0

14466

In order to make the process of working behind a personal computer screen tireless, it is important to choose the right chair or armchair. Particular attention should be paid if you need to choose furniture for a gamer or freelancer - in such cases, spending time at the computer increases, which means comfortable sitting is necessary to maintain posture. Often, not finding suitable furniture, they come to the decision that it is easier to build a computer chair with their own hands - in this case, you can not only save money, but also create a design according to the given parameters. There are many advantages to assembling yourself, for example, pride in the resulting unique product, as well as valuable work experience.

DIY home chair

Now let's look at making a regular home chair with our own hands. Unfortunately, there were quite a few photographs; there was no time to take photographs. The main stages were recorded in a timely manner, switching from a tedious workflow.

I wanted to get an ordinary chair, and not just some incomprehensible rookery. So that it is strong and stable, like store-bought options. I had to look on the Internet for views and drawings of chairs in order to correctly assemble my design. I suggest you immediately look at the photographs of the chair assembly process itself.

At the first stage, a base-frame for the future chair in the form of a semicircle is made. Chipboard with timber is used. The base of the chair was 10 centimeters thick. This will be just enough to secure the walls. And the uprights have the same ultimate function.

Hardboard was perfect for the back, and plywood for the front wall. I drew out all the curves and outlines of the future chair by eye from the remaining wallpaper. Children's wooden cubes were used for the base.

The next step was to glue cardboard to fill the interior space. During the work, we even had to change the glue; the initially chosen PVA did not work. The walls swelled and became like a wafer, the glue was replaced with ordinary wood glue. It turned out to be the best choice of all that was offered. There was even an idea for a rocking chair with my own hands, but I will implement the idea a little later.

After looking at the photo, you can immediately easily understand how the finished walls were obtained. For leveling I used a regular knife; the material is easy to cut and can be deformed.

At the next stage, work with instant adhesive and foam rubber, seal the entire surface with a layer of foam rubber, leaving no bald spots or uncovered areas. A cover must be sewn onto a monotonous surface.

Well, we have reached the final stage, when we pull on the cover and get a beautiful finished chair. The product turned out to be quite heavy, but it will be completely safe for children, which can be considered a plus. As for the fabric used, nothing was bought anywhere. We used scraps and sewing scraps available at home.

We wanted temporary furniture; no one planned to make a chair that would last forever. The fabric on the armrests, despite being well tacked with glue, will peel off over time. If we say a little about the design of the chair, it turned out to be simply indestructible.

Repair options

If the permanent contact or crosspiece fails, you can do the repair yourself. Broken piastres, pneumatic cartridges, and swing mechanisms will have to be replaced with new parts. The same rule applies to damaged wheels.

Replacing rollers

Over time, the rollers may fall out of the beams of the cross due to wear of the plugs, especially if the latter are made of aluminum or plastic. To repair these elements, you need to perform a number of actions:

- The chair is turned over so that the rollers are on top.

- The wheels are removed from the cross. To do this, you just need to pull them towards you.

- Remove the casings from the beams of the cross using a screwdriver.

- Damaged plugs are pulled out of the housing.

- Install new seals and assemble the parts in the reverse order: casings, then rollers.

A broken wheel is treated with superglue or replaced with a new one. A common cause of breakage is the accumulation of debris, hairs, and threads. In this case, the rollers are removed, cleaned, and installed in their original place.

If the socket for fixing the axle of the wheels in an office chair fails, most likely you will have to change the crosspiece.

Use a screwdriver to pry off the fastener and remove the support

Install new wheels

Breakage of piastres

You can repair an office chair yourself if the technician has experience working with mechanics. First of all, it is necessary to clarify what material the crosspiece is made of. It is better to replace the plastic part immediately, since it is pointless to restore a fragile product. Restoration of piastres is carried out as follows:

- The chair is turned over, for convenience, its seat is placed on a chair so that the back is pressed against the floor surface.

- The wheels are removed from the mounts.

- Unscrew the 4 bolts that secure the rocking mechanism and piaster to the seat.

- Disconnect the gas lift by lightly tapping it with a rubber or wooden hammer. You must act carefully, otherwise the mechanism will become deformed and become unusable. The “stuck” compound is treated with a special liquid.

- Using a screwdriver, remove the pneumatic cartridge stopper, the washer, and then the gas lift rod.

- The piastra is knocked down with gentle tapping.

- Repairing a plastic part involves gluing and soldering, but these methods are only relevant if there is minor damage.

- The broken beam of the crosspiece is fixed with plastic or metal plates, secured with screws or superglue. Metal parts are restored by welding.

Types and models of Ikea children's chairs, the best designs and colors

Repairing a computer chair must be done very carefully and carefully. Careless handling can lead to damage to the piastres or pneumatic chuck.

Unscrew the bolts

Knock down the piastra with light taps

Screw on a new one

Destruction of the swing mechanism

If the swing mechanism breaks down, you will have to replace it. The part is attached to the seat with 4 screws, so for dismantling you need to perform a number of steps:

- All connecting bolts are unscrewed with a screwdriver.

- The pneumatic cartridge is carefully knocked out of the mounts.

- Drill holes in the part or use adapter plates.

- Replace the damaged element.

A computer chair is a popular type of furniture, but most models are made in China. Domestic spare parts that can be found in the relevant departments are not suitable for them. In this case, you will have to order parts or try to repair the swing mechanism yourself (for this you will need a welding machine).

Features of placing a chair on the balcony, suitable furniture models

Unscrew the bolts

Carefully knock out the air chuck

Screw on a new part

Connect with gas lift

Air chuck failure

The pneumatic cartridge is a two-chamber product, inside of which there is air under pressure. The gas lift cannot be disassembled and repaired at home; only a complete replacement of the part is possible. To repair an office chair with your own hands, you must follow the instructions:

- Disconnect the fasteners that hold the mechanism. To do this, remove several screws from the seat.

- The seat is removed, the gas lift is removed, after lightly hitting the structure from the side of the cross.

- The mechanism is removed from the metal case using a wooden or bronze drift.

- A new pneumatic cartridge is installed in the crosspiece and fixed to the seat.

The mechanism may break due to careless handling of the office chair, exceeding the recommended loads, or prolonged use. Self-disassembly of the pneumatic chuck is strictly prohibited, as the technician may receive serious injuries. The optimal solution would be to purchase a new part and replace the damaged one.

Destruction of permanent contact

Thanks to permanent contact, the office chair provides reliable support for the spine. If a part breaks, you do not need to purchase a new one; you can repair it yourself. The necessary actions will depend on the nature of the failure:

- Deformation of the thrust spring, bending of the brackets. To restore elements, it is necessary to return them to their original shape.

- Wear of screw fasteners. In this case, only replacing them will help.

- Loose backs. Sealing the permanent contact connections will help get rid of this problem.

A step-by-step description of the steps will help you figure out how to properly repair an office chair without resorting to the services of specialists. Usually, work on replacing and restoring elements does not cause difficulties for home craftsmen. After repairs, it is necessary to follow the standard rules for operating furniture, and then the products will last longer.

Manufacturing process

We start by making the back and seat.

- We take a sheet of plywood and transfer the image of the back, seat, and armrests. The shape, size and type of chair on which you plan to spend time in front of the computer depend entirely on your imagination. Consider your preferences, height, weight. Take standard sizes or create your own.

- We carefully cut out the parts along the contour with a jigsaw, sand the edges and surface with sandpaper. Give them smoothness and evenness.

- Preparing the base of the chair. The most important requirements for this part are reliability and stability. The model will depend on what kind of base you plan to make - like a regular chair with 4 legs or with one, but ending with a cross and wheels. If you plan to stick to the classic shape of a computer chair, then prepare a reliable steel pipe, channel, or corner with wheels as the base. But in this case there will be no possibility of adjusting the height of the product; immediately select the necessary one. Don't forget about the wheels; their sizes should also be taken into account when calculating. Yes, it cannot be raised or lowered, but its main advantage is absolute stability.

- We design the back. Whether to allow height adjustment or not is your decision. The part fixed in one position will be made of a metal profile. We give it the shape of the letter “X” or a frame, then fasten it to the base by welding or bolts. Mobility is achieved by a frame fixed to a hinge, a bar with holes attached to the back, and bolted to the seat. So, we get fixing strips on both sides at a certain angle.

- A computer chair differs from a regular chair in one detail - the presence of armrests. Usually they are made in the form of the letter “P” - the top one should be positioned so that the elbows rest comfortably on it, and the lower part of the “letter” is secured to the base using welding or bolts. But this is usually the case - you are the chief designer, whatever form you choose, so it will be.

- Now the final stage. Direct assembly of the chair. We sand the body parts, coat them with primer, and paint. Let it dry completely. Then the armrests and seat are attached to the structure using bolts or screws. We attach legs or a cross to the base. It can be made from different materials - metal, wood or plastic, but the main requirement is that it must be durable and withstand the weight of the user.

Wheels designed for the chair are attached to the legs of the chair. We fix the foam rubber on the seat, back, and armrests with tape and ropes. Try to evenly distribute the material over the surface of the parts. To add aesthetics, we stretch padding polyester or thick upholstery fabric over it. We fasten the fabric using a furniture stapler. Now the final stroke - we cover all the “unsightly” parts of the product with a cloth. We measure the sizes of such parts and cut the fabric.

When we start cutting out the parts, we need to add an allowance of 2 cm in each direction. We apply the resulting blanket so as to hide the stapler staples, folding the edges.

Well, the main work has been completed. Your DIY computer chair is ready. A new piece of furniture will delight you for a long time. Now we are redecorating the rest of the workspace to match the new chair.

Grinding

Once your armrests have finally taken the desired shape, proceed to their final finishing. Go over the elements again with a rasp and coarse sandpaper. Next, bring the surface of the armrests to a perfectly smooth state using fine sandpaper.

I draw a wonderful pattern without lifting the spoon: a signature roll with an unusual cut

“Dreaming is the only right thing”: Japanese wisdom of Haruki Murakami

Unusual preparation of an ordinary egg: the trick is in the length

Making your own chair

The sequence of making a chair yourself looks like this:

It is necessary to cut out the bases for the back and seat from a sheet of plywood. Also, if this is intended by the design, you can also make a base for the armrests. The resulting elements will need to be sanded. It is always worth considering the weight and height of the future user, as well as the design idea. Using a welding machine, you need to make the base of the chair. This can be a classic style with four legs or a more intricate model. The main thing here is the stability and reliability of the structure. The material can be metal pipes, angles, profiles or channels. Making a chair yourself means there is no height adjustment. Therefore, it is necessary to calculate in advance the optimal dimensions, taking into account the diameter of the wheels and the thickness of the foam rubber. As for the back of the computer chair, here you can adjust the height. Whether this function is needed or not is an individual question. The fixed version is simple to make: a metal profile in the shape of a cross or rectangle is attached to the base with bolts or it can be welded. The design that allows you to adjust the backrest looks a little more complicated. Here it is necessary to make an adapter. The frame is made on hinges, and slats with holes are attached to the back. Bolts are installed to the seat. As a result, you should get a structure of two fixation strips. The presence of armrests is also determined independently. They are attached to the base by welding. Their shape should resemble the letter “P”. In this case, the upper part of the armrest should be directly under the user’s limb

When taking measurements, it is important to take into account the thickness of the foam. The next step is grinding the structure. Particular attention should be paid to welding seams

It is necessary to clean the body from dust and dirt, prime it and apply the required number of layers of paint. After complete drying, you can install the seat and armrests. This is done using bolts or self-tapping screws. Wheels are screwed to the legs. A layer of dense foam rubber is glued to the back, seat and armrests. Synthetic padding is applied on top and upholstery material is applied. You can use a furniture stapler to secure the fabric. For cladding, every detail is cut out in advance. Approximately 20 mm of material is left on each side for allowances. The finished backs and seats are attached with the curved edges inward. This way the staples from the furniture stapler are hidden.

Some useful tips:

- Old parts of chairs or furniture that are out of order or simply not in use will allow you to save on material. It might even save you from welding work.

- Using old upholstery as a stencil will simplify the patterning process.

- The presence of a working lift from an unnecessary chair will allow you to create an adjustable structure.

Before you get started, you should evaluate your options and decide whether buying a ready-made chair would be a more appropriate option.

Why we abandoned vinyl and fabric covering

As you know, the armrests of office chairs are most often covered with vinyl. Unfortunately, this material, as well as the fabric used in combination with it, is not particularly durable. Actually, this is why the armrests wear out over time.

To avoid having to repair our chair again in the future, my husband decided to abandon the fragile vinyl and fabric, replacing them with wooden cladding. Thus, in the end, we got a beautiful and at the same time quite easy-to-use computer chair with almost “eternal” armrests.

Failure is an opportunity to learn: several differences between emotionally intelligent people

Rare pygmy giraffes accidentally discovered in Uganda and Namibia

Political scientists assessed the availability of vaccination in Russian regions

Why do you need play furniture?

Modern humanity can no longer imagine its existence without IT technologies and modern gadgets. Coming home from work or after school, you want to escape from the everyday problems of the outside world and, sitting comfortably in your favorite chair, immerse yourself in the virtual world of games and entertainment. In order for such a vacation to bring complete pleasure, and damage to health to be minimized, it is necessary to properly arrange the playing area.

A standard computer chair is not entirely suitable for these purposes, despite the fact that it is also quite comfortable. It is perfect for short work at the computer, but not for hours of gaming gatherings. A special gaming chair is an improved office chair, which, thanks to its comfortable and reliable design, ergonomics and high functionality, will give you not only comfort, but will also allow you to completely immerse yourself in a real world of amazing adventures.

Product disassembly stages

If an office chair breaks, the first thing you need to do is disassemble the structure. To do this, you will need a rubber hammer, slotted and Phillips screwdrivers, and a ring drift. All actions are carried out in stages:

- First of all, remove the seat, turn the chair over, and remove the fasteners.

- Unscrew the bolts that secure the armrests and remove these parts along with the plates.

- Disconnect the fasteners holding the permanent contact.

- The crosspiece is separated from the pneumatic chuck by gently tapping the connection with a hammer.

- The wheels are removed from the mounting sockets, and the plugs located in the steel case are removed. The procedure is performed using a slotted screwdriver.

Review of popular models of Ikea computer chairs for adults and children

It is recommended to carry out all manipulations with the mechanisms while holding the structure suspended so as not to break the fragile plastic parts. For the same reason, you should not use physical force when unscrewing fasteners. After completing the dismantling of the computer chair, you need to collect all the parts in one place so as not to lose anything.

Tools and materials

You can make good and comfortable chairs with your own hands using different materials.

The chair can be built not only from profile boards, bars or metal, but also from barrels, tires, tires, polypropylene and PVC pipes.

The most commonly used materials for the manufacture of the frame base of chairs are:

willow vine is a beautiful material that is afraid of moisture;

To make a chair yourself, you need to stock up on all the necessary materials and tools. If you plan to make a frame-type structure, you will need the following devices:

- drill;

- a sheet of sandpaper;

- jigsaw;

- pencil and ruler.

Materials that will be useful:

- lumber (most craftsmen prefer 20 mm plywood);

- screws;

- thin nails;

- foam rubber and upholstery material for furniture structures;

- special wood glue;

- stain;

- high quality glossy paint.

They also require different tools and materials.

Tools that will be useful:

- chalk, pencil and ruler;

- sewing machine;

- pins and scissors;

- thread and needle.

The materials you will need are:

- material that will be used for the internal and external covers of the chair;

- suitable filler (home craftsmen often turn to inexpensive foam rubber);

- 2 zippers: with a length of 40 cm and 1 m.

Also, to carry out various works you will need the following tools:

- drill;

- hammer;

- compass;

- meter;

- screwdriver;

- self-tapping screws

Let's consider what types of upholstery are the most popular and relevant.

Faux suede. A beautiful looking material that does not require complex and constant maintenance. The main advantage of artificial suede is its breathability, wear resistance and durability - it is not so easy to tear. In addition, such upholstery will not fade from light.

Wood as the main material

Making a wooden chair can be quite easy if you choose the appropriate method. You can use an old armchair or stool if it is not possible to purchase individual parts. Even from a banquette you can make a small chair that any child will like. To create a classic chair, boards, bars, and logs are usually used. A solid wood product has a number of advantages over other pieces of furniture, because wood is an environmentally friendly material that is absolutely harmless to health.

Natural wood is not a cheap material, but it is the key to the quality of a homemade chair. Once you are confident that the wood is of high quality, you can begin creating a work of art. There should be no knots or cracks on solid wood or bars. All parts must be carefully polished, and only then proceed to assembly. A special coating will protect the material from insect attack and drying out.

To make a chair, it is better to use oak, birch, ash or alder, because they have a unique beauty. These materials allow the product to serve for a long time without squeaking or cracking. The beauty of the product can be emphasized by high-quality textiles that will be used for its upholstery.

Wood is very durable and can compete even with metal. It does not lend itself to plastic deformation and withstands shocks and loads well. It is easy to work with, and therefore you can make a chair from wood yourself. The disadvantages of this material include intolerance to moisture and high temperatures. When exposed to water, wood swells and crumbles, so you need to first coat it with varnish.

DIY rocking chair

During the manufacturing process the following will be required:

- plywood sheets;

- cardboard;

- putty;

- dye;

- pencil;

- ruler;

- tape measure;

- sandpaper

- jigsaw;

- fasteners;

- drill.

Step-by-step instruction

Step one: prepare the details. The entire structure of the chair consists of two side parts, three horizontal connecting strips and 35 crossbars (needed to create the seat).

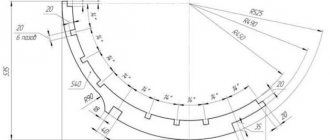

In this design, the most labor-intensive stage is the creation of the sidewalls, so it is recommended to mark them on cardboard, then cut them out, and only then transfer them to the wood.

Side parts diagram

Step two: to make the side parts you need to take multi-layer plywood 3 centimeters thick

Then you should transfer the part from the cardboard to the plywood sheet and carefully cut it out with an electric jigsaw

It is necessary to make such parts in the amount of 2 pieces

Step three: after which the side parts must be thoroughly sanded with sandpaper and their edges trimmed using a grinder or milling equipment.

Hand router is suitable for cut processing

Step four: from plywood of the same thickness you will need to make horizontal connecting strips 120 centimeters long and 10 centimeters wide. After which they need to be sanded with sandpaper, but you should not process the edges with a router.

Cut three horizontal strips

Cutting into slats

If the prepared planks are not thick enough, do the following:

- cut the board into several slats with a width equal to the required thickness of the armrest;

The first Brazilian citizens were vaccinated with the Sputnik V coronavirus vaccine

Due to verification of a fake page, Lyudmila Artemyeva wants to sue Instagram

With the help of 60,000 bees and his skill, the artist sculpted a bust of Nefertiti

- Turn each rail 90 degrees on its end and cut out an element from it according to the template;

- glue all the resulting elements into a solid armrest.

Sometimes armrests in office chairs are simply straight. In this case, skip steps 4, 5 and 6 and go straight to step seven.