The bed is the piece of furniture on which people rest and gain strength before starting a new day.

Everyone knows that sleep should be not only comfortable and enjoyable, but also useful. In any furniture store you can choose a bed of different shapes, sizes, designs and materials. But, if you have carpentry skills, you can make its frame yourself.

Advantages

The main advantages of making a bed on your own include:

saving money;- the opportunity to make a product to your taste, according to your own sketches and from any materials;

- confidence in the environmental friendliness, safety and reliability of the product;

- the opportunity to express your imagination and realize it.

Having made the bed frame yourself, you can be sure that such a product will be in a single copy. Consequently, you will become the happy owner of an exclusive piece of furniture, with which you can not only sleep comfortably, but also read a book or watch TV.

Material

Any manufacture of wooden furniture requires careful selection of building materials. But all of it will be:

- environmentally friendly;

- durable;

- aesthetic.

Information : the tree smells good, is breathable and hypoallergenic.

When creating a wooden bed frame, you can use different materials:

- timber _ Such a product will be distinguished by its luxurious appearance, practicality and ease of manufacture. This furniture can be carved or upholstered;

- boards _ They must be of high quality and free from knots or any other defects. Since the presence of knots will take a lot of your free time to polish them;

- logs _ This building material is used quite rarely, but the products are exclusive and unique;

- array . Such furniture will tell a lot about the impeccable taste of its owners and their position in society. To ensure that the product will serve you for decades, give preference to the following types of wood: alder, oak, beech, ash, pine.

First stage

At the beginning, we prepare the materials and necessary tools. The most suitable material for our base is pine timber, which can be purchased at a hardware store or at a sawmill.

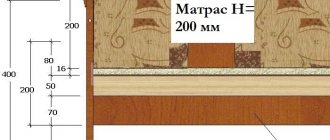

Its dimensions are 50 mm by 50 mm. The base for the mattress will be furniture laminated chipboard, and we will make decorative elements of the bed from the slab material. To calculate what length of timber to buy, you need to understand where it will be used. The timber will be used to strengthen the base, to support the base on which the mattress will rest. In our case, the most optimal size for the length of the beam is 4.5 meters. You need a couple of such bars. Since the elements made from beams will not be visible in our bed, you can purchase unplaned timber. It is better if it is cut to size on site. Such timber will be more convenient to transport.

Be sure to check how it was stored before purchasing the timber. It should be stored under cover. Pay attention to how it was laid, whether spacers were used between layers. Otherwise, you may end up with low-quality material, with mold, darkening or cyanosis. Such timber is often severely deformed due to drying.

If the timber was stored in unsuitable storage conditions, do not buy it, because you can choose a more suitable, high-quality material. For example, laminated veneer lumber. Such timber costs much more, but the quality of your product will increase significantly. Here you should not save money. After all, we do it for ourselves, our loved ones.

The next stage is preparing the base parts

The head of the bed needs to be made beautifully and neatly. The head back will be made of slab material and furniture chipboard. Make sure that the texture of the headboard material is directed from top to bottom or bottom to top, that is, it is transverse. It is good to process the bottom edge with a milling cutter according to the prepared sketch; this will give the finished product an aesthetic appearance. Take all this into account when cutting the material.

We make the holder from a block 20 cm long. It is fixed across the width and in the center, at a height of 15 cm from the bottom edge. We secure them with self-tapping screws and put them on glue.

The holder is fixed in the center of the beam. It is necessary to fix the racks on the sides of the head cloth. They are made from slab material.

Wood species

You can make a wooden bed from different types of wood:

pine trees

This material is in demand due to its presentable appearance and high technical characteristics. This product will delight you not only with its beautiful texture, but also with its pleasant pine aroma. Products that have been well sanded and varnished are highly resistant to the formation of fungi and do not rot;- oak _ This wood is considered elite. It is distinguished by its luxurious appearance, environmental friendliness, and the ability to create patterns and ornaments on the product;

- beech _ Such beds are distinguished by their original cut patterns, durability and strength. Beech models look noble and fit classic motifs;

- birch trees This type of wood is easy to process, has a high level of strength and elasticity, and is attractive.

Attention : when choosing wood, you should base it on what kind of bed model you need.

To make a wooden product look aesthetically pleasing, but not cost too much, you should know some secrets :

- for decoration and frame it is worth taking expensive material (oak);

- for making legs, cheaper wood (pine) is suitable;

- and for the slats that will be located inside the product, you can choose the simplest option (birch).

Drawing 160 by 200

Before you start making a bed, you should decide on its size. The ideal option for two adults would be a double model with dimensions of 160x200 cm.

This drawing should indicate all the main points for the manufacture of furniture:

- exact dimensions;

- assembly materials;

- fasteners.

At the stage of drawing up the drawing, it is important to determine not only the size of the bed, but also the height of the legs of the product. To do this, just imagine from what height it will be most convenient for you to get up.

Attention : too low products, although they are original, are impractical and completely inconvenient to use.

At the stage of creating the diagram, decide on the headboard and footboard . Consider whether you might want to make the product functional and equip it with drawers for linen or a lifting mechanism.

Making a mattress using natural materials

Before you make a mattress with your own hands, you should ensure that you have the following materials:

- adhesive composition;

- fabric for sewing a cover;

- filler (the material must be sufficiently elastic);

- sewing machine and other sewing accessories.

In most cases, a single piece of foam rubber is used as a filler. A layer of coconut coir or polyurethane foam will improve the orthopedic qualities of the mattress. A moderately hard surface is more comfortable for the spine. It is also possible to use struttofiber to make mattresses for a crib. In this case, the foam layer will be on one side, and the coconut fiber will be on the opposite side. You will also need a cover. Natural (breathable) fabrics are used to make the structure. Linen or calico are used most often. Upcoming manipulations

Before you begin the upcoming manipulations aimed at sewing a mattress, you should measure the dimensions of the sleeping area. At this stage, a tape measure is used, after which the frame is assembled. Dense polyurethane foam 5-10 cm thick should be used as a base. We sew a mattress 15 cm thick. A smaller thickness of a children's mattress will cause discomfort to a child or an adult, depending on the purpose of the structure (play or relaxation). Accuracy in dimensions is important, so measurements are taken several times.

The comfort and stability of the future structure will depend on the quality of the materials used. Next, the filler is laid. When using a single piece, a sharp knife (stationery or shoemaker) is used to adjust the material to the dimensions of the frame. You have to cut out an even piece. If several sheets of foam rubber are used, the individual elements are glued together with special glue.

How to make slats and base

With the choice of materials, selection of design and determination of dimensions, you can proceed directly to the manufacture of individual elements of the product. To do this, you should pick up a drawing to check all sizes. The production of parts will proceed as follows :

- We take lumber.

- Mark the cut lines on it with a pencil.

- Using a ruler and a cutter, we detail individual elements.

After manufacturing all the necessary parts, you can begin processing them:

- remove all knots and defects with sandpaper . To do this, we prepared in advance several different types of sandpaper: coarse, medium, fine;

- the headboard and end boards with an electric planer .

Now you need to make the slatted base of the product. Slats are slats that are attached to the base of the bed at a certain distance. This distance should not exceed the width of the lamella itself. The slats are necessary to give the bed an orthopedic effect and to ensure ventilation of the mattress.

It is better to use birch to make them . Since this material is flexible, elastic, and easy to process.

Important : for a double model, it will be enough to make 30 slats.

When making lamellas, you should adhere to the following rules :

- the thickness of each part should be 0.8 cm;

- it is better to give the product a curved shape;

- the width of the lamella can vary between 5.3 – 6.8 cm;

- they are installed on the base of the frame with a distance from each other from 2 to 6 cm.

You can attach the slats to the frame in different ways:

- self-tapping screws;

- using thick edge tape;

- onto the prepared bars.

Stages of work taking into account the model

Depending on the model, the algorithm for making a bed will differ. Those who have not done this kind of work before should start with simple options. It is also recommended to study master classes in advance.

Children's room made of chipboard

In order to make a bed from chipboard for a child, you will need:

- 1 solid sheet of chipboard (you need to choose a good quality chipboard);

- 2 side drawers;

- 2 bars (of the same length as the drawers);

- 1 or 2 boards or timber to give rigidity to the entire structure (it is also possible to use furniture panels);

- 1 front wall of the box;

- 10-15 slats along the width of the bed;

- 4 legs with plugs on them.

This is a simple and beautiful model. The child is guaranteed to like it. It will be possible to assemble it from improvised means.

The assembly process begins with drilling holes for confirmations. You will need special drills (7 x 70); in extreme cases, regular drills (7 x 5) will do. You can assemble a chipboard bed with your own hands as follows:

- We fasten the headboard material to the drawers using metal corners.

- We attach the footboard using the same principle.

- We fasten the joints with confirmations. The result is a rectangular box for a child's bed.

- We install a support crossbar in the middle. To make the structure more stable, it is recommended to add another leg approximately in the middle.

- We fasten the bars to the sidewalls from the inside with confirmations.

- We insert the legs into the inner corners (under the block).

- We lay a grid of slats on the support beam and bars along the entire length. It is important to maintain the same distance between them. Their total number depends on the calculated width and size of the gaps.

- We screw the slats to the support and bars. If they are not available, making a bed from furniture panels will be even easier.

- If the project included decorative parts, we attach them.

The advantage of such furniture is that it is quickly and easily assembled. The result is a do-it-yourself single bed. You can make a drawing for it yourself or use ready-made calculations. To save time, it is recommended to purchase laminated material, since making a bed from chipboard with your own hands will be much easier.

The main material in this case is chipboard. Plates can be toxic, so it is necessary to check whether the manufacturer has certificates and how safe their products are.

Headboard drawing

Headboard assembly

Foothills

Side wall

Assembly diagram

Finished bed

Japanese style double room

According to the drawings, you can also make a Japanese-style bed with your own hands quite quickly. This model has a laconic design that will look organic in any interior. The bed is reliable and simple, does not require a lot of time and materials. An ordinary Japanese bed has the following parameters:

- length and height of the footboard – 1.6 x 1.2 m;

- headboard length and height – 1.6 x 1.5 m;

- length of side bars – 2.08 m;

- height of legs – 30 cm.

Functionality and model range of massage beds, indications for use

Naturally, the parameters may vary depending on the size of the mattress. To make such a bed you will need:

- furniture board (beech or pine is recommended);

- beam;

- fiberboard sheet;

- plywood:

- logs;

- middle beam.

To make a homemade plywood bed look unusual, it is decorated with decorative elements.

After cutting, there should be parts for the sides of the frame, four legs, elements for the footboard and headboard. So, the base for the bed is first assembled with your own hands, then strengthened with corners. The frame is mounted on self-tapping screws. The stiffening ribs are fixed with bolts from the inside. If the furniture is wide, it is necessary to tighten the frame with a longitudinal beam in the middle. After this, all that remains is to attach the slatted base and headboard.

Cut out parts

Assemble the frame

Install legs

Attach the headboard

Make a slatted base

Cover the headboard with fabric

Floating made of wood and metal

This design is not placed on the floor in the usual way. It seems that it is hanging in the air, but in fact the supports are securely hidden. You can enhance the effect with lighting from below. This is ideal furniture for high-tech style, but it is extremely rare. If there is a model, it is too expensive, so it is better to get by with a bed made by yourself.

For work you will need wood, a square metal pipe and combined materials. Instructions for making furniture:

- We start the assembly from the support. This is the part that will bear the main burden. We connect thick boards for support with self-tapping screws, treating the joints with glue. It is recommended to use metal corners for reinforcement.

- We install crossbars inside the contour.

- In the corners there are posts made of timber or boards placed at the ends.

- Now we assemble the frame on which the mattress is placed. We lay a board panel or several sheets of plywood on it, and fasten the outer sides around the perimeter. All that remains is to decorate the hand-made bed under the ceiling.

The support, frame and frame of a floating bed can be made of metal.

Assemble the support

Install crossbars

Add timber posts at the corners

Assemble the frame for the mattress, fasten it to the support

Lay the bed base

Secure the outer sides

Decorate the bed

With PVC pipe base

A bed for a country house is often made from these materials due to their low cost and availability. It is with them that beginners are recommended to start. You can assemble a swing bed with your own hands from PVC pipes and make it a two-tier bed.

Having decided to assemble furniture from plastic pipes, the master has complete freedom for creativity. To make a bed for a summer house with your own hands, pipe sections are glued together to form a base. A mattress and pillows are placed on top. If a bunk bed is being made, the joints should be fastened with fittings and glue to ensure that the structure is as strong as possible.

Cut pipes to the required sizes, assemble the structure

Install the mattress

Foldable to wall

This is the ideal pull-out bed for small spaces. It is equipped with a lifting mechanism that allows you to place it against the wall during the day, leaving more free space in the apartment. The folding bed can be easily installed according to the drawings. To make it you will need:

- transformation mechanism;

- beam;

- plywood;

- chipboard;

- furniture panels;

- legs.

Installation begins with the box. On its walls we mark how we will attach the mechanism. We fix it to the wall with self-tapping screws and metal corners, then assemble the frame from timber. We cover the frame with boards. At the last stage, we attach the bottom to the bottom.

Making your own furniture is not at all difficult, even if you are planning a rocking bed. The main thing is to apply imagination and skill. If the necessary tools are not available, you can rent them to save money.

Assemble the base

Make a body

Attach to wall

Assemble the bed frame

Connect the frame to the body

Reinforce the structure with a crossbar and install a base

Attach decorative doors

Ready product

Assembling a double bed

The assembly of a double bed is as follows:

We set the footboard and headboard vertically and support them with some objects.- We apply the drawers and check the evenness of the corners.

- We mark the points for the dowels and connect the drawers to the backs.

- We remove the drawers and drill holes in them .

- We assemble the structure by choosing holes on the backs.

- We proceed to the complete assembly of the base - we drive the dowels into the grooves and lubricate the parts with glue . For better fastening of parts, we wrap the product with rope.

- Leave the product for several days until the glue dries completely.

- Next, we make the flooring . For the slatted bottom, we distribute special holders along the frame.

- We select the spaces between the slats so that the mattress can easily be supported on them.

- We connect the slats with longitudinal bars.

- Now you can start installing the legs . To do this, we fix the beams on the inside of the corners of the frame.

That's the whole simple process of assembling a wooden bed frame.

Important : in order not to spoil the appearance of the bed, choose screws whose thickness will not exceed the thickness of the boards.

Making a bed frame

It begins with cutting the material according to the drawn up sketches in accordance with the dimensions according to the drawing. The process of forming a frame from hardwood. Having cut the parts to the dimensions required according to the drawing, we drill holes in each for fasteners up to 30 mm in size.

The end parts of the boards are carefully cleaned with sandpaper or a sanding machine. Then we cover the parts with adhesive for wooden surfaces in two layers, always waiting for the previous one to dry.

Afterwards, fasteners are inserted into the finished holes, and the parts are assembled. Remember that the screws are drilled into the component frame of the board at an angle. At the end of the work, the straightness of the corner joints is carefully checked. You can proceed to the next stage of assembling the frame.

Finishing

To make a wooden product attractive, it must be covered with stain and varnished two to three times . This will not only give the bed a presentable appearance, but will also improve its performance characteristics.

When choosing a varnish, give preference to polyurethane-based material. It is harmless and does not release toxins. In addition, this material is wear-resistant and resistant to mechanical damage.

Attention : by giving preference to matte varnish, dust and scratches will be less noticeable on the product. And the glossy coating will immediately reveal all your mistakes in work (irregularities, cuts and other defects).

Some people prefer fabric and foam upholstery. But this is suitable for products made from cheap lumber. The beautiful texture of oak or beech should not be hidden under fabric . If desired, the product can be painted, choosing a color that matches the overall interior. Again, this option is not suitable for elite and noble wood. You can also emphasize the originality of the product and make decoupage on its headboard.

Advice : if you are serious about furniture for the bedroom, try making a dressing table, bedside table and changing table. You might also be interested in a loft-style wardrobe or table.

Now it's time to start decorating the product.

The easiest way is to level the surface of the wood with fine-grained sandpaper or a sanding machine, treat it with stain and varnish in 2-3 layers (the next layer is applied only after the previous one has dried, this will avoid cracking of the coating).

If pine boards are used to assemble the product, then there is no need to use stain. Due to the high resin content, pine may change its appearance - called tiger stripes will appear on it. It is enough to treat wood of this type with varnish.

If the master plans to upholster the bed with soft fabric, then for the work he will need the appropriate material, a furniture stapler, and staples. It is advisable to place thin foam rubber under the fabric and attach it with curly nails. You can cover not only the external, but also the internal elements of a wooden structure with fabric, this will reduce the likelihood of contamination of the mattress.

Photo

Despite its apparent simplicity, assembling the frame leaves ample opportunity for self-expression: