01.10.2019

4892 views,

When choosing pieces of furniture, one of the main priorities remains their functionality. A bed with a lifting mechanism in the bedroom is not only a sleeping place, but also an effective component of furniture.

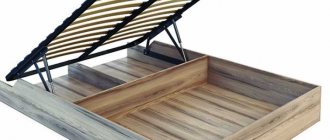

Beds with a lifting mechanism got their name due to the presence of a special elevator, which allows you to lift the mattress above the bed frame with just one movement. The box under the bed is often called a linen closet because it is where bed linens, pillows, and blankets are usually stored. In essence, such a bed is a mechanized system designed both for relaxation and for storing things.

Design of beds with microlift

A bed with a microlift when assembled is no different from its conventional counterparts. It consists of several elements, the main ones being:

- solid base with bottom and partitions;

- upper lifting part with slats;

- mattress;

- two or more microlifts;

- headboard, legs, lifting handles.

Furniture manufacturers pay attention to the quality of each individual part and the assembly of the entire system as a whole. In the production of beds, the practicality of materials is not the least important.

Manufacturing materials

Solid wood, laminated chipboard, plywood of various thicknesses, fiberboard and MDF are used everywhere in modern bed production. To optimize the price of the final product, these materials are usually used in various combinations. Traditionally, the most expensive remains an array of valuable wood species. A high-quality solid oak bed can serve more than one generation of users.

In the manufacture of beds in the budget sector and the middle price category, laminated chipboard, chipboard and pine timber are most often used for the manufacture of frames, fiberboard for the lower parts of the boxes, and birch plywood for slats. As for the materials for upholstery of beds, their number is measured in hundreds: from elite and expensive types of leather and tapestry to practical flock and artificial suede.

Materials

The main materials for making a bed frame are:

- Solid wood. This is a strong, environmentally friendly, durable raw material. The most popular furniture is made of oak, ash, beech, and alder. Some models can be made entirely of wood, while others use only wooden overlays.

- Metal. Characterized by high service life and mechanical stability. Welded and forged beds are made from this material. The latter are distinguished by their special sophistication and elegance. However, metal structures are quite massive, so they are not recommended for installation in small rooms.

- MDF and chipboard. Such products are popular due to their good quality-to-cost ratio. They are characterized by environmental friendliness, aesthetics, and a wide range of colors. Can imitate any type of wood. However, in terms of their performance properties they are inferior to wooden and metal models.

Criteria for choosing a mattress for a double bed, the best manufacturers

Different materials are used for upholstery: textiles, leather, eco-leather. The fabric can be plain or with a pattern. Among textiles, the most popular are jacquard, flock, chenille, and velor. Leather upholstery is often used in exclusive interiors. This solution is especially relevant for the head of the bed. As an analogue, you can choose eco-leather. It is environmentally friendly and affordable, and in appearance it is very reminiscent of natural raw materials.

A leather sofa bed is characterized by high durability, aesthetics, and a wide range of colors, but it is not cheap.

Solid wood

Metal

MDF

laminated chipboard

Textile

Eco leather

Advantages of beds with lifting mechanisms

When furnishing any space, especially limited space, each of us tries to use it as fully and comfortably as possible. In this regard, a bed with a microlift is undoubtedly an ideal solution. Everything that was used for a restful sleep at night can be put into the bed box in less than a minute, and just as quickly taken out before bed. Compared to beds with drawers, this system does not rely on the space around the bed, which is often severely limited by the small size of bedrooms.

Along with the rational use of space, the design of beds with a lifting mechanism makes it possible to choose a mattress in accordance with your requirements and preferences. Having decided to purchase a bed equipped with microlifts, you should pay attention to a number of points, taking into account which will help you purchase a functional and high-quality piece of furniture.

Specialized medical beds

People after operations and injuries need not only care, but also medical beds for the disabled and bedridden patients. Such models are supplemented with special mechanisms. They are necessary so that the patient can lie comfortably in a certain position or independently change the angle of inclination.

When making furniture, manufacturers are guided by the recommendations of doctors.

A bed for the disabled makes it easier to care for the patient. It will be easier to approach it, it is possible to connect additional devices and carry out procedures. The convenient design will protect against bedsores. A bed for bedridden patients is selected according to the type of drive. You can adjust the position manually or using buttons and a remote control. The choice depends on the condition of the patient and whether he can move on his own.

Features and options for placing a bed in a niche, furniture sizes

An orthopedic bed with a lifting function consists of a certain number of adjustable sections. In this case, a person is able to select the desired angle of inclination. The patient can be carefully seated or laid on such furniture, tilted to the right or left.

Mechanisms, their type and quantity

Different models of beds with lifting mechanisms can be equipped with different types of microlifts. By design, the following types are distinguished:

- simple devices on hinges that require significant effort to lift and hold the mattress;

- lifts on coil springs;

- microlifts with installed gas shock absorbers (gas lifts).

The first type of device is both the simplest in design and the cheapest. True, it can only be called a lift conditionally. However, hinged devices, due to their low cost, are great for small beds with light mattresses.

Lifts with coil springs are reliable and time-tested devices for beds in the mid-price segment. They are distinguished by high reliability and durability at low cost.

Gas-filled shock absorbers, successfully borrowed from the automotive industry, appeared in furniture production relatively recently. The smooth running and almost silent operation of gas lifts are highly valued by lovers of high-quality furniture. Among the disadvantages of such devices, some experts note high cost and limited resources. Be that as it may, well-known manufacturers produce gas-filled shock absorbers that can work for many years, and the trend is towards reducing their cost.

Having understood the structure of the lifting mechanisms, you should definitely pay attention to their number. It may vary. If two lifts are enough for an ordinary single or double bed, then three or more lifts are installed to lift large and heavy mattresses. The main thing is to ensure that the upper part of the bed is raised and lowered with minimal physical effort. High-quality mechanisms are equipped with special clamps that allow you to fix the upper frame in the open position both at an angle and horizontally. It should be understood that the number of lifts increases the cost of the entire system.

Upper frame and slats

The ease of use and durability of the bed largely depend on the slatted block, which takes on the weight of the mattress and the people lying on the bed. The frame of the block itself can either be made of wooden beams or have an all-welded metal structure. The second option is usually used in expensive bed models. Their high cost is more than compensated by the complete absence of unpleasant squeaks and an almost unlimited service life. In addition, the metal frame is much more reliable in places where lifts are attached, which take on serious loads.

Another important element of beds with lifting mechanisms are slats. They not only serve as support for the mattress, but are also responsible for improving its anatomical functions. Located at a certain distance from each other, the lamellas must be both rigid and elastic. In order for the slats to best perform their functions, they are made from multi-layer birch plywood. In high-quality bed models, slats made of five- or seven-layer plywood are installed. When choosing a lamella base, you need to pay attention to the distance between the lamellas. The smaller it is, the better. On average this figure is 5 cm.

Which mechanism is better to choose a lifting model?

It's hard to argue with the obvious benefits of using space under your bed to store all sorts of things. The space of the under-bed box is comparable to the volume of a clothes closet.

The most convenient access there can be provided by a lifting mechanism that unfolds the base of the mattress. There are several options for such designs, differing in mechanism and principle of operation.

Gas lift

Gas lift is a pneumatic type auxiliary mechanism. It consists of a cylinder, a piston and a retractable rod. The internal space of such a device is filled with air, which acts as a spring.

This mechanism is the most convenient and is installed on more expensive bed models.

Gas lift lifting bed.

Springs

A simpler mechanism involves the use of an ordinary coiled spring made of elastic steel. Having received the initial impulse, she herself brings the base of the bed to a vertical position.

Spring lifting mechanism.

Manual lifting mechanism

Small beds are sometimes equipped with a simple lever design, which requires significant effort to operate. Products of this type are considered a simple and reliable budget option. Before purchasing such furniture, you must make sure that your physical fitness is sufficient.

Manual lifting mechanism.

Features of models and small details

Considering that the main advantage of beds with lifting mechanisms is saving space, manufacturers are trying to optimize this parameter. This can be achieved by installing sliding panels in the bed frame, which form sections with a “double bottom”. You can put things that are not frequently used there, and put a pillow or blanket on top.

An interesting solution could be a removable cover on the bed frame. If you want to refresh your bedroom interior after a couple of years of using the bed, changing the cover will allow you to do this in a matter of minutes.

In high-quality bed models, everything is thought through to the smallest detail. Rounded edges, soft upholstery and legs located at some distance from the edge of the base can protect against bruises and abrasions, and the use of high-quality fastening elements can protect against annoying squeaks.

When purchasing a bed with a lifting mechanism, the buyer receives a spacious closet as a bonus, which is a very important advantage for small apartments. The best solution is beds with gas-filled closers. They cost a little more, but they perform better than others in operation.