In the modern market of goods and services you can find absolutely everything, but many people prefer to make a piece of furniture themselves, without the help of specialists. A self-made double bed, drawings and diagrams of which are attached, can become a real decoration of the bedroom interior. To make such a bed, you need to familiarize yourself with the general recommendations of specialists, make a drawing and a plan of sequential actions. The drawing is needed to calculate the necessary materials, funds for their purchase and draw up a sequence of installation work.

Preparatory work

A do-it-yourself double bed has a number of advantages - it is the ability to choose the required size, design, shape of the legs, as well as the quality of the finished product in the final result, thanks to which the bedroom turns into a masterpiece.

The main details in its manufacture are:

- design, which can be classic or with a lifting system;

- a drawing to assist in the preparation and manufacture of parts;

- plan of sequential actions.

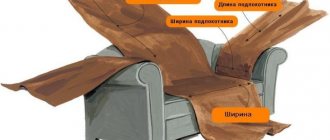

Layout of a double bed including mattress

Drawings and diagrams

No work on the manufacture of interior items is complete without drawings and diagrams. The production of a double design was no exception. Below you can see several options for drawings and diagrams often used in the manufacture of double models.

Having decided on the type and size of the double bed, you need to make a detailed drawing. The scheme allows you to buy the required amount of building materials of a certain size or order their production in a furniture workshop. The drawing is also used throughout the entire construction process, for making individual elements with your own hands and their fastenings.

Double bed with several drawers

Assembly diagram

Bed with two drawers on the sides

Main details

Beds with nightstands

Side view

Frame assembly

Materials and tools for work

A double bed can be regular or with a lifting mechanism. Their manufacturing technique is slightly different from each other, since a product with a lifting mechanism has an additional box for storing things and a lifting bed frame. In order to determine the size of the product, you need to take into account the dimensions of the factory mattress that you plan to purchase. To make a standard double bed with your own hands, you will need the following materials.

| Bed parts | Material | Dimensions of parts after cutting |

| Frame | 4 boards 240x30x2.5 | 2 boards 205x30x2.5 2 boards 148.5x30x2.54 |

| Support beams | 3 boards 3x10x240 | 3 boards 3x10x202 |

| Decorative finishing | 3 boards 2.5x5x240 | 2 boards 2.5x5x157.5 1 board 2.5x5x202 |

| Legs | 1 block 10x10x240 | 6 bars 10x10x10.5 |

| Slatted bottom | 19 boards 2.5x7.5x240 | 19 boards 2.5x7.5x148 |

When choosing a material, many are faced with wood of different quality. Experts recommend choosing high-quality wood only for the supporting structure. For the legs and bottom slats, you can purchase second-rate material. If you don’t have enough money for quality material, you can purchase chipboard or plywood.

If you plan to make a product with a lifting mechanism, then you will need a little more materials. Since, in addition to the main frame, it is also necessary to make a lifting frame for the berth. For its manufacture, you can use metal building material. The drawing should include not only the building material, but also the type of lifting mechanism, because its installation plays a big role.

Choosing a board

Tools you will need:

- roulette;

- pencil or marker;

- brushes;

- sandpaper;

- wood putty;

- varnish, stain;

- wood glue;

- self-tapping screws (30, 50, 60 mm);

- measuring square;

- drill;

- jigsaw;

- clamps;

- grinding machine;

- construction stapler;

- hacksaw.

When cutting parts according to the dimensions of the drawing, you need to mark them as accurately as possible.

What you will need

To make a bed with your own hands, you need to calculate the amount of material, fasteners, and accessories required in accordance with the drawing, and prepare a set of tools for the job. Depending on the type of design, additional consumables may be required.

Selection of construction material

When constructing a double bed, the choice of building material affects the performance characteristics and general appearance of the product.

To select raw materials for self-production of a bed, it is necessary to analyze the nuances of processing, operational features, and cost of the material.

- Natural wood is an environmentally friendly material with a long service life. Processing raw materials requires some experience, so wood is often chosen only for creating a frame.

- MDF is not as durable, but is much cheaper. All the main elements of the bed are usually made from it.

- Chipboard or laminated chipboard do not differ in strength and durability compared to other building materials. Raw materials are used for the production of auxiliary and decorative parts.

- Metal requires skills in working with a welding machine. Such a bed will be durable, reliable and will last for many years.

When creating a design, you can combine materials. For a product of increased strength, a metal frame with a wooden finish is suitable, and the timber frame is complemented with plywood parts.

It is better for an inexperienced craftsman to use soft wood species (pine, cedar, linden); they are easier to process.

Tools and additional materials

The set of tools and equipment for the job depends on the selected material.

To make a wooden double bed, a standard set of fixtures and components is required:

- drill;

- jigsaw or hacksaw;

- screwdriver;

- self-tapping screws;

- metal corners;

- furniture glue;

- building level;

- roulette;

- abrasive (sandpaper) paper or grinder;

- varnish for wooden surfaces.

Experienced craftsmen decorate a wooden bed with patterned headboards using special milling equipment.

To make a metal bed, you need to prepare the tools according to the list:

- welding machine;

- Bulgarian;

- drill;

- roulette;

- metal brush or file for cleaning and polishing surfaces;

- primer for metal;

- varnish or paint.

Creating forged items requires experience with forging equipment, which can be borrowed or rented.

For a bed with pull-out niches, you need to buy metal roller guides. The lifting design of the product involves the design and installation of a folding mechanism.

Attaching supports for slatted bottom

The supports for laying the slats are attached according to the same principle as the frame.

Technology for fastening supports for slatted bottom:

- in the support boards it is necessary to drill holes for the thickness of the screws, in increments of 25 cm;

- to fasten the boards, it is better to place the frame on its side and, having drawn a line at a distance of 5 cm from its bottom, you can proceed to the installation steps;

To attach the boards, I placed the frame on its side

- Before attaching the support boards, they must be lubricated with wood glue;

- fastening is carried out along the frame along its edges, using 50 mm self-tapping screws;

- For stability while the glue dries, the support block must be pressed; for this you can use clamps. An example can be seen in the photo;

The frame with the block was fixed until completely dry.

- the middle support board is attached parallel to the previous two, at the same height, by drilling holes in its ends;

- the remaining holes from the fasteners must be sealed with putty and cleaned with sandpaper after it dries.

How to make a double bed: step-by-step instructions

A double bed made of wood is considered the simplest and most uncomplicated product. Creation begins with choosing the type of structure and determining the dimensions. The drawing is drawn up to calculate the necessary materials and the costs of their purchase. A detailed diagram of the product shows the sequence of installation work. Next comes the stage of preparing raw materials for work, manufacturing parts, and assembly.

Calculations and drawing creation

The drawing is needed to calculate the necessary materials, funds for their purchase and draw up a sequence of installation work.

The diagram indicates the dimensions of each part and the final product in centimeters, the order of assembly of the elements (frame, base, legs, headboard, footboard, side panels), places and number of fasteners.

Calculation of materials for a wooden bed for a 200x160 cm mattress:

- board 40 x 100 x 3000 mm - 2 pcs.;

- block 40 x 60 x 2000 mm - 6 pcs.;

- fence board 20 x 80 x 2000 mm - 15 pcs.;

- board 20 x 146 x 6000 mm - 1 pc.

The dimensions of the boards and beams for the future bed depend on additional options (drawers, lifting mechanisms, etc.).

When determining the dimensions of the bed, you should start from the size of the mattress, which you should buy before making a double bed. Its actual dimensions may differ from those declared by the manufacturer.

Preparatory stage

After purchase, the material should lie in the house for 3-4 days to adapt to the climatic conditions of the room.

Before cutting the parts, the wood is sanded, irregularities and jags are eliminated. Treat the surface with an antiseptic and pest repellent.

Making bed parts

A double bed consists of a power frame and base supports. The base for the mattress is made from a sheet of chipboard or transverse slats - lamellas.

The headboard and backrest are optional. Beds in the minimalist style do not include these elements.

Frame

The supporting structure is the frame to which the headboard, footboard, side drawers and mattress base are attached. The finished boards (165 cm - 2 pcs. and 205 cm - 2 pcs.) are joined into a box at right angles, the ends are glued together and fixed with metal corners on self-tapping screws. The result is a rectangular-shaped structure.

Base

The supports for the lamellas are made from the beams that were used in the manufacture of the frame. The wood is sawn into sections corresponding to the length of the sides of the bed, and fastened along the inner perimeter of the frame. The support boards are attached to the frame in increments of 25 - 30 cm.

Supports

On the longitudinal side of the rigidity, which runs in the middle of the frame, you need to install 1-2 legs at an equal distance from each other and relative to the backs of the frame. 4 legs for the frame itself are attached to its corners with fasteners. The height and type of legs are determined depending on the preferences of the owners and the stylistic affiliation of the product.

Some models do not provide this element at all. The bed is installed directly on the frame support beams or on the side backrests.

Legs

Making legs with your own hands is the easiest step in the entire construction process.

The whole manufacturing process:

- the prepared timber with a cross-section of 10x10 cm needs to be cut into 6 bars 10.5 cm long;

Blank for future legs

- fastening is carried out to the support bars;

- to strengthen the frame, two additional legs are attached under the central support, at a distance of 50 cm from the edges of the frame;

- To decorate them, you can give them any shape. You can saw off one of the corners approximately 3 cm from the bottom, at an angle of 45 degrees, as in the photo;

- Upon completion of the work, all sides must be sanded.

Fastening all created elements:

- as mentioned above, the legs are attached to the frame support boards. To do this, you need to use 60 mm self-tapping screws. You need to spend at least two on each leg;

This is what the leg mounting looks like from the inside

- holes are pre-drilled with a drill, a drill whose diameter coincides with the cross-section of the screws.

Legs attached to the frame

Before screwing in the screws, you must first drill holes, which will reduce the risk of splitting the boards.

Step-by-step master class on making popular models

Instructions on how to make a wooden bed yourself will definitely be useful not only for beginners in carpentry, but also for professional craftsmen. Technologies and materials are constantly changing, providing new ideas to make life easier.

Made of solid pine with drawers

The most affordable and easiest option for making it yourself is a bed made of solid pine, which can be processed quite well. An additional plus is the fragrant smell, which promotes sound sleep and good rest.

The work is performed in the following sequence:

- All structural elements are marked and cut according to the drawing.

- Assemble the footboard, center partition and side parts of the bed.

- Mount the frame and base under the mattress.

- The boxes are installed, the bottom is reinforced with planks, and the bottom is made of chipboard or plywood. Two transverse guides are installed on the sides.

- The drawer handle can be cut out at the front, or you can use special fittings for it.

When working, use sharpened drills and only new discs. A dull end will “tear” the fibers, so the edges will have to be cleaned and sanded.

From logs

Furniture in this design is more suitable for a rustic style. It is important to take into account that it requires a sufficiently large free space for placement. If the bedroom is small, it is better to choose another option so as not to visually make the room even smaller.

Use logs with a trunk diameter of at least 20 cm, boards for the supporting structure, the thickness of which is at least 2.5–3 cm. The internal perimeter of the frame will be secured from the beams. Sequence of work:

- Marked pieces of logs are laid around the perimeter, cuts are made at the ends, fastening is carried out with self-tapping screws or dowels.

- A support beam is installed in the middle of the structure, and a support board is installed parallel to the side logs.

- Boards are placed in a perpendicular direction to support the mattress.

- Legs made of logs are fixed at the corners of the frame, installation is carried out using self-tapping screws, but it is better to secure the structure with grooves (cuts).

- The end parts of the bed are reinforced with beams or logs of smaller diameter, which serve as stiffeners.

- The headboard can also be made using parallel rows of logs, planks or beams.

Options for large bed sizes, their main pros and cons

If installed correctly, such a bed will last for several decades. It is better to renew the coating periodically, because natural wood is a “tidbit” for many insects. Antibacterial impregnation and pest repellent compounds are chosen from special ones, labeled “For wood.” A carved back and headboard will be a suitable decoration, but it is better to avoid fabric decor.

From furniture board

The material consists of glued wood panels. Due to additional heat treatment, the sheet becomes dense and monolithic, resistant to temperature, moisture and bacteria. It is convenient to work with him, you can bring original ideas to life.

You will need to complete the following steps:

- Blanks are cut from the sheet according to the drawing.

- The frame of the product is assembled and reinforced along the perimeter with beams.

- The bottom can be made of plywood or chipboard, reinforced with corners and a partition installed in the middle - here you can store bedding or things.

- Mount the base under the mattress; instead of slats, you can also use a shield.

- A lifting mechanism is installed to provide access to the drawers below.

- Cuts and corners are polished and treated with suitable compounds.

The application of stain to vertical elements occurs from bottom to top. After this, the products must be varnished to fix the color and protect the surface from external influences.

Decorative elements

Decorative elements play a big role in finishing the product; thanks to them, the bedroom will sparkle with new colors. One of the options for finishing elements is wooden slats, 5 by 2.5 cm thick, which should also be included in the drawing.

Manufacturing process:

- it is necessary to make the required size of slats from the prepared materials;

- the prepared slats must be sanded and painted with stain, the color of which is chosen based on personal preferences and the design of the room;

- after drying, they are coated with water-based varnish;

- After opening the first layer of varnish, you need to sand the slats to prevent the appearance of all kinds of bubbles. Next, apply two more layers of varnish;

- The painting procedure must also be carried out with the legs.

Fastening:

- decorative trim is attached with glue;

- it is necessary to apply glue to the surface of the frame and finishing slats;

- using clamps, press them for a while, preferably until the glue dries completely;

- all excess glue must be wiped off with a damp cloth;

- The slats can be fastened using either nails or self-tapping screws.

Fastening the lifting mechanism requires additional skills, since its installation must be of high quality and safe. There are three types of mechanisms, each of which is installed differently. Therefore, having chosen a certain type, you need to carefully study its installation diagram or seek the help of specialists.

Materials for making beds

- Mattresses

- Beds

- Pillows

- Dream

Introduction

| Selecting a mattress |

| What is the correct mattress or mattress? |

| The history of the mattress from the beginning to the present day. |

Classification

| Types of bed mattresses (classification) |

| Spring mattresses |

| Springless mattresses |

Materials

| Polyurethane foam |

| Memory |

| Natural latex |

| Strutto |

| Thermal felt |

| Sisal |

Orthopedics

| Orthopedic mattresses: definition and varieties |

| Technology for the production of orthopedic mattresses |

Mattresses and human health

| The influence of mattresses on human health |

| Use of mattresses in medicine |

| Magnetic mattresses - a revolution or a fake sensation? |

| Mattresses with massage |

| Mattresses for allergy sufferers |

Selecting a mattress

| How to choose the right mattress |

| Custom or factory made mattresses. What to choose? |

Other

| Mattress care |

| Myths about mattresses |

| Prospects for the development of the mattress market in Russia |

| Round mattresses, advantages and disadvantages |

Beds

| Beds: description and purpose. Variety of models. |

| History of beds |

| Beds with the latest technology |

| Medical beds |

| Materials for making beds |

| Sofa or bed? |

| Bed care |

| Bedroom styles |

| Hammocks. Advantages and disadvantages |

| How to choose the right bed? |

| Zero gravity beds are a requirement for the space age |

| Feng Shui about the placement of beds |

| Folding beds: a modern bed replacement |

| Round beds in the interior of the bedroom |

Pillows

| Pillow: definition, purpose, varieties |

| The path of pillow development - from the Stone Age to modern times |

| Materials for pillows (cases and fillings) |

| Care of pillows, their service life |

| Modern pillows - a symbiosis of traditions and new technologies |

| The shape of the pillow is an important part of a good sleep |

| The influence of pillows on human health and sleep |

| Use of pillows in medicine |

| Choosing pillows: what to look for |

| Pillows for children |

| Hard or soft? |

| Pillowcases are an important bedding item |

| Choosing a pillow for people with allergies |

| Herbal pillows |

Dream

| Sleep hygiene |

| Health and sleep |

| The influence of sleep on learning ability |

| Common misconceptions about sleep |

| Prophetic dreams, where do they come from? |

| The influence of bedding on sleep quality |

| The effect of nutrition on sleep quality |

Beds are interior items that we use more than anything else. We spend about 8 hours every day on them. Today you can find a huge number of beds on sale. However, most of them are made from a small number of materials.

Tree

This material is used to make the backs of expensive beds, as well as side elements, frames, etc. It is also used in the production of sofas, where load-bearing structures are made from it - frames, legs and other elements. In this case, various woods can be used. In inexpensive beds, this can be pine; for more expensive models, beech, oak, birch, and even mahogany wood are used. In sofas, the most inexpensive wood is used, because it is often almost completely or completely hidden behind the upholstery elements. All visible wooden elements are carefully processed and coated with glossy or matte varnish. The varnish prevents moisture from entering the wood, so it retains its appearance and shape and does not crack or deform.

When choosing wood, it is important to consider that each of them has its own color and texture. They can give the product additional beauty.

The wood used for the production of internal elements is not varnished, but must be treated to prevent the appearance of wood-boring beetles, which can destroy the product faster than the most merciless use.

Pressed slabs

Pressed boards include particleboard (chipboard) and fibreboard (MDF). Both types of boards are made from sawdust or fibers that are glued and pressed. However, in MDF the pressing process occurs at elevated pressures and temperatures, which provides them with higher strength. When choosing chipboard, it is important to pay attention to the density. Today, materials with densities ranging from low to high are available on the market. At the same time, the quality of low-density chipboard is such that they can be used to create unloaded or lightly loaded elements. And contact with water is generally contraindicated for them: slabs with low density quickly swell and swell.

The chipboard surface is covered with veneer and laminated. Lamination performs several functions at once. Firstly, it gives the product aesthetic beauty. Secondly, it protects the slab from absorbing atmospheric moisture. Thirdly, the coating prevents chips from falling out of the slab. Finally, it prevents the adhesive components from evaporating into the environment. Some of these ingredients are potentially harmful. Therefore, reducing emissions of these substances is extremely important.

Metals

The most common metal used for making beds is carbon steel. It is used to produce forged backs, legs, frames, bed mesh, mattress springs, as well as various fasteners. In addition to ordinary steel, stainless steel can be used. It has increased strength and excellent appearance (especially after polishing). Legs are often made from stainless steel.

In addition, metals such as aluminum, copper, bronze, etc. can be used. Elements made from them are often decorative and rarely functional.

Metals are durable, resistant to direct sunlight, high and low temperatures, and even less sensitive to moisture than wood. With proper care, a metal bed can last for decades without losing its appearance or quality.

Padding elements

When making sofas, you cannot do without padding. Even if everything is made of wood, the seat and back of the sofa inevitably have to be made soft (which is why the sofa is classified as upholstered furniture). Foam rubber is most often used for these purposes. In this case, often the lower part of the sofa seat and back is a spring block, and its covering is made of foam rubber.

Today there is a fairly wide selection of foam rubber on the market, up to materials with a density of 45 kg/m3 and even up to 85 kg/m3. Naturally, the higher the density of the foam rubber, the harder the sofa seat will be. It is also a fact that dense foam rubbers are compressed less and last longer. Cheap sofas use very loose foam. As a result, their owners literally fall into them, which is very uncomfortable, not to mention the fact that it does not provide an anatomically correct body position.

Upholstery

Thick fabrics are used as upholstery. This is a very important element. It must withstand many years of use and get dirty as little as possible. Stains should come off easily. Today, jacquard, silk, suede, flock, tapestry and other materials are often used for these purposes. Leather is also often used; it is used in the production of expensive models.

When choosing a sofa or bed, it is extremely important to pay attention to what they are made of. Not only their service life and reliability depend on this, but also the health of those who will rest on them.

Reiki

To make classic beds with your own hands, the slats are laid on the support boards of the frame. And in products with a lifting mechanism, they are placed on a lifting frame. Or it is possible to lay them on two frames at the same time, since on the frame they are used for the bottom, and on the lifting frame, for laying the mattress.

The slats are made very simply:

- according to the given dimensions, it is necessary to measure the length of the slats and cut them from purchased boards;

Marking boards for making slats

- for convenience and practicality, so that there are no discrepancies in the length of the slats, the first plank can be used as a sample, and subsequent planks can be marked on its basis;

- Having finished the process of making slats, you need to sand each one.