The main advantage of folding furniture is its compactness when folded. Thanks to ingenious or simple mechanisms, it is possible to store stools and chairs in a closet, small niche, or other places in an apartment or cottage. And as soon as the need arises, they quickly and easily allow you to seat a large group at the table.

The most popular material for making such items with your own hands is plywood. It is easy to use and affordable. Chairs made from this wood material are strong and reliable; they can easily complement any interior or can be decorated to match it with textile pillows and covers.

Product options

Regular and laminated plywood is often used for furniture production. It is considered the best material for beginning furniture makers, since it does not require special knowledge in the field of design or processing skills. There are several types of plywood chairs:

- Stools are traditional models that are suitable for absolutely any home or apartment. All structural elements are smooth and straight - few of them are required, so the chair can be assembled with minimal use of tools.

- Folding ones are suitable for those who like to travel, because when folded, such furniture will not take up much space in the trunk. The design is more complex than that of a stationary chair, however, even a beginner can master it.

- Transformers combine several purposes at once. A chair that can turn into a comfortable lounger with room for legs, furniture with folding tables and many other options are exactly transformers.

Designer chairs represent a separate category. Plywood has excellent flexibility, thanks to which a skilled craftsman can give it any unusual shape. Graceful curves and expensive finishes are the distinctive features of this type of furniture. The disadvantage of such products is that they do not always match the interior.

For self-production, ordinary stools or folding chairs are most often chosen. The main advantages of creating furniture with your own hands:

- saving money due to the low cost of raw materials;

- the ability to design a suitable model for a specific interior;

- Valuable experience is gained during the production process.

A hand-made plywood chair, if decorated beautifully, can be a wonderful gift for a loved one.

Stools

Folding

Transformers

Designer

Home chairs

A massive wooden chair is considered comfortable and durable. Thanks to its design, it is stable and reliable. The product is suitable for both adults and children. Kids will not be afraid, and the chair will withstand any load.

There are standard types of products:

- chair with soft seat;

- armchair chair;

- folding chair;

- transformable chair.

The aesthetics and comfort of these models are quite high. The choice of manufacturing style and material depends on your desire. If you need to make a durable but lightweight chair, use plywood or boards.

The elegance of the design is determined by the carved legs and backs. Each of the above types has its own special use, creating coziness and providing maximum comfort for home, work or leisure.

Design and size of the structure

When choosing a model, you should first of all focus on its safety and level of comfort. It is necessary to take a responsible approach to the selection of materials for the structure and the development of dimensions. What nuances should you pay attention to:

- The load-bearing elements, that is, the frame, are created from thick plywood of at least 18 mm. The backrests with a seat can be made from 14 mm sheet - this is sufficient for an adult. It is permissible to make children's furniture from plywood sheets with a smaller (2-3 mm) thickness.

- The height of the product for an adult user is selected from the range of 42–48 cm. For more accurate indicators, you need to measure the existing chairs and adjust the height “to suit you.” For children, 25–35 cm is enough, but it should be taken into account that the sitting person’s legs should be at a right angle.

- When using furniture outdoors or in rooms with high levels of moisture, it is better to prepare plywood with a laminated layer. Moisture-resistant sheets impregnated with a special composition are also suitable for these purposes.

- For the best appearance, it is recommended to use grade 1 or 2 plywood. Less quality material is less amenable to sanding and painting.

- For your home, it is better to make stools or designer seating options. Transformable and folding chairs are suitable for garages and utility rooms.

- The design for the chair is chosen according to the existing or planned interior. Seats intended for auxiliary rooms or buildings usually look quite laconic.

When choosing a chair model, you need to rely on your ability to handle wood and the availability of the necessary tools. The simplest designs can be made using a saw and screwdriver, while more intricate designs will require specialized equipment.

For the frame of the product, it is recommended to use plywood with a thickness of at least 18 mm, while the back and seat can be made from 14 mm sheet

The height of an adult product usually does not exceed the range of 42–48 cm; for children, 25–35 cm is enough

To use furniture outdoors, it is better to give preference to plywood with a laminated layer or moisture-resistant material

Products made from 1st or 2nd grade plywood look more aesthetically pleasing.

For home use, it is better to make stools or designer chair options

The design of the product is selected taking into account the interior features of the room where it will be used

Stages of self-production

To create really good plywood chairs, you just need to divide the whole process into stages and strictly follow the instructions. Any work begins with the creation of a drawing, which indicates the dimensions and attachment points. Without it, there is a high risk of making an uncomfortable, disproportionate piece of furniture.

Types of chairs for schoolchildren, the best brands, selection criteria

Creating a project is divided into stages:

- A drawing of a diagram showing the parameters of the dimensions and proportions of the product.

- Drawing of the components of a plywood chair in a schematic representation.

- Bringing each element to meet expectations, checking the specified dimensions.

- Development of a drawing on graph paper. The components correspond to the dimensions of the plywood sheet (this is necessary to save materials and eliminate errors).

- Templates are created that will later allow parameters to be transferred along the contour to the source material.

You can make your own drawings using design programs. They allow you to do this faster and more accurately. Such services eliminate errors, and the finished project can be printed in any format.

How and how to reupholster a chair with your own hands, step-by-step procedure

Having prepared, you can proceed to the main stages of creating furniture:

- Transferring the drawing to a sheet of plywood with the required parameters.

- Cutting blanks with a jigsaw, this must be done in compliance with predetermined parameters and lines.

- Process the edges and the entire canvas using sandpaper, bringing the grain size to a minimum. The task will be simplified by the use of electric grinders.

- Application of paint and impregnation.

If you do not have the skills to create projects and draw, ready-made materials can be found on specialized websites and forums. As a rule, these are tested samples implemented by other craftsmen.

Transferring the drawing to a sheet of plywood

Cutting blanks with a jigsaw

Processing the edges and the entire canvas with sandpaper or a sander

Application of impregnation and paint coating

Simple stool

This seat option is not complicated. To implement it, you will need a jigsaw (preferably an electric one), as well as plywood with a thickness of no more than 20 cm. Fastening is carried out using three self-tapping screws, which require a screwdriver. Sandpaper with a grit range of P100–P400 will help bring furniture to excellent condition.

Further work is extremely simple:

- Three support plates are cut off, which will be the legs. Also, according to the drawing, the seat is made.

- Using a jigsaw, connecting grooves are created in the plates. The edges require sanding to help prevent the wood from splitting.

- The legs are connected using grooves by inserting into each other. For greater strength, wood glue may be added.

- The seat is attached using self-tapping screws, which fasten it to the legs through an embedded part.

The stool can be made in 1-2 hours, but processing and painting the plywood may take a little longer.

Using a jigsaw, cut out the seat and three support plates that will be the legs, make grooves in them

Connect the legs by inserting the grooves into each other

Check the reliability of the structure, if necessary, apply wood glue to the joints

Secure the seat with self-tapping screws through the embedded part

Making a stool takes 1–2 hours

If desired, the product can be painted in any color

Folding

The folding design is compact and convenient; it does not require much material. However, the process itself requires more advanced carpentry skills. The tools you will need are an electric jigsaw, a screwdriver for placing fasteners, a drill with the diameter of self-tapping screws, and emery. Plywood is taken with a thickness of 16 to 20 mm, and the fasteners will be furniture hinges.

How to properly sew covers of different models for chairs, tips for housewives

After preparation, you can start working:

- The diagram is redrawn on a sheet of plywood according to the dimensions.

- The elements are cut with a jigsaw.

- The edges and the rest of the space are treated with sandpaper.

- The points where the hinge mechanisms will be installed are marked.

- Holes for self-tapping screws are cut using a drill. If you try to simply screw in the fasteners, the material will quickly delaminate.

- The loops are fixed to the elements. For better aesthetics, they can be covered with fabric strips.

Since a folding chair made of plywood requires complex drawings, it is better to turn to specialized websites or specialists for them.

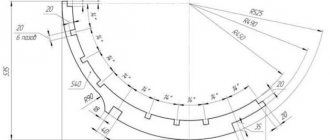

Folding chair drawing

Finished goods

Decor options

The final finishing, which gives the product a complete look, is carried out before the furniture is assembled into a single structure. However, this should be done only after adjusting all the elements, because having remade them, the master will be faced with the need to re-decorate. Particular attention must be paid to sanding the edge parts remaining from the jigsaw. The main fabric is brought to P600 grit.

To apply varnish, you must first coat the plywood with stain or a special impregnation that adds moisture resistance and prevents the material from drying out. Paint is rarely used, mainly for children's furniture. Products for adults are coated with wear-resistant varnish as standard.

An additional decoration for a plywood chair can be a designer pattern that matches the interior of the room. If you have stencils (or talent), you can draw a cartoon character, an ornament, or landscapes on a stool. An optional, but stylish and functional element will be the piping along the edge of the soft seat, giving the product a finished look.

Making home furniture yourself requires at least basic skills and abilities. But making a chair from plywood with your own hands is not difficult, you just need to familiarize yourself with the production technology and the requirements for materials. Such a responsible approach will give the highest quality results.

Simplicity, convenience and comfort - do-it-yourself folding furniture

It is worth noting that a beautiful plywood chair can perform not only a decorative function, but also a practical one. Especially when we are talking about folding chairs, which, due to their compactness and ease of assembly, will be useful for any summer resident or fisherman. The design of folding plywood furniture we offer is quite simple and allows you to make a chair with your own hands quite quickly and with minimal financial costs.

As the fitter Mechnikov said in the well-known film, when the experienced swindler Ostap Bender is trying to get his goods as quickly as possible - “Money in the morning, chairs in the evening!” So in our case - having spent very little money in the morning, by the evening you can get a comfortable plywood chair with an unusual design.