Main varieties

When arranging a kitchen space, it is necessary to make the right choice of equipment, as well as decide on the installation location. For this purpose, there are varieties of fully built-in hoods:

- Fully built-in horizontal hoods. For this purpose, a cabinet without a bottom is used. The equipment can be completely hidden by walls. Sometimes its bottom panel partially protrudes beyond the dimensions of the furniture. Installation is carried out directly above the cooking zone.

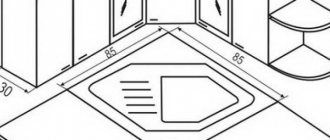

- Vertical hoods, built into a wall niche.

- Hood built into the countertop. Such equipment is placed near the food preparation area, and the stove itself is mounted in the set. During operation, the doors open and contaminated air enters without having time to disperse throughout the kitchen space.

- Flat. They are fastened directly to the bottom of the cabinet.

- Telescopic. They are distinguished by the presence of a retractable panel. It moves out during cooking. Sometimes this process happens automatically.

Types of built-in hoods by configuration

According to the configuration, hoods can be horizontal or vertical - this means the location relative to the hob. Horizontal appliances are the most common; they are located directly above the stove, which allows them to effectively capture rising steam. An example of such a classic solution is shown in the photo below.

Hood with retractable panel and built-in lighting

If you don’t need a cabinet above the hob, you can install a vertical hood. They can also be built-in, but not into furniture, but into the wall. The option is difficult to execute, so we can often see them open. The suction panel of such a hood is inclined at an obtuse angle relative to the stove. The lid, which in the open position becomes something like a catcher, helps to draw in steam better. There are also models designed differently.

Vertical hood

This design is not entirely convenient due to the fact that dirt and grease will actively accumulate on the internal surfaces, and washing them is not so easy.

Device principle

If the horizontal version of the equipment can be installed in any box, then the vertical version must be mounted in a specially prepared niche. An important design element is the cap. Splashes that fly during cooking are caught by this part.

Hoods are either flow-through or recirculating. In the first case, air is removed through ventilation ducts. For this purpose, air ducts are used, which come in round and square sections.

Depending on the material used, there are 2 types of products:

- Plastic. This is a good option, since air passes through smooth walls without resistance and dirt is less easily retained. To form a turn, a knee is required. In these places, the preconditions for turbulence are created, which is a disadvantage of this type of air duct.

- Corrugated. The presence of folds interferes with the passage of air and causes additional noise. The advantage is that there is no need for adapters. The corrugated product bends easily and can be mounted at any angle.

If there are no ventilation ducts, a hole is simply made in the wall.

The air flow is driven by fans built into the system. Recirculation systems are based on the fact that the air flow after cleaning is not removed, but returned back. The main component of such a hood is a filter for trapping fat. It is located in the retractable part. Here the air is cleaned of fatty components, then passes through a series of carbon filters and moves back.

We recommend reading: Review of 5 hoods built into the design of a wall-hung kitchen cabinet

What are the features of installing a built-in hood?

Currently, both in Moscow and in other cities, all kinds of built-in products have gained wide popularity. This applies to both furniture and various gadgets and other things. The kitchen hood was no exception. This design allows you to use the device comfortably without making significant changes to the interior design. In order to “hide” the device, it is optimal to use a hanging cabinet. Install it above the stove, and place a built-in hood inside.

The advantages of a built-in hood are its following features:

- The device is difficult to notice with the naked eye. It does not stand out from the general background in any way, unlike standard island and dome models.

- Great variability in product sizes. You can choose a built-in hood with any parameters depending on the size of your kitchen. Common options today are products designed to be installed above slabs of 45, 50, 60, 80 or 90 cm width.

- Even the most compact models demonstrate high operating efficiency. They easily draw in air, filtering it.

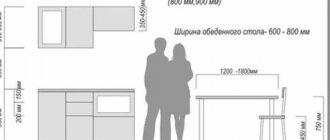

When choosing a built-in hood, first of all check whether its size matches the size of the box where you plan to install it. The box refers to the furniture in which the purchased model will be hidden. You need to take her measurements in advance before going to the store. You should also pay attention to another seemingly insignificant detail. You will not be able to use the device comfortably if it is much smaller than the stove. In this case, there is a possibility that the air will not be sucked in intensively, as a result of which unpleasant odors will remain in the room. The installation height of the built-in hood is also very important.

Each of the models of built-in kitchen hoods on sale can be classified into one of two types of design . They differ significantly from each other in the installation method.

Circulating or ductless

The peculiarity of devices of this type is that the volume of processed air does not change. The same air is simply filtered throughout the entire operation of the device. The use of such a built-in hood does not require installation outside.

Flow-through or with duct

This option perhaps demonstrates a higher quality of work and is preferable to purchase. Unlike models of the previous type, polluted air here is removed outside, after which fresh and filtered air enters the room.

In addition, there is a classification based on one more criterion. In accordance with it, built-in exhaust devices are divided into models:

- Horizontal . Devices of this type are the most common today. They can be seen in most modern apartments, the owners of which have decided to purchase a built-in hood model. The device is installed in a cabinet or box that is hung above the stove.

- Vertical . To use them, you do not have to purchase hanging furniture. You can install such a built-in hood into a wall. The only disadvantage here is the high labor intensity of the work carried out. For the device to work, it must be placed in a pre-made niche. Creating a recess, in fact, is the most difficult moment in the process of installing a vertical built-in hood.

Take the test

Regardless of which model of built-in hood was purchased and on what principle it will work, it will definitely have a filter. It is called fat-trapping or fat-trapping. To begin air purification, the retractable part of the hood is placed above the stove. This is where the filter is located. Devices of different types can have one of two operating modes: recirculation or exhaust. This was discussed in more detail above. If you are dealing with the first type of device, the filter must have a carbon base.

In addition, built-in hoods differ in the type of control .

Electronic devices are the most expensive option of all existing ones, but such a high cost is due to the corresponding quality of the device. Before buying such a hood, carefully study the list of functions it performs and think about whether you will use them all. If there is a possibility that most of the device’s capabilities will not be used, it makes sense to purchase a more budget model.

As an example of the functions that complement electronic built-in hoods, we can cite:

- the ability to switch different operating modes, in particular, interval mode (the device turns on every hour to prevent air stagnation in the room);

- change of operating modes (available in all types of built-in hoods);

- notification in the form of indicator signals in case of problems with the filter;

- automatic start and shutdown;

- the presence of a sensor that turns on the light above the stove when a person approaches and much more.

Equipment advantages

Since the installation of the hood is done flush into a niche or hidden by a box, no attention is paid to the external design. There are also other advantages:

- The installation process is not difficult. The equipment is installed by 1 person.

- Hoods are not only push-button, but also touch-sensitive. This is convenient because your hands are often covered in fat. With this system of operation, turning on and off is carried out with a light touch of the hand.

- Availability of automatic switching mode, backlight and timer.

- Large size range. This makes it possible to make a choice based on the existing parameters of the cabinet.

- Availability of models with remote control.

- Possibility of changing dirty filters.

- During operation, the installation creates a slight noise.

Selection of air ducts

To connect the hood to the air duct, it is necessary to install a connecting air duct. It is common to use two types:

- Gflexible metal corrugated pipeline. Easy to install, does not require the use of components, does not load supporting structures. The appearance of such pipelines is unattractive, so it is customary to hide them in a box made of plasterboard, plywood or other sheet materials with subsequent finishing.

Flexible metal duct - Plastic air ducts. Smooth pipelines of round or rectangular cross-section have an attractive appearance and do not create noise during operation. They require the use of additional elements - corners, turns, adapters, which complicates installation.

Plastic air ducts

Attention! When choosing an air duct, you need to remember about the throughput. The size of the pipeline should not be smaller than the ventilation vent in the wall.

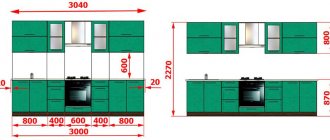

Size specifications

Equipment parameters are selected depending on the kitchen area. The larger it is, the larger the hood is required. This is especially true for the cap. This design element allows you to capture a larger volume of air.

To choose the right hood , you need to take the dimensions of the slab. This is important because the device must be approximately the same width. In this case, optimal operating mode will be ensured. The reference point is 60 cm with a range of hood sizes from 45 to 90 cm.

Small parameters indicate low power of the installation. Large ones, on the contrary, occupy a significant amount of space, which ensures good air purification. The most convenient option is to select a hood if there are no tiles. Then all the dimensions are put together. The main condition is the size of the hood, which should cover the cooking area.

Installation rules

The installation of a built-in hood in the kitchen is carried out in a closet. There are several ways to do this:

- A box without a bottom is ordered. And the necessary holes are drilled in its shelves and top.

- The cabinet is made by hand.

- A ready-made design is used. The bottom is removed and holes are formed.

We recommend that you read: Supply ventilation systems in a private house

If you use the third method, then complete disassembly of the furniture is not required. The operating procedure is as follows:

- The doors are removed. The fastenings of the side walls and rear plane are unscrewed from below. After this, the bottom comes away on its own.

- The fasteners are attached to the inner shelf. To do this, it is removed. A hole with a diameter of 10 cm is cut in it for the air duct. Then the shelf is applied to the body of the device, and the places for screwing in the screws are marked.

- Using metal corners, the hood is fixed to the shelf, and the entire structure is installed in the cabinet.

- The last stage is the installation of the air duct. To do this, a corrugated or plastic pipe is inserted through the upper hole. The joints with the equipment are coated with glue and secured with a clamp. It should be remembered that over time this unit will require disassembly to clean the device. The second part of the air duct is connected to the ventilation duct.

During installation, it is necessary to maintain a distance from the hood to the tile, which should be 80 cm. Pay attention to the proximity of the socket. Do not allow hanging wires near a hot surface.

Features of operation

During operation, the usual requirements are observed. The device should not overheat and water should not come into contact with it. Pay attention to wires that should not touch the hot surface. In addition, the following maintenance is carried out:

- The grease filter is cleaned regularly. To do this, it is removed and washed using detergent. Then it is put in place.

- A critical element of a recirculation hood is the carbon filter. It needs to be replaced every six months, since during this period it loses its properties.

- Attention is drawn to the retractable panel. The resulting layer of fat is removed so that the element moves without difficulty.

- The touch panel is being wiped. There are always fingerprints on this part of the device. If a thick layer of fat appears, the equipment will be harder to turn on.

- It is necessary to ensure the cleanliness of the front panel even when turning on the button. Fat gets into the cracks and the buttons stick.

We recommend reading: Reducing air humidity

Top rated manufacturers

Many companies are engaged in the production of fully built-in hoods. To understand which hood option is better, you need to study the characteristics of the most rated manufacturers:

- Bosch. The company produces both premium and more affordable products. Some models are equipped with an automatic system; all options are reliable and silent.

- Krona. Sells reliable kitchen products that are in great demand.

- Elikor. The products have a unique design. Gilding and decorative carvings stand out on the surface.

- Hephaestus. Both low and high power models are available.

Installing a built-in hood in the kitchen allows you not only to clean the air, but also to save space. The equipment located in the cabinet fits well into the overall design of the kitchen. All air ducts and wires are hidden.

Reviews of fully built-in hoods

Such devices are suitable for kitchens in which every centimeter of space is worth its weight in gold. Consumers note that telescopic devices are the most effective and convenient. Horizontal ones also have a large number of positive responses.

The demand for remote, fully built-in kitchen hoods is also growing (reviews confirm this). Useful programs that will come in handy during operation: automatic backlight activation, filter indicator and automatic start.

CONCLUSION

The article examines 4 types of integrated devices, as well as how to install a fully built-in hood in a cabinet. When choosing a specific model, you should pay attention to the individual characteristics of the furniture, the layout of the kitchen and the main parameters of the appliance. The main indicators include: width, power and noise level. Before installation, you need to read the instructions that come with the device.