The cost of furnishings directly depends on the material they are made from. Laminated chipboards are widely used in furniture production - the products are inexpensive, have a wide range of models and a variety of shades and textures. To increase strength, moisture resistance and decorativeness, particle boards are covered with a laminated front layer in the form of a film based on melamine resins. You can make furniture with your own hands from laminated chipboard, but it is worth considering that if you cut it yourself, you can get chips on the front surface. Experts recommend making a drawing of the future product and ordering cutting of parts in a store or furniture workshop using special equipment.

DIY furniture from laminated chipboard

Features of the material

Prices for laminated chipboard

Laminated chipboard

Laminated chipboard contains natural wood - in structure it is chipboards that have undergone high-quality sanding and covered with melamine film. It is this coating that distinguishes the two types of slabs. Laminated chipboard has high moisture resistance and greater strength than conventional boards.

The laminated surface exhibits greater resistance to mechanical influences, as well as to chemically active substances - acetone, gasoline, alcohol, acids, solvents, coffee. Therefore, furniture made from chipboard can often be found in public places: in reception areas, in offices, in multifunctional centers, in educational institutions, in cafes, in kindergartens, in playrooms and children's rooms, in the kitchen.

The advantage of the material is the variety of its shades and textures

The film not only gives the material excellent performance characteristics, but also allows you to give it a unique appearance - from any shades and textures of natural wood, to images applied according to individual sketches. The ability to choose any shade allows you to produce cabinet furniture for any interior. This is especially true for children's rooms, where bright, rich colors are welcome. Bright furniture is also used for advertising and trade stands, as a body for reception desks with the possibility of being manufactured in the company’s colors with a logo.

Multifunctional cabinet furniture

Note! The laminated layer makes the surface of the chipboard monolithic and does not allow harmful substances that may be contained inside its structure to pass through.

The formation of the laminated layer occurs by pressing paper, which acquires properties comparable to plastic, filled with melamine resin under pressure (up to 28 MPa) and high temperature (up to 210 degrees). Decorative paper impregnated with resin is pressed into the top layer of chipboard.

The surface of such a plate, among other things, is heat-resistant, which allows you to place hot dishes on it - this has made laminated chipboard a popular material for making kitchen countertops.

Cutting laminated chipboard

Main assembly steps

Before making furniture, prepare a drawing of the future product. It is necessary to once again check the dimensions of the cabinet schematically marked on paper with the proportions of the prepared parts.

- Mark the extra centimeters of the laminated chipboard panels using a simple pencil, saw off along the lines with a wood hacksaw, clean the edges and cover them with an edge.

- Attach the side, bottom and top panels to the rear panel using a screwdriver and self-tapping screws.

- Before hanging the doors, mark the locations for the hinges. If the sashes are heavy, increase the number of fasteners, otherwise over time the panels may warp under their own weight. The distance from the edge to the bottom and top loops should not be less than 12-13 cm.

- Fasten the hinges and check the operation of the doors. They should fit tightly, without gaps or displacements. Don't forget to embed the mini-lock.

- For a cabinet with sliding doors, you should choose a roller mechanism that will be located at the top and bottom of the panels. Most often, aluminum elements are used for this.

- If legs are intended, then they need to be made before hanging the doors. After assembling cabinet furniture with your own hands is completed, check the stability of the structure, how level the cabinet is and whether it “sinks” to one side or another.

- Using self-tapping screws and strips, make supports for the shelves. The latter are adjusted to size after assembling the cabinet body. Special holders are sold for glass shelves that will not damage the base.

- It is better to equip drawers (if any) with guides, then they will slide out easily and freely, without the possibility of warping and getting stuck.

The selected material - chipboard, chipboard or solid wood panels - must be properly processed

When making cabinet furniture, pay attention to the fact that laminated chipboard may crumble during insertion of fasteners. The material requires accuracy and precision in outlines and actions.

Drying time is required after each coat is applied.

Pros and cons of using laminated chipboard for making furniture

The advantages of laminated chipboard include the following:

- Low cost.

- Easy processing.

- Ability to cut parts of any shape.

- The presence of a safe edge at the ends.

- The ability to create furniture with rounded corners, which is especially important for children's furniture.

- Excellent performance properties: mechanical, thermal, chemical resistance, moisture resistance.

- Preservation of operational properties throughout the entire life of the furniture.

- Wide range of colors.

- Easy care, possibility of daily wet treatment.

The laminating layer protects the boards from the negative effects of moisture, which makes it possible to make furniture from them for rooms with high humidity.

Kitchen set made of laminated chipboard

The disadvantages of laminated chipboards include the fact that they contain formaldehyde, however, the laminating layer and the sealed edge at the ends of the furniture completely neutralize the release of harmful substances into the environment. The edge also protects the slabs from moisture, which can cause them to swell.

Edge

As noted earlier, any part made of laminated chipboard must have an edge that will protect the material from moisture and the environment from the harmful effects of formaldehyde. Having a drawing of the product in hand, you can order sawing and edging from a specialized company that has special equipment. In the future, you can assemble the finished product yourself.

Melamine edge

Table 1. Types of edges

| Edge type | Description |

Melamine | The budget option is not of very good quality. Using an iron, you can glue it yourself. |

PVC | This edge is fixed using special equipment during the cutting of individual parts. It is made with a thickness of 0.4 mm and 2. A thin edge is made on the invisible ends, and a thicker one on the outside, where more serious impacts are possible. |

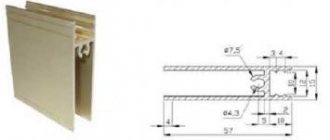

T-shaped mortise | A rare type of edge in use, which has a T-shaped section and is fixed into a groove at the cut. |

U-shaped waybill | A significant disadvantage is that the edges protruding a few millimeters are vulnerable to contamination. The advantage will be the ability to hide a poorly executed cut. |

Types of laminated chipboard structures

The use of laminated chipboard is widespread in various industries, one of which is furniture production. Laminated chipboard is used not only for the manufacture of simple furnishings, but also multifunctional furniture structures.

Kitchen set in modern style

Manufacturing of facades

The material from which the visible parts of the furniture are made, forming its decorative appearance - facades, must have an aesthetic appearance, match the style and color scheme of the interior, and also be moisture- and wear-resistant. If you need to make a drawer inside the cabinet, you can use a simpler material - 16 mm thick laminated chipboard with a 2 mm PVC edge. If this is the façade of a kitchen unit, then it must be made of beautiful and reliable material.

Minimalist facade of a kitchen unit made of laminated chipboard

The size of the standard facade is 2 mm smaller than the cabinet dimensions on each side. That is, if the cabinet is 60 cm wide, then the front will be 59.6 cm wide.

Dependence of furniture parameters and human anthropometric data

Kitchen furniture, first of all, should be ergonomic - convenient, comfortable and safe to use. Thus, floor and low wall cabinets have a height of 71.5 - 72.5 cm (it is worth taking into account the height from the floor to the top of the tabletop - at least 82 cm), and high wall cabinets - 91.5 - 92.5 cm. When manufacturing furniture according to an individual drawing, the anthropometric data of the apartment owner are taken into account when developing the latter.

Basic parameters of the kitchen set

Laminated chipboard facades differ from MDF in that it is not possible to create a relief pattern on their surface. However, this material is perfectly used to create sets in a modern style, the appearance of which requires minimal decor and conciseness. You can increase the decorativeness of the set by using fittings and inserts made of colored or embossed glass.

How to make a kitchen set yourself, what designs are the most convenient and reliable? More details in a special article.

Hidden elements – bottom and walls

To make the back wall of the box and its bottom, laminated fiberboards with a thickness of 3 to 5 mm are used. Their shade is selected to match the color of the chipboard used and fixed with the smooth side inward.

LDVP

Fastening LDVP is most often done using nails or self-tapping screws with a press washer. To prevent the plate from cracking, you must first make a hole for the screw and only then screw it in. When making drawers, a sheet of HDF can be fixed into a groove.

If it is necessary to increase the load-bearing capacity of the product, then the bottom is made of laminated chipboard.

Manufacturing of countertops

A horizontal work plane intended for preparing and eating food, performing activities related to reading books, writing, drawing, using a computer is called a tabletop.

Edge cutting

To design the working surface of the kitchen set, special laminated chipboards with a thickness of 28 to 38 mm, characterized by increased moisture resistance, are used. On their surface there is durable plastic, which is fixed using the “postforming” technology.

This technology consists of lining a chipboard slab with thin-thick laminated paper plastic under pressure and exposure to a temperature of 90 or 180 degrees. The difference is that in the first case, the slab is covered with plastic on the main side and at the ends, and silicone sealant is used to treat the joint of the coating.

Drip evacuation

In the second case (at a temperature of 180 degrees), the plastic completely covers the stove, going around the end of the tabletop, and sticks to it from the bottom, forming a drip tray. This is an important detail that protects the inside of the stove from moisture.

Note! For the manufacture of kitchen countertops, moisture-resistant chipboards are used - they are green when cut.

The most vulnerable point of a laminated chipboard kitchen countertop is the end cut, which must be hidden. In conditions of high humidity and intense operating load, a regular melamine edge will quickly cease to cope with its task. Therefore, aluminum end strips are used to protect the ends of kitchen worktops. There are also corner and connecting strips used to connect several modules that form a single tabletop - they cover the joints, protecting them from dirt and moisture.

Types of aluminum strips

Also, for protective and decorative purposes, a special plinth is used at the junction of the table top with the wall, when a decorative element of the required shade is attached to the guide.

From below, the tabletop is fixed to the floor cabinets using short self-tapping screws and horizontal spacers - this allows you to maintain the integrity of the smooth front surface.

Method of fixing the tabletop

Manufacturing of sliding doors

The sliding wardrobe is very popular - this method of opening the door allows you to save free space, which is important for small rooms. There are many models of sliding wardrobes: straight, five-walled, corner, trapezoidal, radius. Also, the main difference lies in the type of construction - stationary or built-in. In the first case, the cabinet is a box with two side walls and a back wall. In the second case, the side walls may be absent if the cabinet is built into a niche. If it is built into a corner, then you can dispense with one side wall. In this case, part of the load is distributed to the walls.

Basic elements of a wardrobe

The main element of such a cabinet is a sliding door, which, when opened, moves using rollers along guides. A sheet of laminated chipboard is inserted into a profiled frame; to achieve a decorative effect, it can be combined with other materials, separating them using an aluminum profile. The width of one door should not exceed 1 m.

Operating principle of roller guides

The guides along which the canvas moves are installed from below and from above. The upper guide is needed to fix the blade, and the lower one is needed for its smooth movement.

Plastic is used to make the lower rollers. The device is equipped with a shock-absorbing spring and an adjustment screw for adjusting the height. The upper rollers have a rubberized surface.

Accessories for sliding doors

Prices for components for sliding doors

Accessories for sliding doors

In a special article, we will look at the advantages of sliding wardrobes, the main nuances of their installation, and give detailed instructions on how to independently assemble a spacious wardrobe for a small hallway.

Video - Stages of assembling a sliding door at home

Making a drawer

A drawer is a convenient storage element, which is present in cabinet furniture models made from chipboard for any purpose - in a kitchen set, in a desk and office cabinet, in a closet, at the bottom of a bed.

Chipboard chest of drawers with drawers on roller guides

The main element of the design is the guide, which ensures smooth opening of the drawer. There are two types of guides: roller and ball.

The roller guides are fixed to the bottom of the box. Movement occurs using rollers. The peculiarity is that the drawer will not extend completely. If it is heavy, then there is a risk of the drawer falling out when it is opened more than halfway.

The situation is different with ball guides, which allow you to safely pull out the drawer to its full length, while the structure moves smoothly and there is no risk of it falling out.

Ball guides

Table 2. How to assemble a simple roll-out box on roller guides

| Illustration | Description |

Step 1 | One drawer will require two slides on each side. One will be attached to the side wall of the drawer, the second to the inner wall of the cabinet or cabinet. |

Step 2 | When attaching the guide to the cabinet wall, 2 mm are removed from the edge. |

Step 3 | Fix the guide with self-tapping screws so that their head does not protrude. |

Step 4 | The back wall and sides have an edge on one side and holes for Euroscrews on both sides. |

Step 5 | There is a groove on the facade for attaching HDF. |

Step 6 | The drawer front is fixed to the side walls using an eccentric tie. Screw a “Twister” screw into the hole until it stops |

Step 7 | Wooden dowels are inserted into holes with a diameter of 7 mm, which can be lubricated with PVA glue for reliable fixation. |

Step 8 | The eccentric is inserted with an arrow into the outlet hole at the end. |

Step 9 | The part is installed and tightened clockwise. |

Step 10 | The rear wall is secured using Euroscrews. |

Step 11 | The HDF sheet is inserted into the groove on the reverse side of the facade and aligned. |

Step 12 | Guides are screwed through the HDF. |

Step 13 | The LDVP is fixed to the back wall with several self-tapping screws. |

Step 14 | At the final stage, screw the handle. |

DIY wardrobe assembly sequence

How to make your own wardrobe in the hallway - this question is often found on forums. Here are simple instructions:

- The base and legs are attached to the bottom.

- Assembling the side panels and central partition, roof (if any). Everything is fastened with mini-clamps or confirmators, eccentrics.

- Installing the top shelf will add rigidity to the finished frame.

- The back is attached if needed.

- We install it for a future location. We check all the walls with a level.

- The internal shelves are marked, according to the project, rods, shelves, hangers, and drawers are installed. Fixed fasteners (confirmations) or removable (shelf holders).

Nuances of assembling the main parts

Cabinet furniture made from laminated chipboard consists of individual elements - lids, tabletops, walls, facades, shelves, which are called parts. Parts can be nested or overlaid depending on the type of assembly, which is chosen based on the upcoming loads. The service life of the structure and its safety depend on this.

So, in a floor-standing cabinet, the load is distributed from top to bottom - from the lid towards the legs, as shown in the first “correct” picture. The lid and bottom of the cabinet are overhead. If they are fixed in a nested manner, as shown in the second figure, then the correct distribution of the load will be hampered by a confirmat - a furniture screw, which will sooner or later pull out under tension, and the part itself will receive damage, which can only be eliminated by completely replacing the element.

Features of fixing parts in the manufacture of a floor cabinet

The situation is different with a wall cabinet. The load falls on the bottom shelf and if it is fixed in an overhead way, then sooner or later the tension screws will tear out and the bottom of the drawer will collapse. Here it is better to fix it using a nested method, when screws screwed in perpendicularly will resist the load.

Features of fixing parts in the manufacture of wall cabinets

General rules for assembling cabinet furniture

To assemble a cabinet or chest of drawers, you must first calculate the parameters of the future product. To make cabinet furniture with your own hands, the first thing you need to do is make a drawing with the dimensions of all the parts.

Before making furniture, prepare a drawing of the future product.

You also need to determine what material you will use during assembly. Depending on this, fasteners, tools and auxiliary arsenal (sandpaper, etc.) are selected.

You also need to determine what material you will use during assembly.

Wood as a material can be “capricious”; it is important to choose high-quality boards with a good, even texture, dried and processed. Birch, poplar, maple, aspen and other hardwoods are suitable. Conifers require special conditions, so pine or spruce must be selected in combination with some other variety. Try not to select layered rocks so that the base does not split during processing.

When making cabinet furniture, pay attention to the fact that laminated chipboard may crumble during insertion of fasteners.

Do-it-yourself cabinet furniture can be made of chipboard, MDF or laminated chipboard (the latter option is the most common). These materials are processed differently.

The material requires accuracy and precision in outlines and actions.

All details of the future cabinet must be carefully checked against the drawings and carefully adjusted to the intended dimensions.

Wood as a material can be “capricious”; it is important to choose high-quality boards with a good, even texture, dried and processed.

A specialized store will help you make adjustments (trimming). This can also be done using a ruler, pencil and a wood saw at home.

If desired, you can improve the appearance with original inserts.

Chipboard panels must be coated with a protective compound - this will reduce the risk of evaporation of resinous substances. Other materials do not require this approach.

Do-it-yourself cabinet furniture can be made of chipboard, MDF or laminated chipboard (the latter option is the most common).

Types of fasteners

Modern fasteners that are used when assembling furniture ensure the strength and durability of the structure, as well as its aesthetic appearance, since parts are fixed in a hidden way whenever possible, and those fasteners that remain outside are masked using special plastic linings to match the furniture .

Table 3. Types of fasteners

| Name of fastening element | Description |

Dowel | Dowels made of wood are used for preliminary fixation of two parts. After this, the structure is fastened with hardware. |

Furniture corner | Serves for fixing parts located at an angle of 90 degrees. This method is popular, but somewhat outdated and has its drawbacks - the element is not hidden, looks bulky and becomes loose over time. Corners come in plastic and metal. |

Confirmat | Modern furniture in most cases is assembled using confirmats - furniture screws, the threads of which, compared to conventional self-tapping screws, are larger, which ensures better fixation in the solid slab. After the screw is screwed in, the visible metal part is masked using a plastic plug to match the furniture. |

Eccentric coupler | Hidden fasteners used in the assembly of modern cabinet furniture from laminated chipboard. The holes for it are made in the factory using a Forstner drill. Considering that the thickness of the slab is 16 mm, and 12 mm must be selected for fasteners, the drilling accuracy must be ideal. |

Pinch bolt | Used to tighten two parts together. For example, bed bases and headboards. |

Selection of furniture fittings

In addition to fastening elements, there are other furniture fittings, without which the product will lose its decorative and functional qualities.

Table 4. Types of furniture fittings

| Name | Description |

Pen | A necessary element that provides convenience when opening doors and drawers. Fixed with screws. Selected in accordance with the color scheme and style of the furniture facade. |

Legs | For the stability of the structure, especially when the floor surface is not too flat, choose products with height adjustment. The material must be practical and durable, moisture-resistant and resistant to mechanical stress. The appearance is also selected according to the design style. |

| Silicone damper | An inconspicuous but important detail that ensures silent closing of the doors. Fixed from below and from above on the door or end of the cabinet. |

Loops | An important element that ensures the opening of the sash. Equipped with a mechanism for adjusting the height and depth of the door. |

Wheels | Used for comfortable operation of roll-out drawers and cabinets. |

Stubs | Masking fasteners. Matched to match the body. |

Shelf supports | Used for fixing additional shelves in wardrobes and racks. |

Hooks | They are used inside wardrobes and on panels in hallways. |

Crossbars and bars | They may have different cross-sections and radii. Used in wardrobes. |

Lock | Used for doors and drawers in cabinets and office shelving. |

Video – Furniture fittings

How to assemble a cabinet from chipboard with your own hands

Even a beginner can assemble a simple cabinet; to do this, you need to follow the following steps sequentially.

Table 5. Instructions for assembling the cabinet

Prices for the range of drills

Drill

| Illustration | Description |

Step 1 | First, you need to make a sketch of the future product in order to have a clear idea of the size and number of parts, fasteners and accessories. |

Step 2 | The cutting of parts is ordered from a specialized company or in a furniture shop, whose specialists must be provided with a clear list of parts with dimensions and designation of the sides to be edged. Where laminate edges will be made, subtract 2 mm. For example, if the length of the part in the drawing is 1085 mm, in fact it is necessary to cut out a part with a width of 1083 mm. |

Step 3 | Important! When calculating the distance of the walls on both sides of the box, take into account 13.5 mm on each side per rail. |

Step 4 | It is recommended to make the top cover of the cabinet 3-5 cm wider than the base. This will allow you to install it so that from below it does not rest against the baseboard or sockets on the wall. |

Step 5 | After the guide location line has been drawn and the element has been attached, using an awl, a mark is made at the locations of the holes where the self-tapping screw will be screwed in. |

Step 6 | Guides for drawers are screwed to the side walls according to the markings. |

Step 7 | Markings for confirmations are applied to the side walls. |

Step 8 | The drilling point is marked using a sharp awl. |

Step 9 | The hole is drilled so that the screw head is subsequently hidden under a decorative rivet. |

Step 10 | To fix the top cover, wooden dowels with a diameter of 8 mm are used, holes for which are drilled using a metal drill, onto which contrasting electrical tape is wound, indicating the drilling depth (12 mm) with a plate thickness of 16 mm. |

Step 11 | The distance from the edge is 8 mm. |

Step 12 | The dowels are fixed with PVA glue. |

Step 13 | To install the central partition, measure the length of the dowels installed in the lid array. |

Step 14 | Drill holes for dowels to the required depth according to the markings. The drill must be kept strictly horizontal. |

Step 15 | The dowels are lubricated with PVA glue and a partition is installed. |

Step 16 | Connect the table top to the side walls. |

Step 17 | A shelf is fixed to the confirmations. Using a clamp, fix the shelf and crossbar at a right angle. |

Step 18 | According to the markings, fix the shelf with a confirmation to the partition in the center. |

Step 19 | Using the method described above, another partition and shelf are installed. |

Step 20 | The decorative edge should be located on the outside of the product. |

Step 21 | At the next stage, partitions with guides and shelves are installed. |

Step 22 | To protect the floor covering, felt pads with a self-adhesive backing are used. |

Step 23 | When assembling the box, the distance from the edge under the confirmation is 8 mm. It is enough to retreat 30 mm from below and above. |

Step 24 | The bottom of the LDVP box is fixed with furniture nails. |

Step 25 | After the box is assembled, check its diagonals. |

Step 26 | Guides are fixed to the ends of the box. |

Step 27 | A handle is screwed to the front of the drawer. |

Step 28 | Drill holes for screws. Fix the facade. The screw heads are masked with decorative rivets to match the furniture. |

Assembly is the main stage of making a cabinet with your own hands from chipboard

Once all the necessary elements and fittings are ready, you can begin assembling the structure itself . It is carried out in the following order:

- Using a drill and special confirmation drills, we prepare holes for the joints. It is necessary to take into account all openings: for shelves, hangers, partitions, etc.

- We connect the bottom, sides and top of the cabinet together. To do this, just arm yourself with a screwdriver and screws. First of all, we lay the lower part, then we attach the side walls to it one by one and lay the upper partition on the U-shaped structure.

- At the base of the cabinet we install fasteners for shelves, hooks and other elements. Their correct installation can be checked using a level. Opposite fastenings must be placed strictly horizontally.

- At the very end, the hinged doors for the closet are attached. Before installation, it is better to install the handles, because in the future this will be more difficult to do.

The last step is to sand the appearance of the cabinet. A decorative edge is glued along all cut edges of the chipboard boards. All confirmations are hidden under special plugs, the color of which matches the design of the entire structure. Also, if desired, you can install mirrors, lighting and other functional or decorative elements.

Don't miss our article: Assembling a built-in wardrobe-bed with a lifting mechanism. It will be useful if you like to create furniture at home with your own hands.

The resulting cabinet, with a responsible approach to its manufacture, will have fairly high strength and stability. But most importantly, it will be a unique element of your interior that fits perfectly into the dimensions of the room. Moreover, the price of such furniture is significantly lower than the cost of similar models in the store.