Every person strives to make their bedroom as comfortable, cozy and stylish as possible.

And for this it is necessary to make not only high-quality repairs, but also to choose the right furniture items. Particular attention should be paid to the bed, which is an attribute of this room. It can be of any configuration, shape, design, size and materials of manufacture.

Advantages

The bed can be purchased ready-made at a furniture store or made with your own hands. The second option is more preferable. Especially if you know how to work with lumber and have power tools in your arsenal. Then you can not only save your own savings on buying a bed, but also make a safe, environmentally friendly, practical and functional bed with your own hands.

The main advantages of making furniture items yourself include:

- saving the family budget;

- the ability to make a bed of any design;

- the ability to independently select the optimal manufacturing materials and fittings;

- a pleasant pastime doing your favorite carpentry.

The main thing is to make a product that fits the overall interior of the room. And to do this, it’s important to choose consumables wisely.

Homemade bed from pallets

Modern youth with unconventional views on life know how to find beauty in the most unusual things. When working on the interior design of an apartment, the emphasis is on convenience and comfort at the lowest cost.

A bold solution in this case is to make your own bed base from old wooden pallets. To do this, you will need a minimum set of materials, tools, skills and facilities.

Four pallets should be placed close to each other on the floor and secured together with connecting strips. Two trays are installed vertically at the head of the bed and firmly attached to the wall. Now you should place the mattress and secure the restrictive beam around the perimeter. Cheap, cheap, simple and in step with fashion.

Manufacturing of components

As for individual elements, any bed will consist of:

- frame;

- slats;

- headboard and footboard.

When making a bed, special attention is paid to its frame. It must be durable, reliable and able to withstand heavy loads. Inexpensive but durable wood (pine or birch) is suitable for these purposes .

Attention : when choosing materials for making the bed frame, check it for defects and flaws.

Headboard and footboard

When making a headboard and footboard, you can show maximum imagination. Various materials are appropriate here, including textiles. For classic interiors, it is advisable to use natural solid wood, which can be carved or aged using the technique.

For modern interiors, MDF or chipboard are more suitable. Although these bed elements take on significant loads, they are more decorative elements . These bed elements can be decorated:

- carving;

- decoupage;

- artistic painting;

- cover with textiles.

When making slats, you should choose elastic and resilient wood, for example, pine or ash. The lamellas are made quite easily.

Help : the width of the lamellas should vary between 5 - 10 cm, and they are installed at a distance of 5-8 cm from each other.

Constructions

By type of design, all beds are divided into:

Beds for newborns.

They are designed for use from the first days of birth of the baby up to 3 years. Such products must be made from high-quality and environmentally friendly wood. They should not have sharp corners or burrs, and they should be as easy to use as possible.- House beds.

This model can completely change the interior of a child's room. It is suitable for preschool children. For girls it is recommended to make products in the form of fairytale castles, and for boys in the form of their favorite cartoon characters. - Bed-car. Such products are distinguished not only by their aesthetic appearance. They are quite ergonomic, practical and easy to use. When building a bed, you must first focus on its ease of use.

Loft bed. This option is suitable for a small apartment. This model is produced in different variations. It is compact in size, easy to use and easy to assemble.- Podium bed. This type of bed is more often used in spacious bedrooms. Its main advantages include functionality, the possibility of zoning the room, and an unusual appearance. You can make a podium bed with your own hands in different types of designs.

- Bed with lifting mechanism. Such models are suitable for small spaces where every free meter is valued. Under the sleeping area of the product there will be a spacious niche for personal belongings and bedding.

- The chair-bed is ideal for installation in a living room or children's room. It can be made with or without a frame. Each individual option has its own advantages. In any case, the chair bed will save free space and, if necessary, will turn into an additional sleeping place.

- Transformable bed. This furniture is distinguished not only by its versatility, but also by its original design and wide range of models. This furniture can be combined with a wardrobe, table, chest of drawers and other furniture items.

Selection of materials

You need to start by choosing materials for a homemade bed. Three integral structural elements of this furniture: box, base and headboard. Making beds is a process in which every detail needs to be given special attention.

For the box

This element is made from MDF, natural wood or chipboard. At home, it will be easiest to work with the latter material; moreover, it is the most budget option. Chipboard is of low quality and fragility, and this is its main drawback. Moreover, low-quality material contains formaldehyde resins, which are hazardous to health. It begins to release harmful substances under the influence of humidity and heat.

A beautiful MDF bed will be much more expensive, but of better quality. To make these boards, wood chips are used, compressed under pressure and high temperatures. In this case, harmful resins are not used, so the material is environmentally friendly; it is often used in the production of children's furniture. A box made of natural wood will be the most expensive, but it will also last much longer than chipboard and MDF. In this case, the owner will be provided with pleasant tactile sensations, and a special smell will be in the bedroom.

If you decide to make a bed with your own hands, it is better to order cutting at a specialized place. It costs very little, but it will save a lot of time and will be made much better.

MDF

Natural wood

Chipboard

For the base

When making a bed for the bedroom yourself, you should decide on the material for the base and choose wood, metal, chipboard or MDF. The first option is popular among those who value high quality furniture. This material has excellent performance and technical characteristics. The array itself is environmentally friendly, strong and durable. You can assemble furniture from logs or boards. Teak and mahogany are perfect for making a bed base. The most commonly used are oak, beech, pine, ash, cherry, birch, and alder.

Soft woods work best. Pine practically does not crack, while alder often cracks when drilling.

Chipboard and MDF are much cheaper than wood. The toxicity of the first material frightens many, but only low-quality products pose harm. MDF is the best option and is easy to process. In modern interiors, you can increasingly come across interesting ideas on how to make a bed out of metal. This is a particularly durable material, characterized by durability and wear resistance. Such structures are often treated with silver or bronze, covered with fabric or leather. The result is original furniture that will fit seamlessly into a bedroom in modern, country or high-tech style. Another variety is a bed made from a profile pipe. It is not difficult to make such models if you have the skills to work with metal, a workshop and all the necessary equipment.

What types of beds are made of solid oak, their advantages and disadvantages

Tree

Metal

Chipboard

MDF

For headboard

The headboard is an important part of the furniture. This is the first thing the eye stops at, so the detail can set the style of the entire bedroom and have a decisive influence on the interior design. The headboard can be soft. It is important that the material from which the upholstery is made retains its presentable appearance over time. Artificial and natural leather withstand any impact, and also look very stylish. Textiles can also be used for upholstery. A headboard covered with velor, suede or microfiber will look homely. Models with a carriage coupler are very interesting and unusual.

A rigid headboard will make the bed look antique. There are many more design options here. A classic example is a backrest made of wood. Alternatives can be metal, wood panels, plastic, tempered glass and even mirrors. Finally, there may be no headboard at all, which looks very original. In such cases, it is recommended to decorate the wall to form an impromptu backrest from scrap materials.

Faux leather

Genuine Leather

Velours

Suede

Microfiber

Wood panels

Metal

Tree

Plastic

Scheme, project, sketch and drawing with dimensions

Before you start making a bed, you need to decide on its design, dimensions, and materials of manufacture. Next, you need to make a competent design of the future product. The prepared drawing must indicate all the nuances and subtleties: materials for manufacturing individual elements, their exact dimensions, fasteners.

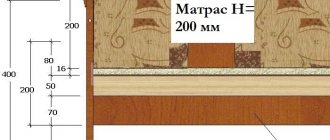

Before making a detailed diagram of the future product, you need to decide on the dimensions of the mattress . It's best to buy it in advance.

Also, when making a bed, you should adhere to certain parameters:

- the distance from the floor to the frame should vary between 25 - 30 cm;

- the width of a one-and-a-half product should be 150 cm, double - 180 cm;

- the length of the bed must be at least 2 meters;

- The height of the headboard should not exceed 80 cm.

How easy is it to make and assemble it yourself at home?

Now you can proceed directly to detailing and assembling parts. The work process begins with marking the lumber. Before you start cutting, carefully check everything again with the drawing .

Attention : it is recommended to mark cutting lines using a ruler cutter.

After manufacturing all the necessary parts, you can proceed directly to assembling the product. This process is carried out in the following sequence :

We make the bed frame, fastening all the parts with self-tapping dowels.

Experts recommend screwing in screws at an angle. After twisting all the parts, their edges must be processed with a mini plane or sander. Now it’s worth arming yourself with a square to check all the corners of the structure.- Next we move on to making the slatted bottom support. To do this, we drill holes in the boards at a certain distance.

- Now let's start making and installing the legs. To do this, we use timber with a section of 100 by 100 mm. If desired, you can make 4 or 6 legs. They are fastened with self-tapping screws (2 for each leg).

- After the main supporting structure is ready and assembled, it is necessary to begin laying the slats. They are placed at a distance of 3-5 cm from each other.

- Now you can install the headboard and footboard.

Note: Pre-drilling a hole in the wood will reduce the risk of cracking.

Bed assembly instructions

Having in front of you a working drawing for making a bed from boards yourself, step by step you need to follow the proposed instructions:

First you need to assemble the frame so that the internal dimensions of the rectangle match the size of the mattress. The bars are coated with furniture glue and connected to each other with screws.

Note!

Do-it-yourself screen: a step-by-step master class for creating it yourself. Types of screens, manufacturing materials + design ideasDo-it-yourself installation of interior doors - preparation of the structure, selection of doors, installation step by step + instructions from professionals

DIY shoe rack - types of designs, manufacturing materials, step-by-step master class with simple diagrams and drawings

With the help of a carpenter's corner it will be possible to maintain the right angle of the frame. In the center of the short side of the rectangle you need to install a crossbar made of timber. This will help prevent the central part of the bed from sagging in the future.

Now the timber legs are attached to the inside of the frame. For greater stability of the structure, a fifth leg made of the same timber is installed in the center. The leg is made from two bars connected with glue. In this case, one block is made with a bevel of 30 degrees to the surface of the base.

The bars are tightened with a clamp, excess glue is removed from the surface with a rag. After the glue has dried, use a steel angle to connect the side walls of the frame and the legs with screws.

The inside of the rectangular frame is covered with edged planed boards. Before this operation, the boards should be carefully treated with a sanding machine so that the surface does not have any roughness. The boards are laid on the frame's fixing strip and secured with screws, leaving a gap of twenty millimeters for ventilation of the mattress.

The headboard is made from edged boards. You can attach the head of the bed firmly to the wall or hang it from the frame on hinges. A reliable option would be to attach it to the frame using screws. The boards of the headboard can be attached to the bars at intervals of fifty millimeters, this will make the entire structure presentable.

The next stage of assembly is coating with stain and clear varnish. The surface should be coated with varnish several times to achieve the desired result. After covering the first layer, you need to wait until it dries completely and sand the entire surface with a sander.

Note!

Do-it-yourself sliding wardrobe - manufacturing manual with a full description of the stages, types of structures, choice of manufacturing materials (photo + video)Do-it-yourself carriage screed: step-by-step instructions for creating it yourself, diagrams and drawings for beginners, selection of materials and tools (photo + video)

DIY stool - types of stools, manufacturing materials, step-by-step master class with simple diagrams and drawings for beginners

The painting process should take place in conditions of good ventilation in the room. After final drying, you can lay the mattress and use a homemade love bed.

Interesting ideas to make it beautiful

After making and assembling the bed, you need to move on to its finishing:

- All parts are carefully polished with a grinder or sandpaper.

- If desired, the boards can be covered with stain.

- Next, the bed is varnished in several layers.

Tip : A good wardrobe (or even a cardboard wardrobe), dressing table or bedside table can also come in handy in the bedroom.

Double bed

It is not always possible for the bedroom area to accommodate two cribs and provide comfortable accommodation for children of different sexes. A good option is to make a homemade wooden bunk bed at home.

To do this, you need to stock up on bars, planed boards of different thicknesses, reinforced steel corners, and multi-layer plywood. Amateur skills in using hand-held electric tools are quite enough to solve the problem. First, you should assemble two wooden rectangles the size of the mattress. Determine the size of the load-bearing bars by calculation and fasten the frames into a single structure using screws.

To increase the load-bearing capacity of the structure, the junction of the beds and frame bars should be reinforced with steel corners. The interior space of the beds must be covered with sheets of thick plywood along the supporting planks.

Now you can eliminate minor imperfections, use pigment to give the desired color, and cover it several times with colorless varnish. It is better to assemble a two-tier structure immediately in the sleeping area. Before assembly, it is advisable to obtain recommendations from professionals in terms of making a bunk bed from wood yourself. The bulkiness of the structure will not allow it to be moved into the room when assembled.

Photo

A bed is not only a place of rest, but also an important element of furniture that sets the tone for the entire home: