Furniture plywood is popular among manufacturers due to its environmental safety and high wear resistance. But there are not many companies that can offer ready-made kitchens made from this material. But maybe you should think about making a headset with your own hands? This task is within the power of everyone - you just need to develop a kitchen project, make furniture drawings, and then, after preparing the necessary tools, you can proceed directly to the implementation of your plan.

Making a kitchen set with your own hands not only allows you to save money, but also makes high-quality furniture that can last at least 20 years. A serious advantage of this option is that the homemade set will fit exactly into the space allocated for it in the kitchen . Although this process will take a long time, once the work is completed you will get maximum pleasure from using your homemade furniture.

What to make kitchen furniture from?

One of the important issues that have to be resolved when making furniture from plywood with your own hands is related to the choice of material. Here it is necessary to take into account a number of indicators:

- The quality of the plywood.

- leaf appearance.

- Wood species. It is best to choose deciduous ones, which are less susceptible to temperature fluctuations and high humidity.

- Manufacturer country. It is more advisable to buy Russian-made lumber, which, unlike its Chinese counterparts, has the necessary environmental friendliness. You should also not think about buying Finnish plywood, since its cost is excessively high.

If we take into account the standard size of a plywood sheet, material properties, quality, grade and cost, then the best option available is FK grade lumber.

The purchased lumber must be of grade ½, and the sheet must have dimensions of 1525 × 1525 with a thickness of 6, 12 and 18 mm .

To make homemade furniture, you can take laminated sheets, but then the material will cost you a little more than FK brand plywood.

What to look for when choosing plywood

Veneer made from coniferous or birch wood is used to make plywood. Coniferous plywood is characterized by a more attractive appearance and strength. Veneer sheets are glued together at high temperature and pressure, forming a monolithic slab of a given thickness. In this case, each layer is laid perpendicular to the previous one - this makes the plywood resistant to deformation.

Birch plywood

Plywood can be sanded or unsanded, and, depending on its performance properties, is divided into several categories.

Table 1. Plywood categories

| Appearance of material and markings | Description |

FOF | The front layer of this moisture-resistant laminated plywood has a special coating in the form of PVC film, which provides additional protection against moisture. |

FSF | Formaldehyde resins are used for gluing sheets, so this material is not desirable for making furniture, despite the fact that plywood of this brand is highly moisture- and wear-resistant. |

FC | This type of material has a wide range of applications. FC plywood is durable, moisture-resistant and environmentally friendly, therefore it is widely used for interior design and furniture manufacturing. |

FBS | When making bakelite plywood, a varnish composition of the same name is used, with which each sheet of veneer is impregnated, and then all layers of the slab are glued together using it. The material is characterized by unique performance qualities: strength, durability, resistance to deformation, and aggressive substances. This type of plywood is environmentally friendly, so it can be used for making children's furniture. |

FBA | To glue veneer in the production of this type of plywood, natural albumin-casein glue is used, making the material environmentally friendly and safe. However, the moisture resistance of FBA plywood is low. |

Note! The safest is plywood made in accordance with safety certificates E1 and E0.

The thickness of plywood sheets varies from 1.6 to 76 mm; sheets with a thickness from 6.4 to 19 mm are more often used.

Prices for sheet plywood

Plywood sheets

Kitchen measurements and design project

Before making furniture from plywood, it is recommended to take measurements and then draw up a sketch of the set based on them. Then you will have confidence that the furniture will be of high quality and reliable. But the main reason why you should start making furniture yourself is the individuality of execution.

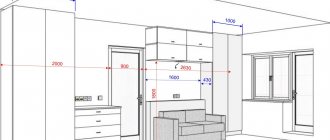

In the process of creating a drawing of a kitchen set, it is necessary to take into account ergonomic indicators, the height of the housewife, the size of the kitchen space, as well as the wishes of family members.

Stage No. 1 - kitchen measurements

When taking measurements of the kitchen, it is imperative to include projections, niches and communications in the final results. All this must be depicted on a sheet of graph paper , observing the pre-selected scale. Don't forget about high technology - there is no need to waste time drawing a drawing by hand if this can be done using computer programs for creating 3D sketches.

This No. 2 is drawing development

On a sheet of graph paper you need to draw a draft version of the future look of the kitchen made of plywood, and show in it the locations of household appliances. Next, you should decide the size of the furniture sections - cabinets, shelves and drawers. Having displayed all the details in the project, it is necessary to remember that kitchen furniture must meet the requirement of ergonomics.

Information with recommended sizes for various elements of the kitchen set will help you with this:

- For drawers, the optimal width is 30–40 cm;

- There should be a spacing of 30 cm between the plywood shelves;

- For shelves, the same width is maintained as for the cabinet - 36 mm (for the frame, 18 mm plywood is used);

- The distance between the upper and lower tiers is 45–65 cm.

Stage No. 3 - drawing up a design project

The sketch must show the dimensions of the cabinets, cabinets, drawers and shelves obtained as a result of the measurements taken. In addition, it is necessary to calculate the dimensions of the facades, including technological gaps in the final results. To maintain dimensional accuracy, measurements must be taken separately for each piece of furniture . When developing drawings of modules, they are presented in two projections, and each must indicate the exact dimensions, dimensions of technological holes and grooves. This will simplify the task of choosing the size of plywood sheets, which will help you save as much as possible on the purchase of material.

Plywood processing

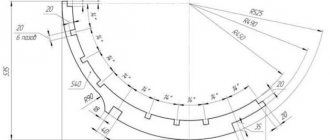

Processing plywood along the contour for the manufacture of future products

It doesn't matter if you're a skilled woodworker, carpenter, or just an enthusiast who wants to make your own furniture - you'll need to cut plywood or veneered wood. Learning to cut without tearing is not that easy. It has a different structure. Thus, some species are highly susceptible to splitting during processing. It doesn't really matter what cutting tool you use because it's not about the cutting tool. Each cutting tool must be used in a specific way to cut without tearing.

Methods for cutting plywood using discs on a table

Preparation of materials and accessories

Now it’s time to decide what kind of plywood, fasteners and additional accessories we will need to make the kitchen set.

To correctly determine the size of plywood sheets, it is necessary to understand what elements we will have to manufacture:

- Thickness 18 mm. A frame is made from this material, and shelves are cut out for cabinets.

- Thickness 12 mm. Material with this value is used for the manufacture of facades of floor cabinets.

- Thickness 6 mm. Material with this indicator is necessary to create doors for wall cabinets, which must additionally be equipped with stiffeners.

Fasteners

Having successfully completed the previous step, you need to decide on the type of fasteners for the parts. Based on the practice of making furniture from plywood with your own hands , screws alone are often enough to reliably connect elements. With it you can avoid such serious problems as delamination and crumbling of plywood sheets, loosening of hardware in holes.

Working at home with furniture minifixes is quite difficult, since it is necessary to ensure the highest accuracy when cutting holes in three planes. Having in hand a drawing containing the exact dimensions of the product, you can use the services of specialized workshops, entrusting them with the work of making holes.

Thus, to create fastening joints you cannot do without the following materials:

- Screws, minifixes or confirmats;

- Silicone based adhesive and sealant.

Fittings and finishing

For the final stage of work, you will have to purchase handles, hinges and closers. You may also need decorative plugs in case it was decided not to use minifixes. It should be taken into account that in kitchen furniture made of plywood, fancy fittings should be used to a minimum.

Painting work can be done using putty and paint; in the case of film gluing, putty and self-adhesive are used . You can give furniture a finished look using stain and varnish.

Required tools and materials

To make plywood furniture you will need the following tools:

- jigsaw;

- drill;

- medium and fine grit sandpaper;

- roulette;

- pencil.

Sandpaper can be replaced with a sander.

You will also need the following materials:

- plywood;

- fasteners (screws, steel angles, brackets for hanging on the wall);

- fittings (handles, hinges, drawer guides);

- paint and varnish.

If you don’t want to paint and varnish your own product, you can take a simpler route - cover it with polyvinyl chloride film. It is quite durable and imitates the pattern of natural wood quite well.

It’s also a good idea to stock up on wood putty. There is a high probability that a small amount of material will chip during operation.

screwdriver

Tool preparation

In each case, the set of tools will be different. It all depends on the plywood sawing method you choose. It is best if this work is carried out in a furniture workshop , since here it is necessary to ensure high accuracy and use a plunge-cut saw with an attachment for cutting sheet materials.

The furniture assembly process cannot be carried out without the following tools:

- Plunge saw, jigsaw, hacksaw.

- Tape measure, square and ruler.

- Cordless screwdriver, drill and drill set.

- Hammer, mallet, chisels, files, plane, chisel.

Key Features

Even an inexperienced craftsman can build a partition from plywood. For the wall you should take high quality materials. It will help zone the space in a studio apartment. The plywood structure will not disturb the environmentally friendly atmosphere in a wooden house. Doesn't require a lot of money. If you take into account the subtleties correctly, you can differentiate between large and small rooms.

Experts give several examples. They will help you correctly use plywood sheets in houses and apartments:

- In the office. A partition separates the sleeping area from the table.

- Between the living room and kitchen. If the zones are combined in one room, you can use carved partitions with floral patterns.

- Hallway. An interesting and multifunctional separation of the entrance door from the living area.

- Children's room. A light wall will create comfort, the baby will have a place to sleep, and a separate corner for studying.

- Adjacent bathroom. A plywood partition can be used to isolate the bathtub from the toilet. The material should be coated with moisture-repellent impregnation.

When creating an interior design, it is necessary to take into account the main characteristics of the material. The plywood sold differs in thickness, quality, and appearance.

The video shows an interesting model of a fence made of plywood and wooden blocks:

Preparing parts

First, a plywood sheet is taken, on which the details of the future headset are marked. You can cut at home only if you have the necessary tools. Otherwise, this work is performed in a furniture workshop. Before processing, plywood blanks must be sanded and sanded. If, after completing the main stage, you are going to cover the parts with paint or stick a film on the set, then the elements need to be puttied in two layers , and then sanded. You can save yourself from such labor-intensive work if you decide to work with furniture laminated plywood. It already has a film on it, and there is no need for additional processing.

Interesting ideas for plywood furniture

Here are a few photos from which you can draw interesting ideas for designer plywood furniture.

Making a headset

The main operations that you will have to perform when making furniture from plywood are assembling the frame, hanging doors and installing shelves and drawers.

Plywood is a fairly durable lumber, so there is no need to use timber when assembling the frame. But first you need to mark the place for fasteners - screws or confirmations, depending on the option you choose. Next, take a special step drill , with which you need to make holes with threaded and non-threaded parts, as well as a recess for the Euroscrew head. If you use a classic screw, it is enough to perform countersinking using a drill of a larger diameter.

To create a connection on the front side, minifixes are used. Then you won’t have to waste time installing decorative plugs, but if they are missing, you can use Euroscrews. Before finally fixing the fastening joints, the ends must be treated with silicone sealant.

Furniture assembly

The workpieces are fastened together using screws and steel angles. However, there is one limitation here: if the plywood is too thin, this joining method is not suitable. You will have to glue the sheets together. Traditionally, thick PVA glue is used for this with the addition of a certain amount of small wood shavings.

It is also possible to use epoxy resin. However, this glue is much more expensive than PVA, so it is advisable to use it only if we are talking about a small piece of furniture (for example, a children's chair).

In order to make the connection more durable, grooves are cut in one part of the sheets, and wedges that fit into them are cut in the other. The joints of the parts are glued. You can also screw self-tapping screws into the grooves. There are a couple of things to keep in mind here:

- screws should not be visible, otherwise it will spoil the appearance of the furniture product;

- The screws must be screwed in very carefully, as they can split the layers of veneer that make up the plywood.

Headset assembly

The assembly of a plywood kitchen set can be considered complete only after the doors are hung on the frame and shelves and drawers are installed. It is necessary to first mark and drill holes for the fittings; the installation of guides under the drawers must be completed before assembling the frame.

For doors, plywood sheets 6 mm thick are used. To give them increased stability, additional stiffening ribs are installed. Plywood shelves are made of 18 mm thick material . They must be prepared accordingly - chamfer the front edges, putty the sections or sand them for painting or covering with film. If you are going to apply varnish, then just sanding is enough.

Furniture made of laminated plywood looks most attractive. It is popular among many home craftsmen due to the variety of shades, which makes it possible to choose the material taking into account a specific design.

Wardrobe hangers

If your closet is made of plywood, then don’t stop there, why not also make hangers from it. The whole family will definitely enjoy this creative process: dad saws, mom sands, and the children draw.

Isn’t happiness hidden behind such simple things?!?!

DIY tabletop

When making a work surface, you can use such a popular material as laminate. It is not only affordable, but is also able to give the work surface an aesthetic appearance. To do this, you can choose a coating in accordance with the shade of the headset or achieve a contrast effect. Particular attention should be paid to the panel joints - they need to be treated with sealant. This way it will be reliably protected from the negative effects of moisture. To protect the front edge, it is necessary to install a decorative metal corner on it.

Laminated plywood comes in a variety of sizes and is highly moisture resistant, making it also suitable for making countertops . This solution is very practical due to the presence of a film that provides the countertop with good protection from liquids. The edges also cannot be considered a weak link in the design of the tabletop, since they are treated with a moisture-repellent composition.

Features of material processing in the manufacture of kitchen furniture

Large kitchen made of plywood, made by yourself

The strength and durability of plywood are the reasons why many quality kitchen cabinets feature plywood construction. Kitchen cabinets experience a lot of wear and tear. They open and close throughout the day. They are exposed to moisture, grease, heat, etc. Plywood can withstand all of this, which is why it is good as a material for building things around the house.

If you decide to start making kitchen furniture, consider factors such as the overall layout of the kitchen and the dampness of the room, which will spoil your design; Correctly calculate the thickness of the doors used during construction.

Interesting kitchen made of plywood with a work surface and a bar counter

Final finishing

For beginners, the subtleties of work sometimes cause difficulties. To avoid repeating common mistakes, you need to follow the recommendations of experienced builders:

- It is better to spray paint wide areas of the structure.

- It is more convenient to handle medium-sized surfaces with a roller.

- Multifaceted, shaped elements and hard-to-reach corners can be painted over with a paint brush.

- To work with paints and varnishes, use a foam roller, this way you can avoid lint residue from fur devices.

- To ensure uniform coloring, work is carried out in the longitudinal direction of the plywood fibers.

- Apply the second coat of paint after the previous one has dried.

Attention! In order to get a rich color as a result of the work done, it is not necessary to apply a thick layer of paint. Two treatments are enough.

An original carved product for the living room or bedroom

If the master wants to achieve a perfectly smooth glossy finish, the partition is opened with high-quality varnish. The final layer is applied with a sprayer, which allows you to evenly cover the surface. If you don't have one, a regular roller will do. Hard-to-reach areas are coated with a brush. After the manipulations have been completed, the wall must be allowed to dry.

More interesting and educational information on this topic is presented in the video: