29272

Some modern interior items are expensive, but not very high quality. This leads to the fact that many people are thinking about making furniture with their own hands at home, for which different materials can be used, with environmentally friendly wood being considered the most preferable. If you independently implement unique ideas, you can count on the formation of truly original and unique designs that will fit well into the interior.

The main advantages of wooden furniture

Wood is an excellent material for creating cozy and unique furniture. Even the development of technological progress and the emergence of many innovative materials have not made the manufacture of wooden furniture less popular.

Wood, unlike artificial materials, not only does not emit harmful substances, but, on the contrary, creates a favorable microclimate. Natural resins and essential oils secreted by wood have a healing effect on the body and purify the air in the house.

The main advantages of such furniture include:

Wood

- Environmental friendliness - creating furniture from wood brings special energy and an aura of pure living nature to the room.

- Exceptional strength and longevity of the material – especially in hardwoods.

- Easy to repair - over time, damaged parts can be replaced.

- Comfort – such items are ergonomic and manufactured taking into account the most convenient designs.

- Variety of design solutions.

- Presentable appearance - it’s not without reason that solid natural wood is used to make classic luxury style furniture.

The main styles that have wooden furniture in their arsenal

Wooden kitchen furniture for a dining room or a cozy cafe

Many talented designers work with solid wood furniture. It is a mistake to think that it can only decorate rooms decorated in a classical style. There are directions in which you can successfully fit wooden furniture:

- Country. Its distinctive features are angularity, rough lines, and the absence of artificial surface treatments. Wood is an ideal working material for furniture decorating a room in country style. These can be dachas, private houses, inside of which you can easily create a primitive atmosphere.

Spacious and bright rustic living room in country style

- Eco style. For admirers of this trend, it is not fashion trends that are important, but naturalness and naturalness. They are close to the country style, the only difference is the shades; in the first option, bright and dark tones can be used, while in the second, preference is given to light, natural ones. Eco-style rooms require a large amount of modern technology, while wooden furniture will make the interior softer and more sophisticated.

Wooden table with carved legs for interior decoration in eco-style

- Provence. This trend is well known in the world of women's interior design. Its distinctive features: a large number of flowers, silver, cute dishes. This is a “warm, cozy” style. You don’t want to leave such a kitchen and living room, so a wicker chair or wooden table will fit perfectly into it. But the main thing here is not to overdo it; massive elements will attract too much attention and be perceived separately from all other thematic elements.

Interior in a romantic Provence style with wooden furniture

In other styles you can also see wooden furniture, but in smaller quantities. For example, in the minimalism and modernist trends, additional wooden accessories are very popular: lamps, clocks, figurines, vases.

Wooden interior design in minimalist style

Suitable wood species for making furniture

About 40 types of wood are known to be used, which are classified as soft or hard. For the construction of load-bearing frames that bear heavy loads, only hard rocks are used. Wood, which is a soft species, is used only for the manufacture of parts not designed for high loads.

Many deciduous tree species are classified as hard. They grow slowly and their wood has a higher density (mass) relative to a unit volume. Beech, birch, elm, ash, and aspen are most often used to make furniture. And also super-hard species: oak, white acacia, boxwood, hornbeam.

Comparison of wood hardness

- Beech is very resistant to deformation, has good bending ability and is therefore often used for making furniture where bends are required.

- Birch – valued for its ease of processing, strength, and elasticity. Easily ground and polished, suitable for creating imitations of valuable species.

- Elm is a durable, moisture-resistant wood; processing parts made from it is very easy.

- Ash – has a beautiful texture, is not inferior in strength to oak, and is resistant to biological influences.

- Aspen - easily amenable to all types of processing, except polishing. Often used to make curved parts.

- Oak – has incredible strength and durability, excellent decorative properties. This material symbolizes luxury and nobility.

- White acacia is wear-resistant. Even if no protective compounds were used in the manufacture of furniture, it is resistant to fungi and mold.

- Boxwood is a hard wood with a fine texture. Works well on a lathe, but is difficult to work with manually.

- Hornbeam - with hard, durable wood, difficult to process. It is used only for the manufacture of wooden furniture in single copies.

Softwood

Most coniferous wood species are considered soft: pine, spruce, cedar, fir. Hardwood softwoods used to make furniture include cherry, alder, poplar, linden, and maple. All these trees grow quite quickly and therefore their wood density is low.

Lumber characteristics table

- Pine is the most common material due to its beneficial qualities and low price.

- Spruce – has good mechanical strength, but is susceptible to rotting and therefore must be treated with an antiseptic.

- Cedar is durable, has a beautiful texture, is easy to process, and the surface is smooth. Used to create luxury interiors.

- Fir is not inferior in strength to spruce and is more resistant to rotting. It lends itself well to all types of mechanical processing, gluing, and painting.

- Cherry is easy to process and polish, resistant to fungi, has a beautiful reddish texture, and is one of the favorite materials among designers.

- Alder - has a beautiful texture, is well processed to a perfectly smooth surface, and is suitable for imitation of many species.

- Poplar - has loose wood, is easy to process, but difficult to sand. When creating furniture, the surface is finished with veneer.

- Linden - easy to process, a favorite material for wood carving.

Selection of materials and necessary tools

In the factory, special equipment is used:

- jointing machines (for planing), thicknessing machines (for milling);

- edgebanding, milling, grinding installations.

Tools for making wooden furniture

For manufacturing at home, they mainly use improvised tools, and if the work is done in a garage or other utility and fairly spacious room, then you can install a small machine. Such devices are not cheap and are worthwhile if they are required for frequent use.

If conditions do not allow or when you need to do a one-time job, then the blanks can be ordered directly from workshops, and then assembled at home. Based on the sketch, the parts will be cut out to the required sizes and even the ends will be processed.

Some simple models can be made entirely at home using fairly simple tools. For example, to make a simple table or stool you will need the following list of tools:

- Hand tools - knife, screwdriver, hammer, pliers, furniture stapler, router, ruler, tape measure, pencil, screwdriver, etc.

- Electric – drill, screwdriver, plane, circular saw, jigsaw, etc.

- Brush, paint and varnish materials.

- Furniture fittings.

For complex models, the list of professional tools will be larger. You don't have to buy them all. Some that are rarely needed for work can be rented.

Example of a drawing of chair parts

Wooden furniture is connected in two ways: detachable or permanent. Both of them are divided into several types:

- Detachable - for beads with a flange or nut, plastic parts with metal inserts, compression, socket-type compensation.

- One-piece - butt or socket welding, mechanical fittings, adhesive socket welding, socket welding with embedded heaters.

Unusual furniture

Unusual furniture is that which can be called non-standard and even bold. Certain patterns are alien to her. Such furniture can be either cabinet or upholstered. It is made from various materials. For example, a bedside table made from old magazines or a sofa from an old bathtub or barrels.

At the moment, there are a huge number of interesting pieces of furniture that previously could only be dreamed of.

Thanks to the imagination of the manufacturers, there are no restrictions, a person can arrange the room to his taste, as soon as he wishes. Book sofas and transformers are especially popular now. They are unique in their functionality and can be transformed into other types of furniture.

Namely, in:

- Several soft chairs;

- Small corner sofas;

- Double bed.

Non-standard furniture for children's rooms is very interesting. For example, a bunk bed, where instead of the first tier you can put a desk or cabinets. Most often, such furniture is made of wood. Laminated chipboard, chipboard, fiberboard are not as durable and environmentally friendly as wood. It must be remembered that any non-standard piece of furniture must be combined with the interior of the room.

Stages of making wood furniture

A full-fledged process at a wooden furniture manufacturing enterprise includes the following stages:

Scheme for manufacturing a furniture panel

- raw materials warehouse;

- workshop for blanks;

- Assembly shop;

- paint shop;

- drying chamber;

- warehouse of finished furniture.

To make home furniture yourself, you need to do the work in the following sequence:

- Marking all elements and cutting out.

- Their processing, depending on the sketch.

- Preparing holes for fasteners: marking, drilling.

- Surface grinding or other processing according to the sketch.

- Painting or varnishing.

- Assembly of finished furniture structures.

Before starting work, you need to carefully think through all the details, drawing up a sketch of the future furniture. It is important to have a good idea of how it will look in the room. You can view examples of similar work on the Internet.

When your own project is ready for implementation, then it’s time to start drawing up detailed drawings. High-quality furniture can only be made with high precision of all parts so that their combination during assembly is perfect. The quality of manufacturing wooden furniture also depends on the correct choice of materials, fittings, and the use of professional tools.

Scheme for making a garden chair

Original furniture made from wooden pallets

Usually, wooden pallets that remain after construction are thrown into the trash, but few people know that this material can be reused. You can make wonderful furniture from pallets. Although, in order for the final result to be surprising, you will have to work a little - sand the pallets and paint them. A few hours and a wonderful sofa will appear in the living room. If the square meters of the apartment do not allow you to place such furniture, then at the dacha it will be able to take its rightful place. The main “advantage” of such a homemade sofa is the large voids where you can store a huge amount of necessary things.

You can also build a real bed from wooden pallets, designed for several people. In a particular case, pallets are stacked in several tiers. This structure will be quite stable, even if it is not strengthened. When the bed becomes unnecessary, it can be easily dismantled. Wooden pallets are quite cheap, so using them to solve the problem of furniture availability is very easy. At the dacha, on the balcony, thanks to wooden pallets, you can arrange a resting place with comfortable benches. They will become more comfortable and beautiful if you decorate them with pillows and a blanket. The service life of furniture made from pallets depends entirely on its owner. If you sand the wood, then prime it with a special product and paint it, the pallets will last a very long time.

Technologies used

First, a project for future furniture is drawn up. If it is complex, then diagrams are made in several projections. The drawings indicate all dimensions, joints, etc. Then materials are selected and tools are prepared. Calculations when preparing wooden parts must be accurate so that they coincide during assembly.

When working with tools, safety precautions must be observed. The use of each of them requires certain skills and knowledge of operating instructions. Be sure to wear a protective mask or goggles while working.

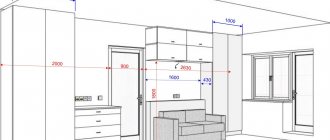

Three-section cabinet diagram

When you don’t have enough experience, you first need to practice on unnecessary materials so as not to spoil the furniture blanks. If everything works out well, then you can start processing the finishing parts.

At the final stage, sanding, applying a protective layer (paint, varnish), and decorative finishing are carried out. Painting should be carried out in a well-ventilated area. To decorate furniture, it is important to master the skills of the selected finishing technologies - patination, craquelure, decoupage, etc.

For beginners, it's best to try making simple models first to gain basic skills. Over time, experience is gained and the execution of even the most complex products becomes possible. Handmade furniture will always delight the craftsman and inspire new projects.

Drawings of wooden furniture and the process of its manufacture

There are a lot of options for homemade wooden furniture with your own hands. Before starting production of the intended item, you need to take care of the following aspects: choose the material, decide on the purpose, purpose.

Finished furniture has excellent resistance to various mechanical damage, which is why some wood products can be used for about 100 years without any problems.

Wood itself can be divided into:

- soft species: conifers, aspen, poplar;

- hard: garden materials, oak, acacia;

- moisture resistant: cedar, linden.

Each master must determine for himself which varieties are most suitable for his work. Of course, this will depend on the room that he is going to equip: living room, children's room, gazebo, bathhouse, etc.

In this matter, it is important to select the appropriate material, prepare all the equipment, and only then start working.

Getting the appropriate tools is also an important preparation step:

- planer, jointer;

- hacksaw;

- drill;

- chisels;

- grinding accessories, etc.

It is imperative to draw accurate diagrams. or find a suitable one on the Internet:

- the drawing must show the entire structure and each part separately;

- the correct drawing will make it possible to calculate the amount of wood required;

- the diagram should also contain small elements - corresponding marks and dots;

- 3D mockups of various products are popular today.

To make furniture yourself, you will need to develop a drawing and assembly diagram for the product.

The entire workflow will be divided into stages:

- Selection of drawings. Markings on wood.

- Working with workpieces: sawing and processing.

- Making the necessary openings.

- Installation of the structure.

- The final phase: painting, varnishing, drying the object.

Anyone, even the most novice master, can draw a drawing of future furniture with their own hands.

Note. It is not necessary to order certain types of wood; you can use material that is available in virtually every house, barn, or summer cottage. Boards, columns, pallets, parts of old furniture, etc.

It should be taken into account that there are a huge number of different subtypes and design innovations of various furniture. The most popular items that are made by hand are the following.

Furniture drawings with dimensions allow you to assemble furniture with your own hands, which will fit perfectly into the interior of an apartment or house.

Bed

How to make a bed at home? The recommendations look like this:

- a diagram is made;

- materials and tools are selected;

- a frame is created - this will require bars (they need to be fastened with self-tapping screws);

- the necessary surfaces are sanded and painted, if required;

- supports for the bottom are created (openings are made in the structure and beams are attached);

- symmetrical slats are attached to the supports;

- now it’s up to the legs, which will also be made from blocks (4.6 pieces);

- the legs are mounted to the main elements of the bed;

- sanding, varnishing.

It is possible to make a bed with your own hands from a tight budget to an exclusive class.

The dimensions of the structure must be taken into account immediately in the drawings. Such a bed looks attractive in a country house where Eco style will always be a priority.

Make a double bed like this with your own hands. Simple design, traditional and modern.

Stool

In labor lessons and at school, the ability to make a stool is considered necessary knowledge for boys. This is a must-have piece of furniture for the kitchen and beyond.

DIY drawing of a simple stool.

To create such a desired product you need:

- go through the preparatory stages (drawing, selection of wood and tools);

- production of the necessary blanks according to the scheme;

- Preparing the seat and attaching the crossbars and supports to it;

- Installing the legs to the seat (you can make a prefabricated structure with crossbars out of them);

- final phase (grinding).

The more complex the configuration of the product and the more elegant and beautiful its appearance.

Bench

Our idea of a dacha is a suburban area where a person works in the garden, but also relaxes in nature. A bench is an attribute of a gazebo, bathhouse, or children's playground. The simplest option is to make it from a log, or two posts and a board without a back. The classic type is a bench with a back; among other things, this is the most comfortable product.

A DIY garden bench can not only save money, but also fulfill individual needs and ideas.

Chair

A good wooden chair can be a source of pride, standing in a place of honor in the living room. Making this item is not difficult:

- preparation of materials, diagrams;

- we make blanks: legs, seat, crossbars, back;

- We work on the principle of making a stool, we simply add a backrest.

To make a chair with your own hands, you do not need to have much experience.

Closet

The production of a cabinet requires a meticulous approach. All measurements must match exactly. Here you need to consider what the doors will be made of (if any). The main thing is to decide for what purposes you need a closet: toys, clothes, books, kitchen utensils. After that, create a diagram and carry out all the work according to the standard procedure.

Today it is impossible to do without cabinets designed to store things.

Additional Information. If a novice craftsman decides to make a table, he should start with simpler options: a gazebo, a children’s table, and then gradually move on to a kitchen table.

Making beautiful wooden furniture, at first glance, is not difficult, but you must have minimal working skills and follow certain recommendations.

Wooden products are comfortable and you can take into account your personal preferences at the design stage.