Types of fittings for wardrobes

Any assembly of cabinet furniture requires, in addition to the main cabinet elements, the use of various fittings. So the finished product is distinguished by reliability, functionality and attractive appearance. Special tools provide not a swing mechanism, but a sliding one.

Special fittings are used for sliding mechanisms.

The fittings ensure installation of a sliding mechanism on the body. Some elements are useful for fastening the corresponding filling into a straight or corner structure.

The sliding system for opening wardrobe doors involves the use of a special set of fittings. It differs from the standard kit used when installing a classic headset. The elements are presented in the following assortment:

- rollers (move the doors);

- stoppers (fix door leaves);

- seals (promote soft closing of doors);

- guides;

- profiles for installation and operation;

- sliding mechanism (ensures the operation of the sashes), etc.

All types of wardrobe fittings have their own characteristics.

Rollers

The doors move freely along the guides thanks to a roller mechanism. The structure itself consists of a base and wheels.

Rollers ensure smooth movement of doors along the guides.

The quality of the fittings affects the softness and reliability of opening doors. Silent bearings are in demand during assembly. Furniture fittings come in two varieties.

Asymmetrical type - used for doors to move freely along the guides from below. All the load goes to the lower part. The upper rollers ensure that the door leaf is positioned in a vertical position. Therefore, such fittings are highly durable.

There are two types of rollers.

When installing this type of rollers, height adjustment is available and a wardrobe with an open handle type is provided.

Symmetrical type - used with a closed handle type. Such fittings are suitable for assembling various types of plastic sashes.

It is worth saying that the symmetrical type of roller in further operation eliminates distortions of the sashes during installation, and the reliability of the furniture structure increases accordingly.

The symmetrical type ensures the reliability of the design.

Stopper

The function of the stoppers, which are located at the edges of the guide profiles, is to slow down the movement of the sash as it approaches the furniture walls. Due to their installation, the doors do not make a knock, which is important for fragile facades. Their number is proportional to the number of doors. Parts attached to the bottom guide ensure reliable fixation of the sashes when opening. The design consists of a metal strip with springs.

The stopper slows down the movement of the door when approaching the wall.

Some consumers consider this type of fittings unnecessary when assembling a wardrobe. This conclusion is correct for a system with two doors. However, with three or more doors, you will not be able to fully use the furniture without this element.

A stopper is required when there are three or more doors.

Sealant (schlegel)

Damper tape, which is applied to door profiles and guides. The element helps reduce noise and vibration.

The seal is a tape that reduces vibration and noise.

The product with pile protects the interior of the cabinet from dust. Seals are installed on the side parts of sliding sashes. They ensure a close fit between the door and the body. Such fittings can be polyurethane or silicone.

The nap seal prevents dust from entering the cabinet.

Schlegel can also be used. This type of fittings is similar to a soft brush, which protects the body from impacts from the doors. It is glued to the vertical profile in a special groove. The height of the pile is selected according to the type of product design.

The silicone seal ensures a better fit of the door to the body.

Closers

The fittings are not included in the standard set and are selected according to individual preferences. The difference between this mechanism is that they can be installed after assembling the furniture structure. Basically, they are universal and can be combined with any façade with aluminum edging.

Closers provide a softer closing mechanism.

The main function of the door closer is to ensure soft closing of the doors. Installation of such a mechanism will not only provide protection from mechanical stress, both to the door itself and to the frame racks on the side. Therefore, with glass and mirror facades, sudden movements can damage the glass.

Guides

They are attached to the top and bottom of the wardrobe. Necessary for free movement of the sashes in a horizontal position and holding them in a vertical plane. Guide profiles are available in various types of parts: steel, plastic and aluminum.

Guides are needed for the movement of doors.

Aluminum guides have the most optimal characteristics. Of all types, they are distinguished by their attractive appearance and good ergonomics. The assortment is presented in various colors. If we compare the cost of aluminum products, the price of such products will be higher for plastic and steel guides. But the price justifies such characteristics as reliability and durability.

Guides are made from different materials.

To mount the furniture frame, you need different guides. It is better to choose according to the selection principle based on the number of wardrobe doors. Installation is carried out with special wood screws.

Profile

On the market, among a large assortment of furniture fittings manufacturers, you can find two types of profiles:

- Steel ones are the most affordable and are used to assemble a budget wardrobe structure. Such products have a limited selection of colors, so they are not often used in packaging.

- Aluminum - products are available in two versions.

The package may include an anodized type or a PVC-sheathed product. A profile made from this material retains its original characteristics for a long time, weighs little and is available in a large selection of colors and textures. The anodized aluminum profile makes the structure strong and durable. The elements are resistant to mechanical stress and do not discolor from ultraviolet rays.

Profiles are available in steel and aluminum.

Sliding systems

Such a mechanism can be presented as a separate element or in a set. Fittings are the main element of a furniture product. It ensures uninterrupted operation of the valves. There are two types:

- Support mechanism - consists of aluminum guides, rollers and a profile for attaching a rigid frame. The main advantage is simple assembly and use in the operation of large cabinets.

- Suspension mechanism - consists of one guide installed at the top of the opening, stoppers and a roller carriage. The big plus is that there is no bar at the bottom and the opening is silent.

Such fittings are selected based on the weight of the sashes and façade finishing.

Pull-out rotating system for sliding wardrobes

For corner wardrobes and models with narrow, deep sections, European hardware manufacturers have created a wonderful design - a rotating and sliding system for storing any items with a supporting steel frame. This device allows you to increase the capacity of the cabinet and ensures the most convenient operation of the wardrobe.

Thanks to its installation, you will not need to sort through clothes on the shelves in the depths of the case in search of the right thing - just pull the frame towards you, and then rotate it around its axis, and any of the compartments of the section will become easily accessible.

Swing-out columns for sliding wardrobes can be installed in sections with a height of 1870-2120 mm and a width of 689-892 mm. In this case, the useful depth of the housing must be at least 550 millimeters. After fixation, the telescopic frame is equipped with hanging mesh baskets and various holders for clothes, including trousers. The complete set of metal elements for storing things is carried out at the request of the client.

Rotating fittings with a supporting frame are an excellent opportunity to carefully systematize the interior space of a dressing room or wardrobe. This device allows you to maintain perfect order and rationally fill the entire body with things from the bottom to the roof, conveniently placing clothes of any shape and size. Styver-100 installs German Kessebohmer swing-and-slide frames with organizational elements that are highly durable and look good inside the cabinet.

How to choose the right accessories

When choosing high-quality furniture fittings, take into account all factors and operating conditions. People who prefer a dynamic opening style additionally purchase closers and spring hinges. For discreet use, furniture with cheaper fittings is suitable.

The following parameters influence the choice:

- dimensions of the door structure;

- total weight;

- material;

- interior filling of furniture.

In addition to these characteristics, appearance is also important. It is important that the furniture fittings fit harmoniously into the overall interior. Metal products can be processed with any decorative coating: silver, gold, brass, chrome, bronze and even cast iron. Try to select accessories in the same style.

Types of furniture fasteners for chipboards

Conventionally, laminated chipboard furniture fasteners when assembling a wardrobe and other furnishings can be divided into two types - hidden and through. As the name implies, in the first case, the connections are visually invisible after assembly, and in the second, the heads of the screw or screw tie are visible.

Screw tie for confirmations (Euroscrews)

Confirmats are a screw with a large thread pitch. The most popular furniture fastener for chipboard panels in the assembly of wardrobe bodies with a thickness of 16-18 and 25mm. In the first case, as a rule, confirmats 5x50 are used, in the second - 7x70.

To connect the parts, it is necessary to drill with a special confirmation drill. It provides the necessary expansion to a diameter of 7-8 mm closer to the head of the confirmat, followed by a countersink for recessing the head from the front side of the chipboard at the attachment point.

Eccentric tie for hidden fastening

There are a lot of varieties of eccentric screeds, as well as names - eccentric, minifix, rafix, etc. All of them are a combination of a rod (rod, dowel) and a head (coupling, eccentric, body) of different shapes.

For different types of connections, specific types of eccentric couplers can be used, with an angular and double rod.

Eccentrics are distinguished by the type of cap - it can be designed for a hexagon, a Phillips screwdriver, or even be equipped with a convenient latch that does not require any hand tools for assembly and disassembly. An eccentric coupler is also distinguished by the shape and length of the rod. For example, the rod of rafixes is very short, because of this the eccentric itself is installed as close as possible to the end of the shelf.

In addition to the obvious advantage over confirmed ones - the possibility of hidden fastening - the eccentric allows you to repeatedly disassemble and reassemble furniture if necessary. At the same time, the attachment points do not become loose and do not lose strength over time.

The only drawback is the difficulty of installation for an inexperienced technician. An eccentric coupler requires precise calculations for installation and an understanding of how best to make the connection. In some cases, hidden fastening of chipboard on eccentrics is accompanied by parallel installation of furniture dowels for additional fixation of the part.

Hidden chipboard fasteners for furniture dowels

Furniture dowels are used extremely rarely to connect parts made of laminated chipboard. This type of fastening is more typical when working with furniture panels, plywood and wood, since it is accompanied by gluing parts and clamping with clamps. When installing a wardrobe, this method of fastening will greatly slow down the process.

But when assembling some individual elements with many partitions, furniture dowels turn out to be indispensable. For example, with cellular partitions in drawers or multi-level open shelves with coaxial joints, it is better and easier to use furniture dowels as hidden fasteners.

Shelf holders for shelves in wardrobes

The simplest shelf holder is a “barrel”, for installation of which you need to make a blind hole with a diameter of 5 mm on the inside of the side of the sliding wardrobe.

Rafixes are also used as shelf holders - an eccentric tie with a short rod. It provides additional fixation of the shelf, while it can also be removed if necessary.

You can also make removable fasteners for the chipboard shelf on shelf holders with fixation, which are installed in a similar way to “barrels”, but have a different shape of the protruding part.

Fasteners for chipboard and glass

Typically, in the design of wardrobes and additional modules, glass is used as shelves. To fasten the glass to the chipboard sidewalls, special shelf holders with a silicone “wrap” are used. It is best to purchase shelf holders with a suction cup for additional fixation of the glass shelf. For installation, you need to make a blind hole with a diameter of 5mm.

If the glass is attached to the chipboard on only one side, then it is installed on special holders with a “girth”, they are called “pelicans”, “toucans”. The size of such shelf holders and the design are selected according to the thickness of the glass and the depth of the shelf being held.

Using screws in assembling sliding wardrobes

The chipboard parts themselves are rarely connected to each other using ordinary screws - confirmats are mainly used. But to install fittings, self-tapping screws of different formats are used, mainly:

- 3.5x16 and 4x16 for fastening drawer guides and other mechanisms.

- 4x20 for attaching pipe flanges, decorative legs, thrust bearings and other fittings to chipboard.

- 4x30 for fastening facades with the body of the drawer, attracting them to the roof slats and the canopy of the wardrobe.

- Self-tapping screws 3x16 or small nails for fastening fiberboard and HDF (back walls and bottoms of drawers).

Before attaching furniture components, markings are first made on the surface of the chipboard using a thin awl. Then screw in the screws with a screwdriver. To attach long self-tapping screws through the slats and the front parts of the drawers, through holes are pre-drilled in the places where the screed is intended.

Fastening chipboard to the wall when installing a wardrobe

Built-in wardrobes often require large spans of horizontal shelves, which need to be attached not to the chipboard sides, but directly to the walls. Plastic “commander” corners in color are widely used to fasten chipboard to walls; they have a neat and modern look.

If the shelf is deep and long, then consoles and mensolo holders with a large shoulder may be required to prevent deflection. There are a lot of similar shelf supports on sale; it is possible to choose an option of a suitable size and design, as well as hidden fasteners.

Filling elements

Products are found in a fixed size, so it is important to take all characteristics into account when designing furniture and when choosing fittings. This way you can correctly distribute all the things in your wardrobe.

An important part of the wardrobe is its content.

Popular filling elements inside include:

- A rod is a metal pipe installed horizontally between two walls.

- A hanger is visually similar to a barbell and is installed across the wardrobe. The structure can be freely moved forward or be a stationary option.

- Trouser - there are several variants of such products. The most optimal model is the use of pins. This design is attached to the back wall or to the side walls.

Some people prefer to install hook-shaped holders in the closet, where ties, belts are hung, and the shoe department is located. Furniture supports and shelf holders are also considered filling elements. Made from metal or plastic.

Components of the kits

In terms of their design, the various mechanisms of sliding doors differ little from each other, except perhaps in the specifics of the displacement of the leaves. Therefore, the kits include almost the same elements; the only difference is in their number and design.

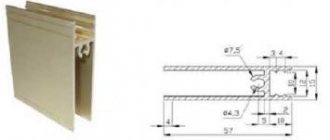

Rails

Profiles are mainly used as guides in sliding door systems.

The difference between them is the number of “tracks”. The specifics of the application depend on how exactly the canvas covers the opening: end-to-end or overlapping. In fact, these are traditional sliding doors, well known to many. When choosing a profile, the metal from which it is made also matters. For massive doors, it is better not to use aluminum (even though it is cheaper); Deformation will cause problems with sliding doors - only steel.

Roller bearings

They also differ in design features. The required number of wheels (and the upper mechanisms can have up to them is determined by the weight of the leaf and the type of sliding system. There are also differences in the arrangement of the wheels themselves: symmetrical or offset (asymmetrical). For doors weighing no more than 80 kg, roller mechanisms with two supports can be used But for massive canvases, at least four are installed, which is associated with an increased load on the structure.

The required number of wheels (and the upper mechanisms can have up to them is determined by the weight of the leaf and the type of sliding system. There are also differences in the arrangement of the wheels themselves: symmetrical or offset (asymmetrical). For doors weighing no more than 80 kg, roller mechanisms with two supports can be used But for massive canvases, at least four are installed, which is associated with an increased load on the structure.

Locking elements

They are not basic, but perform important functions. The first is to prevent a “hard” impact of the door on the wall (if the opening is located close to it) or the roller flying out of the guide. Such parts are called motion limiters. The second is fixing the door in a certain position. This is necessary in order to prevent spontaneous movement of the canvas. This is possible, for example, in the event of a strong draft or disruption of the horizontal orientation of the rails due to shrinkage of the structure.

The sliding door mechanism can be additionally equipped with automation elements (closers, mini-electric motors, cables, hooks, etc.). But they do not make any changes to the principle of its functioning; They only increase ease of use, nothing more.

Fastening wardrobe doors with top rollers

The top door mounts take the form of two rotating wheels that attach to a corner piece with a U-shaped mounting slot. In the normal state, the rollers are located in special grooves and rotate when opening and closing. Therefore, to attach any wardrobe doors with top rollers, choose high-quality fittings.

In some models, the rollers are mounted at the top.

There are spring-loaded upper elements. They are distinguished from standard ones by their size and design. With an open profile, an asymmetrical roller is suitable, and with a closed profile, only a symmetrical version.

The rollers at the top have a supporting function for the entire structure. Their correct installation securely fastens the canvas over the entire plane. The standard set consists not only of rollers, but also rubberized wheels. Rubber reduces the noise level created when the sash moves or knocking when opening roughly.

Varieties

Thanks to a special door opening system, the fittings of a sliding wardrobe will differ significantly from the fittings of its swing counterpart. Today, a standard sliding wardrobe is equipped with the following types of elements:

- profiles – necessary for the operation of doors;

- guides - doors move along them;

- rollers - wheels for moving the sashes;

- stoppers – position locks;

- seals - allow the door not to spoil the surface of the body from the inside;

- sliding system - a type of mechanism for operating the sashes.

Each of the listed types should be considered separately, highlighting the main features.

Profiles

The modern market of furniture fittings for sliding wardrobes classifies profiles into 2 types:

- steel - has a relatively low cost and is often used for economy class sliding wardrobes or domestic models. Externally, it has a limited color palette, which is why it is gradually losing its popularity;

- aluminum - presented in two subtypes at once - a profile with an anodized coating, as well as an option in a PVC shell. Such profiles are durable, light in weight and have a wide range. Aluminum parts are produced in a wide range of colors and textures, so choosing a shade for the product is not difficult.

Profiles for sliding doors made of aluminum with an anodized coating have a particularly hard surface, which is why they are considered durable and resistant to mechanical damage. This product does not scratch or fade in the sun.

If the goal is silent operation of the cabinet and doors, it is better to give preference to an aluminum profile in PVC.

Guides

These parts are supplied in quantities of 2 pieces. for one product. One of them is installed on the top panel of the compartment, the other is mounted on the bottom bar. In the space between the guides there is a door along which it moves. According to the manufacturing materials, the guides are made of plastic, aluminum and steel.

Aluminum guides have excellent characteristics: they are ergonomic and aesthetic, and have a wide range of colors. Despite the relatively high cost, such elements are durable.

Guides for the door mechanism are:

- single-lane;

- two-way;

- three-lane.

This indicator depends on the type of mechanism and the number of doors in the cabinet. The top rails also have several rows according to the number of doors. These parts are installed using wood screws.

Rollers

High-quality rollers are responsible for moving the sashes along the body strip. They consist of a base and wheels that run along guides. The higher the quality of the rollers, the smoother and softer the door will operate. Most elements are equipped with bearings to prevent noise.

Cabinet casters are available in two versions:

- asymmetry - such a device is used to move the door along the lower guide. The entire support of the sash falls on the lower wheel, the upper one is supporting. This roller is suitable for sliding cabinet doors with an open handle. The part itself can be adjusted in height;

- symmetry - this option is installed in systems with a closed cabinet handle. Elements can be built into a product with mirror, glass or plastic facades.

When selecting rollers, you should pay attention to their quality: symmetrical elements allow you to install the door without distortions, ensuring its smooth and precise operation.

Stopper

Fittings for coupe models always include stoppers. They are supplied in quantities of 1 piece. for 1 door. A stopper is installed on the lower aluminum guide in order to fix the door in the right place when opening. It is a thin metal bar with mustaches - springs. The part works according to this principle:

- when the door is opened, the roller moves along the lower guide;

- the wheel runs into the lower plate of the stopper;

- the roller falls into the gap between the plates and the door is blocked.