In the independent production of any cabinet furniture, the main thing is a competent project. If the working drawing of a double bed with drawers is drawn up correctly and rationally, then we can consider that half the work has already been done. Before you start making a double bed with drawers with your own hands, you need to think through the design so that all connections are strong and give the frame rigidity and stability. And they start, of course, from the size of the mattress itself, to which the sleeping place is adjusted.

The nuances of self-assembly of a double bed

The mattress can “lie” on an orthopedic base in the form of a metal frame and lamellas - special flexible slats.

- The orthopedic base, in turn, is attached to the legs (in this case it is completely independent, and the bed frame is “assembled” around it).

- Also, the orthopedic base can be part of the bed. In this case, a panel is provided on the inside of the bed frame on which it will rest.

You can also provide a rigid chipboard base for the mattress.

This is the first point that you need to decide on before you start making a double bed with your own hands: choose what kind of base it will be, hard, made of chipboard or in the form of an orthopedic base, dependent or independent, on its own legs.

The second point is the presence of drawers at the base. Whether they are needed or not - you need to decide right away. In each case, the stiffening ribs in the bed frame can run completely differently. At the same time, the bed itself should remain rigid and not become loose over time.

The same applies to any pull-out modules in the bed frame. If you are planning to implement the idea of a lifting base, some roll-out or reclining elements in the back and base, use only good, high-quality fittings. Since the load on them in almost all cases will be large.

The third point is the choice of material for making a bed with your own hands.

The development of a drawing of a bed made from solid wood, furniture panels and timber will be radically different from a model made from laminated chipboard. In addition, parts made of chipboard require additional edging of the ends (melamine edge or PVC).

Preparing materials

For the bottom you will need a dense and rigid plate. It must withstand the weight of the things stored for storage and not sag. In addition, rollers are attached to it. If the bottom is deformed, the structure will begin to touch the floor and will no longer move easily. In the recommendations on how to make a box under a bed, it is advised to use a sheet of laminated chipboard, plywood of sufficient thickness for the bottom, or assemble it from thin boards. Fiberboard will not work. It is too soft, so it will sag.

To expand the space, you can also use mirrors. Mirror panels or panels, reflecting light, will make the room lighter and larger, as if opening up an additional dimension in it.

The sides are also assembled from hard material.

They use laminated chipboard, but in this case you need to think about how to process the edges of the board. Boards or regular laminate will do. The last option is good because it does not require additional processing and finishing. It already looks attractive. It’s good if you can choose a color that is close to the tone of the furniture. Another advantage of a laminated board is that if the width of one lamella is not enough, you can connect two. This is very easy to do using a mortise-and-tenon type locking connection. Just before snapping it into place it is coated with a suitable glue. If boards are selected, they are more difficult to process. For a high-quality connection, you will need to cut a fold, a small recess. The easiest way to do this is with special equipment in a furniture workshop. If this is not possible, you will have to work with hand tools. It's more difficult and longer.

In addition, the boards require finishing. If they are poorly processed, the surfaces are sanded. So that they are smooth. After this, one or two layers of primer are applied. It prepares the basis for applying paints and varnishes and reduces their subsequent consumption. When the primer dries, the wood is painted in any color you like, covered with varnish or wax.

You will need rollers with a plate to attach to the base. There are four pieces for each container. In addition, you will need corners with which to fix the sides and furniture handles for pulling out containers. For each you will need either one long handle or two shorter ones. Self-tapping screws are used as fasteners.

DIY double bed with drawers made of chipboard

There are no particular difficulties in developing an internal design project for a bed. Unless, of course, you take into account the design of the back - in fact, this is a separate decorative element that can be absolutely anything. But the bed frame itself, on which the mattress is placed, can remain the same for different backrests.

They begin to design a double bed for a specific sleeping place - in fact, for an existing mattress. Its height also matters. For low mattresses (up to 100-150 mm), the base is made higher so that the bed is not too low. But mostly they are designed for a standard height of about 180-200 mm.

Let's say you purchased (or are planning to purchase) a mattress with dimensions of 2000x1800x200.

The mattress should fit freely and with reserve into the box. So that internal restrictions do not interfere with its natural deformations (when you lie down, turn during sleep). Usually a few centimeters are enough. For example, under a 2000x1800 mattress they usually make a double bed with dimensions 2050x1850. Minus the thickness of the side walls and backs (chipboard 16 mm), an opening of 2018x1818 remains under the mattress. Can be reduced to 2010x1810. This is quite enough.

There are no special height standards for double beds. Some people like lower options, while others prefer a higher bed on which they can sit comfortably. Typically the height ranges from 350-450 mm. But, for example, in Europe it is customary to make beds much higher.

Since we are designing a double bed with drawers, we will start from their height, about 200-250 mm. It is enough to make the box for the mattress half the height of the mattress, that is, 100 mm.

Designing a double bed base with your own hands

The bottom of the box for the mattress, which will serve as a base, does not need to be made solid.

- Firstly, a whole sheet of laminated chipboard increases both material consumption and the overall weight of the double bed. The load on the fasteners will be greater. And the cost of furniture too.

- Secondly, there must be air access to the mattress, as in an orthopedic base. Usually holes are drilled in the solid bottom for ventilation.

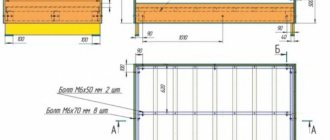

But another solution can be implemented. For example, make a composite base for a double bed mattress with your own hands (such as in the drawing).

Designing a double bed with drawers

In order for the bed to be stable and the bottom strong, longitudinal and transverse stiffening ribs must be provided under it.

Typically, a longitudinal stiffener runs centrally under the base of the bed, and drawers are installed between the transverse ones.

Let's take the height of the ribs equal to 250 mm. The longitudinal length will be 2042 mm, and the transverse length will be 897 mm (this is not difficult to calculate, just take into account the thickness of the chipboard 16 mm on each side and subtract it from the dimensions of the base).

Designing backrests

The backs of a double bed are usually called the headboard and footboard.

The foot of modern double beds is most often made at the same height as the frame. This will allow the owners to beautifully cover the sleeping area with a blanket - it will “hang” on three sides. In our case, it will be 350mm (250mm height of the stiffeners and 100mm height of the box for the mattress).

The headboard is usually decorated in some way - made radius, carved, upholstered in soft fabric or leather. We will make it 1000 mm high and provide an additional panel as decoration. It can also be made contrasting or covered with fabric lined with foam rubber.

At the edges of the headboard they protrude slightly beyond the box, let them be 10 mm each and their width will be 1862 mm (1810+16x2+10x2).

Designing drawers for a double bed

All that remains is to design the drawers for the double bed. And you can move on to calculating the dimensions of the parts (detailing) for cutting.

The depth of the drawers is limited by the length of the guides. Typically a maximum of 600 mm. If we take the height of the box to be 150 mm, then the size of the sides of the box will be 600x150mm

In order for the mechanism to extend correctly, it is necessary to provide a gap between the internal size of the niche and the sides of the drawer, equal to 13 mm on each side.

The length of the longitudinal stiffener is 2042 mm. A transverse rib is placed in the center and forms niches equal to (2042-16)/2=1013mm.

The front and back panels of the drawer (the front of the drawer) will be equal in length to (1013-13x2-16x2) = 955mm, the part itself is 955x150mm.

The bottom of the box made of fiberboard 987x600 needs to be reinforced with rigidity (too large). You can make a partition (its length is 600-16x2=568mm, and its height is the same as the entire box).

All that remains is to calculate the facades. Usually, a gap of 2-3mm is taken away on the sides, and 10mm at the top and bottom, so that the drawers do not “shuffle” on the floor when pulled out. In our case, the length is (2042/2)-2 = 1019 mm, and the height is 250-10 = 240 mm.

We design a storage system

You need to start making a storage box by creating a diagram. To build it, measurements will be required. The distance between the bed legs is measured, since the structure will be placed between them. If you plan to make two containers, the gaps are measured on both sides. Sometimes they are different. The box should fit easily between them. This means that its width should be 15-20 mm less than the obtained value.

To determine the height of the product, you need to measure the distance from the floor to the edge of the bed. Subtract 10-15 mm from the resulting value. If the wheels are planned to be mounted on the sides, they will not increase the overall height. If they are attached under the bottom, you need to subtract their height from the total. Otherwise the product will be too high.

Don't underestimate the power of magnetic shelves: they can be used to effectively store small metal items in the kitchen, bathroom or garage.

It remains to determine the depth of the homemade box. It depends on how much it protrudes from under the bed. If the appearance allows, you can place it flush with the bed. He will become, as it were, a continuation of it. Or push it deeper so that it is invisible. Based on this, the depth of the structure is determined. Based on the obtained values, a drawing is constructed according to which the homemade product will be assembled.

Do-it-yourself calculation of the dimensions of parts for a double bed

It is most convenient to combine all part sizes into one list.

- Sidewall of the box longitudinal 2042x100 (2 pcs.)

- Transverse box side 1810x100 (2 pcs.)

- Narrow base bottom 1810x300 (2 pcs.)

- Wide bottom base 1810x600 (1 piece)

- Longitudinal partition 2042x250 (1 piece)

- Transverse partition 897x250 (2 pcs.)

- Foot 1862x350 (1 piece)

- Headboard 1862x1000 (1 piece)

- Headboard insert 1712x500 (1 piece)

- Box side 600x150 (8 pcs.)

- Drawer front 955x150 (8 pcs.)

- Drawer partition 568x150 (4 pcs.)

- Fiberboard for boxes 600x987 (4 pcs.)

- Facades 1019x240 (4 pcs.)

Next, you need to mark the sides of the parts that will be rolled with an edge. These are the “visible” sides according to the drawing. For example, the details of the box sides are rolled up on both long sides, and the drawer fronts and headboards are rolled up along the perimeter.

All that remains is to cut the material, drill at the joints and assemble it in place.

The nuances of self-assembly of a double bed

The bed occupies a fairly large area and will have to be set strictly level so that the structure does not warp or become loose over time. It is best to use adjustable bearings to make this task easier.

If the bed is level and the guides are screwed strictly coaxially relative to each other (that is, also at the same level), then the drawers will slide easily.

The drawer fronts are attached last. It’s easier to secure them at the desired level than to twist the guides to lower the drawer higher or lower.

The fastening of the backrests should also be postponed “for later”. They have more of a decorative role and should be attached when the entire bed frame is assembled and level.