What is MDF?

Unlike chipboard, MDF is not spelled as written. Fiberboard is MDF. The difference from chipboard is in the material of manufacture. Here fibers are used instead of shavings. MDF is much more environmentally friendly and harmless than chipboard due to the use of paraffin as an adhesive. The lamination process is the same as in the case of chipboard.

MDF is much more environmentally friendly and harmless than chipboard due to the use of paraffin as an adhesive.

MDF countertops with plastic coating are the most modern material. Their properties are similar to chipboard.

- Moisture resistant.

- Good resistance to cleaning agents/detergents.

- Service life more than 10 years.

- Excellent visual performance.

- Affordable price.

Table top made of MDF with plastic coating

MDF countertops have proven themselves on the positive side. They are the most common options in kitchen sets. High environmental friendliness and long service life contribute to this fact. Of course, there is no point in comparing MDF with wood, glass and stone. These expensive materials are of a higher class, and their performance characteristics are an order of magnitude superior.

MDF countertops with plastic coating are the most common options in kitchen sets.

MDF is a budget option. Price/quality that modern families are looking for. If you need to decorate a space in a modern style, using fiberboard is the best solution. It is suitable for High-Tech, Modern, Minimalism, Art Deco and many others. The plastic coating, which is applied using postforming, is finished to match any natural material. For a professional designer, this is an effective find.

If you need to decorate a space in a modern style, using fiberboard is the best solution.

What to do to make your countertop last longer

The countertop in the kitchen is the place where all food preparation processes take place: cutting vegetables, fruits, cheese, beating meat, kneading dough. Sometimes it serves as a dining surface.

For a countertop to serve for a long time, it must be of high quality: durable, resistant to water, household chemicals, high temperatures, and easy to clean.

Monolithic countertops are always preferable. Multiple joints do not add aesthetics to the kitchen set. In addition, cuts are often very vulnerable. It is through them that moisture penetrates into the material. At the joints, the slab may break off, and the protective linings may come off.

The tabletop will last longer:

- If it is made of high-quality, modern material with high resistance to moisture.

- The furniture was assembled by specialists. Sinks, hobs and other appliances are built into countertops. Sometimes the slab has to be cut to length. All sections of the craftsman are treated with special sealants and covered with protective elements. When assembling on your own, this rule is often neglected (or not known about it).

- Correct defects in a timely manner. Plastic and laminated countertops are protected from moisture until cracks form in the coating. Through them, water and dirt penetrate to the wooden base, and the tabletop swells. To prevent this from happening, cracks and chips must be repaired immediately or at least sealed.

- Use of water- and dirt-repellent impregnations. First of all, natural wood needs special impregnations. It is recommended to treat it every 1-12 months.

Materials used

When you visit a Leroy Merlin store or other online stores, you will find a huge assortment of countertops that are installed in the kitchen and bathroom.

We are talking about products for the kitchen, although similar designs can be used for the bathroom. You decide.

As for materials, there are several options:

- MDF;

- chipboard;

- tree;

- stone;

- granite;

- marble;

- acrylic;

- glass;

- stainless steel

Since some of the presented materials are already resistant to moisture by nature, I propose to focus on countertops based on chipboard, MDF and natural wood. Such designs are quite inexpensive, they can be found in a wide range in St. Petersburg, cities like Moscow, Kyiv, Kharkov, Chelyabinsk and Novosibirsk

Yes, in principle, in every city where there are furniture stores, there will probably be countertops that suit you

Such designs are quite inexpensive, they can be found in a wide range in St. Petersburg, cities like Moscow, Kyiv, Kharkov, Chelyabinsk and Novosibirsk. Yes, in principle, in every city where there are furniture stores, there will probably be countertops that suit you.

4070m dunes union

Chipboard and MDF

In terms of price and quality, laminated chipboard coating is considered one of the best options. To create a laminated surface, the coating is made of moisture-resistant plastic. Good examples of quality production can be seen among the HPL or Egger assortment.

In total, the laminated surface should have 3 layers:

- kraft paper;

- decorative coating;

- protective coating made of acrylic and melamine resin.

The paper is impregnated with synthetic resins, which allows you to create a durable multi-layer structure.

The outer layer provides such countertops with excellent properties in terms of wear resistance, light protection and heat resistance. They do not become deformed if dishes, sharp objects accidentally fall on the countertop, or if powerful detergents are accidentally spilled.

5004/s satin 600 3000 38 1u cedar

But high-quality lamination is not always performed by manufacturers. I would like to note that such products should be green in cross-section. This color is due to the use of special impregnations, which increases the moisture resistance of chipboard and MDF.

If you buy a low-grade design, you cannot count on its long service life. With constant exposure to moisture, gradual swelling occurs.

I accidentally conducted an experiment myself, leaving a section of a chipboard tabletop in water. Nothing actually happened to the material itself. That is, it did not become saturated with moisture and did not swell. But water leaked between the chipboard and the plastic surface used for lamination. Here she was just deformed.

It is unlikely that this could happen in real conditions. Only if the lamination is not completely done, there are rough seams or cuts that will be constantly exposed to moisture.

6402m metropolitan 1200 3000 38 2u union

Tree

Wood countertops are highly valued by designers, although a real housewife will probably tell you that wood is not the best option for a kitchen.

Similar designs are made from solid walnut, cherry and oak. These are the most popular tree species.

Wood is considered extremely sensitive to possible damage and does not like contact with liquids or hot objects, which makes caring for such a tabletop much more difficult.

I would advise you to avoid using wood if you want a truly high-quality, moisture-resistant countertop. It will not last long, and caring for it is too difficult. It is better to buy an excellent dining table made of wood.

Alternative options

I will briefly describe several other options that allow you to count on moisture resistance when choosing a countertop from the specified materials.

As you can see, there are worthy options on this list, and there are also those that are better to avoid. What do you think about this? Be sure to write your reviews if you have experience working with such countertops. Explain their strengths and weaknesses using personal example.

Still, the greatest demand among us is for moisture-resistant countertops made on the basis of chipboard and MDF. This is due to the reasonable price and good performance characteristics.

How to properly care for different countertops

Countertops made of stone, wood and artificial materials have different maintenance preferences. But this does not change the general rules. Need to:

- Wipe off dirt immediately. This is especially true for coffee, wine, fruit juices and all “colored” traces of food and liquids. This will prevent stains and the formation of dried crusts. When removing the latter, scratches may appear on the surface.

- Use mild detergents (dishwashing detergent) or special ones designed to care for a specific material. Too aggressive a chemical is more likely to damage the coating. Some folk remedies can also be dangerous. For example, ammonia and coarse table salt.

- Use cutting boards and heat-protective mats (hot mats). No matter what the manufacturer promises, and no matter how strong the countertop may seem, you should not place a hot frying pan on the work surface. The same goes for cutting food on it. It is especially important to follow this rule for laminated and wooden countertops.

Made of wood, chipboard, MDF

Most countertops are made from chipboard and MDF (wood chips and wood fibers). They are much cheaper than natural wood, but both have a common weak point - poor resistance to moisture. You need to care for them as follows:

- Wipe up all liquids immediately.

- Wash with a slightly damp cloth.

- When installing the meat grinder, use a soft pad that will protect the wood from deformation.

- Coat natural wood with protective impregnation.

It is forbidden:

- Place dishes on a surface with a temperature above 100 degrees.

- Use aggressive household chemicals.

- Spill boiling water on the table.

- Cut food directly on the work surface.

- Use steel wool.

Laminated and plastic

The most popular type of countertops. The chipboard board is laminated or coated with plastic, which makes it moisture resistant. Rules of care:

- Wash with a gentle detergent and a soft cloth.

- After washing, wipe dry.

- Repair defects in the coating in a timely manner.

We recommend: Effective products for bleaching enamel cookware

It is forbidden:

- Hit the surface with force.

- Place hot objects on the table.

- Leave the countertop wet for a long time.

- Throw forks and knives at her.

- Use caustic detergents, abrasive powders, hard scourers, and solvents.

From stone

Stone countertops are considered the most durable. Caring for quartz and ceramic countertops (made of artificial stone) consists of:

- Removing fresh dirt with soapy water and a cloth (brush).

- To clean old stains, apply a non-abrasive cleaner for 10 minutes and then wipe with a cloth.

- Metal marks from the knife are removed with the fleecy side of the sponge.

It is forbidden:

- Expose the stone countertop to sudden temperature changes.

- Drop heavy objects on it.

Acrylic countertops are resistant to heat, scratches, acids, acetone, alkali and other solvents. Natural stone – stains. They need to be coated with special compounds (water repellents) that clog the pores.

Stainless steel

Stainless steel countertops are resistant to high temperatures and stains. They are not at all afraid of moisture and are “friendly” with any built-in equipment. Caring for them is simple:

- Grease and other contaminants are wiped off with a soft cloth soaked in soapy water.

- Dry stains are pre-soaked.

- Polished stainless steel is wiped in the direction of grinding.

- If scratches and abrasions appear on the surface, the tabletop is polished or sanded.

It is forbidden:

- Use hard brushes, sponges, and cleaning products with hard particles.

- Detergents containing chlorine and ammonia.

- Drop heavy objects (dents will form).

Will this countertop suit my design?

Wooden surfaces in the kitchen also offer wide design possibilities and are a current trend. Here's what designers think about it.

“The world is becoming more urbanized, and people are experiencing stress due to lack of communication with nature. Natural materials in the interior, such as wood, stone, clay, help modern people feel comfortable in the “concrete jungle,” comments Valentina Konstantinova, creative designer.

The designer gives examples of using wooden tabletops in “star” interiors: “Jake Gyllenhaal, the star of the movie Source Code, uses a wooden tabletop in a Provence-style interior. The kitchen backsplash is finished with small boar tiles, and the furniture is exactly like in the south of France: soft blue with a chamfer and retro handles.

Since wood is not a moisture-resistant material, the part of the countertop adjacent to the sink can be replaced with an artificial stone surface, as in Sarah Jessica Parker's kitchen. The wooden countertop fits perfectly into the modern urban interior of the actress’s kitchen, built on contrasts of textures and colors - white stone and dark brown wood.”

Designer of the interior studio LOFT & HOME Anastasia Yarysheva believes that you can find a place for wood in the kitchen in any style, it is only important to approach the matter correctly. “So, a tabletop made of solid wood with knots, uneven texture, and aging effects will suit a kitchen in a rustic or loft style

But smooth wooden surfaces will look great in modern interiors, high-tech, especially tinted in white, black or graphite - such a tabletop will combine effectively with chrome and glass surfaces

It’s worth paying attention to options made from laminated wood – perhaps even from different species: the rhythmic pattern of the elements can emphasize the beautiful geometry of the room

Installation of chipboard countertops

Chipboard installation includes:

- measurements and cutting;

- edge processing;

- fastening and joining two sheets if necessary;

- sealing and installation of baseboards;

- cut out hole for sink and faucet.

First, measurements are taken and then the sheet is cut based on them. In this case, the length is measured taking into account the strip overlapping the ends. You can cut off the excess from the sheet using a hacksaw or jigsaw. If there are protrusions on the wall, then all the required recesses are cut out on the tabletop in advance.

Reference . The difficulty of installation lies in the careful cutting of the table top. Mechanical damage to the laminated layer leaves unsightly marks. Fastening the tabletop involves installing additional moisture-insulating elements - jumpers, plugs, corners made of aluminum and plastic.

The ends are lubricated with silicone sealant, an aluminum strip is applied and it is leveled flush. Secure the bar with small self-tapping screws and remove excess silicone. The edge of the surface that remains closed is decorated with edge tape.

Fill the rear upper edge of the cabinets with sealant. The back end of the tabletop is also generously lubricated with the same silicone. Plastic or metal corners are attached to the cabinet under the sink.

Important . It is necessary to adjust the height of the legs of the floor cabinets of the kitchen unit using a building level. If the legs are not adjustable, then adjusting wedges and plastic spacers are placed under them.

The countertop slab is carefully placed on the cabinets and either pressed tightly against the wall, or a 5mm gap is left from the wall, leaving a protrusion above the cabinets at the front.

Attach the countertop to the kitchen unit (not to the wall!). To do this, screw 30 mm screws under the countertop into the existing holes (16 mm under the sink). Install the plinth between the apron, table top and on the sides. If a corner fastening of the tabletop is performed, then the joint seam is hidden with an aluminum profile.

Important ! In custom kitchens, the work surface is common to all lower cabinets. If you are assembling a kitchen set from factory-assembled modules, then most likely you will need to connect all the countertops. All the necessary cuts are made in the plane, after which the connecting elements are inserted into the grooves and firmly pulled together. At the last stage, a hole for the sink is cut out.

How to properly replace a countertop

If we are talking about replacing the surface on an already installed headset, proceed as follows:

- the old surface is dismantled without damaging the kitchen unit - the sink and baseboard are removed and all fasteners are removed;

- the new surface must be adjusted to the wall and to the existing dimensions of the furniture;

- the height is controlled especially carefully, since it is important that the structure rests evenly on existing pieces of furniture;

- the resulting edges on the chipboard surface must be sealed, otherwise moisture getting inside will lead to swelling and destruction of the structure;

- fastening the tabletop also involves connecting several elements into one so that their height along the wall is the same, and there are no gaps between the elements.

The tabletop must be fixed to each of the lower cabinets with screws through stiffeners or corners. The screw pitch is at least 50 cm. All cut and sawn ends of the chipboard that are not covered with a protective film, including holes for built-in appliances and sinks, must be thoroughly coated with silicone sealant.

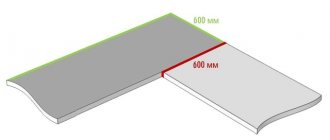

Important . The chipboard tabletop should be supported along its entire length; no parts of it should “hang in the air.” The supports are the walls of the cabinets and the stiffeners located between them. A gap in support at the locations of built-in appliances (for example, a dishwasher) up to 60 cm in length is allowed.

You can securely screw a screw into a chipboard board only once; it will not hold properly again. If you fail to do this the first time, it is better to change the mounting location or pour a couple of drops of epoxy glue into the hole. It is better to make holes for built-in appliances in the countertop directly at the assembly site.

If a product is ordered from a manufacturer with a ready-made hole, it should be transported especially carefully; the tabletop may simply break. Connecting slabs in a corner kitchen should only be done using special screw ties; this is the only reliable way to fix them.

Features of the production of wooden countertops

The basis for the manufacture of countertops is furniture board - a wood board that consists of small elements using serrated gluing. This material is very durable, but with sudden changes in temperature and humidity it can change its linear size. And that is why before purchasing a countertop you need to study the manufacturing details.

To avoid deformation during the production of furniture panels, gluing should occur according to the principle of perpendicular direction of the fibers of parts close to each other

Also no less important is the quality of the wood itself, it must be high, and before manufacturing the product it must be dried in a special chamber

One thing you need to know is that the cost of the countertop determines its quality, since the higher the value of the countertop itself, the more responsible the manufacturer is in its selection, which means that the likelihood of purchasing defective products is very low. And if there is one, the consumer has the right to return the product to the manufacturer.

How to update wood countertops?

Sooner or later, the surface of the wooden tabletop will have to be renewed - the wood will have to be re-saturated with oil. How often should this be done?

“It’s difficult to name a specific period; a lot depends on the specific operating conditions,” answers the Belinka brand technologist. — To understand whether it’s time to renew the countertop, apply a few drops of water to the surface and observe - if the wood quickly absorbs them, it’s time to take out a jar of oil. However, don’t worry, applying oil is not a difficult task, every housewife can handle it on her own.”

We wrote more about how to refresh treated wood surfaces in our blog.

Tabletop care

If you properly care for wooden furniture in the kitchen, then the question of how and what to cover a wooden countertop would not arise. It is clear that this element of furniture is one of the most loaded. Imagine what is happening in the work area when lunch is being prepared.

Of course, you need to be careful, of course, you need to spare the money that was invested in the headset itself. But what to do if things go wrong, if a masterpiece of culinary or culinary art is created in the kitchen? But often the housewife has to prepare several dishes literally in half an hour, since our modern times are dictated by the speed of life. Therefore, scratches from knives, marks from hot dishes, chips from a fallen pan, and so on, may appear on the kitchen countertop. This means that all this brings closer the time when this surface will no longer shine with novelty. That is, it will have to be repaired.

What can I recommend? First of all, do not cut anything on the countertop; use cutting boards; fortunately, today there is a huge variety of this product on the market. Use special coasters for hot dishes. In general, do not put them aside; let one or two always be present in the work area. Do not hang large dishes on the rails; that is not what they are designed for.

Read also: Connecting tabletops at an angle

Even all these tips cannot solve the problem in question. Therefore, small defects in a wooden tabletop are a reality that you will have to deal with constantly. But they can also be corrected with small means. Here are just a few useful tips on how to cover a wooden countertop in the kitchen if it has minor flaws.

- If small scratches appear, they can be veiled, for example, by soaking them with cotton wool soaked in strongly brewed black tea. You can use a walnut, rubbing the scratch with its kernel. You can even use machine oil for this.

- If the scratches are deep, then this area will need to be first treated with coarse-grained sandpaper, then sanded with fine-grained sandpaper, and finally polished with felt.

- The most difficult thing to deal with is minor abrasions on the surface of a wooden table. They stand out strongly on the surface with their pale appearance. If the flaw is not severe, then you can use the same black tea. But if the abrasion has reached the wood itself, having gone through all the protective layers, then you will have to clean this area and apply a new layer of oil or varnish.

Alternative options

The easiest way to answer the question of how to cover a wooden tabletop is to paint it. That is, you remove all the old coatings, seal surface defects with putty, sand it, and the last stage is applying paint.

You can cover a wooden surface with self-adhesive vinyl film. Fortunately, the options for its decorative design are enormous: the structure of wood, stone, leather, plain films, and so on. The most important thing is that all preliminary operations are carried out using the technology described above. And the sticker process itself is not very complicated.

It is important here that wrinkles and bubbles do not form on the surface of the new table, so you need to carefully smooth out the laid material, using, for example, a plastic spatula or a paint roller. I would like to remind you about this option for finishing an old tabletop, such as decoupage

Essentially, this is an applique that is made either from paper or fabric. Apply drawings to the surface of the table, gluing them with PVA glue or a special compound. And a colorless varnish is applied on top in several layers

I would like to remind you about this option for finishing an old tabletop, such as decoupage. Essentially, this is an applique that is made either from paper or fabric. Apply drawings to the surface of the table, gluing them with PVA glue or a special compound. And a colorless varnish is applied on top in several layers.

As you can see, there are quite a few ways to update kitchen countertops. What material to choose for this is up to everyone to decide for themselves. But, as practice shows, the majority of home craftsmen usually choose varnish. This is a simple application, plus long-term operation of the wooden product itself.

The varnished surface of the table is very aesthetically pleasing, practical, and also functional. A layer of varnish helps protect the surface and also prevents destruction, as it protects the wood well from moisture and other damage. Varnishing is especially important for worktops in the kitchen - wooden countertops are constantly exposed to mechanical stress and moisture. Let's see what varnish is used for a wooden table, how to properly prepare a wooden surface, and also how to apply the varnish correctly.

Kitchen and other furniture is made mainly of wood. The wood can be natural or it can be various materials made from shavings - MDF, chipboard, fiberboard and others. Tables can be without any coating or the surface can be treated with paints and varnishes.

Among the main advantages of wood are high thermal insulation, attractive and aesthetic appearance, a huge number of shapes, and ease of restoration. Along with the advantages, there are also disadvantages - wooden surfaces become dirty very quickly, the material is quite flammable, and is easily scratched due to even minor mechanical damage.

Oil wax for Osmo countertops

Osmo oil consumption per 1 m2 is almost two times less than traditional varnish or paint

Treating the surface of a countertop is not a simple matter. After all, it is the one that constantly comes into contact with food products, and therefore should not contain substances hazardous to health. In addition, this part of the table is regularly exposed to mechanical stress, so the top wooden covering must be resistant to abrasion and moisture. Just such a product is a hard wax-based oil from the German company Osmo.

The ideally selected composition of oil and wax components preserves the natural tone of the wood, serves as reliable protection against external factors, and is also completely safe for human health. It can have the effects of wet wood, a silk-matte surface or emphasize the natural grain of the wood. All products are certified and meet European quality standards.

Advantages of using oil – Osmo wax

The countertop surface is an area that is exposed to external factors every day. Food, papers, objects are placed on it, and hot coffee or tea can be spilled. As a result, the coating quickly wears out, cracks and peels. Oils from the German company Osmo are made using hard wax, which penetrates the pores of wood and creates a durable, moisture-repellent coating.

He is not afraid of mechanical stress or hot liquids. Spilled wine or coffee will not leave noticeable stains. And if this happens, then you can revive the damaged area in a few minutes. In addition to the above positive qualities, osmo oils have a couple of more significant advantages.

- Completely protect wood from rotting and deformation.

- Extend the life of the tree by two times.

- They have the highest degree of environmental cleanliness.

- Preserve the structure and highlight the unique grain of the wood.

Oil consumption per 1 m2 is almost two times less than traditional varnish or paint.

Features of using oil for Osmo countertops

Applying topoil 3058 oil suspension to furniture is not particularly difficult. Even a child can cope with this task. It does not need to be diluted, just mixed thoroughly. The oil layer can be applied with a flat brush, microfiber roller or sponge. During the work, a respirator or gauze bandage is not required. The oil is completely safe and does not emit harmful substances.

Procedure step by step:

- Prepare the work surface by final sanding.

- Apply a thin layer of oil mixture along the grain.

- Allow 8-10 hours to dry.

- Apply a second coat of topoil.

- After 7-10 minutes, remove excess.

It is important to note that a wet or frozen surface is considered unsuitable for coating with oil. The wood needs to dry and only then treat it with an oil mixture.

How to choose wood

The choice of wood will determine the appearance of the table, its strength and the level of complexity of manufacturing.

The tree classification can be structured as follows:

- Soft type: pine, spruce, fir, cedar and other woods.

- Hard type: oak, birch, beech, ash, maple, walnut, fruit tree wood.

- Very hard type: boxwood, yew, dogwood, birch wood

Once the choice of material has been made, we begin processing it.

According to the needs of different people, as well as in the case of individual distinctive situations, different characteristics of wood or its features are important:

- Rot resistant.

- Texture of the material.

- Price of raw materials.

To make a table, we need high-quality dried wood.

If your goal is to make furniture for a living space (and not just practice a skill), then you need to take into account the quality of materials without neglecting them. Dry lumber must be used. How it will be dried is up to you. Evaluate in advance whether you can properly dry the wood at home; if this is not possible, it will be more profitable and reasonable to order ready-made material. During drying, the wood will be deformed, this must be taken into account, but purchasing already dry wood is much more expensive. For high-quality drying at home you will need:

- constantly stable temperature conditions, otherwise the material will dry in waves;

- good ventilation in the room, no draft;

- It should be remembered that this process is very long; the material must be dried without being shifted from place to place for about six months.

Then think about the design of the product.

- Tabletop.

The shape of the tabletop can be round, square, rectangular, oval.

Here, strength plays an important role, as does the absence or low absorption of moisture by wood. Optimal material: pine, oak. For a pine tabletop, choose cheap but high-quality material - without rotten areas, cracks, protruding knots and other unnecessary defects.

- Table legs.

The legs can be made of a different material than the tabletop, and can be of the most bizarre shape.

Optimal material: birch, it is strong enough for constant load; boxwood and acacia are also suitable.

To make a table from wood, the material must first be treated with sandpaper. If you are just starting your carpentry career, you should use birch, pine, oak, acacia and boxwood in your work.

Unlike other materials, wood has a number of advantages.

There are several advantages when using wood in construction:

- easily subject to various processing;

- sufficiently resistant to changes in temperature and humidity;

- good shock absorption: practically no chips or scratches;

- simply undergoing restoration;

- environmentally friendly material;

- the cost varies depending on the type of wood and processing methods;

- the material is easy to saw, cut, and chip with special tools;

- does not require careful and constant care

- external aesthetics.

However, there are also a number of disadvantages.

That being said, there are some significant disadvantages to keep in mind:

- the cost is significantly higher compared to other materials;

- wood can become deformed under the influence of weight;

- without the use of special coatings it is not resistant to mold and mildew, corrosion;

- wood cannot be called a moisture-resistant material;

- Over time, the above aesthetic appearance may be significantly lost.

If you make a table and benches in the same style, you will get a very nice furniture composition for your home, cottage or garden.

Wood protective coating

A high-quality coating will protect the wooden tabletop from moisture penetration, scratches and stubborn stains. The tree is covered with:

- Oil and wax. The oil-wax mixture penetrates the wood structure and makes the countertop moisture resistant. The ideal option is bio-impregnation with beeswax and vegetable oil. Mineral and synthetic oils are also used.

- Water-dispersed compositions and varnish. The wood is covered with stain or colored glaze, and then varnished. It is important that the varnish is moisture resistant. It is applied in 2-3 layers. A durable film is formed on the surface, protecting the wood from damage.

- Polyurethane varnishes. Unlike conventional varnishes, they create an elastic film on the surface. She is not afraid of hot objects, does not chip, does not scratch. It comes in glossy, matte and semi-matte. Its only drawback is the high price.

We recommend: 6 rules for general kitchen cleaning – we can get it done as quickly as possible

No. 8. Glass tabletop - the embodiment of style

This is one of the most unique options for organizing countertops in the kitchen. It looks great, but at the same time has excellent performance. Such tabletops are made from tempered glass, which can withstand strong impacts, but if something happens it is not capable of injuring a person, because when damaged, large fragments with blunt edges are formed. Among the main advantages of glass countertops:

- high heat resistance;

- strength;

- moisture resistance;

- easy to maintain, but you need to be careful with abrasive substances;

- variety of appearance, because the image can be anything: solid color, abstraction, any ornaments, paintings and photos.

Disadvantages include a fairly high price, not very high wear resistance, and the fact that over time, chips will begin to appear on the surface. But with all this, the glass countertop looks very impressive and can become a highlight and decoration of the kitchen.

The nuances of choosing a wooden countertop

So that all of the above problems arise as rarely as possible, and no repair work is required. When choosing a wooden work surface for the kitchen, you need to take into account a number of nuances.

Material. If we talk about wood, the best options are oak, teak, walnut and beech and others. These breeds are strong and durable. But they are also the most expensive. If you choose other options, pine is the best. It contains resins that protect the wood from rotting.

Manufacturing method. Solid countertops (solid), which were mentioned above, are not affordable for everyone. Therefore, in the selection process, people often give options to glued models. The latter, especially if they consist of different types of wood, can combine strength, visual appeal and positive features of all types of wood that compose them. Veneer is a very thin covering of natural wood. In the case of the tabletop, he covers it with a slab of MDF or inexpensive types of wood. Finally, laminated options based on chipboard or MDF are very popular. They have a wide variety of appearances.

How to choose the right option?

Choosing a countertop is not an easy task. A huge number of factors come into play here. The key ones are:

- material;

- method of fastening and installation;

- dimensions;

- compliance with the general stylistic decision;

- ease of use.

Material

The material is the determining factor. The service life of the product depends on what material is used. Thickness is also important. Thin materials are not always able to withstand the load. Thick slabs, for example, chipboard, are also not a guarantee of long service life. If you choose natural materials - wood or stone, then you should not make the tabletop too thick.

Mounting and installation

Here everything depends on the choice of floor cabinets or brackets, whether they will be large or not. In the first option, the tabletop is installed on the cabinets and attached directly to them. The load is distributed evenly

It is important to calculate everything correctly here. If you are not confident in your abilities, then seek help from professionals

If you choose mounting on brackets, then you should take into account the thickness of the tabletop. You need to choose the most reliable materials and optimal thickness.

Dimensions

- Length. It all depends on your wishes, but you should focus on the standard length parameters: 1000, 1260, 2460, 3050, 3500 and 4100 mm. Also be guided by the area of the room.

- The standard width or depth of products is 600 mm. But this does not mean that you should have just such a countertop. If you have a huge kitchen, you can make the work surface wider. But if, on the contrary, every centimeter is important, then it is quite possible to reduce the size to 51 cm. Or maybe you want to divide the space into zones and make an island in the center? This will also require additional measurements. And more often than not, standards are inappropriate here.

- Thickness. There are also standards here. 27-38 mm are the parameters of solid wood and MDF. But stone and acrylic can be thinner, it all depends on how much load your table must withstand. Don't forget to consider aesthetics as well. The tabletop should fit harmoniously into the interior without weighing it down.

Compliance with the general style

This point should be given attention when planning. You need to measure the kitchen area and perimeter, as well as each wall separately.

This is necessary in order to determine not only the width and length of the tabletop, but also the height of the upper cabinets

Now it is important to decide on the location of the stove, sink and appliances, if it is built-in. It is worth determining what kind of kitchen set it will be - with a right angle or a beveled one.

Or maybe you will have a set along one wall - linear, and as an addition - a bar counter or an island in the middle.

Now it's worth looking at the color. Manufacturers often offer countertops in different shades. MDF and chipboard have the widest range. Wood is always chic and expensive, and its natural structure is always stylish. The color should be chosen very carefully.

Ease of use

Finally, it is important to decide whether your kitchen will be practical. Do you like everything about it, or maybe you should add some details or change the dimensions?

It all depends on your taste and wishes. Remember that standard countertops are a much more profitable option in terms of finance, but is it right for you? Such surfaces can be installed and, if necessary, repaired independently. That is, you don’t have to look for a specialist and spend money in vain.

A tabletop ordered according to your individual drawing is original and stylish. This will definitely not happen to anyone. You will enjoy every time you are in the kitchen. But the cost is most often very high. This largely depends on the material. Also, when installing a non-standard countertop, you will need to contact a specialist who will competently carry out the installation depending on the load distribution. Whichever option you choose, weigh the pros and cons and find what suits you. And the tips from our article will certainly help you with this.

How to choose a countertop for the kitchen is described in the following video.

Lamination with plastic

To use chipboard as a working surface, it is laminated, that is, it is endowed with protective properties. In this case, the surface and edge are lined with the same plastic, and the joint is closed so that moisture does not get inside the chipboard.

Lamination has a number of advantages for use in the kitchen:

- resistance to mechanical damage (scratches, abrasions);

- resistance to ultraviolet radiation and high temperature (up to 180̊C);

- resistance to moisture;

- hygiene (plastic does not absorb moisture and is easy to clean);

- wide palette of colors and textures.

Manufacturing companies offer a large selection of finishing materials for lamination: transparent plexiglass, PVC sheets, polystyrene, polycarbonate-based plastic, natural veneer (expensive and beautiful, but very whimsical). The choice is determined by operating conditions and financial capabilities.

Attention ! Although the laminating layer protects the board from moisture, it is better to choose a material with increased moisture resistance marked “B”. The edge of such a kitchen work surface should be made from PVC tape.

Most often, furniture factories use decorative paper-laminated material HPL (high pressure laminates). It is strong and durable, less susceptible to mechanical stress, and does not fade.

The plastic should be thick - this characteristic determines the durability of the kitchen surface. The thickness of Italian and German plastic is 0.8 mm, Polish and Russian - 0.4-0.5 mm. The thicker plastic can withstand temperatures up to 160 degrees and easily resists stains from coffee, red wine, beets and other liquids with dyes.

Interesting ! Plastics can be stylized to resemble various types of wood, stone, matte and glossy solid colors, metallic and fantasy special effects.

Features of choosing a headset shape

If the kitchen is large and square, the choice is a corner U-shape. This set assumes the presence of three spacious countertops for preparing dishes, many drawers and cabinets for storing food and utensils.

For smaller rooms, choose an L-shaped set, which is installed on two adjacent walls. With this layout, built-in household appliances, rotating and pull-out sections for storing kitchen utensils are used.

In any corner layout, it is important to follow the rule of the working triangle, according to which the refrigerator, hob and sink form the corners of the figure with each other. In this case, the optimal distance between two elements is at least 80 cm

For kitchens no more than 12 square meters. m use linear headsets. All elements are installed along one wall. The advantages of the layout include its compactness, the disadvantages are the lack of storage space.

Instead of a dining area, small kitchens have bar counters, and a niche under the window sill is used as an additional drawer. When arranging a long and narrow kitchen, use a parallel linear set. At the same time, experts advise not to forget about the rule of the working triangle.

Coating process

Proper treatment of a wooden surface is the key to its long service life. This rule especially applies to kitchen countertops.

In addition to the fact that you need to choose the right treatment product, it is also important to properly prepare the surface, apply protection and dry. The following describes the process of how to coat surfaces using oil compositions as an example.

The coating process follows certain rules.

Preparing the wooden surface

The first step will be to clean the countertop from all kinds of dirt and greasy marks. Next it is dried.

Before coating, the surface must be cleaned of dirt.

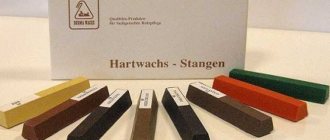

To ensure that the oil adheres well and is absorbed, the wood is sanded, starting with coarser abrasives, gradually moving to finer ones. Also, after each abrasive, the coating is cleaned. You may need to putty it to remove deeper scratches. A special restoration kit based on wax is ideal.

The wood should be sanded so that the coating lays more evenly.

Preparation of the product

The main thing you need to pay attention to when choosing a coating is its quality. A good protective agent will protect the wooden surface from mechanical damage and moisture and give it a shiny, renewed look.

The coating must be of high quality to provide the furniture with protection and a well-groomed appearance.

The product must also be prepared. Before treating a wooden countertop in the kitchen, the composition must be thoroughly mixed for 5 minutes.

The product must be mixed well.

Application

The composition is applied with a brush or cloth, and the latter should not leave lint on the surface. It will take about 12 hours for the first layer to dry. Then you can apply the next one, and so on. The number of layers will directly depend on how the product is applied. Using a brush, two treatments are enough; a fabric coating will require up to 4 layers.

Use a brush or cloth for application.

When the product is well absorbed, the entire treated area is thoroughly wiped with a soft and clean cloth.

After the product has been absorbed, wipe the surface with a cloth.

Drying

Drying time varies from several hours to several days. Naturally based oils or mixtures containing acrylic require a longer drying period. They can also increase strength gradually

It is important not to use a freshly treated countertop for some time.

After applying the coating, it is important to let the furniture dry

Oil, wax or varnish?

Caring for and proper use of a wooden countertop will extend its life.

A high-quality coating with good compounds will give a wooden tabletop a beautiful look and protect it from moisture and aggressive detergents.

In order for the tabletop to last longer and maintain its appearance, do not cut anything directly on the wood and do not test the surface for fire resistance and heat resistance.

How to cover a wooden tabletop so that it lasts as long as possible and at the same time remains beautiful?

- Oil, wax.

- Alkyd coatings.

- Water-dispersed compositions.

Depending on the coating, the same type of wood looks different: polyurethane gel, glossy varnish, wood oil

Ideally impregnated with oil, oil-wax. Oil, nourishing the wood structure, gives it water-repellent properties. When properly treated with good oil and wax, the countertop becomes resistant to household chemicals and detergents, which are often used for washing kitchen utensils.

The ideal option for protecting a wooden tabletop is a bio-impregnation based on natural vegetable oils and beeswax.

Apply the oil coating either with a brush or a rag evenly over the entire surface.

A special oil designed to impregnate wood that comes into contact with food will ensure environmentally friendly processing.

Oils for treating wooden countertops can be vegetable, synthetic or mineral

You can apply colored glaze, stain, and other water-dispersed coatings followed by application of varnish. The properties of the varnish used, its resistance to moisture, and multi-layer coating are important.

The varnish treatment option is better because the wood is coated with a protective layer, which is much stronger than oil protection.

A high-quality coating is carried out in several layers - two or three - regardless of the paint composition. Do not mix alkyd and acrylic coatings. Before covering the countertop with the base compound, it is important to select the appropriate primer.

Preparing a wooden table for varnishing

You can use a primer that matches the natural color of the wood, or a colored primer that matches the color of the varnish that will be used on the wood.

Advice!

For maximum durability, the coating should be renewed one year after application. It takes time for the product to “get used” to the surface at different temperatures. When exposed to external conditions, microcracks appear on the surface of the coatings, which are visually indistinguishable. Therefore, it will be useful to lightly sand the top layer and apply a new layer with the same composition.

Sand the surface and apply a layer of varnish along the wood grain

Beech wood before and after treatment: on the left – untreated beech, in the center – after treatment with white oil, on the right – oil varnish

The quality of the coating can be tested in the following way: apply a few drops of water to the countertop and observe how quickly they are absorbed. A good coating has excellent water-repellent properties.

Exposure to water can only be short-term - otherwise the wood will have to be sanded and waxed again

It is important to consider the drying time of the compositions; it can vary from several hours to several days. Natural oils and acrylic mixtures have a long drying period or accumulate strength gradually over time, so it is important to limit the use of the countertop during the drying period.

It is impossible to protect wood from scratches and mechanical influences with paints and oils, so there is only one way out - treat wooden countertops with the utmost care.

Wooden countertops are an excellent solution for modern kitchens

The slight carelessness of the wooden surface will give the kitchen...humanity. Isn't that what we value most? Humanity... Kitchen? Why not?

A place for wood can be found in a kitchen in any style, it is only important to approach the matter correctly

A wooden countertop in the kitchen is a beautiful and high-quality material that will decorate your kitchen