21862

Corner furniture will help you properly arrange a recreation area in a small living space. It fits perfectly into the geometry of the room, retains maximum usable area, providing enough space for guests. You can save money on buying furniture of a similar configuration if you assemble a corner sofa with your own hands, showing not only the skills of working with various materials, but also the abilities of a designer. The main thing is to be extremely careful in your work, not to rush, and the result will delight you with beauty and durability.

Peculiarities

Everyone knows that a sofa plays an important role in any residential or non-residential premises. On it, people receive guests, relax in the company of their nearest and dearest while watching TV or playing board games, and sleep at night.

Recently, instead of the usual straight models, people prefer to install corner sofas, which are distinguished by functionality and rational use of free space. Before you start making a sofa, you need to decide on its:

- Appointment. Think in advance about which room the product will be placed in. The dimensions and design of the furniture will directly depend on this. A corner sofa can be built for a comfortable family time in the living room, or you can make a small product for the kitchen.

Shape and size.

Here it is worth starting only from personal wishes and preferences, as well as from the features of the room where it will stand. For small rooms it is better to make compact and ergonomic models, and in a spacious living room it is worth installing a roomy and large corner sofa. As for the shape, it can be varied: in the form of the letter L, U-shaped, with or without armrests.- Filler. As a rule, foam rubber, padding polyester and holofiber are used as filler for upholstered furniture . Their choice must be taken with full responsibility. Here, the thickness of the material, its density, elasticity and resilience, as well as rigidity play an important role.

- Functionality. Some consumers prefer furniture with spacious drawers where they can store bedding or personal items. Also, corner sofas are often equipped with shelves and bookcases.

Wood or pallet frame?

Having decided to make a corner sofa, people must competently approach the choice of materials. They must be environmentally friendly, safe, durable and easy to use.

Advice: for beginners in carpentry, you should avoid materials such as laminated boards and large-section timber. Because they are expensive and difficult to process.

As for the variety of materials from which a sofa frame can be made, these include:

Pallets.

This material is budget-friendly. The process of making a corner sofa from pallets will take a minimum of free time. As a result, you will get an original model that harmoniously fits into loft, Provence or minimalism styles.- Beam. It is used in the manufacture of load-bearing parts of the frame. Glued laminated timber is most often used to create sidewalls . Its advantages include a perfectly smooth surface, ease of use and high technical performance.

- Plywood. It is of high quality, durable and easy to use. The unique properties of plywood are directly related to its production. Thanks to a special technology for gluing veneer sheets, the material has high strength. Plywood is much stronger than timber . Frames made from it do not deform during long-term use, do not absorb moisture, and do not dry out.

Natural array.

This type of furniture is a classic and is in great demand. Wooden furniture looks harmonious in different interiors. It is distinguished by its naturalness, environmental friendliness, aesthetics and long service life. You can make a sofa frame from different types of wood: birch, pine, oak, larch, beech, walnut, ash. Each individual option has its own advantages and technical characteristics.The frame of a pine sofa, although it has an affordable price, will not please its owners with its high quality. It is quite difficult to find high quality wood on the market. Because of this, the sofa will quickly fail and lose its attractive appearance. To prevent mold and fungi from appearing on the product, you must choose well-dried wood. Birch in the manufacture of frames is also affordable in terms of price, but has higher quality indicators . Such products will turn out to be quite durable and reliable.

Help : the most reliable and durable are sofas whose frame is made of timber and plywood or only plywood.

If you plan to make a large model, then it is recommended to make the bottom bar of the product from wood or chipboard.

Assembling the right side

After the left side has been successfully assembled, the question of how to make a corner sofa yourself is almost resolved. We begin to assemble the elements of the right side, not forgetting that its bottom will serve as a linen drawer. Using the already familiar method, we attach longitudinal beams to two identical side parts, then transverse ones.

Having assembled the frame according to the drawing, we sew up the bottom with plywood. We twist the backrest and screw the chipboard to it. After this, the side openings are closed with cut out slabs. The back of the sofa is covered with chipboard only if it will stand in the middle of the room. After this, we drill holes for the microlift. Bolts for fastening the lifting mechanism should be M6x30, with furniture heads.

Upholstery selection

When it comes to textiles, there are no limits to your imagination. The most common and popular upholstery materials are:

Velveteen. The fabric has a velvet texture, which is pleasant and soft to the touch. The material attracts buyers with its pleasant shimmer and high density .

As a rule, when upholstering upholstered furniture with corduroy, consumers give preference to plain materials or with checkered and striped prints. When stains appear on the surface, they can be easily and simply removed using stain removers.- Chenille. It has unique strength. Therefore, it is often used as upholstery for upholstered furniture. This material is warm and pleasant to the touch. It can be easily cleaned from stains with vinegar or alcohol.

- Flock. It is considered the most durable, reliable, environmentally friendly and beautiful material. In appearance, flock is similar to velvet. It is half made of synthetic fibers, therefore easy to clean and durable.

- Jacquard. Dense and elegant fabric, characterized by a specific weaving thread. It does not fade in the sun, is not subject to abrasion, and retains its bright colors for many years.

- Tapestry. Its technical characteristics are similar to jacquard. This fabric is reversible. Its advantages include strength and wear resistance. The presence of a special impregnation on the material prevents the appearance of stains and dirt .

Natural or artificial leather.

Although genuine leather has a high cost, it is distinguished by its strength, durability, and scratch resistance. This material breathes on its own, mold does not form on its surface, and is resistant to temperature changes. Leatherette costs much less, but is in no way inferior in technical qualities. Ornaments and patterns are applied to it, and the material goes on sale in a wide color palette.

All of the above materials have such positive qualities as:

- hypoallergenic;

- breathability;

- environmental friendliness;

- durability.

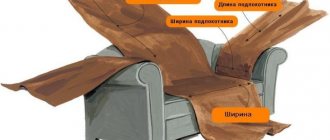

Drawing

In order to avoid problems when cutting and assembling parts during the manufacturing of a corner sofa, it is necessary to make a preliminary drawing of the future product. It will need to indicate the dimensions of all individual elements, methods of attaching them to each other and materials of manufacture. You can make a drawing in different ways:

- Draw your own version of the furniture on a piece of paper. In this case, you need to be able to calculate dimensions and draw in different projections.

- Find the best option on the Internet and modify it in your own way. This is the easiest way when you can choose an original design with all sizes and mounting methods.

- Use a special program on your computer. In this case, you need to be able to work with the cutting program. As a result, you will get a diagram in all variations and with the designation of all elements.

It is necessary to indicate on the drawing:

- the dimensions of the sofa and the overall dimensions of all components;

- back angle;

- when manufacturing a folding model, it is necessary to specify the transformation mechanism;

- thickness and hardness of upholstery.

Attention : when creating a drawing, it is necessary to take into account the projections of all working units of the furniture item.

Therefore, you cannot do without the ability to work with computer programs or the basics of drawing.

The procedure for transforming “sofa-bed”

Folding out the sofa takes place in 2 steps, but we will look at the process in a little more detail:

- Grasp the special loops or brackets located on the lower side of the seat with your hands.

- Move upwards and towards yourself to activate the mechanism. The seat will rise above the sofa and move forward.

Raise the sofa seat by pulling it up and forward - Place the seat legs on the floor. In this position, access to the linen drawer is open.

Lower the seat to a new position - Lower the back of the sofa, turning it from a vertical position to a horizontal one.

Turn the back of the sofa

The process of unfolding a sofa can be depicted schematically.

The pantograph sofa unfolds in two stages

And the bed can also easily be moved to the “sofa” position:

- Raise the backrest to an upright position.

- Raise the seat and push it towards the backrest.

Video: how the pantograph transformation mechanism works

Tools and materials

To make a corner sofa you will need to prepare the following materials:

Laminated chipboard or fiberboard for creating the bottom of drawers.- Legs for a sofa. These can be both purchased products and those made independently from timber. But there must be at least 9 of them.

- When making a folding model, you need to buy a folding mechanism.

- Filler. This role can be played by foam rubber, holofiber, padding polyester.

- Threads and fabric for upholstery.

- Self-tapping screws, screws and other fastening elements.

Tools you will need:

- screwdriver or electric drill;

- wood hacksaw or hand saw;

- sewing machine for sewing covers;

- upholstery stapler.

Kitchen corner renovation and restoration

If the kitchen corner, assembled with your own hands, begins to look unsightly, it can be restored, returning it to its original appearance. The method depends on which part of the furniture requires updating - the frame or the upholstery.

Frame

The front parts of the frame, made of wood or plywood, can be painted, varnished, or stained.

To do this you need:

- Remove fabric-covered elements.

- Remove the old coating, if any. Remaining paint can be removed with sandpaper.

- Seal the fittings or other parts of the frame that should not be exposed to paint with masking tape.

- Using a ditch and a brush, carefully coat the kitchen corner with 1-2 layers of varnish, stain or paint.

Upholstery replacement

The process of replacing faded, stained or torn upholstery is quite simple. There is no need to completely disassemble the kitchen corner - you need to remove the sofa seats from their hinges and dismantle the backs.

After removing the fabric, pulling out the staples, tear off the foam rubber from the strips. Cut out parts of the required size from foam rubber and fabric (faux leather, velor, microfiber, etc.), taking into account the dimensions of the wooden elements. Then reupholster, proceeding in the same way as when making furniture.

Replacing foam rubber and upholstery on a sofa: before and after

Making a kitchen corner with your own hands is not too difficult. The main thing is to accurately cut out all the parts, adhering to the dimensions indicated in the drawings. Even a slight deviation can lead to distortion of the structure.

Assembly diagram step by step

The general assembly diagram for a corner sofa will look like this:

- First, the armrests are assembled from timber and foam rubber.

- The frame of the left part of the product is mounted.

- The right side frame is assembled.

- Upholstery work is being carried out.

More detailed instructions for making and assembling a soft corner sofa for the living room or bedroom are as follows.

How to make armrests?

A corner sofa requires the manufacture of two mirrored armrests. Their length should be 90 cm, width – 20 cm, height – 55 cm. To make the armrests, take chipboard and 2 beams. The screws will be screwed from the chipboard into the timber in increments of every 20 cm .

The top and bottom of the armrests are cut out of chipboard and attached to wooden slats. Next, vertical support bars are installed on top and bottom of the sidewalls. As a result, you should get some kind of box, which will have one side, top, bottom and an open front wall with vertical elements. Now the armrests can be covered with foam rubber.

Right part

Next, according to the drawing, the remaining parts of the box are cut out and fixed with nails. To give the frame strength, you can additionally glue all fastening elements.

On the inside of the sidewall, in the place where the seat will be located, a chipboard overlay is installed. All sides of the product are covered with foam rubber, except for the back wall .

Now a second armrest is made, which is a mirror image of the first. The seat side and back are made from chipboard. The elements are fastened together with plywood.

We make two more similar parts for the second part and fasten them together in the same way. A vertical beam is screwed to the two sidewalls.

Important : To strengthen the structure, it is recommended to reinforce the rear wall with vertical support bars.

Let's move on to assembling the frame for the inclined back. For this, a support frame and two vertical slats are used. The manufactured frame must fit tightly into the previously assembled frame.

Now the seat is made from plywood. The thickness of the plywood must be at least 8 mm. The seat is installed on the frame only after it has been covered with foam rubber and upholstered with fabric.

Left side

Now let's start assembling the left side. This process is complicated by the presence of linen drawers. The left side of the sofa is assembled according to the same pattern.

First, the necessary sidewall parts are made from chipboard and fastened together with plywood and timber. All blanks are mounted on a frame and reinforced with vertical bars . Next, a frame for the backrest is made and a lifting mechanism is installed. The assembled frame is covered with foam rubber and covered with fabric.

Step-by-step instructions for upholstery

As for the finishing of the corner sofa, it is worth including the process of upholstering the product with materials. Work is carried out in the following sequence:

First, measurements are taken of all the parts that will be covered with materials and they are cut.- Before upholstery, all elements of the sofa are covered with foam rubber and padding polyester.

Since foam rubber will quickly lose its shape upon contact with fabric. A padding polyester layer will prevent wear of the foam rubber and make the seat and back softer and more comfortable to use . - The armrests are covered not with padding polyester, but with non-woven materials, for example, agrotextiles or spunbond.

- Three additional pillows must be placed on the back of the seat. Their inner cover is made of non-woven material, and the outer cover is made of beautiful and practical fabric.

Important : when cutting, you need to make allowances of a few centimeters on each side. Therefore, experts recommend not cutting out all the fabric at once. First, work is carried out on one part in order to understand how many centimeters should be left for allowances.

Tip : for the bedroom you can try making a couch, ottoman or sofa.

And next to the sofa, a coffee or glass table or even an ottoman will look good.

Corner sofas in the interior

The corner sofa is gaining more and more popularity due to the possibility of rational use of the useful space of the apartment, especially such rarely used space as a corner and a window sill. They look beautiful in any interior and are often equipped with spacious linen drawers and transformation mechanisms that allow you to turn them into a comfortable bed at the right time.

Corner sofas have been deservedly used in kitchens for a long time. With their help, it is convenient and effective to divide the space of combined rooms, such as a kitchen, dining room, living room or bedroom.

For owners of small apartments, such pieces of furniture will allow you to get in one piece a comfortable and roomy sofa for 5 seats or more, an extra bed and a drawer for storing linen or rarely used items.

Many craftsmen make corner sofas with their own hands. After all, for those who want to acquire such a product, purchasing a factory-made product may require large financial costs. In addition, often the room does not accommodate standard models.

Photo

The results of the work may look the same as in the photos presented: