Types and types of locks

The design of a furniture lock is determined by the material on which it is installed.

This is explained by the fact that the lock is designed for a certain thickness of the door or drawer front and a different method of fastening (for example, you cannot screw a self-tapping screw into glass). Castles are divided into:

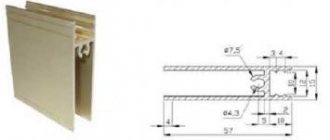

- furniture locks for chipboard and wood (as a rule, designed for a thickness of 16-18 mm) When attaching furniture locks to chipboard and wood, practically no problems arise: a hole is drilled for the cylinder, and the lock body is attached on the reverse side. On the outside, the hole for the larva can be decorated with decorative overlays.

- furniture locks for glass (usually glass with a thickness of 5-6 mm is used, rarely 8 mm) Locks for glass are universal; glass of any thickness used can be secured in them. They are also suitable for metal (e.g. metal cabinets, mailboxes). Glass locks come in mortise locks (requiring glass drilling) and overhead locks. The difficulty of installing mortise locks is that not every manufacturer has the ability to drill glass well and accurately install a lock in these holes. Thus, drilling requires a special machine with drills for diamond-coated glass, drilling glass from both sides at the same time. In this case, a cooling emulsion should be supplied, which makes the process better. Such a machine costs from 5 thousand EUROS.

Therefore, rim locks are most often used for glass doors, for the installation of which it is not necessary to drill the glass. These locks have an “L-shaped bar” that fits over the glass. Screws are inserted into the holes in the bar and the lock is pressed against the glass through a plastic spacer.

Locks also vary depending on what they are for: drawers, sliding doors, or hinged doors. Locks for swing doors are divided into locks for one door and for double doors.

In addition, locks differ in the principle of operation of the mechanism: with a retractable tongue, rotary, push-button, harpoon-shaped, rack and pinion with a locking mechanism.

The designs and mechanisms of operation of locks in most manufacturing countries are very similar, so we will focus on the main models that are a priority for the Russian market.

High-tech models

In addition to traditional options operating on a mechanical principle, there are more modern high-tech models. Among them there are the following varieties:

- Coded. There are electronic and mechanical versions. They work on the principle of typing a specific sequence of characters using a keyboard or rotary rollers. In addition, this product may have a magnetic key. The peculiarity of this model is the large number of options for digital combinations. One of them is the key. The advantage of this design is the ability to find the desired combination by selecting options. If you go through the combinations for a long time, sooner or later the desired sequence of numbers will be found. This feature comes in handy when a combination is forgotten or lost. The disadvantage is that they are quite large in size, which complicates installation and can ruin the appearance of the furniture.

- Electromagnetic lock. Driven by power supply. A strong magnetic field is generated, retracting the latch and allowing the door to open. It locks in the usual way, like any spring type. Installation consists of attaching the mechanism itself and connecting the power wire to the electromagnet. The advantage of such locks is that it is impossible to pick up a master key, as well as their resistance to corrosion. Users note durability and ease of installation. The disadvantage is that it stops working when there is a power outage. The situation can be corrected by using a backup power source.

- Electromechanical. It is a set of a lock mechanism, a power source and a control unit. If there is a sudden power outage, programming failures are often observed, which requires reconfiguring the system. This procedure is not particularly difficult. Disadvantages are sensitivity to moisture and tendency to form condensation. Not suitable for installation in areas with high humidity, such as a bathroom.

- Electronic. One of the most modern, advanced models. The key to such locks is digital cards or chips. Installation first requires the installation of a mechanical drive, then the connection of an electronic recognition system. The advantage is the absence of a regular key and the impossibility of counterfeiting a chip or card. In this case, the code combination is quickly changed if necessary. The electronic lock is sensitive to temperature changes, power surges, and short-lived.

Types of accessories for upholstered furniture, functionality and characteristics

Each furniture lock has one degree or another of reliability. The most burglar-resistant types of locking mechanisms are: electronic, coded, and mortise lever.

Modern models are usually used for office furniture. At home, they are inappropriate and spoil the appearance of the headset.

Code

Electromagnetic

Electromechanical

Electronic

Lock manufacturers

On the Russian market you can find furniture locks from a variety of countries. But the most common are locks made in China, Taiwan, Italy, Germany and Austria. There are also locks of domestic production, but, as a rule, they are of the simplest designs.

Taiwanese locks were among the first to appear in Russia; the products are of fairly high quality and occupy an average price niche (on average, the price of one lock is 1.5-3 USD).

But the domestic market demanded cheaper locks, which was the reason for the appearance of Chinese products. Chinese locks basically copy the designs of Taiwanese locks, but are in a completely different niche, both in quality and price. It is almost impossible to predict how long a Chinese-made lock will last. Nevertheless, these locks are in steady demand, since for many domestic manufacturers the issue of their low cost is a priority.

At the same time, lately there has been interest in expensive accessories. This is how Italian locks appeared on the market. As for countries such as Austria and Germany, their products are distinguished by the highest quality at a consistently high price. The consumption of such locks in Russia is more individual than mass.

Closer for sliding system

This is a whole system that includes stoppers, limiters, latches and other elements so that the doors automatically close smoothly and are comfortable to use. Every third model requires several closers at the same time due to the need to close the doors in different directions. Adapters that regulate the operation of the system are installed in the upper part of the cabinet, and the closer is installed in the upper part of the guide yard.

It is worth noting another significant role that is controlled by the automatic system - security. This device minimizes the likelihood of injury when closing the cabinet abruptly.

In addition to providing safety to the owners, the structure itself has an increased level of protection against loosening. This opportunity arises due to the shock-absorbing effect that is introduced into the automatic door closer systems.

To select an automatic closer system, you should pay attention to the following factors:

- dimensions and weight of the wardrobe;

- directions for closing and opening the sliding system;

- material of manufacture of the system itself (aluminum structure or steel).

The installed systems are in demand and extremely popular due to the fact that they combine:

- Ease of use. You just need to push the door and it will smoothly close on its own. Children or pets will not be able to do this. The effort that needs to be made is not noticeable for an adult, but for children even an animal will cause difficulties.

- Aesthetic appearance. The door is always in the right position and closed for a fee.

- Safe to use. When closing the doors, neither children nor pets will be harmed. Often when playing, children can sharply push the door, and the system slows it down 5-7 centimeters from the wall itself and slowly closes it, preventing injury and damaging the cabinet body.

- Reliability. Steel and aluminum structures allow the mechanism to be used for a long time.

Leaf parsley, varieties, benefits, cultivation features, care

You can learn how to install a stopper with a shock absorber on a sliding wardrobe from the video.

Finishing touch

The service life of a lock depends, first of all, on its quality: the better it is assembled, the stronger the material, the longer the lock will last. Good locks, in addition, should not change their color or fade, that is, they should have a high-quality coating.

Also, when purchasing a lock, you should pay attention to how smoothly the mechanism works, and most importantly, the key from one lock should not fit another. Manufacturers of quality locks have thousands of different combinations to avoid this situation.

You can familiarize yourself with all of the above lock models in more detail in the electronic catalog or at the MDM office, where professional managers will show you each model in action and choose the best option for you.

Come and choose “Locks worthy of your furniture”!

Choosing a pen?

For the sliding system, you can choose a handle that will have the most suitable design. All existing varieties differ from each other in individual details, and therefore which option ultimately turns out to be acceptable will depend on:

- Design features of the door;

- Doorway size;

- Dimensions of the door leaf;

- Sash material;

- Personal preference.

Potato digger for walk-behind tractor - do-it-yourself features

All handles are mortise, and their handle is most often an ordinary recess used to open the sash.

Independent models

These handles got their name because they are not connected to any locking mechanism. Their design does not imply the installation of any kind of lock or elementary latch. If it is necessary to fix the sash in the closed position, to the leaf and side wall. The force generated must be sufficient to prevent the closed sash from moving.

Attention! If the door installation was carried out according to all the rules, you can safely refuse such a handle.

The popularity of independent handles is due to their:

- Fairly simple design;

- Low cost;

- Easy to install.

Most often these are mortise products placed inside the sash during installation. The handle does not extend beyond the door leaf, which makes it possible to open/close the door even with limited surrounding space. This model is suitable for cassette sliding systems, which can be completely hidden in the wall during the opening process. The installed handle in this case greatly facilitates the process of operating the door system.

Mortise with latch

This handle is initially equipped with a locking mechanism that allows you to open and close the latch when the need arises. In terms of their design, such handles are similar to models installed on swing doors, but they have some differences.

Firstly, the handle is made much smaller. Secondly, the latch comes out of the hole in the strike plate after turning a small handle or moving the slider. Both options assume that the parts used to open the door are located in a special recess on the door handle. As a result, the installation of such a handle is possible on doors that are used in limited conditions, for example, on cassette doors.

Handle with lock

This model differs from previous versions by the presence of a special hole designed to accommodate a keyhole. Manufacturers offer models that already have a cylinder of a locking design built into the handle, adapted to the operating features of the sliding door.

Article on the topic: What types of interior compartment doors are there?