In what areas of life and for whom is a business idea relevant?

Beautiful handmade items have always been highly valued. Market growth and increased supply have changed that. The most valuable steel

items made by hand. Moreover, in addition to the completed thing, a person receives a good time and new skills.

The specificity of products made from epoxy resin is that any product

turns out to be unique. They are often used in the design of a room,

decor. Also, there is almost no competition in this niche, which is favorable

will affect business.

What does a novice master need?

Although epoxy is a very pleasant and flexible material, it will be extremely difficult to make furniture from it without the necessary skills. It is not enough to just watch a video or attend a master class once. A beginner in this business will need:

- Practice pouring and sanding. To begin with, you should learn how to create high-quality formwork, pour resin, and process it after hardening. The goal is to gain the skill of making different shapes. It is also important to mix the solution correctly, use good hardeners and other plasticizers.

- Choose “your” material.” It is recommended to buy several types of epoxy to see which one is best for working with wood. A good resin should not turn yellow, crack after hardening, or release harmful substances, for example, at high temperatures. Its consistency is similar to vegetable oil, it is easy to mix and pour into the mold.

Useful to know > What dishes can be made from epoxy resin, manufacturing process

- Try combining wood and epoxy. The presence of a large number of pores in wood leads to the fact that the resin quickly fills all the holes. In addition, air can be forced into the solution, creating a large number of bubbles in it. Finally, the wrong size ratio of the wood and resin parts can cause the mold to split. That is why it is necessary to practice working with both materials, processing boards, and carefully sealing joints and seams.

Creating such furniture involves the use of various woodworking and sanding tools. Before work, be sure to familiarize yourself with the rules for using epoxy resin, precautions and safety precautions. Eyes, skin and respiratory tract must be protected. You need to work in a well-ventilated area and on a flat surface.

Creating epoxy furniture requires not only the ability to work with your hands, but also artistic vision. The master must imagine the object in advance, make a sketch, and then use materials wisely to realize his plan.

Pros and cons of a business idea

Here, as in any other business, there are advantages and disadvantages.

Let's take a closer look at them.

Advantages:

- Simplicity. The business is quite simple and a novice entrepreneur will be able to control all processes independently.

- Sales of goods. After each course, you will have items made by your students. You can sell them, which will give you additional profit.

- Part-time job. An important advantage of this business is that it can be used as a part-time job and will allow you to keep your current job.

Flaws:

- Search for clients. At the initial stage of your business, you may have problems finding your target audience. Later, as your business gains momentum, clients themselves will begin to flock to you.

- Growth limit. Unfortunately, there isn't a huge scope for growth here, and at some point you'll hit a breaking point. If you plan to increase your income from these master classes, you will need to open additional points.

- Expansion cost. If you decide to grow your business, you must be prepared for significant investments.

Manufacturing technique in general

In general, the manufacture of wooden furniture using epoxy resin follows a general scheme, but in each specific case additional steps may be added to the standard steps. This depends on many factors: the characteristics of the resin, the type of future product, the tools used, and so on.

Materials and tools

First of all, you need to buy epoxy and select wood. The breed can be any. By the way, there are also no special requirements for the quality of boards or slabs, the main thing is that they are dry. Defects can become the highlight of the furniture, so their presence is desirable, but not essential. Wood with flaws can even be obtained for free, since it is not used in production. You will also need:

- hardener;

- dyes, coloring pastes and pigments to give color to the resin;

- chisel;

- hammer;

- milling machine;

- sanding machine and belts of different grain sizes, from small grain to maximum;

- compositions for wood protective treatment;

- drill;

- screws, nails and other small items.

Useful to know > How epoxy resin rings are made, what types they are

You definitely need a formwork material that will not adhere to the resin; this can be acrylic, plywood covered with masking tape, or plastic structures.

Stages of work

You can start working directly only after a suitable room has been found and prepared, safety precautions have been observed and all materials and tools are available. Basic steps:

- Working with wood. If necessary, it must be sanded well. Next, divide into the required parts and treat the surface with a special compound. The sides that will border the resin should first be coated with the solution and allowed to harden. As noted above, this is necessary so that the epoxy fills all the pores and air does not penetrate into the resin layer. Once cured, it will be impossible to get rid of the bubbles.

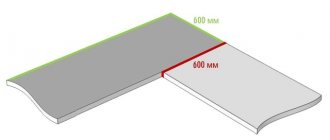

- Preparing the mold for pouring. It must be done in such a way that the wooden part of the product fits completely. All seams and joints must be taped or sealed with sealant (silicone).

- Mixing and pouring resin. It is necessary to strictly observe the proportions indicated on the packaging. Additionally, coloring pigments and, optionally, phosphors are added to the solution. When pouring, you need to make sure that the resin spreads evenly over the mold. While it is drying, it is worth covering the formwork to prevent dust from entering. Duration of hardening is at least 24 hours. In some cases it may take longer. In this case, you need to ensure that the room has an optimal temperature, since the resin completely sets only in warmth.

- Treatment. Once the mold is removed, sanding and polishing begins. If necessary, irregularities and excess pieces are sawed off. To give the surface a gloss, special pastes are used.

- Final works. They consist of attaching fittings, additional polishing, and varnishing.

Epoxy resin furniture can also be decorated with different elements. For example, pebbles, beads, fresh flowers. Any decor must be added at the pouring stage. Moreover, in this case it is worth making several layers, giving each one enough time to set.

Useful to know > What types of knife handles are made from epoxy resin and how they are made

You can make furniture from epoxy resin and wood yourself. However, this will require training, good skill, effort and time. If you like this kind of work and are ready to face difficulties and overcome them, then you should try to create the desired piece of furniture. But if you want to get a finished product quickly, inexpensively and with a minimum of effort, you should purchase it at a salon or order it from a craftsman. The price of such furniture will depend on its type, size, type of wood used and other factors.

Necessary documents for business registration

To conduct business you will need registration. Register your business in the form of an individual entrepreneur, because this way you will reduce the cost of paying taxes. If you

decide to expand, you can also easily register an LLC.

To register an individual entrepreneur you will need the following documents

- Application for business registration, filled out according to the sample

- Copies of all pages of the passport

- Receipt for payment of state duty

- Premises rental agreement

Business expenses

Business expenses are extremely small and will total about 35,000 rubles. Moreover

the lion's share of funds will be spent on the purchase of epoxy resin.

Monthly expenses will be much higher than at the start and

will amount to 50,000 rubles.

One-time expenses

Start-up costs are very minimal and amount to 35,000 rubles. Detailed list

includes the following items:

- Purchase of epoxy resin – 20,000 rubles

- Purchase of consumables – 10,000 rubles

- Conducting an advertising campaign – 3,000 rubles

- Payment for services of transport companies – 2,000 rubles

Monthly expenses

Monthly expenses total 50,000 rubles. More detailed article

expenses consists of the following items:

- Purchase of necessary equipment – 20,000 rubles

- Rental payment – 16,000 rubles

- Repeated purchase of epoxy resin – 10,000 rubles

- Advertising and business promotion – 2,000 rubles

- Payment for services of transport companies – 2,000 rubles

The amount of monthly expenses is very approximate, because some consumables

remain or it is possible to reuse them, which is essential

reduces the cost of purchasing them.

Necessary equipment for production

Any business requires certain equipment. So, to carry out

For master classes, in addition to epoxy resin, you will need the following equipment:

- Disposable gloves (50 pairs) – 300 rubles

- Disposable aprons (10 pieces) – 400 rubles

- Disposable respirators (5 pieces) – 250 rubles

- Working tablecloth for the table (1 piece) – 800 rubles

- Disposable cups (1 package) – 100 rubles

- Syringes (10 pieces) – 200 rubles

- Toothpicks (1 package) – 50 rubles

- Sandpaper (1 pack) – 100 rubles

The total cost of all consumables will be 2,200 rubles. The amount is small, but if you use it sparingly, then these funds, designed for one master class, can be reduced. To save money, don't throw away unused items, but save them for your next workshop.

In addition to the above, you can also additionally purchase watch movements and dials for making your own watches. Such things are very popular in the market, and therefore there will be a demand for them.

Equipment

The required set of tools and equipment depends on the type of products being manufactured. Let's look at a sample list:

- tools - mini drill, jewelry scales, tweezers, grinding machine for surface treatment;

- silicone molds (molds) for filling;

- furniture - table and chair, rack and shelves for storing materials;

- consumables: syringes, cups, stirring sticks;

- personal protective equipment – respirator and gloves;

- tools for working with wood (if a combination of resin and wood is planned) - milling machine, jigsaw, etc.

Resin molds

Premises requirements

To locate your business you will need premises. Art school or workshop classes are best. As for the requirements, they are not very strict. So, the classroom in which you are going to conduct classes must accommodate at least 5 people and have a good and strong table. Since epoxy resin does not have a positive effect on the body in an uncured state, the vapors should be removed from the room. Therefore, the room for master classes must have good ventilation.

Considering the fact that classes will be held weekly, get ready for

payment of rent in the amount of 16,000 rubles. It is possible that master classes will be

order clients to come to your facility. This way you can set your own price tag depending on your expected expenses.

Preparation and processing

Having prepared the texture in this way, you next need to figure out how to make sure that the boards lie and do not move when the epoxy is poured. To do this, you need to press the boards with clamps, and equip the places where there will be rivers, from the end and below, with neat but strong formwork. Moreover, there should be no leaks at the bottom when filling. If this problem is solved competently, then everything should work out. You should follow a step-by-step algorithm for creating a table.

Expert opinion

Oleg Vasiliev

Master of making furniture and interior items from epoxy resin. She creates unique items to order in her own production.

Ask a question to the master

The requirements for formwork are quite serious. In order for it to be easily separated from the epoxy river after completion of the work, it must have weak adhesion to the cured resin, or coated with an appropriate material, for example, polyethylene, PVC tape or a special release wax. In addition, it must fit very tightly to the boards to avoid leaks, even the slightest. The uncured resin has excellent flow even through a small gap.

- Prepare the mixture. Epoxy resin is mixed with hardener in the required proportion. Mix the contents thoroughly and slowly. Then add dye. Naturally, the river should be blue, but you can achieve a certain effect in the design of the color when the backlight is installed. But this work is carried out later, during the next pours, and the first one must be done smoothly and without any special frills.

- Pour in, and then wait for the composition to dry. Different brands of resin harden differently. It will take at least a day for the first layer to harden. With the next fills, you can add slightly different colors, make them brighter or lighter in saturation. And even integrate different design elements without disturbing the picture of two rivers on the table, but on the contrary, improving the color. Complete filling is done in several stages. After pouring the composition flush with the boards, the entire structure must be allowed to harden thoroughly.

Useful to know > How to make your own sink from epoxy resin

- After the mixture has hardened, use a grinding machine to sand the entire surface of the table. Next, treat with skins of different brands. As the masters say, there is no need to shy away from handmade work. A machine will not polish as accurately as a faithful human hand. After polishing, it is permissible to spray coat the entire area of the table with colorless varnish.

- Finally, you should make a base, which can be made of metal or wood, your choice.