the best option for guides is not so difficult. If you need an economical option for furniture with small drawers, you can opt for roller guides. And if you want to protect yourself and your loved ones from frequent breakdowns and endless furniture repairs, choose ball guides of any type and design. If you want to equip your furniture with the latest technology, choose tandem boxes equipped with additional functions.

Types of guides: metaboxes and tandemboxes

Based on the two previous types of guides, more advanced drawers are produced.

These guide systems have appeared relatively recently.

- Metaboxes are boxes with roller systems and side walls with guides. The supporting components of this type of retractable system are attached to the walls of the furniture.

The main advantage is that the drawers are pulled out 3/4.Roller guides, presented as metaboxes, are stronger and more reliable than conventional systems. Metaboxes are distinguished by durable plastic rollers, as well as standard box sizes. They are made from thin and durable sheets of steel and, if necessary, painted in a color suitable for the furniture.

The top mounts provide additional security and eliminate any wobble. - Tandem boxes are made on the basis of ball retractable systems, they are based on chipboard, but the side parts are sometimes made of metal or glass.

Tandemboxes can withstand loads several times greater than metaboxes.The height of tandem boxes allows them to be used in furniture where high drawers are needed. The prices for tandem boxes are higher, but considering the quality, they are worth it.

The tandembox consists of two metal sides in which ball guides are hidden.

Tandemboxes and metaboxes

These are new items. You can find them in stores quite recently. The main differences are that the guide is located inside the side metal wall, there is a closer and dampers.

Advantages - original design solution, aesthetics, ability to withstand heavy loads, ease of use, durability. Disadvantages - the use of special marking devices is required.

Selection of guides

To choose a guide system that will serve for a long time, you first need to pay attention to the thickness of the metal. Especially if these are roller guides.

Roller guides are the simplest guides in terms of design and installation.

This parameter determines how much and how the fittings will work. The ideal thickness is 1-1.2 mm. Having decided to buy a smaller option, there is no guarantee that the drawers will last for a long period.

The roller guides are coated with durable epoxy enamel.

The choice of fittings also involves a preliminary inspection of the product: it is important that the guides are smooth and free of defects.

Be sure to check the rollers or balls, they must function properly.

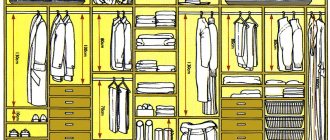

Guides for sliding wardrobes: general information about fittings

Guides, as part of furniture fittings, perform a vital function. Thanks to these elements, the sliding system together with the doors operates easily, freely and quietly. The operating principle of this design is quite simple: the door leaves move along sliding wardrobe rails using rollers or balls.

The Versailles sliding system is equipped with reliable and durable fittings

Versailles is the most common and popular type of sliding system, which is found in compartment-type cabinets. This popularity is due to the presence of durable, reliable and high-quality components, as well as easy-to-use internal filling elements. Sliding systems are additionally equipped with stoppers, seals and rollers for sliding wardrobes. Guides with such a complex design eliminate the possibility of door panels being skewed and closing randomly.

Sliding system components and requirements for guides for sliding doors

The width of the guides for the sliding wardrobe and other parameters of the fittings should be selected taking into account the characteristics of the door leaf. In this case, the weight and dimensions of each sash, as well as the material from which they are made, must be taken into account. Guides for sliding systems usually come with furniture, so there is no need to purchase such elements separately. However, they may be needed if the fittings fail and require complete or partial replacement.

Helpful advice! If you select guides that meet basic quality requirements, then such products can be used for a long time.

If the installation of guides for wardrobe doors is done correctly, then the opening and closing of the door will occur in the same plane. Together with other fittings, this type of product is part of the sliding system. Requirements for guides:

Guides for sliding doors are selected based on the weight and material of the doors

- High level of strength - good strength characteristics ensure a long service life of the sliding system, even if it is used regularly.

- Aesthetics – the guides must match the style of the room where the cabinet is located, as well as the design of the furniture itself.

- Convenience - the sliding system should be so simple and easy to use that any user can open and close the cabinet doors without any problems.

The standard equipment of the sliding system is the same in all compartment designs. But the list of additional accessories may vary depending on the cabinet model and its internal contents.

The sliding system includes the following elements:

- upper and lower guides for the wardrobe, along which the door leaf moves;

- profiles with vertical and horizontal installation types for reliable fixation of all elements of internal filling;

- closers for smooth movement of the sashes;

- silicone seal;

- a system consisting of lower and upper rollers for sliding wardrobe doors, which ensures their free and silent movement;

- screws as fasteners;

- stops for fixing the door leaf in a certain area (they look like spring brackets);

- brushes.

Guides must be strong, durable and easy to use

Types of guide profiles for sliding doors: classification by type of material

When choosing guides for a wardrobe, you must pay attention to the material they are made of. The following raw materials are used for the production of these products:

- plastic;

- aluminum;

- steel.

Plastic guide profiles have the lowest price. Such products do not have a long service life and high reliability. They can be used without problems for 5-7 years. For this reason, many consumers prefer to avoid purchasing furniture with plastic components.

Helpful advice! To extend the service life of the sliding system, it is advisable to use plastic sliding wardrobe guides only in combination with parts made of metal.

Guides for wardrobe doors are made of plastic, aluminum or steel

Steel is used to make fairly strong and reliable products. However, the size of the guides for the wardrobe, including their thickness, must be selected taking into account the parameters of the door leaf. If the fittings are selected correctly, the service life of the sliding system will be long. The price of such profiles is considered affordable for most buyers and, as a rule, it corresponds to the quality level of these products. Sometimes there are options that are not as durable and easy to install as we would like.

The highest quality parts are made from aluminum. These profiles are usually installed in expensive and luxury models. Aluminum slides are designed for cabinets that are 4 m or more in height. Such products are distinguished by an extensive palette of colors and a large selection of decorative design options.

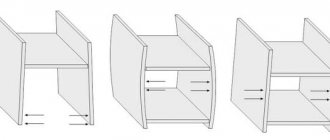

Installation of roller guides for drawers

- Installation should begin by attaching two guides to the bottom of the drawer. At this time, the roller is located at the back wall of the drawer, the second end of the strip should rest against the front.

Boxes on which the guides will be installed.

Attaching the guide to the side surface of the drawer. - The plank is attached to the bottom of the box with self-tapping screws; it should not be attached to the sides, because the second roller moves along the side. You should pay attention to the screw caps. They should be below the surface of the bar so as not to interfere with the movement of the box.

Drawer with installed guides.

Marking guides on the walls of the facade. - It is necessary to attach the second pair of guides to the furniture body by making preliminary marks with a pencil. When the location for the guide is marked, it is applied to the mark and secured using self-tapping screws.

We repeat this manipulation for all three pairs of guides.

Assembling the box with installed guides.

We install the drawers themselves inside the box and get a finished piece of furniture.

How to repair a drawer on ball guides

If, after installing the ball guides for the drawer, the structure moves quite tightly, this indicates an incorrect calculation of the dimensions of the structure or illiterate installation of the runners. In this case, you need to check the width of the product. If necessary, it is worth reducing the front trims. Before starting installation, check the diagonal.

Helpful advice! To ensure free movement of the box, you can spray a couple of drops of special oil on the guides.

If, after installing the drawer guides, the structure slides out spontaneously, in this case, you should check the fixing part of the narrow strip located at the back. There is a bracket that, when closed, goes around the silicone sleeve. This position ensures reliable fixation of the element in the closed position. For a tighter fastening, tighten the bracket.

When inserting a drawer, the bar may become blocked, which is why the product will not fit into the niche, as it will rest against the fastening of the balls. To fix this problem, the box is completely removed and the fasteners are unbent to the sides.

To make the guides move freely, you can sprinkle a couple of drops of special oil on them

Important! To carry out repairs, the structure should be pulled out exactly before disassembling the drawer guides.

If the bottom of the drawer is in a groove, it may pop out when you first load it. It should be reinforced with thin strips or screwed to the bottom ends of the box with self-tapping screws.