Design features of a computer chair

Repairing an office chair with your own hands requires some knowledge. There are many features to consider when purchasing furniture. You should not buy products where the manufacturer does not provide a warranty of at least one and a half years. Otherwise, you will have to constantly repair the product, which will cause significant difficulties.

One of the most common causes of failure is the gas lift, as the part that is most susceptible to wear.

Note! After the warranty period has expired, the likelihood of breakdown increases. It is necessary to understand what caused the failure of a certain part. This will help avoid unnecessary hassle. The causes of malfunctions may be different. The sooner the problem is identified, the faster the repair at home will proceed.

Structurally, the product consists of several elements: a back, a seat, a cross part with rollers for moving on the floor. If any of these components fail, the chair cannot be used. It is necessary to repair the damage in order to continue to use the furniture normally.

If you are faced with a malfunction of your computer chair, you need to find out which part requires repair.

The product includes the following components:

- Piastra. Made from high quality metal. This element is made in the form of a lever. Used to change the height of the seat relative to other components.

- Rollers. Depending on the manufacturer, they may consist of metal or plastic. The first option is more preferable, as it has high performance properties. The hinge mount is made of metal. It connects to the main structure to allow movement on a smooth floor surface.

- Base. It can be metal or plastic. The first option is more preferable, as it has high strength and reliability compared to plastic. The latter breaks down faster under the influence of high physical stress.

- Permanent contact. It is a connecting component. Used to attach the seat and backrest. Allows you to change the position of the backrest relative to the vertical.

- Rocking mechanism. Responsible for deviations and fixation of the seat in one position. More expensive models are equipped with complex mechanisms that provide more stable fixation and smooth rocking when leaning on the back of the seat.

- Gas elevator. This detail is important for a computer chair. Responsible for elasticity. When a part breaks, this property is reduced, causing discomfort to the owner.

Note! Most modern products are also equipped with armrests. Depending on the cost of the model, the material used to make the part may differ: plastic or anodized steel.

Parts may be required for replacement. They can be purchased in specialized stores. You can also purchase spare parts on the manufacturer's official website. It is for this reason that it is recommended to buy only furniture from trusted companies. This makes it possible to repair the product at minimal cost, using available materials and simple tools that are found in every home.

Before you begin repairing a computer chair, experts recommend carefully studying the types and design features of such products.

How to repair it yourself

If the crosspiece and permanent contact fail, you can repair these parts yourself, without resorting to the services of a service center. If the pneumatic cartridge, piaster or swing mechanism is broken, they must be replaced. The same goes for rollers. If repairing it yourself seems difficult, you can contact specialists; they will repair the furniture quickly and efficiently.

Damage to the cross and replacement of rollers

In the event of such a breakdown, it is very easy to repair an office chair with your own hands. If the rays of the cross are not connected firmly, the part begins to wobble and loses stability. To fix the problem, you need to insert a hollow plastic tube of smaller diameter inside the base. It must be firmly fixed in the center of the structure.

The pipe will play the role of a kind of rod on which the base rests. To replace worn rollers, you need to carefully remove them from their slots, without using physical effort, and install new ones. Anyone who has repaired a base knows: it is not at all difficult.

We knock out the gas lift from the cross

Installing a new cross

Making videos

Inserting new videos

Breakage of piastres

This type of breakdown occurs frequently in office chairs. If the piastre fails, it must be carefully removed from the pneumatic chuck. These two parts are connected using the cone method. There are no threads, so no screwdriver is needed. To separate the gas lift and piastra, hit them forcefully with a mallet. As a rule, one hit is enough. Next, you should replace the piastra with the broken foot with a new one.

Separating the gas lift and piastra

We attach the new piastra to the seat

Destruction of the swing mechanism

In the event of such a breakdown, the metal structural element must be replaced. However, if you have a welding machine, you can eliminate the malfunction, and the swing mechanism will last for a long time. If a decision is made to replace a part, it must be dismantled. The mechanism is connected to the seat using four screws, so you will need a shaped screwdriver. For disassembly you need:

- unscrew the bolts connecting the mechanism to the seat of the chair;

- knock out the pneumatic cartridge from the mount;

- drill holes in the element and replace it.

If you don't have a drill at hand, you can use so-called adapter plates. It should be borne in mind that Russian-made swinging mechanisms are not suitable for Chinese office furniture. The difference in size is approximately 50 mm.

Unscrew the bolts

We knock out the pneumatic cartridge

Drill holes and tighten bolts

Connecting

Air chuck failure

An old, worn gas lift must be replaced. Some craftsmen repair it, but after repair the pneumatic cartridge still will not last long. It needs to be dismantled and replaced with a new one. To do this, disconnect the seat and use a hammer to knock the gas lift out of the crosspiece. The main thing is not to damage the base. After this, a new pneumatic cartridge is inserted. It is attached to old bolts. You can first watch a video on the topic “repairing a gas lift” or consult a service center.

Removing the seat

We knock out the gas lift from the cross

Insert a new pneumatic cartridge

Destruction of permanent contact

Breakage of permanent contact is a common occurrence. It is not necessary to purchase a new part; you can repair the old one. This type of DIY office chair repair will not take much time and effort. The main thing is to identify the cause of the malfunction.

If the thrust spring is deformed, it must be returned to its original shape. The same goes for brackets. However, if the screw fasteners are worn out, you will have to replace them with new ones. If the back of the chair is wobbly, the permanent contact connections need to be sealed and tightened.

Permanent contact

What is a gas lift for an office chair?

This part is a hydraulic gas control system. It is an intermediate and main component that is responsible for the versatility of the chair.

A chair gas lift or lifting mechanism is designed to adjust the height of an office chair.

Important! If you have no experience with replacement, you should find out how to repair a gas lift chair. It is necessary to strictly follow the instructions. Otherwise, it is better to entrust the task to a specialist who has extensive experience in performing such tasks.

Externally, the pneumatic device looks like a tube. It fits two elements with different diameters. It also consists of several key components:

- Gas valve. Responsible for maintaining a uniform sitting position. With it you can set the desired height of the chair. It is activated only at the moment when it is necessary to change the seat position.

- Seal. Individual parts that are responsible for the tightness of the entire structure.

- Button. Located in the inner part of the tube of the pneumatic device. When pressed, the chair rises or lowers - the gas valve opening mechanism is activated.

- Cavity. This element is also used to activate the seat changing mechanism.

- Bearing. This component is responsible for rotating the chair around its axis. Provides smooth position changes.

- Stock. Appears depending on seat position and height.

It may be necessary to replace the faulty part with a new one, no matter what, from a whole chair or purchased in a store.

This design is indispensable, as it increases the performance characteristics of the computer chair. In particular, such a chair is convenient for use by several people of different sizes.

Other reasons for using gas lift include:

- Easy to adjust the seat. To change the height of the chair, just press one button. There is no need to perform any complex manipulations.

- Increased comfort. The chair reduces the load on the spine and back, which allows you to constantly sit in the same position and maintain posture. This option is responsible for depreciation.

- Rotation. This system allows you to rotate the chair in a circle without any extra effort. All movements are simplified as much as possible for the convenience of users.

Assemble the crosspiece, replacing the wheels, and insert the new gas lift with the bottom side into the corresponding hole.

All capabilities of computer chairs are determined by the presence of gas lift. It is also important to distribute the load correctly. Otherwise, rapid breakdown of the main components of the structure is possible.

Office chair falls down: causes of breakdown, fix it yourself

If your office chair drops down, or the position adjustment mechanism does not work, and the chair is stuck, the gas lift may be the cause of the problem. You can take the chair to a special workshop for repair. You can also save money by repairing the chair or replacing broken parts yourself.

Common Causes of Stool Breakage

Almost all chair failures are associated with gas lift. It is located in the main part of the chair, to which the seat and crosspiece are mounted.

There are 3 most common breakdowns associated with lowering the chair down. Below we will describe what to do in each case. The breakdowns are as follows:

- The crosspiece is damaged. The problem is damage where the beams meet. The base consists of a hollow structure and a polypropylene pipe located inside. The latter needs to be secured to the damaged beams and the main part of the chair.

- The swing mechanism is broken. If the chair does not stay straight, the mechanism responsible for rocking is most likely damaged.

- The pneumatic cartridge is broken. The pneumatic cartridge is a two-chamber structure with air inside. The design also includes an adjustment lever. When it is pressed, the valve blocks the passage of air into the chambers. If the gas lift rod does not extend while being placed on the valve, it means that the damage is associated with the piston or seal.

Note! Do not repair plastic parts using glue or a soldering iron. Due to heavy loads on the legs, the structure may break. Therefore, there is no point in trying to restore the damaged part. It is best to completely replace the part with a new one made from the same material.

What you need to repair a chair

First, you need to understand what parts a computer chair consists of. It consists of:

- Cross of five rays. It is made of plastic or iron. The latter material is stronger, but more expensive.

- Wheels. Like the previous part, they can be made of plastic and metal. All fastenings and internal hinges are made of iron only. But preference is given to metal wheels, since plastic ones wear out faster.

- Gas lift. This is the leg of the chair. It is responsible for the elasticity of the stool.

- Rocking mechanisms. With their help, you can tilt the chair along its axis and return it to its original position. Modern structures are equipped with mechanisms with axes that move. This ensures smooth swinging.

- Piastra. The part looks like a lever with a metal platform. He changes the height of the chair.

- Permanent contact. This is the name of the connection between the back and seat of the chair. It allows you to change the position of the backrest.

The set of parts listed above is found in almost all office chairs. And each of these parts can be broken.

It all depends on the type of damage. For example, if the crosspiece is damaged, you need the same material from which the crosspiece is made.

For repair you need the following tools:

- Screwdriver.

- New fasteners (if the old ones are broken).

- Drill and drill bits (if you need to make new fastenings).

- Welding machine.

- The part that needs to be replaced.

How to fix a falling office chair

You can repair the chair yourself, but you must strictly follow the instructions. If you are not confident in your abilities, then it is better to immediately contact specialists, otherwise you can completely break the mechanism.

Damage to the cross

A damaged crosspiece can be repaired as follows:

- First you need to unscrew the cross from the chair. For this purpose, videos are made. It is worth noting that they are not fixed too tightly, so it will be enough to remove the fasteners.

- Now we dismantle the piastrum. Fastening to the seat is made using a cone. You can disconnect the gas lift by knocking on the place where the fastening is located.

- Now the release clip is removed. It is located in the recess where the hydraulic elevator is located.

- We knock out the gas lift.

- We repair or replace damaged parts of the five-beam.

- If the damage is severe or some parts are broken, it may not be possible to remove the gas lift. In such cases, it is necessary to remove the cylinder, bearings and seals.

Common breakdowns

Before repairing an office chair gas lift, it is necessary to find out the main causes of the malfunction. Among the main breakdowns, the following should be highlighted:

- The seat of the chair does not rise or fall. The problem is that the lever for adjusting the position is broken. The pressure on the button exceeds the norm, which causes problems.

- Instability. The swing mechanism has failed. The gas lift could break, which leads to loss of durability.

- Disturbance in the movement of wheels. It breaks when the inner part of the wheel mount wears out. The integrity of the bushing is compromised.

- Skew. The seat fastening mechanism is worn out. It can also occur when fatal errors occur during the assembly process.

- Difficulty fixing the back of the chair in one position. There is wear on the backrest and seat fastenings.

Due to the fact that a computer chair is a complex mechanism, mechanical breakdowns often occur during its operation.

If any of the above symptoms occur, inspection and repair are required. Otherwise, using the chair may result in injury.

How to disassemble

You must be able to repair an office chair yourself, since it is not always possible to contact a service center for specialist help. To disassemble the structure, it is necessary to understand in general terms the location of the main structural elements of the product.

First you need to carry out preparatory work.

To do this you need to do the following:

- Turn the furniture so that the back is facing the wall. Press down on the crosspiece without using much force.

- Carefully turn and swing the backrest fastening mechanism

- Separate the hydraulic gas device and the cross part.

- Unscrew each wheel from the cross.

It is important to properly separate the backrest and seat. The integrity of the furniture depends on this. After the preparation has been completed, it is necessary to collect all the parts so as not to lose them.

The most common place for deformation is the intersection of the rays of the cross.

Note! Do not use too much force when disassembling the chair. Otherwise, you risk breaking the fragile plastic under pressure.

To separate the hydraulic gas device without unnecessary effort, you can turn the pneumatic chuck over. After this, it is enough to pry and remove the part with a few careful movements.

All actions must be performed by weight so as not to damage the parts.

Office chair repair

After disassembly has been completed, you can begin repair work. Depending on the type of breakdown, the range of tasks performed will differ. It is important to strictly follow the manufacturer's instructions so as not to aggravate the problem.

To determine the type of malfunction, novice craftsmen should focus on the signs of breakdowns and what is broken.

Replacing legs

This type of breakdown occurs most often, since the main load is applied to this mechanism. To carry out replacement or repair, just carefully remove the part from the mount. It can be removed quite easily; to do this, you need to apply pressure on it. After this, a new part is installed.

The assembly process is carried out in reverse order.

Replacing the cross

Repairing the crosspiece is a responsible task, which determines the operational capabilities of the chair. To increase the tightness, a hollow tube of smaller diameter is inserted inside the mechanism. After this, it is tightly fixed inside.

The tube acts as a rod around which the main part of the part's fastening is based.

Air chuck failure

The hydraulic gas device can be replaced with a new one. You can repair it, but after that the element will not last long. When installing a new product, care should be taken not to damage the base.

The part is fixed using bolts with your own hands.

Destruction of the swing mechanism

If this mechanism breaks down, it is necessary to replace the metal part. This requires disassembling the component using a screwdriver. First, the mounting bolts to the chair are removed, after which the element is removed from the pneumatic chuck.

The backrest falling back is a sign of failure of the position locks.

To perform the described manipulations, you will need a drill. With its help it is much easier to create new holes for mounting the swing mechanism. If you don't have a drill, you can purchase adapter plates. When choosing a spare part, keep in mind that the dimensions of each model are different.

Repair options

If the permanent contact or crosspiece fails, you can do the repair yourself. Broken piastres, pneumatic cartridges, and swing mechanisms will have to be replaced with new parts. The same rule applies to damaged wheels.

Replacing rollers

Over time, the rollers may fall out of the beams of the cross due to wear of the plugs, especially if the latter are made of aluminum or plastic. To repair these elements, you need to perform a number of actions:

- The chair is turned over so that the rollers are on top.

- The wheels are removed from the cross. To do this, you just need to pull them towards you.

- Remove the casings from the beams of the cross using a screwdriver.

- Damaged plugs are pulled out of the housing.

- Install new seals and assemble the parts in the reverse order: casings, then rollers.

A broken wheel is treated with superglue or replaced with a new one. A common cause of breakage is the accumulation of debris, hairs, and threads. In this case, the rollers are removed, cleaned, and installed in their original place.

If the socket for fixing the axle of the wheels in an office chair fails, most likely you will have to change the crosspiece.

Use a screwdriver to pry off the fastener and remove the support

Install new wheels

Breakage of piastres

You can repair an office chair yourself if the technician has experience working with mechanics. First of all, it is necessary to clarify what material the crosspiece is made of. It is better to replace the plastic part immediately, since it is pointless to restore a fragile product. Restoration of piastres is carried out as follows:

- The chair is turned over, for convenience, its seat is placed on a chair so that the back is pressed against the floor surface.

- The wheels are removed from the mounts.

- Unscrew the 4 bolts that secure the rocking mechanism and piaster to the seat.

- Disconnect the gas lift by lightly tapping it with a rubber or wooden hammer. You must act carefully, otherwise the mechanism will become deformed and become unusable. The “stuck” compound is treated with a special liquid.

- Using a screwdriver, remove the pneumatic cartridge stopper, the washer, and then the gas lift rod.

- The piastra is knocked down with gentle tapping.

- Repairing a plastic part involves gluing and soldering, but these methods are only relevant if there is minor damage.

- The broken beam of the crosspiece is fixed with plastic or metal plates, secured with screws or superglue. Metal parts are restored by welding.

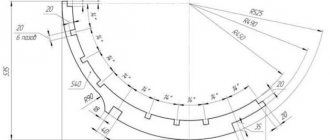

Stages of making a hanging chair with your own hands based on a drawing

Repairing a computer chair must be done very carefully and carefully. Careless handling can lead to damage to the piastres or pneumatic chuck.

Unscrew the bolts Knock down the piastrum with light taps

Screw on a new one

Destruction of the swing mechanism

If the swing mechanism breaks down, you will have to replace it. The part is attached to the seat with 4 screws, so for dismantling you need to perform a number of steps:

- All connecting bolts are unscrewed with a screwdriver.

- The pneumatic cartridge is carefully knocked out of the mounts.

- Drill holes in the part or use adapter plates.

- Replace the damaged element.

A computer chair is a popular type of furniture, but most models are made in China. Domestic spare parts that can be found in the relevant departments are not suitable for them. In this case, you will have to order parts or try to repair the swing mechanism yourself (for this you will need a welding machine).

Characteristics of fashionable glider chairs, advantages of their use

Unscrew the bolts

Carefully knock out the air chuck

Screw on a new part

Connect with gas lift

Air chuck failure

The pneumatic cartridge is a two-chamber product, inside of which there is air under pressure. The gas lift cannot be disassembled and repaired at home; only a complete replacement of the part is possible. To repair an office chair with your own hands, you must follow the instructions:

- Disconnect the fasteners that hold the mechanism. To do this, remove several screws from the seat.

- The seat is removed, the gas lift is removed, after lightly hitting the structure from the side of the cross.

- The mechanism is removed from the metal case using a wooden or bronze drift.

- A new pneumatic cartridge is installed in the crosspiece and fixed to the seat.

The mechanism may break due to careless handling of the office chair, exceeding the recommended loads, or prolonged use. Self-disassembly of the pneumatic chuck is strictly prohibited, as the technician may receive serious injuries. The optimal solution would be to purchase a new part and replace the damaged one.

Destruction of permanent contact

Thanks to permanent contact, the office chair provides reliable support for the spine. If a part breaks, you do not need to purchase a new one; you can repair it yourself. The necessary actions will depend on the nature of the failure:

- Deformation of the thrust spring, bending of the brackets. To restore elements, it is necessary to return them to their original shape.

- Wear of screw fasteners. In this case, only replacing them will help.

- Loose backs. Sealing the permanent contact connections will help get rid of this problem.

A step-by-step description of the steps will help you figure out how to properly repair an office chair without resorting to the services of specialists. Usually, work on replacing and restoring elements does not cause difficulties for home craftsmen. After repairs, it is necessary to follow the standard rules for operating furniture, and then the products will last longer.

Tips for use

A computer chair requires careful handling. This is especially true for an already repaired device. When using, you must adhere to certain rules so as not to break the furniture. Otherwise, the service life of the device will be greatly reduced. The following recommendations from experts should be taken into account:

- It is not recommended to use the product in rooms with high levels of air humidity, as this will quickly damage the integrity of the mechanism.

- If the furniture was delivered at low temperatures, it is prohibited to assemble it immediately after placing it in a warm room. It is better to start installation the next day to avoid compromising the integrity of the structure.

- Do not put pressure on the bolts and main fastening elements of the structure. Plastic does not withstand heavy mechanical loads.

- Do not put a large load on the crosspiece.

A chair that has been exposed to low temperatures is strictly prohibited from immediately being assembled and used; the optimal time for adaptation is 24 hours.

Note! Children should not be allowed to play in office chairs. Because of this, the main mechanisms quickly wear out.

Several people cannot sit on a chair at the same time. Also, do not forget about the fragility of the armrests. If too much pressure is applied, they quickly become unusable. In many models, the fabric is also vulnerable to dust and dirt. Vacuuming frequently is necessary to avoid dirt buildup.

During assembly, extreme care must be taken to avoid stripping the threads by excessively twisting the elements.

An office chair is comfortable and practical furniture. To make it last longer, you need to follow basic principles. Timely replacement of parts will help extend the life of the device.

We should not forget about regular preventive inspection, which includes lubricating all moving elements, as well as tightening loose nuts and screws.