Why is professional pipe attractive for making furniture?

Profile pipes with a rectangular or square cross-section are available in different sizes and with different wall thicknesses. These parameters determine the scope of their purpose. Thick-walled products with a large cross-section are used to construct building frames, fence posts, retaining columns, and decking. And products with more modest parameters are used for the manufacture of facing frames, canopies, canopies, gazebos and greenhouses. Many household products from profile pipes are also made from it, including home and garden furniture. The thin-walled profile of a small section bends easily, which allows you to create from it not only cubic, but also original openwork structures.

Garden bench on a bent frame Source prom.st

This material has many advantages.

- High strength and ability to withstand heavy loads with low weight and size due to four stiffening ribs.

- Dimensional stability under changes in temperature and humidity, resistance to weathering and chemically aggressive substances, which allows you to make outdoor furniture from profile pipes, tables and workbenches for installation in garages and workshops.

- Simplicity and versatility of installation of structures: corrugated pipe is easily cut with an angle grinder; assembly can be carried out either with bolts or by welding.

- Affordable price of material.

- Undemanding to storage conditions.

A standard set of tools available in the arsenal of a home craftsman is quite enough to make a table or other piece of furniture on a metal frame. In the absence of a welding machine, the parts can be connected with bolts, having previously made mounting holes.

Difficulties arise only in the manufacture of bent parts, since this requires a special pipe bending machine. But a large diameter arc can be made without it.

One of the ways to bend a pipe Source simplylivewell.files.wordpress.com

The availability of special protective and decorative coatings for metal makes it possible to give such products any color in order to organically fit them into the interior of the house and extend their service life outdoors.

See also: Catalog of companies that specialize in redevelopment of country houses of any complexity

Calculation of the quantity of materials

To make a standard garden bench you will need at least 2 pieces of 6-meter corrugated pipes with a cross-section of 30*30 mm. Approximate cutting for a bench without a back:

- 2 pcs. 2 meters each for the base of the seat, to which the transverse blanks and legs will be attached;

- 6 pcs. 0.45 m each - transverse blanks from corrugated pipe for seating;

- 6 pcs. 0.6 m each for the legs (supports) of the bench.

From wooden blanks you will need bars with a length of 2 to 2.2 m and a rectangular cross-section of 30*60 (20*50) mm. The bars are attached to the corrugated pipe using bolts with flat heads. Their length is determined by the height of the bar.

If you plan to make a garden bench with a back, then additionally buy a board 30–35 mm thick and a corrugated pipe with a cross-section of 25*25 mm, about 6–8 m.p. Don't forget to purchase plastic plugs to protect the corrugated pipe from the accumulation of rainwater. For stability, metal heels measuring 40*40 mm are welded to the bottom of the legs. The supports themselves are connected to each other either by a metal strip or by a thin corrugated pipe.

To calculate paintwork materials, calculate the area of metal and wood blanks. Based on it, you can determine the volume of primer, varnish and enamel. On the packaging, each manufacturer indicates paint consumption in grams or milliliters per 1 m2.

General recommendations for production

To make a table or chair from a profile pipe, you start, as in any other business, with a project, selection of materials and tools.

Selection of construction and design

The design, shape, size and design of the product are determined by its purpose and the design of the surrounding space into which it should fit harmoniously. Any types of tables are excellent from profile pipes:

- large dining room;

- desk with drawers and shelves;

- desk with an inclined tabletop;

- magazine;

- mobile serving table;

- table for a gazebo or recreation area;

Garden furniture set Source 9dach.ru

- folding transforming table with one or two benches;

- a convenient workbench in the workshop for metalwork.

Having decided on the functionality and location, they begin to create diagrams and drawings. Separately draw the frame for the tabletop and the supporting structure. The simplest one consists of four vertical legs connected by longitudinal, transverse or diagonal jumpers. But you can design more original products from professional pipes.

Table frame with X-shaped legs Source cs1.livemaster.ru

It is advisable to make several projections of the frame: the base and all the sidewalls, which have different numbers and locations of parts. This will allow you to accurately determine the required pipe footage, the number of nodes, decorative elements, etc. A detailed drawing will facilitate the practical stage of work.

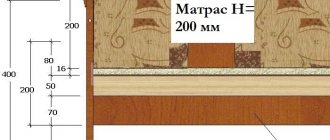

Sofa project

Using fittings, pipes, ropes, and an air mattress, you can create a unique sofa from pipes. The frame, made of aluminum parts, will give the sofa an industrial look. Pipe fittings are tightened without welding, so the structure can be easily disassembled for transport and storage. The pipes are braided with strong ropes, this will form a support for the inflatable pillows. This sofa can be installed indoors and outdoors, near a pool, a river, or in a country house in the shade of trees.

Video description

An example of making a table of an unusual design is shown in the video:

When the frame is ready, it is processed with a grinding disc, smoothing out the welds and removing rust. Then it is primed, coated with paint and allowed to dry.

When making furniture from profile pipes and wood, parts from different materials are fastened with ordinary self-tapping screws. To attach the tabletop, it is laid on the floor or other flat surface, and an inverted frame is installed on it. Mark the mounting holes and drill them into the metal, selecting a drill to match the diameter of the screws. They are screwed in from the side of the frame so that the hardware goes through it and goes deeper into the boards of the table top, but does not go right through them. Why fasteners are selected in advance according to length.

The last stage is sanding and treating the table top made of planed boards with paints and varnishes.

Advantages and disadvantages

Positive sides:

- durability, reliability;

- strength, wear resistance;

- a large selection of shapes and additional decorative elements;

- massiveness, severity.

Negative sides:

- Large mass.

- Without additional treatment, metal surfaces will begin to rust under the influence of environmental factors.

- High price for forged products.

To save money, you can assemble a table, bed or cabinet from metal and wood yourself.

Briefly about the main thing

Profile pipe is an ideal material for making frame furniture. It turns out stylish and beautiful, reliable and durable. To make a table, you need to make a schematic representation of it with dimensions, cut the pipe according to it into pieces of the required length and weld them together or connect them with bolts and nuts. After sanding and painting the finished frame, all that remains is to make and attach the tabletop to it. The bulk of the work will only take a couple of hours.

Ratings 0

Advantages of furniture with a metal frame

8 reasons to order furniture with a metal frame:

- Durability;

- Strength;

- Environmental Safety;

- Stylish look;

- Large selection of colors;

- Easy to assemble;

- A custom-made product will easily fit into any interior;

- Variety of shapes.

The manufacturing process for furniture with a steel frame consists of:

- Design;

- Primary metalworking (cutting sheets, manufacturing and bending the necessary blanks);

- Welding of necessary elements;

- Grinding;

- Assembling the remaining parts of the product;

- Painting with special powder paint.

Creative Shelf Ideas

The constantly growing number of ideas for using water pipes for decoration is explained by the fact that no special knowledge or skills are required when working with them. In the case of metal pipes, you only need a grinder to cut parts of the required sizes, and they are connected to each other using fittings of standard sizes.

Plastic pipes are easier to work with and cheaper. The range of things that can be made from plastic pipes is quite wide - these include shelving, chairs and tables, and even benches. But the simplest option, which is recommended for beginners to start with, is considered to be shelves made from water pipes.

A variety of manufacturing options and methods of using such products satisfy different tastes and needs.

How to make a bookcase from water pipes with your own hands?

A shelving unit is an irreplaceable thing in the house, as well as an interior item that attracts attention. You can make a product with any parameters and sizes. The main thing is to decide on the main characteristics in order to correctly fit it into the room where it will be located. To do this, you should take measurements of the room and, in accordance with them, draw a diagram of the product, determine the number and size of the necessary elements and the order of assembly, and also prepare the necessary tools.

The base for the shelves can be a sheet of chipboard, plywood or other similar material. The product made from metal water pipes can withstand greater loads compared to the plastic version. This should be taken into account when choosing source material.

First you need to prepare all the parts and pieces by cutting them to the required size. Assembly should be carried out in accordance with a previously drawn up diagram, attaching parts to each other using fittings or connections.

This product can be an excellent option for storing tools. For example, in the garage. In addition, you can put gardening tools on its shelves. If the plastic option is chosen, it can be used in a children's room. Plastic shelves are environmentally friendly and do not harm your health. You can put flowers or children's toys on them.

Pipe shelf for shoes

In a similar way, you can use drainpipes to make such a necessary thing in the hallway as a stylish and modern shoe rack.

There is never enough storage space, and if you make it yourself, it will be the envy of your house guests.

Shelf made of pipes in the pantry or kitchen

A simple shelf made of plumbing elements can also be useful when organizing the storage of necessary things or products in the kitchen or pantry.

It is worth choosing a design for the kitchen in such a way that it is in harmony with the external facade of the kitchen furniture and fits well into the existing interior.

Bathroom shelf made of pipes

In the bathroom, a shelf made from copper water pipes would be a stylish and eye-catching solution. The design is made as simply as the previous options.

Copper pipes are more expensive, but the impressive results will exceed all expectations. Cheap plastic elements are also used for the frame. Well-chosen decor will help make the shelf more attractive in appearance.

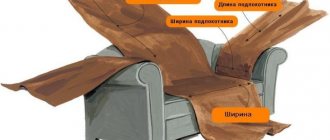

We make a wardrobe ourselves from design to assembly with our own hands

If you make a wardrobe with your own hands, then it can rightfully be considered the most functional piece of furniture.

It fits easily even in a limited area and at the same time you can put almost all things in it.

Such a cabinet is a real find for small apartments and small hallways.

But even in spacious houses there is a place for it, where it can become a real decoration of the room.

In a word, a wardrobe is a universal piece of furniture, which nowadays is difficult to do without.

Looking at the finished wardrobes, it seems that making them is quite difficult. In fact, there is nothing complicated about this, you just need to correctly calculate all its parameters.