The sheen of the gloss, the unique execution - it’s already interesting! Furniture made of epoxy resin combines these qualities. If you look at tables, chairs and other such furniture, you will not find two identical pieces, they are all unique. One secret lies in the author’s imagination, the other in the use of unusual materials and wood. The latter is generally unique from nature.

Epoxy resin blurs the boundaries of wood use. Thanks to it, the widest slabs are often used to make countertops. A slab is a longitudinal section across the entire width of the trunk, often reflecting the profile of the tree.

Harmony of wood and glass

Furniture made of wood and epoxy resin is a composition in which the creations of nature and man are harmoniously intertwined. The unique wood pattern in combination with colored or transparent resin, polished by human hands to a perfect shine, more reminiscent of new glass, will not leave anyone indifferent.

The noble mahogany wood and blue epoxy glass on this table model create a unique design.

Cutting epoxy resin furniture

Sometimes, according to the author's idea, epoxy furniture looks like jewelry. Some of them were not only ground and polished, but also cut.

A stump enclosed in a glass cube, as in the photo, has wide capabilities and can perform several functions at once:

- You can admire such beauty, in which the author managed to combine the ideal with the imperfect, for hours

- you can sit on it or use it as a coffee table,

- and of course, they can decorate the interior of the living room to the delight of all guests.

Preparatory work

To make a river table with epoxy resin, you need to do a few preparatory steps. Especially if this is your first time intending to work with such material. Recommended:

- Practice pouring resin. It is worth buying several small containers of different brands of epoxy. To start, make a small formwork out of acrylic or plastic and try combining resin with pieces of wood.

- Select the appropriate epoxy. The material must be of high quality and harden well. If you plan to make the table transparent, you need to choose a resin that does not give yellowness. If you mix it with dye, then this drawback will not be critical and you can purchase the material at a lower price. When choosing epoxy resin, you should also rely on reviews from people who have been working with this material for a long time.

- Select wood. These can be cuts of old trees (slabs), regular solid wood or composite wooden elements. The main thing is that they match the size of the future table. If they have small chips, gouges, scuffs, or traces of beetles, then this will only enhance the effect of the unusualness of the table.

- Watch some videos. To better imagine the manufacturing process, you should pay attention to the recorded master classes or even attend one of them. Having seen all the work with your own eyes, it is easy to form an opinion about its complexity.

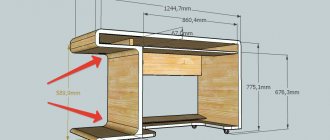

- Make a sketch. Draw the tabletop, mark where the epoxy layer will be located, and how the table will roughly look.

When the preparation is complete, all that remains is to make sure that all the necessary tools and materials are available.

To make a river table you will need the following materials and tools:

- wooden slabs, the species of which can be absolutely any - oak, ash, elm, beech;

- epoxy resin and hardener;

- underframe - legs for the table;

- dyes and phosphors glow in the dark, if desired;

- decorative elements are also optional;

- tools for woodworking - chisel, router and others;

Useful to know > How to create an improvised sea from epoxy resin

- sanding machine with belts of different grain sizes;

- material for formwork construction - acrylic, plastic or self-adhesive film;

- stain, varnish or other protective compounds for wood;

- brushes and rollers;

- plastic container for mixing resin;

- bolts, screws and other construction items.

Be sure to familiarize yourself with safety precautions and study the instructions for using epoxy. For work you will need gloves, glasses, a respirator for grinding work and protective clothing. The resin must be poured on a flat surface.

Furniture reconciling opposing styles

Furniture made of epoxy in the interior looks unusual and you still have to get used to it. It often resembles preserved wood. This applies to products in which the wood is completely embedded in resin.

This approach is associated with know-how, which is suitable both for modern interior styles and, for example, for chalet or country style. Furniture made of resin and wood is a consensus in the battle between opposing styles.

Step-by-step manufacturing technology

When everything is prepared, you can proceed directly to making the table. The step-by-step instructions have several points:

- Preparing the tree. The slabs need to be processed and given the desired shape. If you have one large board, it will need to be broken into two or more pieces. Moreover, the more uneven the edges are, the better. You can use a drill and chisel. Next, the wood needs to be sanded and covered with stain, varnish or other protective compound. If there is bark on the boards, remove or leave it as desired. In the second case, the furniture will look as natural as possible.

- Formwork. It should be slightly larger in size than the future tabletop. It can be made from acrylic or plastic. Another option is formwork made of chipboard or plywood, covered with film inside. It is worth making sure in advance that the film will not stick to the resin. The joints must be sealed with liquid silicone or sealant.

- Preparing for pouring. Coat the edges of the boards that will be in contact with the epoxy with a good layer of resin. This is necessary so that in the future the solution does not penetrate into the pores, and air bubbles from the dry board do not get into it. Give it some time to set.

- Mixing resin. First, a coloring paste is added to the epoxy if necessary, then a hardener. For a better connection, you can use the double mixing method, that is, repeatedly pouring the solution from container to container.

- Filling. Pour the material gradually, making sure that it is evenly distributed throughout the free space. If there are decorative elements in the resin layer, you must first make a base, wait until it sets (wait 2-3 hours), then place the decoration on it and fill it completely. Complete hardening time is at least 24 hours. Then remove the tabletop from the formwork.

- Final processing. If there are uneven spots on the countertop, you need to saw them off. Next, start sanding. You should start with a small-grain belt and finish with a nozzle with 2000-3000 grain. To add gloss, the surface can be treated with polishing paste and then additionally coated with varnish.

- Screwing the foot. Legs can be wooden or metal.

Useful to know > Types of self-leveling floors made of epoxy resin and features of their use

The river table is ready and can decorate the living room, dining room or kitchen of any apartment or house.

As you can see, making an exclusive item is not so easy. You will need a competent approach, perseverance, and accuracy in your work, then with a high degree of probability you can count on a decent result.

Width doesn't matter

Preserving wood in resin allows you to use slabs of even the widest trunks without any consequences during further use, since the access of air and moisture to the wood is closed. Therefore, even the widest tabletop will not dry out over time, will not crack, and will not be driven by a screw. Tables with such a tabletop often compete with classic furniture made of expensive wood.

With your own hands

For creative people, this furniture manufacturing technology incredibly expands the boundaries. In addition, making your own furniture from epoxy resin is not that difficult.

And in the next photo there is another creative model. A chessboard and a photo inside (possibly from travel) make the table playful and emotionally memorable. If you value your photos, then this is a great opportunity to ensure their safety for many years. In the same way, you can create a wall panel with valuable moments.

This material is used to make not only tables, but also other furniture. For example, an epoxy resin chair can easily be turned into a herbarium, as in the photo below. Bright summer wildflowers and green grass will diversify the interior and will be pleasing to the eye. Such furniture, made by creative people, can even have a therapeutic effect. It will undeniably improve your mood and bring joy during the autumn and winter blues.

What does a novice master need?

Although epoxy is a very pleasant and flexible material, it will be extremely difficult to make furniture from it without the necessary skills. It is not enough to just watch a video or attend a master class once. A beginner in this business will need:

- Practice pouring and sanding. To begin with, you should learn how to create high-quality formwork, pour resin, and process it after hardening. The goal is to gain the skill of making different shapes. It is also important to mix the solution correctly, use good hardeners and other plasticizers.

- Choose “your” material.” It is recommended to buy several types of epoxy to see which one is best for working with wood. A good resin should not turn yellow, crack after hardening, or release harmful substances, for example, at high temperatures. Its consistency is similar to vegetable oil, it is easy to mix and pour into the mold.

Useful to know > How to make a brooch from epoxy resin, simple instructions

- Try combining wood and epoxy. The presence of a large number of pores in wood leads to the fact that the resin quickly fills all the holes. In addition, air can be forced into the solution, creating a large number of bubbles in it. Finally, the wrong size ratio of the wood and resin parts can cause the mold to split. That is why it is necessary to practice working with both materials, processing boards, and carefully sealing joints and seams.

Creating such furniture involves the use of various woodworking and sanding tools. Before work, be sure to familiarize yourself with the rules for using epoxy resin, precautions and safety precautions. Eyes, skin and respiratory tract must be protected. You need to work in a well-ventilated area and on a flat surface.

Creating epoxy furniture requires not only the ability to work with your hands, but also artistic vision. The master must imagine the object in advance, make a sketch, and then use materials wisely to realize his plan.

Designer's fantasies

Designers do not stand aside, but quite the opposite - they try to make their subtle, aesthetic contribution in this direction. And the result is these fancy wooden chairs. It’s more likely not even furniture, but exhibits in which the emphasis was placed on unusualness - the way wood supposedly smoothly flows into glass. Such ideas are more suitable for decorating an interior in the avant-garde style. Well, they would even be very suitable as a work of art.

The photo below shows another work - a table made of epoxy resin combined with a material somewhat similar to white beach sand. Excellent art option. No one will refuse to have a piece of paradise island with the ocean at home.

Designers also use improvised materials for their products. So, for example, why not make an epoxy table with old vinyl discs as a decorative part. An unusual and stylish solution, and music lovers will certainly rate it 5 points.

Manufacturing technique in general

In general, the manufacture of wooden furniture using epoxy resin follows a general scheme, but in each specific case additional steps may be added to the standard steps. This depends on many factors: the characteristics of the resin, the type of future product, the tools used, and so on.

Materials and tools

First of all, you need to buy epoxy and select wood. The breed can be any. By the way, there are also no special requirements for the quality of boards or slabs, the main thing is that they are dry. Defects can become the highlight of the furniture, so their presence is desirable, but not essential. Wood with flaws can even be obtained for free, since it is not used in production. You will also need:

- hardener;

- dyes, coloring pastes and pigments to give color to the resin;

- chisel;

- hammer;

- milling machine;

- sanding machine and belts of different grain sizes, from small grain to maximum;

- compositions for wood protective treatment;

- drill;

- screws, nails and other small items.

Useful to know > How to make a table with your own hands from epoxy resin and wooden elements

You definitely need a formwork material that will not adhere to the resin; this can be acrylic, plywood covered with masking tape, or plastic structures.

Stages of work

You can start working directly only after a suitable room has been found and prepared, safety precautions have been observed and all materials and tools are available. Basic steps:

- Working with wood. If necessary, it must be sanded well. Next, divide into the required parts and treat the surface with a special compound. The sides that will border the resin should first be coated with the solution and allowed to harden. As noted above, this is necessary so that the epoxy fills all the pores and air does not penetrate into the resin layer. Once cured, it will be impossible to get rid of the bubbles.

- Preparing the mold for pouring. It must be done in such a way that the wooden part of the product fits completely. All seams and joints must be taped or sealed with sealant (silicone).

- Mixing and pouring resin. It is necessary to strictly observe the proportions indicated on the packaging. Additionally, coloring pigments and, optionally, phosphors are added to the solution. When pouring, you need to make sure that the resin spreads evenly over the mold. While it is drying, it is worth covering the formwork to prevent dust from entering. Duration of hardening is at least 24 hours. In some cases it may take longer. In this case, you need to ensure that the room has an optimal temperature, since the resin completely sets only in warmth.

- Treatment. Once the mold is removed, sanding and polishing begins. If necessary, irregularities and excess pieces are sawed off. To give the surface a gloss, special pastes are used.

- Final works. They consist of attaching fittings, additional polishing, and varnishing.

Epoxy resin furniture can also be decorated with different elements. For example, pebbles, beads, fresh flowers. Any decor must be added at the pouring stage. Moreover, in this case it is worth making several layers, giving each one enough time to set.

Useful to know > What products are currently made from epoxy resin

You can make furniture from epoxy resin and wood yourself. However, this will require training, good skill, effort and time. If you like this kind of work and are ready to face difficulties and overcome them, then you should try to create the desired piece of furniture. But if you want to get a finished product quickly, inexpensively and with a minimum of effort, you should purchase it at a salon or order it from a craftsman. The price of such furniture will depend on its type, size, type of wood used and other factors.

Furniture made from balls

And finally the most extraordinary thing. Sometimes completely unprecedented things are born experimentally. Solid furniture made from balloons is evidence of this. The idea will probably appeal to many who are involved in Hand-Mad.

But it is still not worth using such furniture for its intended purpose; its strength still does not inspire confidence. But it is quite suitable for the role of an art object.