Types of repairs

Chest restoration operations are divided into three classes:

- adjustment;

- redecorating;

- complete renovation.

Products need adjustment after purchase and after complete restoration of the old one. And here we mean adjusting mechanisms, hinges, setting levels, securing loose handles. It happens that you want to repair a chest of drawers, simply updating a boring design or one that has lost its freshness. Then they resort to cosmetic restoration, based on the current condition and the desired result. A complete renovation implies the return of functionality to furniture parts and the replacement of elements that cannot be restored.

Decoupage

This technique is a kind of appliqué made from various materials. Most often they use drawings cut out from napkins or magazines.

It is recommended to layer the paper so that the applique protrudes less above the general level of the facade. The further algorithm of actions is as follows:

- We prepare the surface: remove handles and other fittings, clean the paintwork, sand and repair defects.

- To achieve transparency of the varnish layer, mix white acrylic varnish and white paint.

- We paint the background in the direction of the wood grain.

- We place the prepared pattern, cut out and thinned, symmetrically relative to the facade and cover it with a layer of PVA.

- After letting the glue dry, we treat the surface with fine sandpaper, after which we apply a transparent varnish composition.

- After sanding the dried varnish, apply a new layer. And so on until the desired result is obtained.

A detailed master class on decoupage of furniture from chipboard is in the next video.

Another option for decoupage is the formation of ornaments using putty:

- Mix PVA glue and oil putty until the consistency of thick sour cream.

- We make a stencil of the future design from thick paper or cardboard.

- We fix the stencil on the facade, then apply the prepared solution with a spatula.

- After drying, we sand the ornament and coat it with varnish: first transparent, and then matte.

Decoupage can transform the most unattractive furniture. There are a great many options for the materials and technologies used. It all depends on the imagination and artistic taste of the master.

USEFUL INFORMATION: Mixer combined with drinking water filter

Repair tool

The required set of tools for working with a chest of drawers depends on the nature of the problem, therefore, first carefully inspect the product and make a list of breakdowns. But it’s a good idea to keep the following on hand:

Show hidden content

| Tools | Consumables |

|

|

Coating restoration

A mixture of linseed oil and alcohol will help restore the varnish coating in case of small amounts of damage. It wipes the damaged area, after which it is polished with cloth. The process will be facilitated by using a mixture of GOI paste with kerosene.

In case of large-scale damage, the varnish is washed off using special solvents. The softened composition is removed with a spatula, after which the surface is dried, sanded and re-varnished.

USEFUL INFORMATION: Installing a drinking water filter tap

Frame repair

Since the chest of drawers itself is a load-bearing structure, it is subject to increased requirements for strength and stability. Ideally, it is advised to remove the drawers from the chest of drawers on runners, disassemble the parts, and replace panels that have dried out or cracked. Before screwing furniture bolts, it is important to thoroughly lubricate the joints with PVA glue so that they do not come apart later. After the glue has dried, restoration begins. And to do this, remove the old coating by using a solvent with methylene chloride (allowing it to act for a maximum of half an hour), or by peeling it off with a spatula, knife, or sandpaper. Then the defects are puttied, the surface of the chest of drawers is sanded, thoroughly cleaned and degreased, after which a new selected coating is applied (stain with varnish, tint varnish, paint with varnish, decorative film).

Restoration of drawers

Drawers, for example a desk, are usually overflowing with a wide variety of papers and objects, and they are pulled out and pushed in quite often and abruptly. Naturally, they wear out quickly. Cracks appear, guides wear out, side walls break, back stops fall out, and so on. So, old boxes need qualified repairs and restoration.

Since the end of the 18th century, the sides of drawers have traditionally been fastened with a tongue. The lower part slides in the grooves of the front part. No matter how durable the boxes are, the friction that occurs when manipulating them inevitably leads to wear and tear on the contacting parts. Gradually, wooden surfaces wear out, drawers begin to creak and, eventually, they can jam, which in turn leads to deformation of the furniture frame.

Mandatory preparatory work

Before you begin, you should carefully inspect the drawers to understand the design of the guides and sliding surfaces, and also make sure that they need to be disassembled and repaired. There are several assembly methods depending on the purpose of the furniture and the placement of the drawers.

For any restoration work, first of all, it is necessary to refresh the wood, that is, carry out preventive work: eliminate cracks, fungus, and traces of insect activity.

Condition of the furniture frame

First of all, you need to make sure that the furniture is durable and sufficiently rigid. With the drawers completely closed, check that the guides on which they slide are securely fastened. The absence or presence of frame distortions can be easily checked using a plumb line and level. Even slight wear of the legs makes the entire frame unstable and disrupts its horizontality, which makes it difficult to pull out and push in drawers and accelerates the wear of the wood. In such cases, it is necessary to disassemble the furniture and re-glue it after eliminating the defects of individual parts. The lower part of the box is attached without gluing in the grooves, with several nails at the back wall.

Over time, the bottom of the drawers wears the most. Changes in the original dimensions perpendicular to the direction of the wood grain can reach 5%; as a result, the bottom attached with nails to the back wall of the box can form a small gap with its front part. Therefore, carpenters are in the habit of leaving a small margin at the back of the bottom. In this case, it is enough to pull out the nails, push the bottom of the box forward, then insert it into the grooves of the front part and hammer the nails in again. If the bottom consists of two boards glued together, you should make sure that they are securely glued before installing the bottom in place. If the reserve is not initially provided, a small wooden spacer is used to eliminate the gap.

Spikes:

The tenon joints are easy to disassemble, but the tenons themselves break quite rarely. Gently pry them apart using a wedge and a mallet. Wood glue or fish glue is usually used for joining. Remains of old glue can be removed quite easily with hot water and a brush. After cleaning and drying the parts, re-glue them using the recommended grades of glue.

Side walls:

the presence of grooves makes the lower part of the side walls of the drawer most susceptible to wear. This is where you can often see cracks, and worse, chips. To preserve the original wood as much as possible, the broken pieces can be glued with fairly strong polyvinyl acetate glue (PVA). Its use is recommended only for fastening parts that should not be disassembled later. To preserve the color scheme of the wood, PVA glue can be tinted with pumice. Reinforce the restored parts with small bamboo spikes. Do not use nails: as a result of wear and tear on the wood, their heads may protrude and damage the sliding guides.

If a chipped piece of wood is lost, carefully process the chipped area with a small hacksaw and glue a new, specially cut piece of appropriate size to it.

The most common areas of wear are the bottom edges of the side walls at the back of the drawer. They may become bent or even break. In this case, they should be aligned and then glued with a suitable thin spacer cut from wood. When processing the outer part of the side wall, you cannot use a classic plane; to remove a minimum layer of wood and level the surface, a chisel or a special small plane is more suitable, the front part of which is removed, and the cutting blade slides in front of the tool.

To restore the side of a drawer, cut a thin spacer from suitable wood with a small allowance for adjustment. Then glue, and after the glue has dried, saw off the protruding parts.

Using a ruler, mark a cut line on the side of the box so as to preserve as much of the old wood as possible. For convenience, place the box on the workbench in a vertical position.

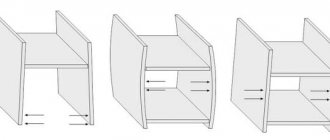

Guides:

they are mounted on the side walls of furniture and consist of several parts. The guide block is glued into the grooves of furniture posts or legs and serves as a support for the drawer. His sides always come forward.

The guide bar is attached to the sliding surfaces and, when moving, gives the box a direction parallel to it. The length of the block should be approximately equal to two-thirds of the length of the box. The base of the drawer is beveled at an angle of 45 to facilitate processing with a plane when installing it on the sliding guide.

Finally, an expansion bar rests on the top of the side walls and prevents the drawer from swinging when it is fully open. At the back, opposite the rack, there is a small wooden stop that limits the movement of the drawer in depth.

How to carry out repairs?

As a rule, guides made of soft wood contribute to wear and tear on furniture. After dismantling, you can turn them over and use them again. This will eliminate the need to cut and glue the gasket, and the furniture will be better preserved.

If you cannot remove the guides, you need to plane the bearing surface and install a gasket. But using a plane in narrow places is difficult and sometimes impossible. In this case, it can be recommended to clean the area with the defect, apply a polymer resin (ED-5 or ED-6) to it and glue a thin wooden plate.

A small addition: adjust the guide slightly above the cross beam of the front part, if it is overhead. This way it won't be damaged when opening the box. Missing or worn guides must be replaced, as they are absolutely necessary for the normal operation of the furniture. Loose stops must also be secured in place or replaced.

Don't forget about the locks

Broken or missing screws or empty mounting holes indicate poor performance of the drawer locks. Reinstall the locks using new mounting screws and pre-cleaning and lubrication.

| Typically, the wood fibers in the lower, back part of the box are directed in the same direction as on its front part. The bottom of the box is nailed to the back wall. | |

| Often the nails rust and are therefore not easy to remove. Saw them with a hacksaw blade, then remove the bottom, install it in the grooves of the front part and secure it with several nails. | |

| Tenon joints come unglued quite often. Before you begin removing any old adhesive residue with hot water, remove the sides of the drawer. You can use a knife or chisel to remove large amounts of old glue. | |

| To attach tenon joints, it is preferable to use glues of animal origin (carpentry or fish glue). To make gluing more effective, heat the bonded surfaces with a paint remover or over a hot plate, while observing fire safety rules and extreme caution. | |

| Tighten the parts to be glued together with clamps, paying special attention to the correct installation of the corners. For this purpose, you can use two slats: compare the length of the diagonals, which should be absolutely the same. | |

| Sectional view of the box: 1. Compensation beam. 2. Sliding guide. 3. Side guide. 4. Side wall of the box. 5. The lower part (bottom) of the box. | |

| Using an electric drill at low speed, drill holes for the bamboo tenons. Such spikes, with a small diameter, have sufficient strength, so they penetrate deep enough into the wall of the box without splitting it. | |

| For more effective gluing, move the damaged parts as far apart as possible. If necessary, completely replace the contacting parts and secure them with bamboo spikes. | |

| The small height of the side walls of the box can make it somewhat difficult to tighten them with a clamp. To compensate for the difference in levels, place a small stop on the back of the side wall, and then other stops on top and bottom. | |

| Turn the box over and use a ruler to make sure the top and bottom planes of its side walls are parallel. If the front side is strictly horizontal, as a result of wear, a noticeable bevel may appear on them, descending towards the back wall of the box. | |

| Completely eliminate the bevel using a plane, thereby restoring the horizontal planes. | |

| Use a jigsaw to cut the appropriate spacer along the grain of the wood. Before sawing, the surfaces to be glued must be carefully planed with a plane, since if the gasket is small, it will be impossible to clamp it in a vice. | |

| Carefully apply PVA glue to both surfaces to be glued. The glue, usually white, in this case is tinted with pumice. After the glue dries and is processed with a plane, the gluing line will become almost invisible. | |

| For proper installation, the gasket is made with a small margin in height, width and length. | |

| To process the glued gasket, use a special plane. Remove any protruding parts, being careful not to damage the wood of the furniture. | |

| Using a ruler, mark a cut line on the side of the box so as to preserve as much of the old wood as possible. For convenience, place the box on the workbench in a vertical position. | |

| Over time, sliding guides, made of soft wood, expand and increase in height. Thus, they wear out more and more, and burrs form, preventing the drawer from moving out. | |

| If it is not possible to remove the guides, plane them in place to remove burrs. Only the sliding guide is processed, while the side guide bar serves as a support. | |

| Glue a spacer cut from durable wood such as beech to the surface of the side rail. In this case there is no need to allow for post-processing of the gasket; adjust its position in place before gluing, as this operation will be difficult later. | |

| Due to limited access to the processing area, planing slides and bars without dismantling furniture requires certain skills, as well as the use of special tools, such as a plane with two replaceable blades. | |

| The last stage of work on restoring the guides is the adjustment or replacement of the stops. In this case, the wooden support is nailed to the back post of the desk without removing the drawer from it. |

Solving problems with the design of dresser drawers

Often there is a repair of drawers, which consists of correcting the fastenings of the bottom or facade. With the overhead type of installation, the drawers are pulled out, old nails or staples are removed from the bottom, and then the panel is nailed into place with new fasteners. With a mortise type of bottom (a sheet of plywood or laminated fiberboard fits into the grooves of the side walls), the boxes are disassembled, the grooves are carefully cleaned, the bottom is replaced with a new one from a suitable material and glued into the grooves. The façade that is loose or in need of replacement is unscrewed, coated with PVA in the places where it contacts the front and side walls of the box, and then screwed or nailed with pins (chops), using new fasteners.

Repair and replacement of guides in drawers

It happens that the guides quickly fail because the box is large and heavily loaded. Telescopic (ball) guides allow installation in two rows. In this case, the drawer will be endowed with greater load-bearing capacity and will last longer.

With such an “upgrade,” it is quite possible to replace the bottom made of flexible fiberboard with chipboard or plywood in order to store, say, tools in such a box.

It is better, of course, to replace the metal guides. They don't cost that much. However, if upon visual inspection the rollers are intact, have an even shape, and only the metal of the runners is bent, you can try to return it to its original shape. To do this, use a vice, pliers and other hand tools.

Repair of ball or roller drawer hardware

The type of retractable fittings dictates how to resolve problems. If the roller version (metabox) has become difficult to guide, then the fasteners may have sagged and then unscrew the runners and then attach them in the correct place, making sure the surfaces are horizontal. If the metal parts are deformed under the weight of the contents of the box, the guides will need to be replaced with new ones. After which it is important to adjust the chest of drawers on the roller guides. Ball options (telescopic) are more reliable than roller ones, and often only require proper adjustment, and not repair. If a loss of functionality is noticed (the frame flies off the wheels), the slide is dismantled, disassembled and cleaned, and the wheels are lubricated if necessary.

Video of repairing drop-down drawers

Door repair

A common defect in cabinet furniture is poor functioning of cabinet doors and bedside tables: they warp, do not want to close, and open spontaneously. The reasons are different: incorrect adjustment, defective hinges or magnetic latch, misalignment of the entire structure, swelling or delamination of the material.

Note: changes in the geometry of cabinets are often associated with the unsatisfactory condition of the back wall. The fiberboard sheet nailed there plays the role of a kind of retainer. If necessary, it is changed by cutting out the required fragment to size and attaching it with nails or small screws.

If the problem is in the loop, then replacing it is not always necessary: in most cases, adjustment helps. For this purpose, the design of the device has two screws: one is responsible for the fit of the door to the body, the second regulates its position in the frontal plane, moving it to the right or left.

A loop that has been torn out with meat can be put back in place using screws of a larger diameter. Another option is to drill holes, place wooden dowels in them using wood glue, and then screw fastening screws into them.

If the hinge breaks, it is replaced. Installation in old sockets is simple: mounting screws are screwed into the existing holes. It is more difficult if the hinge is installed in a new place or the door is changed. Assembly occurs in the following order:

- Sockets with a diameter of 35 mm for disc hinges are marked and cut with a milling cutter.

- A hinge plate is inserted into the slot located in the door perpendicular to the end and secured with a pair of self-tapping screws.

- The second plate is placed in the body, secured with screws through special holes in the bosses.

- Screw in the two adjusting screws to achieve the desired door position.

USEFUL INFORMATION: What color to paint the walls in the kitchen

Details of adjusting the hinges are shown in the video.

Spontaneous opening of doors occurs when the magnetic strip is faulty. In some cases, it helps to clean the magnet and the iron plate it attracts from contamination, adjusting their relative position strictly opposite each other. If these measures do not help, then the element is changed.

And one more video: a little trick that will solve the problem of adjusting a cabinet with worn out hinges without replacing them.

Strengthening the structure of drawers and chest of drawers

Very often, a chest of drawers in the basic design does not provide the required level of strength, which is why the panels become deformed, fasteners loosen faster, drawers move out worse or fall out, guides fly off, and a shelf falls. This means that the frame needs to be strengthened. For example, replace a thin bottom made of plastic or fiberboard with a similar thickness made of varnished plywood or laminated chipboard. Strengthen the back wall in the same way. If you plan to heavily load the furniture, it is recommended to additionally tighten the joints (facade - side wall, back wall - frame) with corners.

Repair with self-adhesive film

The self-adhesive film will give the headset a unique appearance.

Repairing facades using film is simple:

- The surface is prepared: the fittings are removed, the facade is sanded, degreased and primed.

- A piece of film is cut with an allowance of 2 cm on each side.

- The protective layer is removed from an area of 10–15 cm, the film is glued to the edge and at the same time smoothed with a piece of fabric.

- Next, gradually unwinding the roll, you need to fix the entire fragment on the facade, avoiding, if possible, the appearance of air bubbles.

- When pasting the ends and rounded areas, it is recommended to slightly heat the film with a hairdryer to make it more elastic.

- If it was not possible to avoid their formation, the bubbles are pierced with a needle or carefully cut to allow air to escape. All that remains is to smooth out the film.

- Excess material is carefully trimmed.

More details in the video.

The use of self-adhesive film during renovation often completely transforms kitchen furniture.

A number of repair recommendations and useful life hacks

- For lightly loaded dresser drawers, eight-millimeter brackets are used when installing the bottom. But, it’s safer to take a hot 10.

- The worse the quality of MDF or chipboard, the thinner the fastening screws are chosen (maximum 3.0 mm).

- If the pins become loose, simply drill out the old holes to a larger diameter and take a larger diameter of the fastener.

- Pins, grooves, and even connections nailed with staples or screws are pre-coated with PVA for reliability.

- To ensure that the chest of drawers does not lose functionality, drawers do not become difficult to pull out, and the shelf doors do not stop closing, in no case should you apply too many layers of paint or varnish. If the appearance still requires a multi-layer coating, first remove the extra 1-2 millimeters of the base with a grinding wheel.

- Extend the life of retractable rollers by regularly applying silicone lubricant. This is, by the way, how to care for furniture from IKEA.

Roller guides and their “convenient” brothers – metaboxes

The advantage is simplicity, low cost, ease of installation, the design is such that the box closes under its own weight - the last few centimeters of closing are downhill. Thanks to this, such guides have become very widespread. The photo of the metabox clearly shows which part of the guide is intended for what. One is attached to the furniture wall (small parts in the photo, load-bearing), the second is attached to the drawer structure. In the case of a metabox, the second part of the set forms the entire side wall of the box. A box with roller guides installed looks like this

However, the main disadvantage of this type of guide is incomplete extension. The drawer can be safely pulled out to approximately 75% depth. Let's see what problems most often arise with such guides. Naturally, we will assume that everything was normal in the “freshly purchased” furniture.

Incorrect installation

This problem is usually diagnosed immediately, even before purchase. A box with a roller guide correctly installed according to the technical gaps moves smoothly, it has a fairly small horizontal play. It is easy to check - try to “sway” the almost closed box left and right by the handle. If there is more than three to five millimeters of play, the installation is incorrect. This may be caused by errors in the dimensions of parts during design, or it may be a technological error in the guide itself. It is no secret that in the modern furniture market there is a sea of small firms that save on literally everything. And cheap guides have questionable gap thickness.

Over time, this problem may arise due to deformation of the structure. A heavily loaded furniture box will become deformed if it is made from a slab of improper thickness. Again, the manufacturer saved and used the material without thinking about the safety factor.

Problems caused by changes in technical clearance are difficult to cope with. Here you already need to intervene in the design, this can be done in 90% of cases and is not very difficult, but this is another rather voluminous topic.

If the drawer does not close on its own when pushed in under its own weight, this is an incorrect installation of the supporting part of the guide. Most often it is not installed horizontally. There is no need to touch the front part during this repair - we don’t want to mess with the appearance of the drawer gables. We unscrew the fasteners - except for one point near the very front roller, align them, and screw them into place. We do this with part of the guide, which is located on the furniture wall.

Excess load

This problem is not as rare as it might seem. The reasons can be either banal, like “the manufacturer saved money” or “well, they put a lot of stuff in,” or non-standard - children simply love to climb the handles of dresser drawers as if on a ladder or use them as a support to climb higher. And since the last thing people save on now is the handles, the guide suffers.

The problem can be solved in two ways. The main symptom is that the front wheel of the supporting part of the guide, the one on the furniture wall, “twists” - the plane ceases to be vertical, the metal in the mounting area is deformed and the wheel begins to catch on the second guide. You can return the wheel to its original position. There is no need to hit with a hammer, the roller can simply be split, but with the help of a vice, holding the bushing, you can return the part to its original position.

However, more often this problem is caused by the manufacturer. There are two main applied standards for metal thickness for such guides - 0.5 and 1 mm. The manufacturer could simply save money. Replacing the guides with thicker ones is not a problem - all fastener locations match. Simply remove the old ones and replace them with new ones.

The older brothers of the roller guide – metaboxes – have the same “diseases”. If it seems to you that this will not help, replace the roller guides with telescopic ones. This is quite easy to do. Below we will talk about roller guides.

Exceeding the effective service life

There's nothing you can do about it. The rollers are plastic and will simply wear out over time. Backlash appears, drawers no longer open so confidently. There is only one way out - replace it. You can, of course, use silicone lubricants for a while, but this will not solve the problem.

Deformation of individual parts

This can happen if the guides are installed carelessly. There are not enough attachment points on the load-bearing part of a furniture wall, for example. Then the guide bends, the connections become loose, this can be detected almost immediately. To avoid such a problem out of the blue, ask the seller to pull out the drawer and make sure that the guides are attached at all points provided for by the design.

The same problem can occur if the load is exceeded. In this case, the lack of proper rigid fastening will only aggravate the situation. It is easy to “treat” – most often it is enough for the parts to be returned to their original shape and secured properly.

Chair repair

Damaged coverings of old kitchen chairs can be restored using the above methods. The exception is furniture with soft seats: re-upholstering them without skill is quite problematic, although possible. But there is a simple option: make a cover. In this case, reupholstery will not be required, and the appearance problem will be solved.

Loose parts are strengthened using wood glue. In exceptional cases, self-tapping screws are used with mandatory drilling of holes for them. Painting and decoupage transform an old, unsightly chair into an original and beautiful piece of furniture.

You should not throw away old kitchen furniture that has lost its outer luster. With a little imagination, you can give it a completely new appearance, adding originality to the interior of your home.