What material are the cabinets made of?

A TV stand is a fairly simple design, the manufacture of which does not require any exclusive materials

It is important to study the description of each of them and choose the most optimal option for yourself.

Table No. 2. Materials for making a TV stand

View, illustration Description

Tree

Wood is the most popular material option, which has been used for a long time for the manufacture of various furniture structures. Typically, products of this type are reliable and quite weighty.

It is important to choose the most suitable array option. So, experts recommend purchasing more durable materials: oak, pine. In addition, wood must be pre-treated and dried - otherwise the structure will quickly become unusable

One of the disadvantages is wood shrinkage. This means that after some time the product may become deformed. In addition, natural material is exposed to microorganisms, which is why it rapidly loses its original appearance. Otherwise, such products will last for many years without any problems. You will only have to periodically replace the varnish coating.

MDF

This is a modern alternative to natural wood. The material is made from a mixture of wood chips, which are pressed under high temperature. For greater strength, MDF sheets are coated on top with a special polymer film, so the boards can be immediately used for making furniture. The main advantage of the material compared to wood is its low price. In addition, MDF does not deform when exposed to moisture and high temperatures.

Chipboard

This material is often used for the manufacture of cabinet and built-in furniture. It is made from wood chips and resin of synthetic origin, which is why it is considered less environmentally friendly compared to previous options. It is better not to saw such material at home, because chips quickly appear on it. Its main advantage is its low cost, so chipboard should only be purchased if you have a very limited budget.

Plastic

This material is not particularly durable and is rarely used for making furniture. In addition, such a design can only support a small TV. In this case, plastic can be used to create additional elements. Among the advantages of the material, it is worth highlighting the variety of colors, so plastic sheets can be used for decorative purposes.

Plywood

Multilayer plywood is often used in the manufacture of furniture. Its main advantage is that it is a natural material obtained by gluing thin plates together. The disadvantages of plywood are that manufacturers often use low-quality glue to connect the plates, and they can come apart layer by layer. In addition, the finished structure will have quite an impressive weight, which is not always convenient. Plywood is often used to make the inner wall of cabinet furniture to reduce the cost of the product.

Drywall

An equally well-known material that is actively used for making furniture. The advantage is that drywall has good resistance to moisture, while it is quite durable. The only downside is that the finished structure requires additional finishing, and this takes time.

Glass

Glass TV stands have an attractive appearance. Such structures do not clutter the room. It is important to remember that only durable glass is allowed to be used for such purposes.

Metal

Rarely used for making furniture. Basically, this material is combined with wood or plasterboard. It is worth noting that metal models of products are heavy.

Required materials and tools

It is important to determine the main material of the TV stand for making it yourself. It should also be in harmony with the interior design. Self-assembly of a TV stand is made from popular building materials:

- plasterboard is a malleable and comfortable material; furniture of unusual shapes is often made from it, but it cannot withstand the loads of heavy equipment;

- Chipboard and plywood are budget options, easy to process, suitable for simple and undemanding products in terms of appearance;

- MDF is a good lightweight material with an attractive appearance, very durable and easy to use;

- natural wood (solid boards or furniture panels) is an ideal material for furniture; it produces uniquely beautiful things, including a bedside table.

Types of TV cabinets, popular shapes, sizes, colors

Additionally, fiberboard is purchased to cover the back wall and bottom of the drawers of the cabinet. In the case of designing an open shelving structure, you can do without it. Particular attention is paid to the selection of accessories for the cabinet. Each person calculates the number of necessary components individually based on the specific model. Required elements include:

- confirmations;

- self-tapping screws;

- small nails;

- shelf supports;

- drawer guides;

- handles or “push mechanisms”;

- hex plugs.

Before assembly, you need to check that you have all the tools that may be needed for the job:

- electric drill with drills 5 and 8 mm;

- screwdriver;

- Phillips screwdrivers;

- hammer;

- roulette;

- ruler;

- level;

- a simple pencil;

- Whatman sheet.

This list can be supplemented with a jigsaw and a grinder if you decide to make the cut yourself. It is worth noting that many companies provide similar services on site. This significantly reduces assembly time.

Drywall

Chipboard

Plywood

MDF

Natural wood

Required Tools

What types of TV stands are there?

Basic materials

The TV stand is not a complex structure. Therefore, you won’t need any unusual or fancy materials to make it yourself.

It is important to focus on the physical properties of the selected sample for manufacturing and the weight of the TV itself

Among the materials used, the following are in greatest demand:

- Tree. It is better to choose furniture panels made of pine. Wood processing cannot be called complex, however, different types of wood can ultimately manifest themselves differently, which should be taken into account at the stage of purchasing material. For example, it is not easy to process hornbeam, and wood brought from exotic countries is deliberately not varnished so as not to spoil the unusual, pristine appearance of the workpiece.

- MDF. It can be laminated or have veneer on the surface. A material that is easy to cut and perfectly holds all fixed fasteners.

- Plywood - consists of many layers, light and quite durable.

- The leader in light weight and low cost is chipboard. If the TV stand is built taking into account the large length and depth of the device, you can not be afraid to place a load of up to 80 kg on top. If the cabinet does not have significant dimensions, and the depth is only 30 cm, you will definitely need to make a frame based on a combination of durable wood or chipboard with metal.

- Fibreboard, as a rule, is successfully used to form the back panel of the product and the bottom of drawers, if they are included in the structure.

- Glass. To make a TV stand with your own hands, tempered glass is suitable, the thickness of which reaches 8 mm and above. Shelves or doors are made from glass components, located mainly near blind compartments.

Wooden TV stand

Purchase of fasteners and fixing elements

If you do not have the ability to cut parts from materials yourself or do not have the necessary skills, you can turn to carpenters who provide cutting services for help.

Traditional confirmations intended for working with furniture, dowels, and screws made of steel and brass are suitable as fastenings. The tools you will need are a drill with attachments, a jigsaw, a hammer, a marker or a pencil for marking. Working with glass requires the presence of glass hinges.

Design Features

The TV stand can be cone-shaped or angular. The first product has the shape of a cone with a mandatory narrowing upward or, conversely, downward; the height does not matter much. However, when expanding the floor base upward, remember the correct proportions of the panel; incorrectly calculated values may make it impossible to use the product, which will constantly “fall” on its side.

Corner TV stand

The model designed for a TV with a wide bottom is more stable. It is possible to make the device yourself, taking into account the correct placement of the fixing elements, which are assembled at an angle of no more than 90 degrees. The drawer should slide easily on the inside surface of the device.

In the cantilever model, the front part acts as the side plane of the cone. In this case, it is better to avoid placing boxes - such a device will become difficult to manufacture independently.

When constructing a corner device, it is important to choose the correct viewing angle that is most comfortable for the eyes of household members. Ideally, the TV and the bedside table under it should be located parallel to the sofa and armchairs placed opposite

Moreover, it is desirable that the base exceeds the dimensions of the equipment screen by at least 35%.

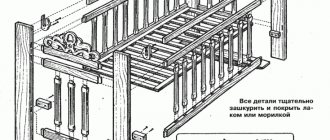

Assembly

After preparing all the parts that act as parts of the future structure, the assembly of this bedside table is carried out. To make your own TV stands truly high-quality and reliable, the basic rules of this process are taken into account:

- All parts are connected. To do this, you can use different fastening methods. Most often, holes are drilled in different elements, after which dowels are used for a reliable connection. Another method involves the use of self-tapping screws designed for working with wood or special confirmations, and the caps of all fasteners should be recessed quite deeply into the material. To prevent them from spoiling the appearance of the structure, special decorative stickers are used. The third option for connecting parts involves the use of eccentrics, which are used everywhere in the process of manufacturing various furniture. The difficulty of this method is that to work with eccentrics you must have the appropriate skills, since if you incorrectly calculate the depth or drill not too accurately, a through hole can be obtained;

- different shelves or doors are installed if they are planned in such a bedside table. Their number may vary, so it is possible to make a bedside table containing the optimal number of different compartments. Their sizes depend on what exactly is planned to be stored here;

- The boxes are being assembled. They are usually made from the same material that was used to create the entire cabinet. The depth and other parameters of such boxes completely depend on what will be contained in them. The facade must certainly be well suited to the entire structure;

- The fittings are fixed, making it easy to use different drawers or cabinets. For this purpose, handles and guides are used along which the boxes move.

Thus, the procedure for creating a cabinet on which the TV will be installed is a fairly simple and understandable process, for which different materials and elements can be used.

There are televisions in every home. Some people have them installed in bedrooms, living rooms, kitchens and children's rooms.

Therefore, TV stands do not lose their relevance.

Expert opinion

Stepanov Mikhail Filippovich

Designer of private and commercial interiors. 5 years of experience.

It is worth noting that they are provided by different manufacturers in a wide range, but if you wish and have some carpentry skills, you can make such a piece of furniture with your own hands.

How to make a sink cabinet with your own hands

It is not always the area of the bathroom or some of its specific features that allow the cabinets offered for sale to be placed there. And many people ask the question: “how to make a cabinet under the bathroom sink with your own hands?” We will try to answer this in the instructions below.

To make a bathroom vanity cabinet with your own hands, you will need tools.

Materials

A do-it-yourself bathtub sink cabinet can be made from the following materials:

- Drywall. It is inexpensive, can be waterproof, and products made from it look beautiful. However, a significant drawback is its fragility, so the frame must be made of a more durable material;

- Tree. It is a durable material, but expensive. In addition, it must be impregnated with special solutions to make it waterproof;

- MDF. Widely used for making DIY washbasin cabinets. Due to special treatment, it is water resistant;

- Plastic. It is also not afraid of moisture, has a long service life, but a significant disadvantage is its vulnerability to mechanical stress, as a result of which scratches appear over time;

- Combined bedside tables. For example, the frame can be made of a wooden block, the sides and doors can be made of MDF, and the tabletop can be made of plasterboard.

Use quality materials to make your vanity cabinet.

Finishing and decorating a bathtub cabinet can be done using self-adhesive film, varnish and waterproof enamels or veneer. The latter is the most expensive, but also the most beautiful material.

Design

Any cabinet under the sink consists of the following parts:

- frame;

- table top;

- sidewalls;

- doors;

- hanging parts.

There are many options for making a cabinet under the sink.

The frame, which is the load-bearing part and takes on the main load, is usually made of wooden blocks. The remaining parts that do not carry loads can be made from any other materials, based on the taste and preferences of the owner.

Connections

Prepare the tool you need in advance. Find on the Internet a ready-made drawing of a cabinet suitable for your bathroom. It must necessarily indicate the dimensions of all parts.

Next, to make a sink cabinet with your own hands, transfer the images of the parts from the drawing to the material of your choice using templates cut from whatman paper. Cut out the parts along the marked lines.

After assembling the product under the bathroom sink with your own hands, you can begin processing the finished structure.

The cutout in the countertop under the sink is done as follows: using a drill, make a hole in the countertop on the cutout line into which the jigsaw blade will fit, and cut along the markings you made.

Before you start work, you should decide on the choice of materials.

Once all the parts are ready, you can begin assembling the frame. Next, attach the countertop to the frame you made, into which you install the sink with the faucet and siphon already assembled.

Installation

Install the structure in its place; for reliability, you can attach the frame to the wall with corners. After this, connect the sewerage system to the siphon and the supply hoses to the mixer. Next, you can install the side of the bedside table in place, install shelves and drawers, and hang doors.

The sink cabinet can also be constructed differently, using slats and boards.

Peculiarities

The main advantages of self-made furniture include the ability to come up with a cabinet design and select building materials.

Despite the large selection of ready-made furniture in stores, consumers are often not satisfied with the dimensions of the product, its color scheme or model. You can make a cabinet yourself that will fully meet all your requirements. In addition, making furniture items yourself will cost much less than buying ready-made ones.

Important: before starting production, decide on the level of your skills. This determines what materials you can use in your work.

Pros and cons of making your own cabinet

The advantages of making and assembling furniture yourself include the following:

- The ability to make furniture exactly according to your parameters, because sometimes you need to make a cabinet of only certain sizes. Of course, you can always use the services of a professional master. It is worth considering that experienced specialists charge quite a large amount for such work, and besides, you will have to wait for some time.

- Work quality control. Not all furniture makers perform their work professionally. At the same time, various shortcomings cannot be detected immediately, but only after some time. When making a cabinet yourself, such problems are completely eliminated.

- Purchase of quality materials. Again, specialists often strive to reduce the cost of a product and purchase materials of the lowest quality, which quickly deteriorate during use, so saving on the services of furniture makers will allow you to purchase reliable materials and accessories.

- The opportunity to realize your creative potential. For many, making furniture becomes a favorite activity that brings pleasure. You can try to master this craft with such small products as a TV stand.

It is important to consider some of the disadvantages of making and subsequently assembling furniture with your own hands:

Any mistakes lead to financial losses. Trying to save money on professional services, there is a risk of irreversibly damaging the structure during installation. Especially often, beginners make mistakes at the stage of cutting parts - in this case, they will have to purchase a new sheet. There is a risk of injury. During the installation process, you will have to work with various tools, the improper use of which sometimes leads to physical injury. This is especially true when working with a circular saw or jigsaw. Parts may be damaged as a result of improper transportation, after which they can only be disposed of and replaced with new ones. The process of making furniture requires physical training, so people who are unable to lift heavy objects should not undertake this task alone. In this case, you can involve friends and relatives in the work.

May require a lot of free time

After all, a beginner is not always able to quickly draw up a drawing, then transfer it to the panel and carefully cut out the parts. At best, all this may take at least two weeks.

Therefore, it is recommended to evaluate all the pros and cons in advance, and only then start creating your own project. In order to eliminate possible errors in the manufacture of furniture, it is recommended to consult in advance regarding the installation of a particular structure with a specialist. This will make you feel more confident

In addition, it is important to carefully take measurements at all stages of the project.

Peculiarities

Modern TV models can be either compact or wide-screen, with the ability to be mounted on the wall using brackets, or simple with installation on a special cabinet or chest of drawers. In order to optimize space, especially in small apartments, flat TV screens are hung on the wall. However, the interior and construction features of the room do not always allow you to install the TV on brackets.

Window openings, bends, the thickness and material of the wall itself can interfere with this installation method.

But it also happens that the features of the living room interior require an individual approach. Products presented in furniture showrooms may not suit the customer in terms of dimensions or other characteristics. It is quite difficult to choose the ideal ready-made option that will correspond to the given size, design, color and functionality.

Therefore, more and more often, TV tables are made to order. But this option is quite expensive. An alternative and interesting solution would be the opportunity to make a cabinet yourself with your own hands.

Preparing for assembly

The first thing you should worry about is creating a concept for the future product. To make the process move faster, look at ready-made cabinets on the Internet. If this is your first job, you will still have to rely on something, adding some of your own elements. There is a rough understanding of what you want, and it’s time to move on to specific actions:

- You will definitely need a drawing. First, measure the place where the future bedside table will be located. Then, create your own drawing, or take a ready-made one, and modify it taking into account the obtained dimensions.

- Now you need to select the material. The criteria that you should focus on will be approximately the following:

- it should not cause you difficulties when working with it;

- must withstand future loads, remember, in addition to the TV, the cabinet very often becomes a storage place for other items;

- safety;

Typically, for the manufacture of such items, materials such as:

- glued wood panels;

- chipboard, mdf;

- plywood;

- various wooden beams;

- solid wood;

- drywall, but only with a reinforced frame;

For beginners, chipboard is best. Easy to work with, reasonable price.

- Before you start creating, you need to make sure that you have the following tool at hand:

- writing object (marker, pencil, etc.);

- construction tape and ruler;

- hacksaw;

- screwdriver and screwdriver;

- jigsaw;

- sander;

- glue;

- self-tapping screws and screws of different lengths;

- a compass, if you have to make rounded workpieces;

The list may vary depending on the tasks assigned.

- Work on the manufacture of a television stand will have the following procedure:

- According to the drawing, patterns of individual elements are made from thick cardboard; you can, of course, do without them, but for this you need to have a certain amount of skill;

- We manufacture elements of the future product using patterns;

- We process the manufactured parts with sandpaper or a sanding machine;

- if the material is made of chipboard, it is worth covering all the edges with decorative tape;

- use a screwdriver and screwdriver to assemble the individual parts together;

To ensure that your cabinet takes its proper place in your apartment, when creating it, apply a good Russian folk saying: “Measure once, cut once.” If everything works out for you, then the next step may be to open a small enterprise for the production of furniture.

Where to put?

When decorating an interior in a loft style, it is important to think through the placement of every detail and piece of furniture. As previously noted, the method of its design and functionality directly depend on the purpose of the room.

In bathroom

The bathroom cabinet is used primarily as a base for the sink. In this case, the bowl can be installed on top or embedded into the structure. The external design determines the design of the room and its color scheme.

A massive cabinet will look especially natural against the background of stone walls.

If the cabinet is made with an emphasis on antiquity, then its design can be emphasized with the help of a forged mirror frame with traces of rust.

Note! When choosing a method for processing the material from which bathroom furniture is made, take into account the special microclimate of the room with high humidity.

Cabinet stylized as a chest

It is worth understanding that, first of all, the furniture in the bathroom must correspond to the operational conditions of the room, have sufficient strength and functionality. Open shelves can be used to store towels and bath accessories.

In the living room

A light or slightly darkened cabinet can be chosen to accommodate modern equipment in the living room. The contrast will emphasize the special charm and originality of the furniture.

Living room in loft style

The living room is the main room in the house, where the whole family gathers in the evenings, receive guests, and celebrate family holidays. Therefore, special attention is paid to the design of a recreation area with upholstered furniture and a TV, the cabinet for placing which is one of the main accent items in the interior - it should have not only a stylish appearance, but also functionality. This piece of furniture allows you to organize a spacious storage area and save free space.

The style of the cabinet should be consistent with the rest of the furniture in the interior

The TV stand should be:

- Durable.

- Wear-resistant.

- Multifunctional.

- Easy to care for.

- Outwardly attractive.

Hanging cabinet in loft style

Modern household appliances are surprisingly combined with shabby brickwork, rough plaster, beams on the ceiling and all kinds of communications - pipes, cables, exhaust ducts, industrial fans.

The main criteria that a loft-style cabinet must meet:

- Functionality.

- Compactness.

- Sustainability.

- Conciseness.

- Strength.

There should be no elaborate decoration or carvings on the surface of the furniture; on the contrary, decorative design is expressed in the presence of cracks, peeling paint, abrasions, stains, and scratches.

A simple but quite roomy model with folding doors

What to look for when choosing

When choosing a TV stand, pay attention to the following characteristics:

- Sustainability.

- Strength.

- Capacity.

- Availability of high-quality fittings.

- Matches the interior style.

A hanging cabinet is visually easier to perceive

The basis of the structure is its frame, assembled from the side walls, lower and upper planes, and the back wall. The rigidity of the connection guarantees the strength and stability of the cabinet.

The size of the cabinet plays an important role.

Table 4. Recommended values for cabinet

| Index | Unit measurements | Recommended value |

| By height | cm | from 50 to 80 |

| By lenght | cm | from 100 to 300 |

| By depth | cm | from 45 to 55 |

A bright hanging cabinet is the main accent in the living room interior

According to the method of arrangement in the interior, cabinets can be floor-standing or hanging. Hanging ones are fixed to the wall using anchors or special furniture canopies. The main requirement is that the load-bearing capacity of the wall must ensure reliable fixation of the furniture element and the ability to withstand not only its weight, but also the weight of the equipment.

The floor model is traditional and, if necessary, can always be moved to another location. This cabinet is equipped with legs, wheels or a plinth.

Floor cabinets are the most stable and can withstand heavy weight

Where to put it?

When choosing the location of the TV stand, consider the following:

- Direct sunlight should not fall on the TV screen, this also applies to artificial additional lighting.

- It is important to take into account the distance from the sofa to the TV screen - it should not be less than three times the size of its diagonal.

- The height distance from the floor to the center of the screen cannot be less than 1.5 m.

- The cabinet is placed near the wall close to the source of electricity - at the stage of repair and removal of electrical points, the location of the TV should already be known.

- The size of the cabinet should allow you to freely position not only the TV, but also other related equipment, taking into account its operational requirements.

Video - Option for making a TV stand in a loft style

In the bedroom

A nightstand in the bedroom is a necessary item. You can’t do without it, since there is always a need to put personal belongings, a phone, a glass of water or a book, or a night light near the bed. Regardless of the level of functionality, there should be a bedside table in one form or another in the bedroom.

Being an independent component in the bedroom, the cabinet will emphasize the chosen interior style with its appearance. For ease of movement, the legs can be equipped with wheels.

Even the simplest bedside table will be useful

What to look for when choosing

The main requirement for all pieces of furniture is its ergonomics. Each piece of furniture must correspond to the anthropometric data of a person - this will be the key to its safe and comfortable operation. In this regard, three key criteria can be identified:

- The height of the product, which should correspond to the height of the bed: this way, the cabinet and bed will not only create an organic ensemble, but also ensure the comfort of using the furniture.

- The width of the product is chosen depending on the size of the bed - this way the bedside table will look more harmonious against its background. The larger the bed, the larger the width of the bedside table.

- The depth of the product is chosen so that the items to be stored fit into it. Usually 50 cm is enough.

Bedside table design option

Structurally, a loft-style bedside table for a bedroom can be used as a floor-mounted or wall-mounted one. There are many design options for the first type - it can stand on legs, have wheels, or be made in the form of a primitive box. Can be equipped with shelves, doors or drawers.

Floor cabinets with square metal frame

Using a hanging bedside table you can create a lighter atmosphere in the room. The peculiarity is that the distance from the floor to the bottom edge of a drawer or shelf can be from 10 to 50 cm. This type of design is especially relevant for small rooms, where it is important not to clutter the space with furniture, given that the bed takes up most of the room.

Bedroom cabinets are distinguished by their shape, which allows the product to fit into any interior.

The round loft-style cabinet looks unusual and can be used as a coffee table

Choosing material for a TV table

Material selection is an important decision for furniture production. Since it depends on this what characteristics the finished product will have

It is worth knowing that some materials are easy and comfortable to work with, while others require certain knowledge from the master or the use of a professional tool. To make the manufacturing and assembly process easy, you should familiarize yourself with the main advantages of various products. So, a TV table can be made from the following materials:

Chipboard is a simple material at an affordable price, made from pressed sawdust, easy to process, has a wide variety of designs, is lightweight, does not require special tools, however, it cannot boast of high strength. MDF is a wood-fiber board that is easy to work with, can be laminated or covered with veneer, finished products based on such a board can be used in conditions of high humidity, the material is environmentally friendly and durable. Plywood is a laminated wood board that has a low specific gravity, it is easy to work with, and the furniture is strong and durable. Furniture boards are planed beams glued together in width and length, made from coniferous wood, easy to process, have an attractive design and an affordable price. Solid wood is the most expensive and valuable material, strong, durable, environmentally friendly and aesthetically pleasing, however, to work with it you must have special machines and tools, when purchasing you should pay attention to the quality of the raw materials, the wood must be dry and free from defects. Combined material (glass, ceramics, plastic, plasterboard) - as a rule, such materials are used as separate elements, for example, shelves, countertops, doors, and so on. Fibreboard is a thin sheet material that is recommended for use on the back wall of the cabinet.

In addition to the material for the cabinet frame, you also need to purchase a number of additional products. In particular, when choosing chipboard or MDF as a base, it is necessary to choose the right edge tape, that is, a product that will hide unsightly end cuts. Today, you can choose from the following types of edges:

- PVC edge;

- melamine (paper) edge;

- aluminum edge.

At home, it is recommended to use a paper edge, since it is the easiest to install; just apply it to the end and heat it with a household iron, while the adhesive layer melts and firmly adheres to the base. Another important point is the choice of fittings and fasteners. Such elements include self-tapping screws, nails, confirmations, telescopic guides, handles, legs and other parts that will help fasten the walls, as well as install shelves and doors.

What to make it from: wood or chipboard?

Depending on the materials chosen for the manufacture of furniture, its appearance, practicality and ease of use will depend. Most often, home craftsmen use for these purposes:

- Natural array. This material is valued at all times for its naturalness and nobleness. You can make a TV stand from any type of tree.

Most often, craftsmen use: oak, ash, pine or birch. For elite and luxurious furniture, which will be the highlight of a classic interior, it is better to choose oak, beech or black walnut .

Linden, birch and pine are considered more budget options. When listing the advantages of solid wood furniture, it is worth highlighting: long service life, elegant appearance, beautiful texture. But not all tree species can be processed at home. For example, making oak furniture without the skills is quite difficult.

- MDF. This material is made from natural wood. TV stands made from MDF are extremely beautiful and aesthetically pleasing. But it costs much more than chipboard. The advantages of the material include: environmental friendliness and safety, low weight and uniform structure.

- Chipboard. This material is considered the most common due to: a large selection of colors, ease of processing, and affordable cost. Chipboard is a natural and safe material that does not emit toxins and does not provoke allergic reactions in people .

- Chipboard.

In principle, this material is practically no different from chipboard. The only thing is that its surface is covered with a melamine film, which increases the material’s resistance to moisture. Like chipboard, laminated chipboard is resistant to defects, environmentally friendly and is supplied by manufacturers in a wide range. - Furniture board. It pleases craftsmen with its even and smooth surface and ease of use. It is attractive in appearance, durable and resistant to cracking. Thanks to the wide range of furniture panels, you can make a bedside table of any thickness.

Divider stand

A popular design technique for decorating a large room is dividing it into zones. A simple but original TV stand can serve as such a separator. The secret of this product lies in its L-shape, which provides not only a place to place equipment, but also a vertical surface on which you can hang a small panel, or simply use it as a fence.

What will be needed to implement the project

Boards (for example, thick plywood):

- 10.5x1x4 inches;

- 5x1x4 inches;

- 5x1x6 inches;

- 15 fence boards of varying widths should be cut to 5 inches in length;

- 4 square bars 1x1x5 inches;

- flat metal staples – 3 straight, 3 angular;

- ½ inch screws for installing metal brackets;

- screws;

- electric drill;

- screwdriver;

- 1.5 inch flat nails;

- glue that is suitable for working with wood;

- spade drill;

- Heavy Duty Velcro;

- white paint, roller, brush;

- extension wire;

- ceiling lamp sockets;

- LED bulbs.

If the parameters of the TV stand in this project do not suit you, you should take individual measurements at the beginning of work. Then recalculate the parameters of the components, namely: height, width, depth. The structure of the shelf is simple, so no drawings are needed.

Instructions for use

- First of all, we assemble the side and middle L-shaped posts (3 identical ones) using metal corners and strips, as shown in the photo. We additionally lubricate the joints of wooden parts with glue. Protruding excess should be removed immediately.

- We attach a wide strip to the lower base of the L-shaped posts, which will be installed on the floor. We prepare the holes, connect them with nails and screws. During operation, we control the connection angle at 90 degrees.

- Assembling the front part of the back of the stand. First, we attach wide boards: one at the top, the second at the bottom. Then we select 1 narrow strip at a time. We install the remaining wide ones between them. We use glue and screws.

- We place the stand-bedside table in a vertical position, lay the boards on a horizontal plane-table top.

- We install the product in order to make the back part. Use boxes or other objects to avoid damaging the stand. We attach only wide planks to nails. In the lower part, you can not install the last board or prepare large holes in it for the wires. You can also make this part removable using Heavy Duty Velcro.

- Attach the strip at the top of the structure. The L-shaped bedside table is almost ready.

- Drill a hole on the front for the wires after you decide where exactly the TV panel will be installed.

- All that remains is to do the finishing coat. Take safety measures and cover the product with white (or other paint of your choice). Let the nightstand dry.

If desired, you can install colored lamps in the niches of the stand. They will provide soft light and a pleasant atmosphere in the dark.

Making a simple bedside table with your own hands

Prices for popular models of jigsaws

Jigsaw

Table 5. Process of making a loft-style cabinet

| Illustration | Description |

| You can use old wooden pallets as a material for making the simplest design of a bedside table. | |

| Before starting work, it is necessary to complete a drawing or sketch of the future product. | |

| In accordance with the drawing, the blanks are assembled - side and rear walls. Individual planks are fixed with glue using wooden pegs inserted into holes drilled at the ends. | |

| Knock down the lower and upper parts of the frame. | |

| All workpieces are carefully polished. | |

| The upper part is assembled from a frame and three planks. | |

| Then, using glue and European screws, the side elements are assembled, securing them to the lower and upper frame of the frame. | |

| The bottom of the drawer is made of plywood. | |

| The front and side parts are also assembled from boards cut from a pallet. | |

| Install the shelf on special stands. | |

| Mark and cut out a hole in the front wall of the box - it will serve as a handle. |