0

3625

Owners of small apartments always feel a lack of free space. It is quite natural that when equipping a home, there is a need to select ergonomic furniture and work surfaces. Designs of standard sizes are not always suitable; you have to order their production according to individual measurements, which increases the cost several times. Meanwhile, having basic skills in working with a drill and a drill bit, it is quite possible to create the desired model of furniture yourself. A good solution for a kitchen or living room, where guests are often located, would be a table-book - it is quite easy to assemble with your own hands, the manufacturing process does not take much time. With a responsible approach to the task, homemade furniture will look no worse than factory furniture, in many ways even much more original and colorful.

What is a book table

The design features are that the tabletop consists of two or three parts, which are mounted on butterfly-type curtains. If a table is not used, the side parts of the tabletop are positioned perpendicular to the floor.

But if necessary, the tabletop unfolds and rests on additional legs. In this case, the area of the tabletop increases several times.

Transformable table: what is it?

A folding product is like a small compact cabinet, which under some circumstances can be turned into a relatively spacious dining table, without making any effort at all. The size of the dining tabletop area varies and directly depends on the folding sides. That is, according to your needs, you can open one or both panels.

The design of such furniture comes in a wide variety of types. As a rule, the tabletop includes three components: a central one and two more, attached to hinges. The main surface of the unfolded object is supported by legs or securely fixed by similar mechanisms.

Moreover, the folding function is not the only advantage of the cabinet, since the “folding bed” includes a niche with drawers, shelves and free space for chairs.

Types and features of tables

There are a variety of models:

- With one side part of the tabletop or with two;

- With and without a bedside table in the central part, from which drawers extend;

- With a different number of additional legs;

- With or without wheels;

- Equipped with folding chairs.

Book tables can have modest dimensions even when unfolded.

Tables differ in the material they are made of, in the quality of the fittings, and in the shape of the table top, which can be either rectangular or with rounded corners. Each person has his own idea of what kind of table-book he needs.

There are many types of book tables available on the market.

If the models available in stores do not meet the requirements or are made of low-quality material, or the assembly leaves much to be desired, you can always read the instructions on how to assemble a table book and make the furniture yourself.

Detailing and components

Let's look at how to make a book table with your own hands using the example of a table made of chipboard without internal filling, with 2 pairs of legs on wheels, made in the form of narrow boxes.

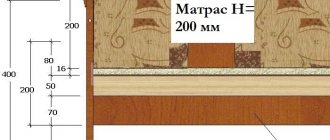

A 16 mm thick chipboard sheet is sawn into the following parts:

- Table top wings – 2 pcs., 800x600 mm.

- The central part of the tabletop is 1 piece, 800x250 mm.

- Sidewalls (central supports) – 2 pcs., 724x250 mm.

- Central stiffeners – 3 pcs., 708x210 mm.

- Vertical strips (racks) of leg boxes – 8 pcs., 644x60.

- Horizontal (overhead) strips for leg boxes – 8 pcs., 340x60 mm.

- Stiffening ribs for leg boxes – 4 pcs., 308x110mm.

Experts recommend using thick metal butterfly hinges instead of traditional piano hinges; they are more rigid and reliable. It is more convenient to make the legs on wheels only if you implement your project, carry out drawings and detailing yourself, do not forget to take into account the height of the wheels when calculating the height of the legs.

You will also need:

- butterfly loops 45 mm long – 18 pcs.;

- corners – 4 pcs.;

- linear caster wheels 29 mm high – 8 pcs.;

- clamps (holders) for the upper wheels of the legs – 4 pcs.;

- adjustable supports or thrust bearings – 4 pcs.;

- self-tapping screws 4x16 - 100 pcs., confirmations 75x5 and plugs for them in the color of the chipboard - 45 pcs.;

- edge for sealing open cuts of laminated chipboard - about 30 m.

After cutting, the parts are edged.

Instead of the usual flat edge, you can run an edge profile along the edge of the tabletop.

How to make a book-table with your own hands

There are several stages of work:

- Design;

- Selection of materials and tools;

- Creation of all details;

- Assembly;

- Decor.

You definitely need to understand exactly what kind of furniture you want to get started.

First draw what kind of table you want.

You can draw the table itself before making the drawing, this will simplify the task.

Attention! Many book table sizes are standard. For example, it is impossible to make the side parts of the tabletop very large; this will affect the height of the table and it will not be very comfortable to sit at it. This must be taken into account when creating a diagram.

Calculation, diagram and drawing

The standard dimensions for a table of this type are 80 cm wide; the central tabletop can be of different sizes, but most often the dimensions are 25x80 cm. This is due to the fact that the book-table often has to be moved, so it should not be very heavy.

The drawing will help you make a table faster.

When assembling a table yourself, additional stiffening ribs are usually provided on additional legs. Many people are tempted to add extra legs on wheels, or even put the entire table on wheels. But this is not a very practical solution.

You can make a book-table yourself without having any special skills.

The fact is that it is indeed easier to move such a table, but it will also be less stable during use. Therefore, it is better to supplement the legs not with wheels, but with rubber or felt pads.

When designing a table, it is important to remember that a rectangular tabletop will look neater when the table is folded, and rounded corners will protect from injuries when the model is unfolded; this is very important, because the transformer is rarely in the unfolded state, which means that the owners of the house and their guests are out of habit will be injured on the corners.

A book table is a portable compact piece of furniture.

Each master can make a specific drawing himself, and it may differ depending on minor differences in the furniture.

Tools and materials

For work we will need:

- Chipboard sheet;

- Pencil;

- Ruler;

- Edge;

- Butterfly loops;

- Screws;

- Screwdriver;

- Sandpaper;

- Hammer;

- Bars;

- Metal corners for attaching the central tabletop to the base;

- File or jigsaw.

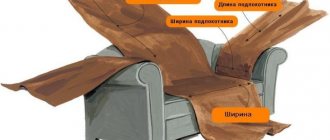

Tools and materials that you may need when carrying out restoration work on chairs.

This list may differ, for example, if you want to make a table on wheels.

Attention! Don't skimp on butterfly hinges. Install 4 small curtains or one long curtain for the entire length of the connection to secure the side table top. If there are fewer fasteners, the table will last less, because the weight of the tabletop, distributed over a small number of screws, will lead to rapid breakage of the furniture.

Table assembly

When cutting out the bars, make sure that they are all even and of the same shape. Sand them thoroughly to remove chips, bumps and splinters. It is best to coat them with varnish before assembly, providing protective functions. The countertop also requires some preparation. If you are using an old board, you should clean it well and then use the same varnish. But. in general, plywood with an average thickness of 2 centimeters is quite suitable for this role.

When making a book table, be sure to use a drawing. Even small discrepancies can affect the strength of the final structure, and gradually becoming looser, it will serve you for a much shorter period of time.

To avoid the need for updating, use a tape measure and a building level in your work, and also tighten all screws tightly and additionally coat the joints with glue.

Manufacturing process

Assembling the product is quite simple if you have the slightest skills and high-quality tools. First you need to construct a base of beams. This will be the box itself and the side legs with additional retractable hinged legs.

However, before proceeding directly to manufacturing, it is worth thinking through everything to the smallest detail.

It is advisable to provide stiffening ribs in the middle on the additional legs and on the base box. At the first stage, it is too early to install the side legs on the hinges; you just need to process all the details for their spectacular appearance. All structures need to be sanded, varnished and set aside while the master works on the upper part.

Perform all actions very carefully.

We cut out the tabletop blanks. We decorate them with a piping and install the central part on the base. After this, we turn the workpiece upside down so that the three component surfaces lie side by side and form an even sheet. In this position, the tabletop elements are connected with hinges.

The simplest one consists of a central part, a tabletop - one or two, and legs.

Only after this, without turning the table over to its natural position, do you need to install additional legs. Make sure that they fit tightly to the tabletop; the slightest miscalculation will result in the table surface being uneven when unfolded.

Manufacturing sequence

- The first stage is creating a sketch. It is impossible to start drawing and subsequent work without having an idea of what the result should be.

- Drawing. A drawing is constructed based on the finished sketch. It, like a sketch, should show the product assembled and unfolded, as well as individual parts. The drawing indicates the number of required parts and dimensions.

- Assembling the central part. It consists of a central tabletop, two sidewalls or racks, and three stiffening ribs. First, the sidewalls, central tabletop or lid, and stiffening ribs are cut out of a sheet of chipboard. To attach the ribs, holes are drilled in the sides of the future table. The sides and ribs are connected, now the center is fixed.

- Legs – sawing out and assembling all elements.

- The central part must be turned over in order to attach the right and left covers to it using hinges.

- Fastening the legs to the central part - holes are drilled and hinges are attached.

Tables with folding chairs hidden under the tabletop.

When assembling, it is important not to forget about sanding the parts to maintain a neat, neat appearance.

When assembling, it is important not to forget about sanding the parts to maintain a neat, neat appearance. The edges are decorated with edging. The sides and legs can be equipped with rubber or felt pads for more convenient unfolding and also to prevent damage to the floor covering.

With shelves or drawers.

The central part must be turned over in order to attach the right and left covers to it using hinges.

Where to put such a table

The advantage of a do-it-yourself table-book based on drawings and diagrams that a person created himself is that you can make furniture to suit any interior. Some people install such furniture in the nursery so that the children have a place to play, but it is enough to lay out the table to create a surface on which the children can both draw, assemble puzzles, and learn their homework.

A table in the living room will allow you to receive guests at any time, and quite a lot. Such furniture is in demand both in offices and stores.

This type of furniture is perfect for studios, lofts and just small apartments.

A folded table-book can be used in the interior as a coffee table, and it can be installed either directly against the wall or in the center of the room or near a window.

A table assembled by yourself will last longer than a budget model, which is comparable in price to this product. Therefore, go for it - and you will enjoy the fruits of your hands for many years and be proud of the result.

DIY transformable kitchen table, drawings, diagrams

Buying furniture is easy. But high-quality transformers are not that cheap. In addition, commercially available furniture may not fully meet your taste and desires in terms of functionality. Making a transformer is possible for anyone who not only knows the names of different tools, but also knows how to handle them. Having skills in this matter is desirable. Even leftovers and trimmings of the required size and tools are suitable for production:

- Saw;

- Electric drill, socket and other wrenches, drills;

- Fasteners, screws, nails;

- Sandpaper, paint;

- Long brass hinges;

- Wooden blocks, corners or pipe scraps for table legs;

- Parts for support rails made of wood.

Before you begin, you will need to make an accurate drawing of the furniture on a reduced scale. It is better to do it on graph paper. The main parts of the table: tabletop, legs (height-adjustable furniture legs can be used), frame.

If you used a drawing from the Internet, it is better to make sure that it is accurate and free of errors before starting work.

Sandwich toaster?

What an idea on how to prepare a delicious breakfast. Check out the Italian style kitchen design in this article.Evaluate the benefits of granite countertops for the kitchen, read on

Work order on how to make a compact transformer

When making a transformer yourself, it is very important to comply with all parameters. A discrepancy of a few millimeters can deprive you of such a necessary product.

Work algorithm:

- Prepare all the elements of the future structure, making sure that they fully comply with the required dimensions. The parts for the legs must be absolutely identical to ensure the stability of the table;

- Draw a line on the inside of the tabletop exactly in the center and cut it into two identical pieces. Attach support rails to each of them;

- To connect the legs, drill holes of the required diameter through each pair of legs. Attach loops parallel to each other;

- Assemble the product.

There are many options for making a transformer. The principle is the same everywhere. Availability of skills, dexterity, and necessary tools. The main thing is not to be afraid and follow the diagrams and all sizes.

A transforming table (extendable table, butterfly table) is an excellent option for a small kitchen. It takes up minimal space, is mobile, easy to fold and can expand to the desired size whenever you need it. Also read about how to choose the right inexpensive bar table for the kitchen.