How to properly install handles on kitchen facades

A kitchen set assembled with your own hands, and this is not so difficult to do, requires the installation of handles on the kitchen facades.

It would seem that there is nothing complicated here, drill holes and screw the fittings onto the screws. But, as practice shows, very often screwed handles begin to interfere with the full opening of furniture doors, this is especially noticeable on corner facades, or blocking of neighboring cabinets or cabinets occurs. Therefore, before installing the handles, you need to try them on. By the way, it should be noted that handles in the form of rails or brackets can be positioned in different ways: all horizontally, all vertically, or combine the installation. So, if you are ready to install handles yourself, then prepare the following tools:

- Drill with a drill 4 or 5 mm in diameter.

- Pencil and ruler (wooden or metal).

- Square.

- Screwdriver.

Calculating the markings for handles

It will be very convenient if you first make a template from cardboard with precisely drilled holes for fastening.

That is, by applying it to the facades of the kitchen set, you can avoid long operations associated with setting the fit dimensions of each handle.

Advantages and disadvantages

A mortise handle is simply irreplaceable when furniture doors interfere with each other when opening. This model has many advantages:

- Versatility. For each piece of furniture, regardless of its purpose, you can choose a suitable handle. Most often, “sinks” are found on cabinets, chests of drawers, computer and desks, dressing rooms, and kitchen cabinets.

- Multifunctionality. A mortise furniture handle can be installed not only on cabinet doors, but also on drawers. Such accessories are convenient to use.

- Diversity. The stores offer a large selection of models. They differ in color, material, shape. You can choose suitable fittings for furniture of any style.

- Attractive price. It depends on the complexity of manufacturing and the quality of the product. But the price range is such that even the most original fittings will remain affordable to the average buyer.

Among the disadvantages is the difficulty of inserting handles into furniture facades. You can’t do this without special skills and the necessary tools. Installing conventional handles does not require such a high level of skill, but the convenience and space savings are worth it.

Versatility

Multifunctionality

Diversity

Attractive price

Setting dimensions and drilling the façade

Let's start by installing handles on the doors of the kitchen unit.

- The door is placed on a flat surface, let it be a table.

- In the corner where it is necessary to install the handle itself, a distance of 5 cm is set aside from one and the second edges.

- Two mutually perpendicular lines are drawn through the points. Their intersection point is the place of the first fastener. In order for the lines to turn out to be mutually perpendicular, it is necessary to use a square to draw them, applying it to the edges of the door.

- Now you need to accurately measure the distance between the mounting holes on the handle itself.

- This value is transferred to the door from the point of intersection of the two lines. If the fitting element will be installed vertically, then the displacement must be carried out downwards, if horizontally, then to the side. The second location for fastening the fittings is indicated. In this way, the exact location of the handles on the facades is determined.

- Now we need to drill. This operation is performed from the front side of the facade. The thing is that when the drill comes out of the material, it may delaminate and chips may appear along the edges. And although they will be closed with the fittings themselves, there is always the possibility of a large chip or crack appearing. Of course, this all depends on the quality of the material used and the sharpness of the drill used. Therefore, when drilling, be careful and carry out this operation carefully.

- So, two mounting holes are drilled, now you need to insert two mounting screws from the back side. Install the handle on the front side and attach it to the facade, screwing in the screws with a screwdriver. If it is not pressed tightly against the door and is loose, then you will have to remove it, put washers under the heads of the screws, and put the fastening back on.

Before screwing on the handles, it is necessary to clean all surfaces from dust and particles of the material from which the facades were made. So, the handles are installed, you can hang the facades on the hinges.

Product design and features

Handles with a latch (or, as the professionals say, with a halyard tongue) contain the following parts:

basic element - rosette or decorative trim;

square pin (profile);

screws for connections.

The end version of the handle is used in cases where the usual version with a latch will not work. It is needed if the sliding door is completely immersed in the wall. In the assortment of retail outlets and in technical descriptions, such an item may be called differently - an end grip or a finger handle. In all three cases we are talking about the same product. If you need to choose a handle for sliding doors with a locking mechanism, you must first determine the operating principle.

Mechanical systems operate precisely thanks to the latch. To close the door, you need to use a special key. The advantage of such a product is high wear resistance and the possibility of long-term operation. Magnetic locks of the simplest type can also be installed on interior doors. There are powerful permanent magnets inside, opposite which there is a steel plate or magnet with the opposite sign.

But electromagnetic constipation does not justify itself. It is expensive and is used mainly in office and administrative premises. If the electrical current is turned off, the system will not work. By the way, only mortise handles can be installed on sliding doors.

Any other type of construction will not allow the sash to go all the way into the pencil case, so the opening will be partially occupied.

Installation on drawer fronts

In principle, this is the same process associated with drilling. The only thing that distinguishes them is the dimensions, which are marked in the center of the drawer front. You must first determine the middle of the facade, that is, by dividing its length in half. And then put 5 cm down from the top edge. This will be the installation center. Now from this point in different directions you need to set aside half the distance between the mounting holes. Let's add that the handles on the drawer fronts are installed horizontally.

Another point to pay attention to is the double wall of the front side. That is, the outer panel is the facade, the inner part is the frame. It is this double wall that will have to be drilled. In this case, you will also have to take into account the fact that to fasten the handle it is necessary to use a screw of a longer length than the standard one. The length of the screw will have to be chosen taking into account the thickness of the two panels of the material used, plus 4-5 mm. And again, the screwed handle should not dangle.

Installation of mortise fittings

Installation in a wooden sheet is carried out by preparing a recess. To do this you will need the following tools:

- Drill-driver.

- Drill.

- Jigsaw.

- Milling machine.

- Plywood or chipboard.

Installation using a crown

Installation of round handles can be done using a crown cutter of the appropriate diameter installed in a drill. After the cutter has been deepened to the required depth, the recess is refined using a router with a finger cutter.

Installation of fittings of any shape can be done using a template:

- First, the hidden handle is separated into its component parts.

- To accurately make the recess, you will need to make a template. To do this, draw the contour of the knot liner on a piece of plywood or chipboard and cut a hole in it with a jigsaw.

- To do this, drill a hole along the inner contour, insert a jigsaw file into it and cut a hole along the contour. This template will be the stop for the copy cutter.

- Then, at the installation site, the outline of the liner is marked on the door leaf. In this case, it is necessary to note the same distance from the end of the door leaf.

- After this, a template is placed on the door leaf so that it coincides with the contours of the liner, and it is fixed with clamps.

- After this, the required depth of the cutter is set. As a rule, sampling is performed in 2-3 passes. Each pass is made no more than 8 mm.

- In this way, a sample is made in the canvas for the liner.

Marking facades for handles

I've almost finished assembling the kitchen, there are still little things left to do, for example, marking and drilling holes in the facades for handles. The handles are attached to two screws, I suspect that if you miss the distance between them by a millimeter, it will be problematic to screw the handle, because it is not flexible at all and it will be impossible to adjust the distance by compressing or stretching it. Are there any generally accepted rules for placing handles? Technical issues - avoid chipping, etc.? Is there a useful article on the topic? I would like to do it carefully and, preferably, the first time

As a rule, the size of the screw is smaller than the size of the adjacent part of the handle, so you will have +/- 1 mm. And of course, accurate markings are the key to success. PS: Post a photo of the pens, if it’s not difficult.

Chips can be avoided if, when drilling, you place a wooden block under the facade on the reverse side.

2maxsa If you screw sharpened screws into one of the handles (sharpening outward), you will get a template that can greatly simplify marking.

Make yourself a template (even from thick cardboard and use it to mark the drilling places on the facades. Apply it to the corner and it will already show you the places to mark. The step of the handles is usually 32 mm. That is, 32; 64; 96; 128 etc. The most common is -96.

The position of the handles is a matter of preference. As a rule, we used to choose the standard 40*40 or 50*50 from the corner for the first hole, but this is for swing doors. In general, it's a matter of taste.

IMHO it is better to drill from the side on which you need to maintain the required size. I don’t remember the diameter of the drill, either 4.5 or 5, but I sharpened it even sharper than for iron, not to mention wood. For what? So that it doesn’t bite into the material too much. This was especially noticeable on pine facades where ordinary drills flew like a bullet. And the fact that on the back side of the facade in the place of drilling is to put a board - this has already been correctly said here. It holds the drill at the exit from the facade and there are fewer chips. Sometimes it’s practically not there if you press the board tightly.

satrap wrote: I don’t remember the diameter of the drill, either 4.5 or 5,

Drill for handles 4 mm.

All about doors

It is difficult to overestimate the advantages of compartment doors, which are among the sliding products. They allow you to save unnecessary space in apartments with small square footage, so their popularity is only growing. It is also attractive that handles for sliding doors differ from the standard ones intended for other door designs. This is due to the fact that traditional devices will interfere with the opening/closing of the sliding system. Therefore, several types of such fittings have been invented, which will allow homeowners to purchase products in accordance with their preferences and wallet.

Installation of handles on furniture facades

Assembling furniture yourself is not difficult - this is what many consumers think when ordering a set. Despite the simplicity and clarity of the designs, many encounter difficulties in the process of installing fittings. Handles that require marking and drilling are especially difficult to install correctly. If you make a mistake in this process, the handles may subsequently interfere with the opening of drawers and adjacent cabinets.

Installing handles on facades involves using the following available tools:

There is a large selection of products, the most common of which are staple or rating models. They can be placed vertically, horizontally or combined. In general, fastening handles can be divided into two types: using a template and without a template.

Installing handles without a template step by step

1. First you need to draw a line where we will mark the distance from the edge. Place the façade on a flat surface.

We apply a tape measure.

We retreat 45-50 mm, depending on the facades.

In my case, I retreated exactly 45 mm.

2. Shifting the tape measure to the left, draw a straight line without lifting the pencil.

3. The next step is to mark the centers of the handle.

To do this, measure the distance between the holes in the handle itself.

The distance is measured strictly from center to center of the hole.

I got 128 mm.

There are generally accepted standards for central holes; the distance between them is always a multiple of 32 mm.

They are:

4. We measure the facade.

It comes out exactly 500 mm.

5. Pick up a calculator.

From the total width of the facade, subtract the distance between the handle holes and divide in half.

500mm - 128mm /2 =186 mm.

6. We measure 186 mm from each edge and get exact marks for drilling holes.

Let's check the result.

Before drilling, it is recommended to “punch” or pierce future holes with an awl, preventing the drill from slipping.

To simplify the installation process, a cardboard template will help, in which you should pre-drill holes for fastenings. Having correctly measured and made the markings, you will only need to adjust the template to the facades of the set.

Types of handles for sliding doors

Users who set out to thoroughly study the issue of the range of handles for installation in sliding doors often encounter a problem. If you understand the issue in depth, it turns out that there are no special varieties of such products.

Rather, we are talking about a single model, which, through the efforts of different manufacturers, is equipped with additional parts and elements, thereby creating the appearance of great diversity. The design of the product remains common to all modifications. Handles installed on interior doors are always mortise. The handle is nothing more than a regular recess into which the fingers of the palm can be easily inserted.

Let's highlight some types of handles designed for sliding doors:

- Independent option . This model is not associated with any locking device in any way. These handles are not designed to work with the latch or lock mechanism. However, they can be equipped with a magnet that firmly fixes the door leaf, preventing it from opening or closing spontaneously. There is no need for a magnet if the door structure was installed by a competent craftsman who promptly and scrupulously leveled it. Among the advantages of the model, it should be noted its affordable cost and primitive design, which makes the handle difficult to break or disable. Another advantage worth mentioning is ease of installation. During installation, the product is placed (embedded) inside the door leaf. Individual parts of the device do not protrude beyond its boundaries, so opening the door does not require much effort. This handle model is optimally suited for cassette sliding doors that are used in cramped conditions. When opened, cassette structures are completely “buried” in the wall, so they are often equipped with an additional handle, with which you can freely “get” them out of the opening in the wall.

- Mortise model with latch . The main difference from the previous modification is the presence of a mechanism that controls the latch. If we talk about the mechanism, it has its own specifics and differs significantly from similar devices that are equipped with handles for swing doors. Firstly, the small dimensions of the part in this case make it possible to place it directly into the recess of the handle itself. This greatly facilitates the operation of the door, even if we are talking about the cassette version, which requires limited working space. The handle itself usually comes in two varieties. One is a small round handle that must be turned to move the latch, the other is made in the form of a slider that moves to the desired position manually.

- Handle-lock. The model differs from the other two by the presence of a keyhole. A door equipped with this modification of the product can be locked with a key. Manufacturers often build a special miniature lock cylinder inside the handle itself.

Mortise handle with latch for sliding door

Independent door handle

Varieties that have a special design scheme and operate on a different principle deserve special comment.

These are handles designed for installation on glass doors with sliding doors, and models designed for sliding wardrobes. Typically, handles in such door structures are installed at the manufacturing plant, so they are worth mentioning only in passing.

- Models for installation in wardrobes . Most often, this modification is structurally combined with the door leaf and represents a small protrusion on it.

- Handles designed for installation on sliding doors made of glass . The most popular option with a removable cylinder deserves special attention. To install such a model, a hole is drilled in the glass surface. The handle is held in the desired position using a sleeve nut. Turning the key securely locks the lock. The locking mechanism with protrusions and the handle in this modification are combined into a single unit.

Conclusion: the range of handles designed for sliding doors cannot be called too diverse. However, it fully satisfies consumer demand for such models.

Marking and fastening to swing doors - stages

1. The door is placed on a table or any flat surface. 2. Count 5 cm from the corners (edges) and place a dot in the places where the handle should be located. 3. Two mutually perpendicular lines are drawn through the points. The location of the first fastening is considered to be the point of first intersection. Be sure to use a square when drawing, applying it to the edges of the door. 4. The distance between the mounting holes is measured on the handle. 5. The distance between the holes is transferred from the intersection point. When installed horizontally, the displacement is carried out to the side, when installed vertically - downwards. The second attachment point is indicated. 6. Drill 2 mounting holes on the front side of the door. This operation should be performed as carefully as possible. 7. Mounting screws are inserted from the rear side. A handle is mounted on the front side. Screwing is done with a screwdriver.

The handles should be attached tightly and not wobble. If this problem exists, you should place washers under the screw caps and re-fasten them.

Anyone who intends to cope with such a task as screwing handles to the kitchen facades of retractable shelves will have to do similar manipulations. The only difference will be the size of the marks in the center of the drawers. Initially, the middle of the facade is calculated, after which 5 cm is counted down from the top edge. This point is the center of the installation. The length of the mounting hole is outlined from the center in different directions. Lines and handles are always horizontal. The façade is illuminated along with the frame. As a rule, longer screws are used.

Form

Along with the unusual design and style of a furniture accessory, its ergonomics are of no small importance. Products should not only aesthetically match the furniture, but also be as comfortable as possible when grasped by hand, and be safe when performing an action. Their shape, size, location and method of fastening determine how easily the furniture doors will open, maintain strength and performance under the influence of long-term use.

Today, the most affordable, popular and practical accessories are bracket handles, presented in the form of curved arcs or metal strips in the shape of the letter “P”. Fitting elements of flat or semicircular shapes are an ideal addition to any cabinet, especially for fans of minimalism. Products with a simple design are as comfortable and functional as possible when used.

Button handles, which are a cup-shaped design with a flat decorative disk at the end of the product body, also do not lose their relevance. A furniture accessory of different shapes and designs suitable for both classic and modern cabinets. Simple connection to the surface makes them convenient to use, where touching the furniture facade is excluded. The handles of this collection are compact, always look stylish, and guarantee reliability and safety.

Leading companies producing furniture fittings, expanding their collections of handles, are offering a new trend in fittings: long handle ratings. Simple, strict lines, functionality, practicality, and durability of the products are ideal for the latest examples of modern furniture.

DIY: How to Install Handles on Drawers or Cabinets

Exterior of a wooden chest of drawers

Do the drawers of your furniture set have no fittings? A strict and minimalist look is great for maintaining the overall style and aesthetic appeal of the interior, but such elements lead to some problems (for example, brittle nails).

If you are tired of such furniture, then in today’s story we have prepared for you an easy and uncomplicated DIY project that will tell you how to transform your chest of drawers and give it greater functionality.

Nuances of choice

The level of comfort, practicality, and service life of the product largely depends on the quality of mortise handles for furniture. It is for this reason that it is so important to carefully select not only cabinets or cabinets, but also accessories for them.

| Selection factors | Characteristic |

| Quality | The level of quality will determine the service life of the product, so you should select only those models that are produced by well-known brands with an excellent reputation. |

| Design | No matter how practical and functional a mortise handle is, if its design does not fit the aesthetics of the headset, there is no point in choosing the product. Be sure to take into account the style direction of the design and color scheme before selecting fittings for the cabinet. |

| Dimensions | The appearance of the product will be more harmonious if the mortise handle matches the size of the façade. Excessively bulky options will burden the space, and too small ones will look unattractive, strange, and whimsical. |

| Price | Experts recommend avoiding purchasing cheap products. Often the mortise mechanism in such structures quickly becomes unusable. As a result, the product begins to loosen, spoiling the quality and appearance of the facade. |

Take into account these recommendations from experienced specialists, and you will certainly make a successful choice of mortise handles for furniture in your home.

Related discussions

Choosing a quality kitchen furniture manufacturer

Help with a kitchen furniture supplier

Kitchen furniture design

Please help me arrange furniture in the kitchen

Architect-designer Diana Mironova

Horizontally centered, including hinged doors

- Like | 2

- Save

Ksenia

- Like | 2

- Save

Credit Ceramica

Horizontally and centrally.

- Like

- Save

Dennis Denny

Don't install THESE handles. They are awful(((

Well, it’s probably better in the center. In general, you should see the kitchen configuration for this, otherwise this is a game of blind cat.

- Like

- Save

Stepanova Natalya

- Like

- Save

Dennis Denny

Stepanova Natalya, I’m afraid nothing can be changed here and there’s nothing to think about too much. At least on the lower front, all the handles will have to be positioned this way. as you drew, and without options. Otherwise, if you put all the handles in the middle, then the door handle under the sink will rest against the handles of the drawers on the right.

If you really want all the handles in the middle (it will look better, no doubt), then it is better to open the door under the sink in the other direction. But then inside the cabinet in the corner we will get almost a dead zone. And if you buy a clever retractable shelf there, it will cost the same as 2 sets of handles :(

Py.Sy.: So the handles still have a slightly golden tint or not? In any case, their configuration does not match the shape of the facades. But this is my opinion, you may well think differently.

- Like | 2

- Save

Stepanova Natalya

- Like

- Save

Dennis Denny

Stepanova Natalya, if it’s more convenient for you to open the top ones (with vertical handles), then nothing in the diagram bothers me. Quite a viable option.

- Like

- Save

The top can be vertical and the bottom horizontal)

- Like

- Save

Liubov Fiore

Do as in the diagram. Also look at modern interiors on YouTube. For example, here https://www.youtube.com/user/chakits1/videos

- Likes: 1

- Save

Manufacturing materials

The market offers a large selection of furniture handles from Russian and foreign manufacturers. A wide variety of materials are used for their manufacture:

- In first place in popularity are furniture mortise handles made of metal. It can be chrome, bronze, aluminum. Such products are distinguished by strength, durability, and practicality. They are not afraid of high humidity and direct sunlight. During the manufacturing process, they are necessarily treated with anti-corrosion agents, so they do not rust and remain in their attractive original form for a long time.

- Plastic handles are also in demand. They are distinguished by a variety of colors, shapes, and are attractive for their low cost. Inferior to metal products in practicality. They quickly develop scratches and, less often, chips. This significantly spoils their appearance, so such products are short-lived in use.

- In third place you can put wooden handles. Correctly selected texture allows them to become one with the facade of the furniture. Such products do not emit hazardous chemicals into the atmosphere, are environmentally friendly, and can be used to create a fashionable interior in a classic style. But wooden fittings have a drawback: they do not tolerate high humidity in the room.

- Ceramic handles look good on light-colored furniture. They are produced in white color, they are practical, have an attractive, laconic design, and also have a long service life.

- If necessary, you can choose glass handles. They are particularly durable, not subject to wear, and cannot be scratched. The “shells” do not change their color and do not fade in the sun. This is a universal, durable model that will suit any interior style.

Scope of application of furniture screws, installation features

To make mortise furniture handles more decorative and wear-resistant, they are painted with special compounds. For this use:

- paint and varnish, galvanic coating;

- hot stamping;

- vacuum spraying.

Enamel, patina, rhinestones and crystals are used to decorate products.

Metal

Plastic

Tree

Ceramics

Glass

Tips for selection and care

Furniture handles are not simple elements of furniture fittings that solve two problems: aesthetics and functionality. The range of products in style, color, shape is quite extensive; to choose the right manufacturer of furniture handles, you need to know that:

- the manufacturer engaged in the development and production of product handles must be known to the consumer, have a high rating and experience;

- the maximum warranty period for the product should not be more than 2 - 3 years;

- color, texture, shape must be seen on samples in the showroom or in the photo in the catalog;

- the assortment should include both cheap and expensive front fittings.

When choosing a product, it is important to pay attention to the size of the handle based on the center-to-center distance, which is the space between two fastening screws, so that during installation it does not extend beyond the surface of the door, is proportional, and is integrally combined with the design of the cabinet. Decorative elements must have a smooth surface, be free of chips, roughness and be in the same color.

Despite the high technical characteristics of furniture front elements, dust accumulates on their surface over time. Proper, regular care of them will extend their service life and preserve their appearance for a long time. So, if the product becomes loose, it needs to be tightened. To remove dirt, use a special spray cleaner that does not contain an abrasive substance.

After wet treatment, the fittings should be wiped dry with a soft cloth or sponge. It is not recommended to clean it with metal brushes, cleaning agents, or washing powders, so as not to spoil the coating of the handle or lead to their complete replacement. If the structure after cleaning has a dull appearance, then you can use a special polish or furniture wax to shine it.

How to choose the right handles - designer tips

Ready-made economy class headsets are already equipped with standard fittings, usually inexpensive and with the simplest design. But if you decide to make a custom-made kitchen, the designer in the salon will definitely offer you to choose handles from the catalog and advise which ones are best suited to a specific model of the set. But you can choose any option that suits your taste best. What should you pay attention to when choosing fittings yourself?

- The most important thing is that the handles should be very comfortable for you, because you will have to open and close kitchen cabinets and drawers many times every day. At the same time, they should fit into the design of your kitchen and look harmonious against the background of the facades.

- The handle, especially a bracket or rail handle, should be easy to grip. Ideally, the width of the palm should fit into it, not a pair of fingers. If you order a kitchen from a salon, be sure to try out the handles you have chosen. Listen to the sensations, whether they fit comfortably in your hand. If you decide to buy kitchen handles online, focus primarily on the center-to-center distance - it must be indicated in the description. As a rule, for a comfortable handle the minimum is 96 mm, 128 mm is better. Measure the width of your palm - it will become a guide for choosing the optimal size.

- The fittings must be safe. No sharp corners or edges, elements that protrude too much above the surface, nicks or defects in the decorative coating. If you have small children, do not forget about safety locks and locks that will prevent them from opening cabinet doors or pulling out dangerous drawers.

- After receiving an order from an online store or paying for a purchase in a regular store, be sure to inspect the appearance and completeness of the fittings and fasteners. All pens must have the same shade of finish. There should be no scratches or chips on the ceramics, the rhinestones should be well secured.

- If the handle on kitchen fronts is located horizontally, it should not be too large relative to the width of the door. Otherwise, when opening the cabinet, it will touch adjacent doors, the wall, drawer fronts and other handles.

- If the kitchen modules are more or less the same size, feel free to use the same handles for all cabinets. If the kitchen front combines large fronts and small drawers, it makes sense to use handles that are commensurate with them. But don't overdo it - 2 sizes (one larger, one smaller) will be enough.

- Massive handles on the upper facades visually greatly overload the kitchen, especially a small one. If you don’t want to use a “push-to-open” mechanism or profile handles, you should choose compact-sized fittings with a laconic, discreet design.

- Pay attention to the combination of the metal tone with the rest of the interior elements of your kitchen. It is better if all metal parts are the same - for example, only bronze, gold or chrome. It is desirable that the surface of the fittings be either matte or shiny. The proximity of both in one kitchen can look disharmonious.

The golden rule for choosing fittings is that they must be proportional to the headset modules. The narrower the façade, the shorter the handle. For standard kitchen modules with a width of 600 mm, long horizontal railing handles with a center distance of 436 mm are often recommended. For doors with a width of 500 mm, you should take a handle no larger than 336 mm. With a width of 450, 400 and 350 mm - no more than 192 mm. For narrow cabinets and drawers with a width of 300 and 200 mm, you should not take handles with a center-to-center distance of more than 96 mm, but it is better to use a button handle, a drop or a shell.

Pay attention to the kitchen modules near the wall. If the cabinets are close to the wall with a minimum gap between them, the door will not open completely, and the handle will rest against the wall with the risk of damaging the wallpaper. In this case, you should choose a smaller handle and place it vertically rather than horizontally - this will increase the opening angle. But the best solution is to move the cabinet away from the wall about five centimeters and cover the gap with a false panel.

Dimensions

When selecting handles for front kitchen cabinets, you should determine the size of the products. The main parameter that you should pay attention to is the center-to-center distance. This is the name of the space between the holes for the mounting screws. It can always be found in the description of handles for kitchen fronts. This indicator can have a size from 16 to 1053 mm.

Popular types of pens:

When choosing kitchen handles, you should take into account the features of their use and the style of kitchen furniture. Photos of different products will help when choosing accessories via the Internet.

Mounting methods

Furniture fittings, integrating into any cabinet facade, are easily installed, taking a convenient position. Considering that the product is located on the front side and has different design features, there are different installation methods. The handles can be attached using glue, screws and screws. The most reliable, durable connection is a metal rod with an external thread and a cap, which minimizes deformation of the surface of the cabinets.

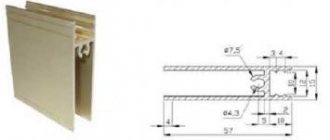

Fastening steel screw, installed at one or two points on the back or front side of the door, diameter 0.4 cm, minimum value 6.4 cm, pitch 3.2 cm. Suitable for any front fittings, except handles “brackets”, “profile” – handles”, which are fixed with a self-tapping screw on the outside of the furniture. Fasteners are installed using a regular screwdriver or screwdriver.

Installation of a furniture accessory involves the use of carpentry and acrylic glue. This method is used extremely rarely, only in cases where the front fittings are presented only as decoration, where the cabinet and handles are made of wood and plastic. Such fixation is not reliable, has low adhesive strength, and cannot be reinstalled if broken.

When installing yourself, in order not to damage the coating of the furniture façade, it is not recommended to turn the handles during fastening. Small products fastened with one screw are not practical to use.

Railing

Mortise