Want to make a table from pipes with your own hands, but need some inspiration first? In this article you will find 25 examples with metal, copper, PVC pipes of different styles and designs to suit every taste. The use of water pipes without problems allows you to create individual table frames of various configurations. The step-by-step instructions provided will leave you with more time to focus on the design, rather than spending a ton of time figuring out how to put it all together. Having figured it out, how to make a table from pipes, you will probably have your own creative ideas. But let’s not forget about PVC pipes, which are also an interesting and creative way to create artistic furniture for your home. The materials are inexpensive and do not require assembly skills, so make a table from PVC pipes even a child can do it. Or maybe you want to make an elegant table with legs made of copper pipes? There are also such examples in this article.

What can be made from PVC pipes.

How to give one shape or another to PVC pipes.

In order for the pipe to be bent or flattened later, it must be heated with a gas burner and immediately given the required shape. As a last resort, if there is no burner in the house, you can heat the tubes over the fire of a gas stove. You can cut the pipes with a metal saw or jigsaw, and you can connect all the parts using cold welding (for this you need to purchase a special adhesive).

Car trunk.

This kind of car trunk can be built from water pipes. A bicycle holder for a car looks no less interesting.

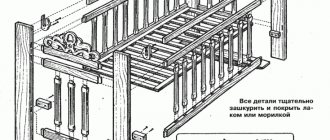

Bed side.

To prevent your child from falling out of bed at night, you can make an improvised side.

Barrier for the doorway.

This kind of gate can be made on the doorway, so that the child will not be able to leave the room.

Vase and flower pots.

By cutting a cylinder of the required length from the pipe and pasting it with a self-adhesive, effective film, you can end up with a wonderful vase, inside of which you can place a glass of water and put fresh flowers.

New Year's decor.

Festive wreath.

We cut pipes of different diameters into small cylinders of equal length, glue them together to form a wreath, paint them with suitable spray paint, drill holes on top and thread a rope, hang the wreath on the wall, and put small New Year's balls into several cylinders.

Wall tree.

We take pipes of different diameters and cut them into cylinders of the same length. We prepare a canvas, glue cylinders onto it, forming the outline of a Christmas tree, create a footrest from a large pipe, hang the composition on the wall, and put various Christmas tree decorations in different cylinders.

Children's waterfall.

To harden a child, you can prepare such an impromptu waterfall by connecting two hoses with water turned on to the footrests of the product, and making holes for water drainage in the top bar.

Children's house.

Children love to build various houses, huts and other shelters; you can make their task easier by preparing a frame from PVC pipes and sewing a cover from waterproof fabric.

Pool awning.

In addition to creating shade, such an awning can also serve as a goal for water polo.

Holder for glasses.

An excellent idea for a street bar, a slot is created in the pipe along the width of the stem of the glass, and holder legs are screwed on top, using which the structure is attached to the ceiling surface.

Place for bicycles.

Such a “stall” for children’s bicycles or scooters will help keep the yard in order.

Cells for wine bottles.

In large cylinders of pipes glued together you can store bottles of wine.

Drill stand.

The drill stand will help you create identical holes in strictly defined places on your products.

Ladders for cats.

Cats are very active creatures that value freedom, so in confined spaces they begin to waste away. To prevent this from happening, they need to be constantly occupied with something, and this interesting design with slides, ladders and crossbars will help in this matter.

Vertical beds for strawberries.

You should drill large holes in a PVC pipe using a drill with a special round attachment, then bury the pipe in the ground and pour soil into it, and then plant strawberry seedlings in the round holes.

Stand for kitchen appliances.

These pipes can make a wonderful stand for forks, knives and spoons.

Stand for scissors, pencils and tools.

Pipe sections attached to a wooden plank can serve as pencil holders. And vertically located cylinders can serve as a supply for tools. To prevent tools from falling down, the bottom of the pipes can be foamed with foam.

Notebook Stand.

These pipes can make a wonderful laptop stand, especially since not very many parts are required, just a few pipes and connecting elements. Finally, the product can be spray painted in any color.

Cells for shoes.

Summer shoes can be stored in tube cells, and to make them look more presentable, they can be covered with a suitable adhesive film.

Organizer for scarves and underwear.

Stores sell special containers with compartments in which you can store linen or other accessories, but you can create such an organizer yourself by simply cutting PVC pipes into shallow cylinders and gluing them together.

Partition for climbing plants.

From such pipes you can create entire fences or partitions along which climbing plants will subsequently weave.

Stand and holder for curling iron or hair dryer.

Thanks to such stands, the hairdryer, straightening iron and curling iron will always be in their places. And also, after use, you don’t have to wait for the curling iron or iron to cool down.

Enclosure for dogs and other domestic animals.

To prevent newborn puppies or kittens from wandering all over the place, you can build a small enclosure for them. Well, for more active animals you can create a large, full-fledged enclosure, not forgetting to cover it with netting.

Holder for watering hose.

To keep your garden hose from getting tangled under your feet, you can store it on this great stand.

Frame for a summer gazebo.

Continuing the topic of what can be made from PVC pipes, we want to show you an excellent seasonal idea for a gazebo. This structure can be covered with an awning on top or light curtains can be hung on the sides, which will now and then billow effectively even with a light breeze.

Frame for outdoor cinema screen.

Fans of watching movies with friends will appreciate the idea of an outdoor screen; its frame can be made from PVC pipes, and the screen itself from the remains of a matte stretch ceiling.

Skittles.

Children will be delighted with this mini bowling alley.

Puppet show.

To create such a children's theater, you just need to assemble the frame and hang the curtains.

Sandbox stand.

It will be more comfortable for a child to play in a sandbox if it is raised above the ground, and sand will not get into the baby’s shoes or clothes.

Rack.

Such a rack will allow you to keep the room in order, as it can accommodate an unlimited number of things and toys.

Frames for pictures and mirrors.

Rings glued together, cut from PVC pipes, will ultimately serve as a wonderful frame for a picture or mirror.

Lamp.

Lamps made from water pipes look very beautiful, especially if the pipes are decorated with rhinestones or complemented with shaped slots. To implement the idea, a base with a light bulb is installed in a pipe with pre-created beautiful and elegant slots, and on the back side of the product a hole is created for the wire to exit. All that remains is to plug the lamp into a socket and enjoy the interesting muted glow.

Table.

You can assemble a wonderful table from PVC pipes, covering it with a wooden tabletop, or build a bench (at the end of the article there will be a video on how to make a bench from such pipes).

Chairs.

Such pipes make excellent garden chairs; smooth lines can be achieved by heating the pipes with a gas burner, using your hands to shape them into the desired shape and leaving them to cool in this state. But even an ordinary geometric chair will look great; the seat can be created from ordinary chintz or cotton fabric. But you can go further and create folding chairs that will be very appropriate on vacation, for example, while fishing.

Clothes dryer.

Such a portable clothes dryer will be very useful in the household, because if necessary, it can be removed from view, and also moved from the shady part of the site to the sunny one. If it suddenly starts to rain, don’t run to remove the still wet clothes, but simply move the dryer under the canopy. Some advantages.

Transport.

Their PVC pipes can be used to create a full-fledged children's transport or trailer; children will be delighted with such cars.

Football goal.

Children can play football freely with such excellent goals.

Chaise longue.

An excellent solution for a summer house is sun loungers assembled from PVC pipes; a sun lounger can be sewn from thick fabric.

Screens and partitions.

Notice how fashionable a partition made from PVC cylinders looks; to do this, you need to cut the pipe into equal sections, and then build a partition out of them, gluing each cylinder to each other. A screen made of PVC pipes, which is a screen with stringed curtains, looks no less interesting.

How to make a bow from PVC pipe:

How to make a bench from PVC pipes:

Dear readers, today we showed you what can be made from PVC pipes, as you can see, there are a lot of ideas, all that remains is to choose the right one for yourself, and slowly bring it to life.

The “Comfort in the House” website reminds its readers that you can subscribe to receive notifications about the release of new reviews (you can subscribe to the newsletter through the form in the sidebar).

The workplace has a special meaning for any master. For some specialties, a desk is simply necessary. But what to do when you have to move frequently and work at different sites? You can’t drag a table from the workshop with you, and someone else’s work may simply not be available. There is definitely a way out, and today we will tell you about it. Homemade products of this type are far from new. Furniture transformers were popular back in the last century. And the masters who focused on such developments sometimes brought them to incredible functionality. The homemade product presented today is simple and at the same time very practical. This is a work table for small jobs with electrical, plumbing, etc. It is compact, lightweight, and does not take up much space. And transferring it from object to object will not be difficult at all. How to make it? Let's find out.

Required materials and tools

Materials:

- Inexpensive furniture board (grade 1-2);

- PVC pipe, diameter – 1 inch or 25 mm;

- PVC fittings (according to the pipe size): 90° angle for fastening the mixer and internal thread - 4 pcs, simple clip - 16 pcs, solder plugs - 8 pcs, coupling with external thread and transition to the pipe - 4 pcs;

- Iron carrying handle;

- A piece of thin-walled furniture pipe, diameter – 25 mm;

- Bolts, nuts, washers, screws;

- Varnish or paint, brush.

Tools:

- Plumbing soldering iron or “iron”;

- Drill or screwdriver;

- Jigsaw;

- Sandpaper or sander;

- Drills, cross bit;

- Tape measure, pencil, ruler, plate or compass for marking the radius of curvature of the tabletop.

Let's start assembling the desktop

Making a countertop

For the tabletop canvas, the author chose pine furniture board. Plywood, OSB or chipboard are also suitable. Everyone can determine the dimensions themselves according to the purpose of their activity. Advice!

It is worth paying attention to the placement of the legs under the table, the length of which is usually at least 70-75 cm. They should not stick out from behind the tabletop, which means its length should exceed this size. We mark the tabletop, starting with the placement of PVC fastening corners with threads. We distribute them over the four corners of the canvas, taking into account that they will be rounded. The author chose bolts as hardware for fastening. The middle of the underframe will not be in demand, so we mark the position of the clips on it. There should be four of them on each side. The interval between them can be minimal, and the distance from both alignment rulers should be less than the length of the legs. The edges of the tabletop can be rounded using a jigsaw. To mark the radius, you can use a plate or compass. Sandpaper or a sander will help to process the sawn edges. Drill all marked holes with a drill or screwdriver. Wood is not a very durable material, so it requires a protective coating. The author chose yacht varnish, which he applied with a brush to both planes of the tabletop. To avoid leaving marks from the finishing stands, it can be hung on any suitable hook.

Making legs and drawers for the table

For the legs, the author chose a PVC pipe with a diameter of 25 mm. Its height must be calculated so that the coupling and plug fit in it. It is better to cut such a pipe with plumbing scissors, but a hacksaw will also work. For rigidity, you can insert metal furniture of suitable size into the PVC pipe. It’s time to make a high-quality connection with a plumbing soldering iron or iron. We set the sleeves to the appropriate size, tighten them with a hex wrench and set the iron to heat up. Next, we insert the pipe and fitting into opposite sleeves, heat them and tightly compress the heated ends, aligning the connection. Each of the four legs must have a plug and a male threaded coupling. The drawbars are intended for fastening the legs together. This design allows for their placement at any level of the leg. They are also soldered with an iron, and are a piece of pipe with two plugs into which clips are screwed (photo). The author made only two of them, although the number may be greater.

Assembling table elements

The tabletop has dried, now you need to install the corners for the legs.

We secure them to the bolts using washers. You can tighten the connection using a ratchet wrench with an appropriate attachment. To fasten them together, we place the remains of the furniture pipe between them, tightly pressing them between the fixed corners. The use of polypropylene (PVC) pipes in the construction industry, as well as for transporting liquid and gaseous substances, began relatively recently. Various scraps of material remaining after completing the main work encourage craftsmen, and today designers, to find new practical uses for them. They make home furniture from plastic pipes with their own hands: cabinets, shelves, stands, chairs, tables, dryers, decor, lamps and even small structures for the country house.

Such wide popularity is dictated by the properties of PVC. Products from it:

- They are light in weight.

- Durable. The only thing to be wary of is that exposure to high temperatures can deform parts.

- Corrosion resistant.

- Inexpensive.

- Easy to work with. When constructing plastic products, the diffusion welding method, gluing parts or threaded fittings are used. Depending on the choice of the master, you will get a permanent connection or a collapsible structure.

- Non-toxic. This characteristic allows the use of PVC pipes for the manufacture of various pieces of furniture for children.

Various tables and small tables are among the most popular types of furniture. We suggest making a simple desktop with your own hands from polypropylene pipes and a hollow door leaf. This tabletop size will allow you to place a laptop, textbooks, notebooks, maps, diagrams, etc. on the surface. Therefore, the product can become a workplace for both a school student and an office employee.

Prepare everything you need

Tools and materials:

- A hacksaw or miter saw to cut material to the desired size.

- A screwdriver or hammer drill will help attach the legs of polypropylene structures to the working surface.

- Threaded screws for 1.25, 1.5 – 15 pcs.

- PVC glue can be replaced with small self-tapping screws.

- End caps – 5 pcs.

- Desk plugs – 5 pcs.

- Cross-shaped plugs – 4 pcs.

- T-shaped regular plugs – 4 pcs.

- T-shaped four-way connectors – 4 pcs.

- PVC pipe sections: 5 pcs. 0.075 m (3 inches), 10 pcs. 0.3 m (12 inches), 4 pcs. 0.5 m (20 inches), 4 pcs. 0.75 m (30 inches) each. In the diagrams, the dimensions of polypropylene pipes are presented in inches.

All T-connectors can be replaced by soldering. Please note that this will slightly reduce the final cost of the table, but its appearance will suffer.

- First of all, we start assembling the left side of the frame. The assembly includes 4-way and regular T-connections, tabletop and flat plugs. All details are shown in the picture.

First, we simply assemble the structure to check the accuracy of the plastic parts. Then we disassemble it and assemble it completely, fastening the joints with glue. After using a special adhesive composition, it will no longer be possible to redo the work.

PVC glue should be applied to the inside of the connecting element. Check that all parts are correctly placed, only then forcefully press the pipe into the hole of the fitting connector and hold for about 30 seconds.

Attention! The adhesive is not recommended for use indoors, so instead you can seal the connection between the pipe and the connector with a screw. Also, if you do not want to erase markings from plastic pipes with acetone or another solvent, place the parts when assembling so that the inscriptions are on the back side.

- At this stage, we assemble ready-made fragments of the PVC structure. It is necessary to place the ends of the polypropylene pipes with their backs into the fittings that correspond to them on the sides: left and right. Everything is shown in detail in the diagram. Assemble the fragments and check for correct assembly. Then completely disassemble and reassemble using adhesive.

Apply the chemical to the inside of the first side fittings, holding the connection for up to 30 seconds until the chemical cures. Then do the same with the second side fragment of the structure. The base frame is completely ready.

- The last stage of DIY work is installing the tabletop on the base. Since the work surface is a hollow door leaf, care should be taken. The space inside is filled with foam, cardboard, or completely free. Inaccurate drilling can damage the entire structure.

- We recommend placing the door face down on a clean, level surface. Install the finished PVC structure symmetrically - the way it should be positioned in its finished form. The table caps will be adjacent to the door.

- Use a pencil to make marks where the holes should be drilled. After this, remove the base from the tabletop.

- Using a screwdriver or drill, screw the screws into all marked places. If the job was easy, you can insert a screwdriver instead of a screw to widen the holes. If there were difficulties (the screw got into the bar), you will not need a screwdriver. For now the screw needs to be removed.

- Place the PVC base on the door, adjust the position so that all the holes line up. Insert the screws and connect the work panel and legs.

It is better to use varnish or paint as a finishing touch. While working at the table, various contaminants will certainly fall on it. Therefore, the coating will protect this furniture from rapid damage and make it easier to care for.

A chair made by yourself will delight you with its lightness, cheapness and practicality. In addition, you must initially decide what size furniture made of plastic pipes you need, and accordingly, adjust the specified parameters of the parts.

For each chair you will need:

- About 3 meters of PVC pipe.

- 8 swivel fittings for right angle connections.

- 6 T-shaped connecting elements.

- Glue intended for joining plastic parts: special or universal.

Attention! If you do not have sufficient experience in connecting plastic pipes, for work, choose not a special quick-drying adhesive composition, but a universal, slower-acting product. In this case, you will get an additional chance to correct a possible error.

- Hacksaw or saw with fine teeth.

- Fabric for sewing the soft part of the seat.

- Sewing machine.

You need to prepare with your own hands the following sizes for a 2-year-old child:

- 7 pieces with seat depth and width (part A) - 25 cm.

- 4 pieces with a distance from the surface to the seat (part B) - 13 cm.

- 4 pieces with armrest height (detail C) – 10 cm.

- 2 pieces with back height (detail D) – 15 cm.

Or, for example, for a child who is already 7 years old:

- Cut the pipe according to the selected parameters.

- First, assemble the part that makes up the back of the chair.

- Assemble the seat and side parts.

- Check the stability of the product.

- Cut a strip of brightly colored cotton fabric 2 times larger than the width of the seat. Fold in half, face inward, sew, turn inside out. At both ends, tuck and sew pockets through which the pipes will be threaded - the top one for the back and the front one for the seat (like in a chaise lounge).

- Disassemble the frame and install the seat in place.

The child will appreciate the new piece of furniture and will be able to easily play with it. The use of plastic water pipes is absolutely harmless; they do not emit toxic substances. And reliable assembly makes the product completely safe.

Furniture for home and garden can be made not only from water pipes, but also from sewer pipes, but the former have significantly higher environmental characteristics. Large-diameter pipes are used to create creative storage systems, original decorative objects, etc.

You can make furniture from pipes with your own hands from leftover materials that are used during installation and repair work on the arrangement of various pipelines. For example, shelves, tables, chairs, and organizers are made from such unusual material.

They are distinguished by their original appearance and can last for several decades without losing it.

Despite the fact that some craftsmen make furniture from metal pipes with their own hands, it is still better to use plastic for this. In this case, polyvinyl chloride or PVC is usually used for such crafts as the cheapest type of plastic. Sewer pipes are mainly made from it because, having all the advantages of polymers, it is quite inexpensive.

Plastic pipes are resistant to rot and rust

If we mention the advantages of plastic products that allow you to make furniture from propylene pipes with your own hands, then these include:

- high strength;

- durability;

- resistance to rot and rust;

- ease of installation.

At the same time, it is always worth remembering that this type of pipe is afraid of exposure to high temperatures, under the influence of which the plastic is deformed. In this regard, in the case when you are going to assemble furniture from water pipes with your own hands and install it in a room where a high temperature will be maintained, for example, in a bathhouse, you should use polypropylene products for this rather than polyvinyl chloride .

Service life of polypropylene pipes

Polypropylene can withstand temperatures up to +60°C and is much stronger than polyvinyl chloride, but products made from it are more expensive.

PVC pipe bone lamp

Important!

The popularity of using plastic pipes in design is explained by the ease of their installation.

The fact is that any product can be assembled from them quite easily using fittings and gluing. At the same time, you can not only make furniture from a profile pipe with your own hands, but also make many other products from them:

- stands;

- decorative elements;

- portable structures;

- small architectural forms.

For example, in the garden you can make original gazebos or benches from plastic pipes. By the way, if necessary, they can be disassembled quite easily. It is also worth noting that some owners of personal plots build completely functional structures from pipes, for example, greenhouses.

Scheme of a gazebo made of PVC pipes

In any case, in order to make various products from plastic pipes, it is enough to know the basic principles of their installation and have a healthy imagination. There is no need to meet any other requirements for this. Therefore, collect the remains of plastic pipes, and also study how you can make furniture from a profile pipe with your own hands in the photo. You can get such educational material on the Internet on specialized sites dedicated to interior design.

Choose: chair or high chair

A chair made by yourself will delight you with its lightness, cheapness and practicality. In addition, you must initially decide what size furniture made of plastic pipes you need, and accordingly, adjust the specified parameters of the parts.

Preparing for work

For each chair you will need:

- About 3 meters of PVC pipe.

- 8 swivel fittings for right angle connections.

- 6 T-shaped connecting elements.

- Glue intended for joining plastic parts: special or universal.

Attention! If you do not have sufficient experience in connecting plastic pipes, for work, choose not a special quick-drying adhesive composition, but a universal, slower-acting product. In this case, you will get an additional chance to correct a possible error.

- Hacksaw or saw with fine teeth.

- Fabric for sewing the soft part of the seat.

- Sewing machine.

You need to prepare with your own hands the following sizes for a 2-year-old child:

- 7 pieces with seat depth and width (part A) - 25 cm.

- 4 pieces with a distance from the surface to the seat (part B) - 13 cm.

- 4 pieces with armrest height (detail C) – 10 cm.

- 2 pieces with back height (detail D) – 15 cm.

Or, for example, for a child who is already 7 years old:

- 7 pcs. A – 41 cm.

- 4 things. H – 25.5 cm.

- 4 things. C – 13 cm.

- 2 pcs. D – 23 cm.

Basics of working with plastic pipes

In order to be able to make furniture from pipes with your own hands, you need to understand the general algorithm for working with plastic.

Types of plastic pipe connections

So, working with them usually includes the following operations:

- selection of installation diagram and drawing up a sketch of the product;

- cutting pipes of the required size in the required quantities;

- assembly of the frame and individual elements using fittings, glue or soldering;

- checking the resulting product for strength.

You can develop an assembly diagram for a particular type of furniture yourself or take it from specialized websites. For example, you can use any classic furniture as a sample. In this case, of course, it is necessary to make allowances for the specific technical characteristics of plastic pipes.

Metal-plastic pipe design

If we talk about small furniture that will not be used in high temperature conditions, then there is not much difference in choosing the type of plastic. The only thing worth paying attention to is the price. The fact is that polyvinyl chloride is much cheaper than polypropylene, so it is quite suitable for such crafts.

You should make furniture from polypropylene pipes with your own hands when increased strength of the product is required. The fact is that such products have walls several tens of mm thick, which allows them to withstand very serious mechanical loads. In the same case, when you need to assemble large furniture, it is recommended to combine pipes made of polypropylene with PVC pipes. For this purpose, PVC products are used to install elements of lightly loaded areas, and polypropylene is used to create a supporting frame.

If you buy pipes, do not purchase products with reinforcement. The fact is that they cost much more than simple ones, but there is no particular benefit from them. In order to distinguish simple pipes from reinforced ones, it is necessary to study their surface. If there is a red, blue or green stripe on it, then these are reinforced pipes and there is no need to buy them.

Important!

To cut the prepared pipes to the required length, you will need to use a pipe cutter or special scissors.

In order to make furniture from pipes with your own hands, you will also need fittings for diffuse welding. In addition, they can be connected with a special glue for plastic. This method is very relevant when you do not have a special welding machine at home. Also in this case, you can use threaded fittings.

Soldering iron for welding plastic pipes

Selection of construction and design

Glamorous pink laptop stand made of plastic pipes

Furniture manufacturing begins with the choice of design and its design implementation. You need to start from the function that the furniture will perform. Then select the design parameters:

- collapsible or solid;

- dimensions of the entire product;

- number of elements and their sizes;

- method of connecting parts of a structure.

Convenient bar counter for a summer residence made of plastic pipes

When thinking about design, you can be inspired by looking at furniture magazines and catalogs, and websites about furniture on the Internet. It will not necessarily be furniture made of polypropylene pipes. Original ideas may arise when viewing furniture options made of rattan, wood, and metal.

Storage stand made of plastic pipes for the boiler room

This stage of work ends with drawing up sketches, determining the necessary materials, and drawing up cost estimates. In this case, it is necessary to take into account how you can use those materials that are already available, as well as availability if materials need to be purchased.

Large and beautiful table with legs made of PVC pipes

What materials are needed

Necessary materials for creating furniture from PVC pipes

After the design is selected, it is necessary to draw up a list of materials and tools needed to create the craft. For this you may need:

- plastic pipes;

- fasteners: glue, screws, self-tapping screws;

- fitting.

Stages of the plastic pipe welding process

Plastic pipes are easy to cut. This leaves a sharp edge with burrs that must be cleaned off. Just cut the thread. When heated, polymer pipes bend well, retaining their new shape after cooling. Sometimes it is easier to bend the frame rather than assemble it using pieces of pipes and fittings.

Plastic pipes of various shapes and fittings for them

Plastic pipes come in several types. They all differ in price and ability to withstand different loads and temperature conditions. Knowing the properties of each type of pipe, you can make the best choice and save money.

They are divided according to purpose:

- plumbing

- sewer.

Variety of types of plastic pipes

From the point of view of making furniture and useful household appliances, sewer pipes, unlike water pipes, benefit from a lower price. They are manufactured in large diameters.

Based on the type of polymer from which the pipes are made, they are divided into:

- polyvinyl chloride (PVC);

PVC pipes of different diameters and colors

- polyethylene (PE);

Large diameter polyethylene pipes, straight and corrugated

- polypropylene (PP).

Polypropylene pipes and fittings for them

They differ slightly in properties. Polyethylene behaves worse at elevated temperatures and under the influence of sunlight; it is elastic. Polypropylene pipes are more durable and rigid. A positive quality of PVC pipes is their increased resistance to chemical attack and reduced flammability. They tolerate ultraviolet exposure very well. The difference in the performance characteristics of polymers in most cases will not be critical for the manufacture of furniture. But differences in price are a factor that should be taken into account. The most expensive are polypropylene. PVC pipes have the optimal price-quality ratio for creating furniture structures.

In addition, pipes can be reinforced or unreinforced. Polymer pipes are most often reinforced with fiberglass or aluminum. The reinforcing layer is soldered between two layers of polymer. This is done to increase strength, rigidity, and reduce linear expansion when heated. Polypropylene reinforced pipes are used for hot water supply. The letters RC are added to the designation of a reinforced pipe. They can also be distinguished by their appearance. In addition, some manufacturers apply a colored stripe along the pipe, informing about the scope of application of the product. Pipes with a blue stripe are used for cold water supply, with a red stripe for hot water or coolant pipelines. The presence of both stripes indicates the versatility of the pipe. It should be borne in mind that reinforced pipes, although stronger, are much more expensive. Make a decision on the advisability of additional expenses for the master.

Trolley with mounting made of plastic pipes

Making a chair from plastic pipes

In order to learn how to assemble furniture from pipes with your own hands, you need to start with fairly simple products. For example, a novice furniture maker can make an ordinary chair. This very simple design consists of a basic frame, legs, a back, and a stand to sit on. In this case, the backrest can be installed here if desired.

This simple design consists of a base frame, legs, a backrest, and a stand on which to sit.

The immediate stages of work on this product are as follows:

- assembly of legs;

- frame installation;

- installation with self-tapping screws to the frame of a stand made of a sheet of plywood;

- welding chair legs;

- testing the structure for strength.

You can make furniture from PVC pipes yourself using this method using fittings. In this case, you can disassemble the structures, if necessary. If you don’t need to do this, use welding. By the way, you can install a seat made of foam rubber on a stand screwed to the frame.

A seat made of foam rubber can be installed on a stand screwed to the frame.

In addition to a chair, a novice home craftsman can gain experience in making plastic products by creating stands and shelves from pipes. There are a huge number of options. For example, the simplest design is made on the basis of a single frame on which special holders are mounted. With their help, a shelf or stand can be attached to the wall.

The simplest design is made on the basis of a single frame on which special holders are mounted

By the way, many people forget that plastic can be further decorated. So, it can be painted quite well with acrylic paints. Another option for decorating products made from it is the use of plastic pipes of different colors. Unfortunately, the range of colors here is small: white, black, gray and brown, but with their help you can create a product that is quite interesting from a color point of view.

However, experienced designers can use such a tool to decorate almost any room in a very unusual way. For example, you can make several original organizers for cleaning products, shoes or toys. Here it is enough to simply glue several tubes together.

You can also make ordinary decorations from plastic, which can combine the functions of the same organizer. For example, using scraps of plastic pipes, mirrors, wooden furniture and room walls are decorated. As a result, a space that is unusual in terms of design and at the same time functional is created.

DIY clothes dryer made from PVC pipes

Frame assembly

Connections in water supply pipes must be tight. This is not necessary for the sun lounger frame. But the structure must be strong enough to support the weight of a person. Therefore, the pipes are joined to the transition parts by welding. Use a machine for welding PVC pipes.

The device operates from the network. Using nozzles, the inner diameter of the coupling and the outer diameter of the pipe are heated to the melting temperature of the plastic. The parts are inserted into one another and pressed tightly.

The order in which the parts are assembled does not matter. When installing a rectangular lounger, it is more convenient to first assemble small frames, then connect them into a three-dimensional structure.

The chaise lounge frames rotate relative to each other. Holes are drilled at the connection point, the axle is inserted, and secured with nuts. If the design provides for a movable stop at the back, stop brackets, metal or plastic, are attached to the screws behind the backrest.

Features of manufacturing furniture for children's rooms

If you decide to seriously make furniture from plastic pipes with your own hands for use in everyday life, you must remember that for a children's room such products must be made taking into account special requirements. The fact is that safety is of great importance to children. In this regard, it is better not to use plastic pipes in the children's room, which can release harmful substances. In addition, furniture made from it should not have sharp corners.

DIY canopy over the crib

If you are going to assemble children's furniture from plastic pipes with your own hands, a photo of each element is worth studying separately. This way, even before the installation process, you can identify the most dangerous elements of the same bunk bed and eliminate them. In addition, based on the photo, you can coordinate the future situation in the child’s room with other members of your family.

It's no secret that after renovation work is completed, leftover materials end up in the house. Thrifty owners are in no hurry to get rid of these things. It turns out that you can make a lot of crafts from them.

Pieces of pipes and extra fittings are no exception. Crafts made from polypropylene allow you to realize any fantasies and make useful things for household use with your own hands.

We invite you to read the article.

Furniture assembly process

In general terms, assembling household items from polypropylene pipes is no different from any other work with this material. You should develop a project for the future product, select PVC pipes of suitable length and diameter, and you can begin assembling it yourself.

Let's look at the technology using the example of assembling a simple chair for a summer house - such as in the photo above. The process will consist of just a few steps:

- Pipes of suitable size are selected; If you don’t find any, you can saw off the excess from plastic elements that are too long.

- Using suitable fittings and a soldering iron, the frame of the product is assembled.

- A soft seat will increase the comfort of using the chair. To make it, you need to take a suitable piece of not too thick plywood, put a square of foam rubber on top of it, which is then covered with thick fabric. It must be larger than the plywood so that the edges can be stapled under the seat.

- The seat is fixed to the frame with self-tapping screws.

- If the furniture is still not comfortable enough, you can make a soft back in the same way.

Of course, the chair can have almost any shape. If you take PVC pipes of larger diameter and bend them with a blowtorch, then attach them to the legs from below, you can get a rocking chair. By extending the seat, you can get a comfortable and waterproof chaise lounge made of plastic pipes that you don’t have to constantly dry.

Other pieces of furniture are assembled in a similar way - clothes dryers, laptop stands, table frames and much more. The design can be very different, and you can improve it a little by painting the resulting product. For this, it is best to use acrylic paint - it looks bright, has many shades and does not deteriorate when cleaning furniture.

DIY polypropylene chair

Crafts in the form of chairs made of polypropylene pipes are easy to assemble with your own hands, for this you need to prepare:

- medium-sized trimmings and fittings suitable for them;

- plywood and, if desired, you can add foam rubber;

- upholstery fabric;

- hacksaw, stapler and self-tapping screws.

The sequence of actions when creating a chair with your own hands:

- Legs are constructed from pipes and fittings using a soldering iron.

- A square or rectangle of the required size is cut out of plywood, it is covered with foam rubber and upholstery fabric. The fabric must be prepared in such a size that it can be secured on the reverse side with staples.

- The seat is secured to the legs with self-tapping screws.

- The back is made in the same way.

Video: making a chair with your own hands

DIY coffee table made from pipes

Loft furniture will always be popular because it is not just a fashion trend, but a special character of the interior. Metal and wood are hallmarks of industrial style. Threaded steel pipes form the perfect frame for a coffee table , which is very easy to assemble with your own hands. Calculate the number of parts needed and their length, then use the connectors to assemble the frame. Spray paint the frame and attach the plywood table top. You can leave the homemade pipe table as is or apply a clear varnish. Plywood is a better choice for the top because it is less expensive than planks.

To assemble the frame, connect two 20 x 200mm pipes using T-fittings for the legs.- Then make brackets from 250mm pipes and screw them to the T-fittings for the legs.

- Connect the legs with a crossbar made of 900 mm pipe. Attach the end caps to the bases of the legs.

- Apply a coat of primer to the frame, then apply 2-3 coats of spray paint. Tip: When spraying, wear a protective mask and work in a well-ventilated area.

- To attach the coffee table top, use a circular saw to cut a sheet of plywood to measure 1000 x 750mm.

- Lay the top face down, center the frame, and attach with screws through the exposed elbows.

- Sand the surface with sandpaper and apply a coat of clear varnish.

Photo source: www.handyman.net.au/diy-steel-pipe-table

Crafts in the form of multi-tiered beds

DIY crafts made from polypropylene pipes turn out to be necessary and practical. This also happens when there is little space on the site. From such pipe-rolling products you can build beds consisting of many tiers.

Setting up a garden bed is not very difficult. Large-diameter pipe products are prepared for them. They are laid on the ground, where the top part is cut off. This is done along the entire length of the product. And holes are drilled from below at equal distances.

The bed blanks are attached to the installed frame, and a drainage layer and soil are poured into them.

These structures do not occupy a large amount of space, the plantings in them do not create shade for each other, and they can be easily disassembled and assembled.

ADVICE. Such a bed can be built even on a balcony, and then the house will always have its own freshly harvested greenery.

Video: Vertical bed

Plastic furniture

They have learned to use pipe-rolling materials in this area. Since polypropylene has a long service life, furniture made from it is durable. For those.

By adding a little imagination and creativity, you can design interesting and stylish furniture crafts that will decorate any room.

Video: furniture

Shelves for the children's room

It cannot be carried away or overturned by strong winds. This dryer can be kept outdoors all the time, and it will not rust or rot. The convenient design makes it possible to move the dryer to the desired location at any time.

Video