A banquette can be called a popular type of furniture for the hallway. Over time, its design has not undergone fundamental changes. This is not only a comfortable pouf on which you can seat guests, but also a stylish piece of furniture; it will look great in the hallway, kitchen, bedroom and living room.

The stores have a huge selection of these soft poufs: with cabinets, shelves, drawers. Each manufacturer designs the banquette at its own discretion. But what to do if you still haven’t found a suitable option for your interior? In this case, the question may arise: how to make a banquette with your own hands?

The basic design of a banquette is quite simple - a stool with a soft seat.

The fabric is folded inward at the edges and secured with staples.

The benefits of a DIY banquette

Anyone who has minimal carpentry skills and is good with a needle can make a bench.

Often the basis of the product is actually a stool.

This product looks very decorative and is quite simple to make.

Let's consider the advantages of a homemade pouf.

- Firstly, you can independently choose the shape, color, and size to your liking. It all depends only on your imagination. Then you can create a banquette that is unlike other factory-made analogues, which will add originality to your interior.

- Secondly, a DIY pouf will cost you much less than a ready-made one from the store.

- Thirdly, you can make a banquette from old furniture that you were already planning to throw away (stool, coffee table), but in this way give it new life.

- Fourthly, creating something useful and beautiful always brings moral satisfaction to the creator. Having done such a thing yourself, you will be able to present your work to guests and receive many compliments as a reward for your work.

A larger banquette, if the size of the hallway allows, is no less easy to make.

From the selected fabric, a fragment of the required size is cut out with an allowance.

Before starting work, you need to think through the design of the product and see what types there are. The bench can be selected according to shape, material and size.

This will require minimal carpentry skills and the ability to hold a needle and thread.

It is recommended to first lay burlap and similar rough material on the bottom, and then secure the foam rubber with glue or a stapler.

Let's look at the main types.

- Forged.

More suitable for an interior in Baroque or Empire style. The product will have forged, twisted bases. More often than not, these specimens do not have built-in shelves, drawers and cabinets. A pouf made in this style will look best in the hallway.

- Made of wood.

These types of products are often very functional: with built-in drawers and cabinets. They will look great in the hallway, kitchen or living room.

- With a backrest.

This small sofa will immediately create an atmosphere of comfort, especially if it is decorated with soft pillows made in the same style. This is the most comfortable and convenient option.

- Collapsible.

This type is more functional: it can be quickly disassembled. All elements are secured with bolts. Therefore, for quick disassembly of the product, the design will be ordinary and not have decorative functions.

- With boxes.

A very useful item for the hallway that will save space.

The “raw materials” for the product are wood materials.

For a soft seat, cut out a piece of foam rubber of the required size.

To make a bench, you also need to familiarize yourself with the types of upholstery that can be used during work.

- Textile.

The bench can be covered with silk, cotton, linen fabric. Textile poufs are easy to care for. A variety of shades is an advantage of this upholstery.

- Leather.

This material is not suitable for every interior, but it will look very expensive and elegant. Disadvantages include high price and difficult maintenance.

- Faux leather.

This option is cheaper than the previous one. It will look as noble as a pouf made of genuine leather. At the same time, leatherette is not capricious in care. Although its service life is significantly shorter than that of its natural “brother”.

Forged models or furniture with an iron frame will require much more serious skills and experience.

It is easiest to make a banquette from old furniture or wood, since forged models and those with an iron frame will require more serious skills and experience from the craftsman.

The filling material, as a rule, is foam rubber - it is quite elastic and holds its shape for a long time.

An attractive look to the legs will be ensured by the use of a hand cutter.

Necessary materials

To work you need to have the following materials.

- For a pouf with legs you will need a wooden beam - 30*40, 30*50 mm. or, if available, you can use old screw-in legs from a stool, table or bench.

- Plywood.

- Fastening materials: staplers, self-tapping screws.

- Varnish, stain or paint.

- High foam.

- Fabric or leather for covering.

- Fabric for finishing the invisible side of the seat.

- Buttons.

- Fabric for the cover (if required).

If a very soft seat is being built, especially with a carriage screed, then in addition to foam rubber, padding polyester is also used.

If a model with legs is being implemented, then 4 wooden planks are attached to the bottom so that they protrude 1–2 cm beyond the edges.

Required Tools

To work you need to have the following tools:

- drill, screwdriver;

- screwdrivers;

- hammer;

- construction stapler;

- sandpaper of different hardness;

- hand cutter (if the base of the pouf is made of timber);

- level;

- thick threads and a large needle;

- scissors;

- roulette;

- chalk;

- sewing machine (if you need to sew a cover).

In addition, paint or stain and varnish may be needed.

The seat is cut out first - its dimensions serve as a starting point, and all other parts, if necessary, are adjusted to fit the seat.

If you do not have sufficient experience in making furniture, then it is better to split the whole process into several days so that every detail is given due attention.

Step 1: Finishing the Legs

If you have ready-made screw-in legs, then they need to be restored. Clean the surface with sandpaper. Then we apply new paint or varnish and stain. It is better to apply in two layers.

If you don’t have ready-made legs, then they need to be made from timber. They will be attached to the seat using screws and corners. If possible, it is better to process the timber using a hand cutter. Such a tool can make non-standard protrusions, and the product will turn out more interesting. We also cover the timber with stain or paint it.

Step 2: Plywood and foam

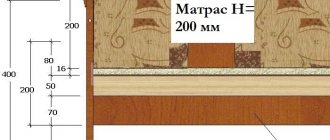

It is necessary to cut the foam rubber of the required size around the plywood. In this case, it should protrude 2-3 cm on each side. We select sizes individually.

Step 3: Mark the plywood

We glue the foam rubber to the plywood, placing the glue closer to the edges. Using a tape measure and chalk, we will draw markings along which we will later sew on buttons. We make several holes in the plywood at the same distance. We try not to touch the foam rubber.

Step 4: Assemble the product, cover it with fabric or leather

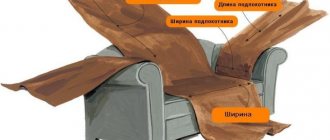

We cut out a square or rectangle from leather or fabric according to the shape of the product. It is necessary to carefully calculate the dimensions of the upholstery and fit them under the seat, leaving a margin of 2-3 cm on each side.

Next, you need to carefully wrap the fabric and secure it with a stapler.

You can start installing buttons. Using a needle, thread the thread first through the button and then out into the hole in the plywood under the seat. For better fixation, you can secure the thread with staples.

You need to cover the rough trim on the back of the seat with a textile cloth. Sew the cut piece along the edge of the bottom part.

If the legs were from another product, then choose a place to place them, fasten their bases with self-tapping screws and screw them in. We attach the timber legs to the seat using self-tapping screws and corners.

The process consists of several stages. All of them are quite simple to implement and require only accuracy and due care.

It is not recommended to make all the necessary parts at once, especially if this is your first experience in furniture production.

Stage three: cut the fabric

There are a lot of options for cutting fabric for sewing a cover. You can make a paper template and cut according to it. However, since the bench seat has a rectangular shape and the sealing material is not fixed to it, you can do it easier and do without creating a pattern.

You need to do the following:

- fold the fabric in half, wrong side up;

- fasten the fabric with tailor's pins in such a way as to completely prevent movement of the material;

- place a foam pillow on the fabric;

- outline it with tailor's chalk or marker, pencil;

- remove the foam cushion;

- trace the applied contour at a distance of a couple of centimeters, this is necessary for seam allowance;

- cut out a rectangle drawn on it from the fabric.

As a result of these actions, you will have two main parts of the case on your hands - the upper and the lower.

The next step is to cut out the strips to cover the ends of the pillow.

You need to cut out:

- a long strip - for the front end of the foam cushion;

- a couple of short strips - to cover the side ends;

- two long narrow strips - for the rear end of the foam cushion.

The dimensions of the strips must correspond to the length, width and thickness of the foam rubber, plus seam allowances. The back stripes are cut taking into account the seam allowance on one edge and the double hem allowance on the other. Of course, a hem requires more fabric than a seam allowance.

A Brazilian travels 36 km by bike every day to take his loved one home.

Rare shot: Viktoria Isakova showed her grown-up daughter from Yuri Moroz (new photo)

“We are still friends”: Derevianko commented on the breakup with his wife

Decoration

It is better to choose buttons to match the color of the upholstery. The quantity depends only on personal preference. You can diversify the bench with a decorative cover, which you can also sew yourself. All you need is skill with a sewing machine.

If you do not have cutting skills, then it is better to use a ready-made product pattern found on the Internet or watch a master class on making it yourself.

The capacity of the banquette is calculated: one person occupies an area of 45*55 cm.

The parts are cut out with a jigsaw and the edges are sanded.

For an Empire or Baroque style interior, you can make a carriage screed. This model looks very interesting and presentable.

The parameters of the hallway and the maximum possible dimensions of the product are determined.

If there are a lot of parts - partitions, shelves, back, it makes sense to make a pattern and then start cutting the plywood panel.

So you learned that making a banquette yourself, with minimal carpentry skills, is quite possible. The main thing is not to rush and pay due attention to each stage. Then the product will turn out neat and beautiful. This type of furniture will not only be useful in terms of comfort and space saving, but will also become a stylish and original addition to the interior.

Choose a model: with a back - quite difficult to implement with a minimum of experience, with shelves, drawers, on legs or supported on the sides, and so on.

Based on the dimensions of the seat, the parameters of the remaining elements are determined and a sketch is drawn.

Stage two: cut the foam rubber

It is necessary to cut out parts from foam rubber that correspond to the size and shape of the bench cover. The foam part may be slightly larger in size than the wooden lid of the banquette, but it cannot be made smaller, because sitting on the furniture will not be entirely comfortable due to the uncovered hard edge.

You need to do the following:

- measure the wooden lid of the banquette;

- mark the foam rubber with a marker or felt-tip pen in accordance with the size of the lid;

- cut out parts from foam rubber along the marking lines.

Cutting foam rubber is not as simple a task as it seems at first glance. The material must be held, and the blade of the breadboard knife must be positioned strictly perpendicular. Of course, the length of the blade must match the thickness of the sheet of foam used. Heating the knife blade facilitates the process of cutting foam rubber, but at the same time causes melting of the material. Therefore, it is not worth making the cutting process easier by heating the blade.

It’s good to wash often: myths about shampoo and hair care that only harm

If there is little snow, there will be no harvest: December 16 is Ivan the Silent Day

Why French children behave well: eight ways to raise them