0

9055

Laminated chipboard is a laminated chipboard impregnated with special compounds. This material is very light compared to wood, so a bed made of chipboard is more mobile than one made of wood. In addition, the material has excellent characteristics: moisture resistance, strength, affordable cost. These qualities have made such products very popular among buyers.

What is the material

Laminated chipboard is a material made from natural wood. It is a chipboard, but with higher quality sanding and applied with a melamine film. The main difference is the coating that is used in the board during pressing. This addition makes the material more durable and moisture resistant. The price of loose raw materials is low, but the design, thanks to the coating, can be very diverse (with wood patterns, different colors).

Manufacturers strictly monitor the safety of the material, bringing the percentage of formaldehyde to a minimum. Some classes of laminated chipboard are not inferior to natural wood in terms of environmental friendliness.

The textures of the material can be as follows:

- vector patterns;

- geometric;

- ornaments;

- imitation of natural wood.

Unfortunately, the material has significant drawbacks. It releases toxic formaldehyde into the air as resin is absorbed into the decorative coating. The way out of the situation is lamination, which is a film of paper with decor with a density of 60-90 g/sq.m. Lamination is the placement of a coating under high pressure and the influence of temperature. The process is carried out in a press, where the paper is made very dense, like plastic. A glossy film appears in the upper part, and in the lower part too, but with the presence of glue. The coating is durable, the resin spreads over the surface of the particle board under a pressure of 25-28 MPa and at temperatures reaching 210 degrees. When laminating, harmful aldehydes do not evaporate from the material.

The chipboard from which beds are made has many advantages:

- safety - the material made from shavings and sawdust as a binder contains formaldehyde, which is harmful to humans. Due to the laminated layer, laminated chipboard does not emit harmful substances;

- rigidity, strength of the material - laminated film is made from paper with the required structure. A high level of rigidity and the necessary friability are achieved by impregnating it with melamine resin. Pressing connects the boards with the film and produces a material of standard thickness;

- resistance to mechanical and thermal damage. The material rarely suffers from scratches or chips; it is not afraid of temperature changes and the touch of hot objects;

- easy care - products do not require special care products. It is enough to wipe the bed with a damp sponge to make the product clean;

- moisture resistance - melamine film reliably protects the structure of the particle board from moisture, protecting the material from rotting and mold formation;

- affordable cost - products are cheaper compared to models made of natural wood.

Along with positive qualities, there are also disadvantages. Laminated chipboard cannot be finely processed, and the presence of formaldehyde is also a disadvantage.

What kind of beds can be made from chipboard, material characteristics

Laminated chipboard is a laminated chipboard impregnated with special compounds. This material is very light compared to wood, so a bed made of chipboard is more mobile than one made of wood.

In addition, the material has excellent characteristics: moisture resistance, strength, affordable cost. These qualities have made such products very popular among buyers.

Existing model options

A bed made of laminated chipboard is made in a variety of configurations: circle, diamond, oval, rectangle. The designs of the models come on four legs, with drawers, and lifting devices. Durable and easy to process, the material, compared to wood, allows you to make any shape and size of bed from it. To work with laminated chipboard, no special complex equipment is required; products can be made with your own hands, having a drawing of the bed design.

Models of laminated chipboard beds are made for adults and children. The furniture is completely safe, reliable in operation, lasts a long time, and does not have an unpleasant odor. Any bed models can be made from this material:

- single;

- one-and-a-half-sleeper;

- double;

- loft bed;

- transformers;

- two-tier.

Double

Bunk

Transformer

Loft bed

Single

One-and-a-half-bed

Beds made of laminated chipboard have a beautiful external design. They are produced with a smooth glossy surface, wood texture, imitating wood with shades from reddish to black. By applying the film, the texture of wood and stone is formed on the chipboard.

High-quality laminated chipboard can be difficult to distinguish from natural wood with good external finishing (textiles, leather). Interesting model options:

- bedroom furniture made of laminated chipboard with leather will fit perfectly into modern high-tech or modern styles. A white bed with a headboard harmonizes well with the light design of the room;

- The brown range of products looks great in the bedroom, bringing relaxation, peace and tranquility. The beige color model is appropriate next to snow-white walls and laminated chipboard wardrobes;

- An interesting loft bed model is ideal for the design of adult and children's bedrooms and is most appropriate in small-sized homes. The products are made durable and multifunctional, thanks to modern laminated chipboard material.

Stages of manufacturing different types of headboards

Before you make a soft or hard headboard with your own hands, you need to calculate the dimensions of the element and prepare drawings based on them. Calculations must be carried out carefully, accurate to the millimeter, so that the finished product fits the bed perfectly in shape and size. If necessary, simple drawings and interesting headboard decor ideas can be found on special thematic resources.

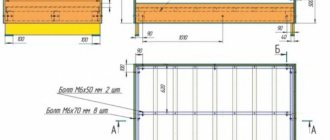

Hard wooden

For work you will need the simplest materials. The headboard can be made in the desired size - for a 1-, 1.5- or 2-bed bed. Before you start manufacturing, you need to prepare:

- chipboard;

- bars;

- jigsaw;

- wood glue;

- matte white paint;

- corners and screws for fastening;

- screwdriver

Step by step guide:

- Cut a piece of plywood to the desired size. The headboard can protrude slightly beyond the edges of the bed or be level with the sides.

- Cut the bars into the required quantity. If desired, paint or varnish them.

- Place long bars horizontally along the edges, and place short ones between them.

- Secure the elements with glue.

- Using angles and screws, screw the headboard to the bed frame.

The bars can be arranged in any order, creating a specific pattern or ornament, fastening them both horizontally and vertically.

A wooden headboard can be made according to the following plan:

- Polish the boards with sandpaper, removing all roughness, burrs and other defects.

- Coat the finished elements with varnish or paint.

- Using screws, build a kind of shield from the boards.

- If desired, reinforce the back with a sheet of plywood.

- Attach the finished headboard to the bed or hang it on the wall in a convenient way.

It is not necessary to make the back in the form of an even rectangle. If the interior style allows, you can imitate a hedge or choose another unusual configuration. The advantages of a board headboard are ease of manufacture and minimal financial costs.

Varieties of beds with a lifting mechanism from the best factories in Italy

Upholstery

The soft version of the headboard can be made in a variety of designs and shapes. It will take a little time to make - about 2 hours. There is no need to wait for the glue or paint to dry.

Necessary materials:

- plywood;

- jigsaw;

- foam;

- stapler;

- decorative fabric;

- loops for mounting the backrest.

Stages of work:

- Cut a piece of plywood to the desired size and shape.

- Place a layer of filler on it.

- Stretch the fabric over the foam rubber so that the edges extend beyond the plywood edging.

- Use a stapler to secure the textiles, making neat folds on the back side of the headboard.

- Using loops, attach the finished product to the bed.

The soft back can be made using another technique:

- Build a frame in the shape of a rectangle from thin beams. The width of the base is selected individually.

- Place several sheets of foam rubber on top of the frame and secure it along the edges with a stapler.

- Cover the workpiece with leather or its equivalent. Make neat turns and trim corners if necessary. Secure the material with a stapler - the soft, practical upholstery is ready.

- Attach the headboard to the bed with loops.

A soft headboard for a bed, made by yourself, can be both part of the overall interior and its accent. The product does not have to be made rectangular - the choice of shape depends on the skills and wishes of the craftsman.

Carriage tie

The carriage screed is a way of decorating the head of a bed, which dates back to the distant past. Previously, royal carriages were decorated this way, but today the method is successfully used by modern designers and furniture manufacturers. A characteristic feature of the carriage tie is a pattern in the form of squares or diamonds, made using large buttons on thick fabric.

To make a headboard with a similar decor option you will need:

- chipboard;

- foam rubber or any other sealant;

- fabric (it’s better to take eco-leather);

- buttons;

- drill;

- knife;

- self-tapping screws;

- stapler;

- threads;

- Crochet hook;

- glue;

- scissors.

Step-by-step production of a headboard with a carriage screed:

- Cut a piece of plywood and a piece of foam rubber; their sizes and shapes should be identical.

- Make markings on the seal in a checkerboard pattern. These will be the places where the buttons are attached.

- Cut holes on the foam rubber, and mark the places for drilling on the plywood.

- Using a drill, drill holes with a diameter of no more than 5–8 mm.

- Glue the foam rubber to the plywood, first making sure that all the notches made coincide with each other.

- Place another sheet of foam rubber on top. Its size on all sides should be 5–7 cm larger than the main frame.

- Spread the fabric on the foam rubber. The margin at the edges should be at least 10 cm.

- Carefully turn the workpiece over and secure all materials protruding beyond the edges on the reverse side using a stapler.

- Secure the buttons on the leg into the prepared holes using a lace and a hook.

- Hang the headboard on the wall in a convenient way or mount it directly to the bed.

Buttons should be covered with fabric. The headboard can be additionally decorated with beads, edging cords and ribbons.

Options for additional components

Beds made of laminated chipboard are equipped with various additional functional elements. A large number of products are equipped with convenient drawers for linen, large niches located on the side or in the front.

The presence of drawers and niches in the bed design is very important for small-sized housing.

Practicality and functionality are inherent in models with folding devices. Spacious storage space opens up after lifting the base of the product. Here you can put not only bed linen, but also various things, clothes, shoes. Additional details in the beds significantly save space in the bedroom. Having such beds, you don’t need extra wardrobes and chests of drawers.

Often beds made of particle board have legs that affect the height of the product. The legs are made of various materials (for example, metal with a chrome surface) and have different configurations, heights and widths.

Bedside tables add versatility and convenience to sleeping areas. Usually they are a continuation of the headboard and furniture frame. Nightstands are produced in the same style as the bed itself.

Bedroom furniture is produced with or without headboards. Headboards most often have soft backs, covered with a variety of materials, including leather, leatherette, and textiles. Headboards are also available in different shapes. Standard beds are those with backrests of medium height and a rectangular or square shape. Instances with original figured forms of headboards are becoming increasingly common.

Often, owners of small apartments purchase a compact ottoman bed made of chipboard. Products are available with lifting devices and drawers for linen. Compartments for placing bedding can be open or closed. Such models take up very little space in the room. The most popular beds are single models or one and a half beds, the low cost of which is one of the advantages of the products.

Working with drawings and detailing

When making a bed with your own hands, drawings play one of the key roles. The final result will depend on how accurately and correctly they are compiled. Without a drawing, the master will not be able to determine how much materials and fittings are needed, or how much the finished product will cost.

Causes of bed squeaking, how to fix it and what to do for prevention

To draw up a diagram yourself, you need to set aside on a sheet of paper segments equal to the length, width and height of the product, and then draw the shape and indicate the dimensions of each part separately. Such detailing is necessary for further cutting of the material. Computer programs and online resources that automatically create a layout based on the user’s measurements can greatly simplify the work. Another option is to find a ready-made drawing of the bed and adjust the parameters, strictly observing all proportions.

You should first draw a bedroom plan to make sure that the bed fits optimally in the room, leaving free passages and space for the rest of the furniture. If not, you will have to change the dimensions to suit specific conditions.

Dimensions

A laminated chipboard bed may differ in various parameters. One of them is classification by size:

- single;

- one and a half;

- double

The dimensions of the berths vary slightly depending on the manufacturer. Standard Russian-made beds are usually made with lengths of 190, 195, 200 cm. Non-standard models have lengths of 210, 220, 230 cm.

The width depends on how many seats the model is designed for.

Single beds have a width of 80, 90, 100, 120 cm, single beds are made with a width of 140-150 cm. The width of spacious double beds is 160, 180, 200 cm. In addition, cribs for very small children and sleeping places of various sizes for children are produced adolescence.

You can purchase a bed made of laminated chipboard of any configuration, color and size to order. In this case, the dimensions of the bed are dictated by the customer. The laminated chipboard bed can be seen in the photos of manufacturers producing modern, reliable furniture that will last for many years and will decorate any interior design.