From the first days, you want to surround your child with everything that is best, safe, reliable, and most importantly, something that will serve faithfully for many years until the baby grows up. For this purpose, as a rule, they choose natural materials that are not capable of laying a “mine” for future oncological diseases, thereby protecting the child from the first days.

Parents always want their children to grow up in a healthy atmosphere.

Why is it better to do it yourself?

A crib is a baby's first fortress. It is there that he sleeps, enjoys life, begins to explore the world, studying everything that surrounds him. But how can you be sure that the coating and materials of the baby bed are safe? Only by making it with your own hands.

It is very important to protect the fragile body from the harmful influences of the external environment.

Smart dads who have their hands in the right place know very well that you can be confident in something only when you have tried it and done it yourself. This is the main advantage of the product. Why is that? Let's do a little comparison.

| Factory | Homemade | ||

| Advantages | Flaws | Advantages | Flaws |

| Don’t waste time - go, buy or order | Not always high quality material | Do you know what it's made of? | Manufacturing is labor-intensive and time-consuming |

| No guarantee of design reliability | Reliable design - tested it myself | ||

| The coating is not always of high quality | High-quality coating - I selected it myself | ||

| Often the surface of the product is not treated | The surface is thoroughly cleaned - after all, the child will “crawl” on it | ||

If you have certain skills, you can make a bed with your own hands.

Types of cribs for babies

Cribs, depending on their design, can be divided into several categories.

Types of cribs by size and dimensions

Classical

The most popular option is a simple rectangular model, mounted on legs or with wheels that ensure its mobility. It is intended, as a rule, for children from birth to three years . The bed can be equipped with drawers, removable side walls, and a lower bottom as the child grows older.

Classic children's bed

Transformer

Beds that can be adjusted depending on the situation will be a real solution in small apartments. When a child appears, in addition to the bed itself, he will need a changing table and a chest of drawers, where everything he needs is stored. In addition, it is convenient when it is possible to expand the structure as the baby grows. For example, a bed combined with a small changing chest can, after some time, be turned into a sleeping place for a teenage child. Round models with a diameter of 0.8 m are suitable for newborns. When the baby grows up, the transformer changes into an oval design. The absence of corners increases the safety of the piece of furniture for children.

Transformable bed

Pendulum

Pendulum mechanisms installed in cribs help babies fall asleep faster. They can be longitudinal, transverse or universal. When choosing a model, you must carefully check the design for the absence of extraneous noise and jerking during operation. Pendulums must be equipped with clamps.

Pendulum crib

Rocking bed

Cradle

If the financial capabilities of the family allow, cradles are installed for the newborn babies. Such designs are designed to provide maximum comfort to the newborn. Limited space creates conditions of complete security . A baby can sleep in a cradle until about six months of age, as it grows quite quickly. Cribs can be functional, equipped with various electronics and toys; simpler ones are intended only for motion sickness. Putting a baby to sleep in a bassinet is much easier than in a regular bed. In addition, many models have remote controls, making life easier for parents. An option for a cradle can be a cradle installed on a standard bed.

Baby cradle

Manege

Beds with sidewalls made of mesh can be easily disassembled and transported if necessary. In such designs, which usually have bright colors, children not only sleep, but also play with pleasure.

Playpen bed

Children's beds can be equipped with drawers, chests of drawers, and changing tables. To make it easier to move furniture around the apartment, rollers are installed, but you must not forget about the latches. Designs can have different shapes, be made in the form of a car, a house or a favorite cartoon character.

Prices for children's beds

Manege

Design and construction of a baby crib

The appearance of a child’s bed determines the comfort of the room, how the child will like it, its comfort and rational distribution of living space.

Thus, design and construction are interrelated.

We all want something original and unusual, unusual for everyday life. But let's be realistic. Why complicate life with an elaborate design of a children's bed in the shape of a car, airplane, baby elephant or steamship, if they are difficult to make? Moreover, what if there is no specialized tool such as a surface planer, CNC router, band saw, etc.? By choosing such a design, you can ruin all the wood without achieving what you want.

Let's focus on a classic crib without frills and tricks, which, although difficult, is quite possible to make from solid wood with your own hands.

Manufacturing stages

Before work, you need to think through all the steps to minimize the possibility of error. When making furniture, it is important to follow the sequence of actions; this will help create a high-quality, unique product.

| Stage | Description |

| Marking | Use a carpenter's pencil to mark the details on the canvas. Marks can be easily removed with an eraser. Repeatedly check the correct dimensions, angles, thickness |

| Working with a saw | Using a jigsaw or saw, cut out all the previously marked parts. To avoid confusion, they are numbered in pencil. Often, for convenience, parts are laid out according to their belonging to the elements of the bed. |

| Preparation of fasteners | Joints for seamless connections and sockets for self-tapping screws are prepared before assembly begins. |

| Preparing parts | Using sandpaper, the surfaces and corners of the parts are processed. A sander will make this process easier. It is unacceptable to leave roughness or unevenness |

| Treatment | The parts are varnished and painted if desired. If the raw materials have not been pre-treated against deformation, then impregnation is also performed before assembly |

| Assembly | Step-by-step connection of parts and elements of the bed. The diagram will help you avoid mistakes |

Preparing parts

A wooden bed must be strong and can withstand the weight of even an adult. The bars and slats are chosen to be durable. At home or in the workshop, they lay out raw materials, tools, and begin preparation:

- Mark the edges of the parts with a pencil;

- elements are numbered and laid out;

- mark the joints;

- drill sockets for self-tapping screws, check symmetry;

- grind surfaces, corners, grooves.

Standard sizes of children's beds, rules for replacing furniture

When everything is ready, the parts are coated with a protective compound. Safe water-based varnishes are better. The sawn bars must dry well so as not to have any foreign smell, sticky layer, or roughness. Assembly can begin only after complete drying.

The assembled parts must be able to withstand the weight of the child and the increased load. Children are restless, this is taken into account when developing a drawing. For a bed with drawers, at this stage the components themselves are assembled and the handles are attached from the inside.

Assembling the frame and base

It is more convenient to assemble a wooden frame first. Check the correctness of the corners of the parts, install the side posts at the required distance, and mark the places where the side panels are attached. Next, they are fixed from the inside at an angle to increase strength. A base of wooden planks is attached to the lower frame from the inside.

When the frame is assembled, the mattress is placed on it for testing.

After assembling the frame, add side boards and install a bed limiter, if necessary. It is cut out in advance from a thin sheet of material, shaped, sanded, and varnished. Be sure to check the strength of the foundation joists.

Next, insert the drawers into the compartments and check that they can be easily pulled out. The handle should be comfortable, the contours of the container should tightly fill the space. They should not form cracks, dangle or sag. It is more difficult to assemble a bed with drawers yourself; you need to take into account the overall strength of the structure with cavities.

Manufacturing and installation of the backrest

According to the drawing, the headboard of the bed is cut out and fitted to the assembled frame. It must fit exactly to size. If errors are found, check:

- mark the correct position of the back;

- draw an edit line with a pencil;

- The excess is sawed off and the edge is sanded.

If the back fits perfectly, it can be decorated with sawn elements, stucco molding, and carvings. It is convenient to carry out manipulations before it is attached to the frame. Using the prepared holes, attach the backrest and screw it to the frame. If you plan to make a canopy, now is the time to secure the slats for it.

Canopy stands should be strong and lightweight and not reduce the functionality of the main structure.

Before final finishing, a piece of furniture is checked for stability, strength, and smoothness. Any possibility of getting a splinter, getting hurt, or hitting yourself must be excluded. Dimensions and dimensions must correspond to the drawings. The bed is almost ready, all that remains is decoration.

Important nuances of choosing a children's red bed, thematic models

Final finishing and decoration

A homemade bed is a reason to be proud. Don't neglect the decorating stage. The product is decorated with drawings, carvings, burning of ornaments, using stencils and stucco molding. The main thing is to comply with the condition - the safety of the baby is more important than design. Bed decor should be made using materials that are harmless to health.

The canopy is the most common decoration element. A light, durable frame is installed above the bed, to which the fabric is attached:

- muslin;

- veil made of silk or cotton fabric;

- organza;

- chiffon;

- other translucent materials.

Often a table or bookcase is placed close to the bed. The one-piece design looks modern and practical. The appearance is influenced by bed linen, which is also easy to sew yourself. For a pillow, it is preferable to choose a filling made from microfiber, bamboo fiber or holofiber. Natural feathers and down can cause allergies.

Tools - a reliable assistant to the master

The complexity of the work depends not only on the design of the product and materials, but also on the availability of tools. Having a real carpentry workshop in your arsenal, you can easily make any product. But what if there is nothing except a garage and a workbench? Can I start working?

No problem! Every man has everything he needs. And we need:

- Drill, with a set of wood drills;

- Planer for cleaning wooden blanks;

- Hacksaw for cutting;

- Set of files for grooves.

A necessary set of tools, without which the entire work project would be impossible.

Having a manual milling machine will greatly facilitate the work of assembling a crib, but if you don’t have one, we’ll make do with the above.

Using a hand router makes the job easier.

Materials and tools

Master classes from experienced specialists contain useful tips on how to properly make a children's bed. Traditionally, the process begins with the selection of materials. Furniture must be safe and comfortable, so the most popular raw materials are:

- natural wood;

- metal;

- plastic;

- chipboard;

- MDF.

Models made from natural wood are environmentally friendly and safe. They do not have a specific odor or toxic elements in their composition. MDF boards are similar in performance to natural wood. Chipboard is somewhat worse, since it contains formaldehyde-based resins. When properly processed, the slabs are safe and cost less than other materials.

A wooden bed is the best choice, but this option will be quite expensive. Very beautiful colored models of different shapes and shades are assembled from plastic, but this material is toxic. It is difficult to choose high-quality synthetic raw materials.

In addition to materials, the master will need:

- special glue;

- self-tapping screws;

- drill;

- roulette;

- sandpaper;

- accessories;

- stain;

- brush.

Characteristics of the “Toddler” children’s bed, modifications and their features

Depending on the type of crib, other tools may be required. By the time the drawing is completed, everything you need should be at hand. This will make the assembly process much easier.

Natural wood

Metal

Chipboard

MDF

Tools

Some features of joinery

To make the furniture reliable, special joinery joints are used in its manufacture. Unlike conventional nail or self-tapping fasteners, such fasteners are more resistant to loosening, do not “fall apart,” and are resistant to mechanical damage.

The main task of choosing a connection method is decorativeness, the desire to make it beautiful and invisible.

Such a connection consists of a blind or through groove and a shank that fits freely into the groove. They are fastened with wood glue. The size of each groove and shank is selected individually, based on the thickness of the wooden workpiece (slats, beams, boards).

When such a connection is made taking into account the arrangement of wood fibers and its texture, it gives the impression that the product is made from a single piece of wood.

First, mark the boundaries of the groove or shank with a pencil. Then an incision of the required depth for the shank is made with a hacksaw, and the groove is drilled out with a drill. Use a chisel to remove excess wood. The edges of the product are smoothed with needle files. If you have a router, set the cutting depth and mill the necessary parts. In addition, using the copying ring that comes with the machine, you can easily make grooves of the desired size.

Crib house - a cozy fairy tale

We all remember the unique feeling and mystery of huts made from blankets. So why not pamper your baby and improve his crib by “building” his own house for him, in which he can sleep so comfortably?

To do this, during the manufacture of the back of the crib, we will make some adjustments.

Namely, by making the railings a little larger, first cutting off their tops at an angle of 75° using a hacksaw or a miter saw. We attach the base of the “roof” of our house to them. It is better to secure the connection with tenons, but given the complexity of such a product, self-tapping screws are also suitable, the main thing is not to forget to glue it.

The last step will be to attach the ridge beam, which will connect the base of the frame of our “house”.

Thus, the baby will receive a personal “fairy tale” made by the caring hands of his father, and the blanket thrown by his mother will serve as a reliable roof.

Put maximum effort, care and love into your product, and such a bed will give your child good dreams, and you – joy and satisfaction from the work done.

Of course, what we have described does not reflect all the subtleties of the process of making a children’s bed with your own hands. During your work, you will encounter many obstacles, and you will have to figure out the nuances more than once. However, we hope that the instructions for making simple furniture that can increase paternal authority to a new level will be useful to both the young father and the head of a family with many children.

Veneered plywood

How to make your own children's bed with drawers

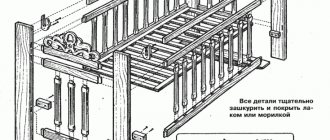

The children's bed we offer is made of laminated plywood 16 mm thick; some elements of the frame and frame can be made of wooden slats 25 mm thick. The presence of special drawers underneath makes it possible to use the children's room with maximum efficiency, it becomes more spacious, there is no need to keep separate furniture for storing bedding or children's toys. This is especially important for small apartments, in which quite a lot of space is “taken away” from children for storing various items, which significantly reduces play areas.

| Children's bed with drawers |

What is the bed made of?

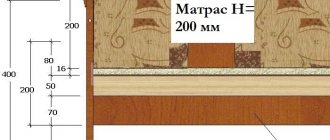

We give you not only a description of the main structural elements, but also all the dimensions. You don’t have to change them, our sizes are adapted to existing mattresses, designed for children from six years old to older teenagers.

- Frame binding (back, longitudinal drawer and legs). Make the outer frame from sheet plywood; it has higher physical strength, which is very important for children's furniture. In addition, the load-bearing external frame must withstand significant static and dynamic loads. And all chipboards react very negatively to dynamic loads and can develop deep cracks. Assemble the harness using minifixes, dowels and confirmations. Use minifixes and dowels when fastening from the front side; the connections will be invisible. It is better to connect the back wall with confirmations; this is done faster, the strength of the connection is quite satisfactory, and the connections in these places are invisible. This side of the bed will be angular and facing the wall.

- Inner frame. These are the slats on which the mattress will rest and the drawers will be placed. Make it from wooden slats and plywood; connections can be made with ordinary self-tapping screws.

- Drawers. Make the facades from laminated plywood; for other elements you can use cheaper materials. Hardware for connecting elements are ordinary self-tapping screws. Make boxes from ordinary plywood or OSB sheets. You can trim the visible edges with a decorative strip of plastic or paper, or you can sand them well and coat them with clear varnish.

| Detailing |

Now let's look at each element of a children's bed in more detail.

Frame strapping

The drawings show the dimensions of the large and small backrests, footboard and drawers. You may have trouble cutting curved elements, don't worry. It is not necessary to observe all the radii of curvature exactly; cut out the parts arbitrarily. The main condition is that the mating parts at the fixation points have the same dimensions. You need to cut out curved parts with an electric jigsaw, followed by finishing with a milling cutter. Try not to sand the edges by hand after cutting. It’s long, uninteresting, and a true master will always have comments regarding the quality. Fastening of visible parts of the frame must be done with confirmations. This type of connection has the highest strength, durability and reliability. In addition, minifixes significantly simplify the process of assembling products. Connect all other parts with confirmations; you can further strengthen the joints with dowels.

For the legs we used ordinary squares cut from plywood. You can install any industrial-made legs on the bed. The main thing is that they raise the bed to the set height and do not interfere with pulling out/pushing drawers. The legs are screwed on with self-tapping screws, the heads must be recessed, there is no need to seal the holes in the heads. If you wish, you can make the legs more attractive and complex in shape. We considered this unnecessary; few people pay attention to the legs; they should only fulfill their functional purpose.

| Harness |

| Small back |

| Foothills |

| Large backrest |

| Tsarga |

Inner frame

These are load-bearing elements in which the drawers will be installed. The internal frame consists of two parts, we recommend making them separately and then connecting them. There is a second manufacturing option - to fix the internal frame on solid longitudinal jumpers, but we do not recommend doing this, there is too great a risk of residual deflection under the weight of the boxes. We made all the frame parts from plywood; you can replace some of them with wooden slats. Tighten the frame cells with intersectional ties with countersunk heads.

Make each cell of the internal frame according to the drawings; buy metal guides for drawers; plastic ones do not meet the increased requirements for physical stability. You can attach the inner frame to the outer frame with self-tapping screws; the heads of the screws should be on the inner invisible side; it is not necessary to recess them.

| Inner frame cell |

| Installing the feet |

Drawers

They are made in the most common and simple way. For the bottom, take thick plywood or OSB, attach it to the walls with self-tapping screws, do not recess the heads. The main thing is that the dimensions of the parts correspond to the values indicated on the drawings, and the angles are exactly 90°. The guides and rollers should be in the middle of the sidewalls, fixed with small self-tapping screws.

Facade panels are somewhat more complex; they consist of three elements. Make them from two sheets of plywood, each 8 millimeters thick; for the handle, take a mortise aluminum profile. We gave the dimensions of the facade taking into account the gaps in height and width. The front panel is assembled from two separate pieces, the background piece is large, the decorative piece is much smaller, the cutouts are made curved for decoration purposes. Choose the radii of curvature yourself, try to ensure that both facades are completely symmetrical.

| Drawers |

| Facade |

| Drawer front diagram |

| Drawer back and front panels |

| Drawer side |

| Drawer bottom |

Some tips

Do not forget that the bed is intended for children, take care of their safety. Remove all sharp corners, check the quality of the cuts and grinding of the edges, make sure that there are no chips and the child cannot be injured. If you need to make a choice between the beauty and safety of a child, always choose the latter.

← Complete project of a frame house KD-64, construction features We are building a frame house according to the project KD-92 →

We recommend watching:

ORGALITE | 3.2mm | 1220 mm x 2140 mm

170 rub.

Plywood LAMINATED FOF | 15mm | 1220 mm x 2440 mm | birch

RUB 2,000 RUB 2,100

Plywood FSF | 10mm | 1500 mm x 3000 mm | birch | grade 4/4 | NS

RUB 1,500

Plywood NEEDLES | 6.5mm | 1220 mm x 2440 mm | coniferous | grade 3/4 | NS

750 rub.

Plywood FSF | 15mm | 1220 mm x 2440 mm | birch | grade 4/4 | NS

RUB 1,300

Plywood FSF | 21mm | 1500 mm x 3000 mm | birch | grade 3/4 | Ш1

RUB 3,600

Plywood FC | 6mm | 1520 mm x 1520 mm | birch | grade 4/4 | NS

400 rub

OSB | 12mm | 1250 mm x 2500 mm

750 rub.

Plywood FSF | 15mm | 1220 mm x 2440 mm | birch | construction | NS

1,200 rub.

Plywood FSF | 6.5mm | 1500 mm x 3000 mm | birch | grade 3/4 | Ш1

RUB 1,800

Plywood FSF | 4mm | 1220 mm x 2440 mm | birch | grade 4/4 | NS

480 rub.

Plywood FSF | 9mm | 1500 mm x 3000 mm | birch | construction | NS

1,200 rub.

Plywood FC | 6mm | 1520 mm x 1520 mm | birch | grade 3/4 | Ш2

500 rub

Plywood FSF | 12mm | 1525 mm x 3050 mm | birch | grade 3/4 | Ш1

RUB 1,600

OSB | 22mm | 1250 mm x 2500 mm

RUB 1,500

Plywood LAMINATED FOF | 15mm | 1500 mm x 3000 mm | birch

RUB 3,500

Plywood FSF | 4mm | 1220 mm x 2440 mm | birch | grade 2/3 | Ш2

700 rub

Plywood FSF | 18mm | 1500 mm x 3000 mm | birch | construction | NS

RUB 2,150

ORGALITE | 3.2mm | 1220 mm x 2440 mm

200 rub

Plywood FSF | 15mm | 1525 mm x 3050 mm | birch | grade 3/4 | Ш1

RUB 1,800

We also recommend reading

10.10.2015 → Beds, sofas

DIY plywood sofa

We will tell you the algorithm for making a simple model of a sofa from plywood. In terms of cost, this is one of the most economical designs; in terms of ease of use, it can satisfy the majority of domestic consumers.

11/10/2015 → Beds, sofas

How to make your own children's bed from boards

The opportunity to please an entire child with a bed made by himself is a great success for all young parents. We will teach you how to make a bed from boards for children from four years old, there are drawings with dimensions.

11/14/2015 → Beds, sofas

Comfortable bed made of sheet plywood

For many of us, it is not always convenient to buy a bed in a store - either the style does not suit, or the price is too high. For those who know how to hold a hammer in their hands, we will tell you how you can make a bed yourself from sheets of plywood.

11/16/2015 → Beds, sofas

A bed made of boards for two people - manufacturing algorithm

Many craftsmen dream of making a real double bed, but not many take on this task, they are afraid of difficulties. In this article we will try to convince them that not everything is so scary, that these works can be done independently.

Comments

No one has left a comment yet