84501

Increasingly, owners of country houses are trying to decorate the interiors of bedrooms with hand-made wooden furniture. Self-made furniture allows you to show the personal talent of the designer, show others your own sense of style, and save on expensive interior items. If you want to surround yourself with stylish and high-quality furniture, then a do-it-yourself double bed is suitable for this, which is easy to make by listening to our advice.

Choosing material

How do you make a double bed with your own hands, the drawings and diagrams of which are given in this article? First you need to decide on the materials. The main thing is to purchase MDF, the thickness of which is three centimeters. You will have to cut out individual parts from it so that their texture resembles expensive wood.

In addition to MDF, it is recommended to buy laminate boards. In this case, during installation work you will need nitro glue, while MDF is normally connected with a simple PVA adhesive. This is one of the reasons why professional craftsmen prefer to work only with MDF. It should be noted that purchasing sheets of material at retail prices is not entirely profitable. If there is a furniture factory in the city, it is best to buy sheets with edges prepared for work there. Interior elements can be prepared from wooden boards, two centimeters thick, or multi-layer plywood.

So, in addition to MDF, you will need to buy:

- sheets of construction plywood (2 x 1.6 m);

- one and a half meter long board (2 x 10 cm);

- beams 8 m long (5 x 5 cm);

- boards 2 m long (4 x 10 cm).

The choice of wood species is at your discretion. But one condition must be met - boards, beams and plywood are purchased edged and planed.

How easy is it to make and assemble it yourself at home?

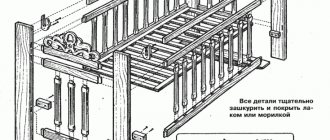

Now you can proceed directly to detailing and assembling parts. The work process begins with marking the lumber. Before you start cutting, carefully check everything again with the drawing .

Attention : it is recommended to mark cutting lines using a ruler cutter.

After manufacturing all the necessary parts, you can proceed directly to assembling the product. This process is carried out in the following sequence :

We make the bed frame, fastening all the parts with self-tapping dowels.

Experts recommend screwing in screws at an angle. After twisting all the parts, their edges must be processed with a mini plane or sander. Now it’s worth arming yourself with a square to check all the corners of the structure.- Next we move on to making the slatted bottom support. To do this, we drill holes in the boards at a certain distance.

- Now let's start making and installing the legs. To do this, we use timber with a section of 100 by 100 mm. If desired, you can make 4 or 6 legs. They are fastened with self-tapping screws (2 for each leg).

- After the main supporting structure is ready and assembled, it is necessary to begin laying the slats. They are placed at a distance of 3-5 cm from each other.

- Now you can install the headboard and footboard.

Note: Pre-drilling a hole in the wood will reduce the risk of cracking.

Tools you will need for your work

To avoid difficulties in making bed elements, fitting them and assembling furniture, you must always have the following assistants on hand:

- a circular saw that is attached to the table;

- miter saw;

- hammer and nails;

- a sander or just a set of sandpaper;

- construction tape, square, marking pencil;

- screwdriver;

- rubber hammer;

- clamps;

- sawing sawhorses;

- socket wrench with a set of removable heads.

Assembling a double bed

The assembly of a double bed is as follows:

We set the footboard and headboard vertically and support them with some objects.- We apply the drawers and check the evenness of the corners.

- We mark the points for the dowels and connect the drawers to the backs.

- We remove the drawers and drill holes in them .

- We assemble the structure by choosing holes on the backs.

- We proceed to the complete assembly of the base - we drive the dowels into the grooves and lubricate the parts with glue . For better fastening of parts, we wrap the product with rope.

- Leave the product for several days until the glue dries completely.

- Next, we make the flooring . For the slatted bottom, we distribute special holders along the frame.

- We select the spaces between the slats so that the mattress can easily be supported on them.

- We connect the slats with longitudinal bars.

- Now you can start installing the legs . To do this, we fix the beams on the inside of the corners of the frame.

That's the whole simple process of assembling a wooden bed frame.

Important : in order not to spoil the appearance of the bed, choose screws whose thickness will not exceed the thickness of the boards.

Drawings of a double bed with drawers

Here are several options for drawings according to which you can make a bed for two beds:

And this model has a drawer at the head in which you can store bed linen:

Another version with drawers located near the floor:

We detail the future bed

We have decided on the materials and tools; now we need to cut out the elements. If there is no special equipment and sufficient free space, then you should seek help from specialists. Moreover, in an apartment it is quite difficult to achieve rectangular sections when cutting. Since the bed is supposed to have a mattress, a base for it should be made of sixteen-millimeter plywood, the parameters of which are 1.6 by 2 meters. The remaining elements should be manufactured in specified quantities according to certain sizes, according to the developed drawing. From the main parts it is necessary to make the upper and lower base of the podium, the top for the headboard (1 piece), transverse stiffeners (at least three), two rigid transverse ribs, four limiters for the headboard and three racks.

Selecting a mattress

In most cases, a double bed made on your own ends up being much cheaper in the long run. And the maximum part of the costs is spent on purchasing a mattress. To purchase it, you need to clarify the dimensions of the bed so as not to remodel it or change the mattress, choosing a model that is suitable in size.

To make the crib comfortable, it is not recommended to save money on this element. The mattress must be of high quality and comfortable, and lie correctly on the base.

Many people try to make it, like a bed, on their own. But such work raises certain difficulties, because you want to do it in such a way that the final mattress turns out to be no worse than an orthopedic one that can be purchased in a store. You need to know that a homemade mattress should not be used by people under twenty-five years of age. And if a person experiences problems with the spine, he should definitely choose an orthopedic model in the store, taking into account his weight category, age and height when purchasing.

How to choose a mattress support

When the design solution for making a bed does not include a side, the mattress will most likely fall off it during sleep. On average, such a product weighs about eighty kilograms and is located on a highly sliding surface. This can cause injury and other unfortunate consequences. In addition, the mattress must be weathered and “breathe”. And a double bed, made by yourself, most often under its base does not have the space necessary for ventilation.

In such cases, the mattress should be attached to the base of the bed, but not tightly. After all, you will have to change the mattress covers, replace the product with a more comfortable one. In such cases, you should use Velcro for clothing. One side is sewn to the mattress, the other is fixed to the bed using a stapler. To improve ventilation, holes should be drilled with a milling cutter.

Stages of work taking into account the model

Depending on the model, the algorithm for making a bed will differ. Those who have not done this kind of work before should start with simple options. It is also recommended to study master classes in advance.

Children's room made of chipboard

In order to make a bed from chipboard for a child, you will need:

- 1 solid sheet of chipboard (you need to choose a good quality chipboard);

- 2 side drawers;

- 2 bars (of the same length as the drawers);

- 1 or 2 boards or timber to give rigidity to the entire structure (it is also possible to use furniture panels);

- 1 front wall of the box;

- 10-15 slats along the width of the bed;

- 4 legs with plugs on them.

This is a simple and beautiful model. The child is guaranteed to like it. It will be possible to assemble it from improvised means.

The assembly process begins with drilling holes for confirmations. You will need special drills (7 x 70); in extreme cases, regular drills (7 x 5) will do. You can assemble a chipboard bed with your own hands as follows:

- We fasten the headboard material to the drawers using metal corners.

- We attach the footboard using the same principle.

- We fasten the joints with confirmations. The result is a rectangular box for a child's bed.

- We install a support crossbar in the middle. To make the structure more stable, it is recommended to add another leg approximately in the middle.

- We fasten the bars to the sidewalls from the inside with confirmations.

- We insert the legs into the inner corners (under the block).

- We lay a grid of slats on the support beam and bars along the entire length. It is important to maintain the same distance between them. Their total number depends on the calculated width and size of the gaps.

- We screw the slats to the support and bars. If they are not available, making a bed from furniture panels will be even easier.

- If the project included decorative parts, we attach them.

The advantage of such furniture is that it is quickly and easily assembled. The result is a do-it-yourself single bed. You can make a drawing for it yourself or use ready-made calculations. To save time, it is recommended to purchase laminated material, since making a bed from chipboard with your own hands will be much easier.

The main material in this case is chipboard. Plates can be toxic, so it is necessary to check whether the manufacturer has certificates and how safe their products are.

Headboard drawing

Headboard assembly

Foothills

Side wall

Assembly diagram

Finished bed

Japanese style double room

According to the drawings, you can also make a Japanese-style bed with your own hands quite quickly. This model has a laconic design that will look organic in any interior. The bed is reliable and simple, does not require a lot of time and materials. An ordinary Japanese bed has the following parameters:

- length and height of the footboard – 1.6 x 1.2 m;

- headboard length and height – 1.6 x 1.5 m;

- length of side bars – 2.08 m;

- height of legs – 30 cm.

Differences in bed sizes in different countries, generally accepted standards

Naturally, the parameters may vary depending on the size of the mattress. To make such a bed you will need:

- furniture board (beech or pine is recommended);

- beam;

- fiberboard sheet;

- plywood:

- logs;

- middle beam.

To make a homemade plywood bed look unusual, it is decorated with decorative elements.

After cutting, there should be parts for the sides of the frame, four legs, elements for the footboard and headboard. So, the base for the bed is first assembled with your own hands, then strengthened with corners. The frame is mounted on self-tapping screws. The stiffening ribs are fixed with bolts from the inside. If the furniture is wide, it is necessary to tighten the frame with a longitudinal beam in the middle. After this, all that remains is to attach the slatted base and headboard.

Cut out parts

Assemble the frame

Install legs

Attach the headboard

Make a slatted base

Cover the headboard with fabric

Floating made of wood and metal

This design is not placed on the floor in the usual way. It seems that it is hanging in the air, but in fact the supports are securely hidden. You can enhance the effect with lighting from below. This is ideal furniture for high-tech style, but it is extremely rare. If there is a model, it is too expensive, so it is better to get by with a bed made by yourself.

For work you will need wood, a square metal pipe and combined materials. Instructions for making furniture:

- We start the assembly from the support. This is the part that will bear the main burden. We connect thick boards for support with self-tapping screws, treating the joints with glue. It is recommended to use metal corners for reinforcement.

- We install crossbars inside the contour.

- In the corners there are posts made of timber or boards placed at the ends.

- Now we assemble the frame on which the mattress is placed. We lay a board panel or several sheets of plywood on it, and fasten the outer sides around the perimeter. All that remains is to decorate the hand-made bed under the ceiling.

The support, frame and frame of a floating bed can be made of metal.

Assemble the support

Install crossbars

Add timber posts at the corners

Assemble the frame for the mattress, fasten it to the support

Lay the bed base

Secure the outer sides

Decorate the bed

With PVC pipe base

A bed for a country house is often made from these materials due to their low cost and availability. It is with them that beginners are recommended to start. You can assemble a swing bed with your own hands from PVC pipes and make it a two-tier bed.

Having decided to assemble furniture from plastic pipes, the master has complete freedom for creativity. To make a bed for a summer house with your own hands, pipe sections are glued together to form a base. A mattress and pillows are placed on top. If a bunk bed is being made, the joints should be fastened with fittings and glue to ensure that the structure is as strong as possible.

Cut pipes to the required sizes, assemble the structure

Install the mattress

Foldable to wall

This is the ideal pull-out bed for small spaces. It is equipped with a lifting mechanism that allows you to place it against the wall during the day, leaving more free space in the apartment. The folding bed can be easily installed according to the drawings. To make it you will need:

- transformation mechanism;

- beam;

- plywood;

- chipboard;

- furniture panels;

- legs.

Installation begins with the box. On its walls we mark how we will attach the mechanism. We fix it to the wall with self-tapping screws and metal corners, then assemble the frame from timber. We cover the frame with boards. At the last stage, we attach the bottom to the bottom.

Making your own furniture is not at all difficult, even if you are planning a rocking bed. The main thing is to apply imagination and skill. If the necessary tools are not available, you can rent them to save money.

Assemble the base

Make a body

Attach to wall

Assemble the bed frame

Connect the frame to the body

Reinforce the structure with a crossbar and install a base

Attach decorative doors

Ready product

Sample instructions on how to make a bed

First, the frame base is prepared. This part of the work is the easiest, because appearance at this stage is not particularly important. All mistakes made in the work can then be easily hidden with decorative finishing.

Now you need to determine the height for the legs (if provided for in the drawings), and add to its data the height of the panel, which is located on the sides. Four pieces of equal length are sawn off from the prepared block. A fastening element is fixed to each of them using self-tapping screws or nails.

If you already have a mattress, you need to measure its width and cut a couple of pieces of board to fit, leaving a small margin. They are fixed into metal fasteners, which are already installed on the legs. The next step is to measure the length of the mattress. Based on the data obtained, we prepare a pair of boards, the length of which is shorter than the mattress board by a value equal to the width of one leg. If the mattress is quite wide, it is recommended to provide an additional support beam in the central part of the frame base. To do this, the distance from the short sidewalls is measured, the board is cut to the required length and inserted into the central part of the base, secured with special metal fasteners.

Boards are attached transversely to a rectangular base, the gaps between which are about five centimeters. With their help, the mattress will be held and additional shock absorption will be created. The length of such boards should match the width of the future bed. They are fastened with screws.

It's time to move on to finishing work. We turn the manufactured frame base upside down. A board intended for finishing is placed along one edge, marked in size and cut. Similar actions are carried out on the second side.

The boards are glued to the frame base using carpentry glue, trimmed along the edges of the legs (top), secured with clamps, and the time required for the adhesive to dry completely is waited.

The edge is mounted on top. To do this, you will need a board whose width is eleven centimeters. It is necessary to cut boards from the workpiece along the length of the sides of the rectangular frame, bevel the ends at an angle equal to forty-five degrees. Small stiffening ribs made from a bar with a cross-section of five by five centimeters are installed on the walls. Everything is secured with glue and nails.

If you want the legs to look aesthetically pleasing, prepare boards that will hide them. Their height should be somewhat less so that the load from the bed does not cause damage. This finish can be secured with glue or self-tapping screws. In this case, you should try to ensure that the fastening points are not noticeable.

Now it's time for the headboard. At the back of each leg we attach boards 5 by 10 cm. Their height exceeds the base, but should not extend beyond the top edge. We grab the boards with clamps and drill holes that should partially go into the legs. We insert the bolts here and tighten them with a wrench, not forgetting the washers. The headboard turns out to be the simplest, in the form of a regular shield, adjusted to the size you need. If you decide to make a bed with a soft headboard, you will have to work a little more, but the task is quite doable.

All that remains is to seal the holes with putty and sand all the elements of the bed. Their surface should be processed until it becomes perfectly smooth. Now you can treat the bed with stain and only then with a varnish composition.

Decorating the bed

If you set out to do something unusual, then you can find a lot of options for designing a bed in a wide variety of styles - from classic to vintage or modern. But the easiest one to start with is painting the frame. To do this you will need stain and varnish. It is not necessary to use a primer - you need to remember that all work with toxic substances will have to be done indoors, so it is advisable to keep it to a minimum. The stain will highlight the texture of the wood, the varnish will smooth the surface and add shine. You can also use special paint that imitates various types of wood. This method will not only decorate the frame, but will also give it a more impressive look. You can upholster the bed with fabric; for this you will need material, foam rubber, a construction stapler and staples.

When painting, it is better to use matte varnish. It will hide imperfections in the wood and will collect less dust and be scratched.

You might be interested to know why foam mattresses are in demand?

Benefits of a homemade bed

The product is environmentally friendly. After all, the work uses materials of natural origin. The bed is durable and can be used for a long time, withstanding significant loads. It is possible to develop design solutions of various shapes, decorate at your discretion, and decorate the front and back walls with wood carvings. Working independently, you can make a bed of the required size, successfully fitting it into the interior of the room. In addition, there is a good opportunity to save money.

A few tips from the experts

If you want a double bed to fully meet your requirements and not be too expensive, try designing it yourself. The material for work should be selected so that it can be processed without difficulty and is not too expensive. It will be easier to purchase ready-made sheets and cut out the necessary elements from them, following your drawings.

It is recommended to acquire all the necessary tools. They will help you in your work and will always be useful in the future.

It is best to make a double mattress to extend its service life and give it strength. It is best if each layer is made of materials of different densities - this will provide additional comfort. Try to make the top layer denser. For cladding and padding, use natural materials that do not contain synthetic or chemical additives. Otherwise, there is a high probability of developing an allergic reaction. It is best if the mattress is purchased in a store.

If such work has never been performed, then it is best to place the double bed on a podium made of laminated chipboard. It’s not difficult to make; any novice craftsman can handle the job. There is no need to rack your brains over the design of retractable elements and lifting parts - free space is already provided on the podium.

It should be remembered that the design of the bed should be in harmony with the room and combined with other furniture.

Sleep is the main form of rest for the body. And to make it healthy and of high quality, you should sleep on a comfortable bed. And if it is also made with your own hands, the holiday will seem doubly pleasant. Go for it, and everything will work out for you!

Final finishing

After the manufacture and assembly of the bed is completed, they move on to its design. The frame is processed using sandpaper, paying attention to all irregularities. For decoration, stain is used, and after it has dried, a special furniture varnish is used. It is recommended to choose quick-drying paints and varnishes that contain polyurethane or acrylic resins.

Review of double beds with a lifting mechanism, selection rules

The headboards of double beds can be made more attractive in appearance by decorating them, installing foam rubber and creating fabric upholstery. If upholstery is not provided for furniture, the back should be thoroughly polished, removing nicks. The treated surface is painted or varnished to increase the protective properties of the wood.

The following materials can be used to decorate the headboard:

- Suede or leather. Not cheap options, suitable for luxurious interiors.

- Eco leather. It has good performance characteristics, relatively affordable cost, practicality and aesthetics.

- Velor or velvet. The advantage of such textiles is their stylish look. The downside is the accumulation of dust, which means you will have to take care of the headboard more often.

The selected material is used to upholster the wooden backrest, securing it with a construction stapler. On a large headboard, the fabric is also fixed on the front side. It is advisable to hide the staples with the help of decorative elements - for example, buttons.

Leather

Suede

Velvet