Repair

0

64 361

Share

Partial restoration of kitchen facades allows you to update the interior, make it fresher, and visually attractive. Replacing a kitchen unit can be quite expensive, so you can only update the facade. This restoration technology will help change the appearance of the furniture, while its main parts will remain old, which will significantly save on replacing cabinets.

- Benefits of façade renovation

- How to fix the problem?

- Using heating devices

- Restoring coating using friction

- Application of glue

Benefits of façade renovation

Self-adhesive film was used to restore the facades. There are times when it begins to come off: if the MDF film has peeled off in the kitchen, you should not rush to replace it with a new one. The film often peels off due to humidity, temperature changes, steam, and the use of low-quality glue.

You should not be surprised if peeling occurs quite quickly, even during loading after manufacture or when the product has a short lifespan. The film peels off from MDF facades for the following reasons:

- The glue is not applied to the entire surface. When the substance is applied manually, the worker often misses sections of the product and the film does not stick to them. You can solve the problem by using colored glue.

- Using a cheap, poor quality substance. Quite often a two-component polyurethane composition is used. It is quite difficult to mix it in the correct proportion, so the glue hardens incorrectly and does not hold well, and bubbles may appear on the film.

- Using expired glue. When using such a material, the film will stick, but will peel off fairly quickly.

- Insufficient temperature during gluing, as a result of which the connection did not go well enough. There can be many reasons: poorly heated film, the vacuum was applied too early, the adhesive layer was thin, the workpieces for the facades were cold, it could have been cold in the workroom, the film was not pressed well enough, due to a weak vacuum supply, the wrong adhesive was chosen, the composition of which does not come into contact with a specific film. The facades themselves could also be used incorrectly: for example, they were located next to heating appliances, a stove, or sources of moisture. Before purchasing, it is important to find out how to properly care for furniture and for what conditions it was made.

What are film facades? Production of facades with PVC film

Film facades are manufactured using modern technologies based on MDF boards (medium density fiberboard). In terms of their parameters, these boards are close to natural wood, but much stronger. They are non-toxic, do not emit harmful substances, and are environmentally friendly. An important property of MDF boards is that they practically do not absorb moisture.

Traditionally, shaped milling is applied to the facade of the slab using modern high-precision machines, ensuring the quality and clarity of the design. When making custom-made furniture, the design can be made according to the customer’s sketches.

The next technological stage in the production of film facades is the application of PVC film to the prepared elements. Film is a very durable material. Usually it has a thickness of 0.3-0.5 mm. When heated, it becomes plastic. It is this property of the film that is used when it is applied to facades using thermal vacuum pressing. In this case, the film lies evenly on the surface of the slab, easily filling all the milling recesses, and after cooling it retains its shape, holds firmly and for a long time.

The variety of patterns of PVC film is ensured by the fact that it accepts printing patterns well and is easy to emboss and dye.

Therefore, the film can be glossy, semi-matte, matte, pearlescent, with a metallic sheen, imitating various wood species, marble, leather, textiles and other materials. In addition, the film can be patinated and varnished.

Such a variety of designs allows you to use furniture with film fronts in any room, with any interior: warm solid colors are suitable for the bedroom, marble or enamel film for the kitchen, wood-look for the living room.

Of course, all the positive properties of film facades are preserved only with strict adherence to manufacturing and storage technology. If the product is manufactured using outdated equipment, in violation of the conditions of production, storage and transportation, there can be no question of quality: the film quickly peels off and loses color. Therefore, it is very important to purchase products from more or less well-known manufacturers that have proven themselves well in the local or national market.

How to fix the problem?

If the film on the facade of the MDF kitchen has peeled off , you need to carefully spread it with glue from the edge and press it down. There is a chance that the film will take the desired shape. Another way to restore the coating is to use an adhesive membrane. To do this, you will need to lay the boards on a dry and flat surface, for example, on a table, cover them with a membrane, and use a vacuum. The membrane should tightly cover the facades. If you want greater reliability, you need to use high-quality glue and heat the material so that it can be activated. Warming up should be done evenly. This method is suitable only for unmilled facades: if the surface is uneven, the membrane will not stick and will quickly peel off. Therefore, it is so important to carry it out correctly, observing certain conditions.

Features of caring for film facades

Caring for film facades is really easy. They should be wiped regularly with a damp soft cloth and any non-aggressive liquid detergent.

In order for furniture facades with PVC film to serve for a long time without losing their performance properties, it is recommended to follow a few simple rules:

- do not expose furniture to heat above 70°, do not place it near an electric stove, heaters,

- lighting fixtures, etc., to avoid film peeling;

- do not expose film facades to cooling below -15°, prolonged exposure to moisture or strong mechanical stress;

- Do not use abrasive, aggressive agents, solvents or liquids containing chlorine to clean facades.

If you treat furniture with film fronts with care, it will delight its owners for a long time with its bright colors and smooth surface.

Author: Alla Dobrokhotova

Using heating devices

If the PVC film peels off from MDF kitchen facades, you can try replacing it with a new film or gluing the old material in place using available electrical appliances. This could be an iron, a powerful home or construction hair dryer. The film needs to be carefully warmed up: it should become quite soft and blurry, but not start to melt. If you have something to try, use these pieces or on an inconspicuous place on the façade. The device is pressed against the edge that is not glued for a few seconds. The film should stretch, the glue should warm up at this moment, and the material should protrude towards the back side of the facade and adhere firmly. If this can be done, then it will be possible to glue the entire facade in this way, in places where the film has retreated.

Advice: the film itself cannot be heated with a hairdryer at close range, as this will curl it and be damaged.

This DIY restoration of kitchen facades requires some skill, but is quite simple to perform and does not require the use of expensive tools or materials. If the inside and corners are poorly glued, you can use a metal rod comparable in size to the frame. First you need to warm it up. For this, you can use, for example, a gas burner.

Restoring coating using friction

Restoring kitchen facades from MDF using this method does not require any available tools at all. In order to glue the separated section of the film, you need to cover it with a rag and start rubbing it with your fingers, pressing the film. If there is adhesive underneath, the temperature from friction in a small area will be enough to activate a chemical reaction and cause the film to stick.

Advice: this method should be used carefully, as there is a high risk of damaging the film, exposing its edge or removing the top layer, which will ruin the appearance of the coating.

Application of glue

Restoring a glossy kitchen can cause some difficulties, since gloss does not tolerate strong physical impact, which is why it should not be roughly rubbed with your fingers or heated closely with any appliances. You can try a safer method - gluing the separated film using “Moment”. Most often, such a film peels off in the kitchen, since it is not affected by hot steam. It is necessary to restore the coating as quickly as possible, otherwise the furniture itself will be damaged. The glue must be applied to the untreated area of the facade and to the film itself along the edge so that it can isolate the seam from negative influences. All this must be done carefully, as the glue easily sticks and gets dirty.

Conclusion: inexpensive do-it-yourself kitchen restoration is quite accessible; it is advisable to look at photos of the finished results in advance. With a careful and competent approach, you can easily restore the appearance of the kitchen without resorting to replacing parts and without spending money and completely replace the facades.

Restoration of facades with decorative film

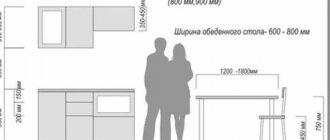

The appearance of the kitchen largely depends on the cladding of the facades. If your kitchen has smooth doors without a relief made of chipboard, then they can be easily covered with vinyl film.

Updating kitchen MDF facades with convexes will be easier if you use an industrial hair dryer. Only a well-heated film can take the desired shape. If there are decorative details on the facades, they must be removed before pasting.

Replacement of the old film is carried out only after removing the previous layer. Remember that decorative film is only applied to prepared surfaces.

It should be taken into account that in production, MDF film facades pass through a special press, which makes it possible to obtain a smooth surface without flaws. At home, MDF can only be covered with self-adhesive.

How to stick PVC film on an MDF facade

After the blanks are laid on a membrane-vacuum press and the PVC film is stretched, the most crucial and, perhaps, the most intriguing moment of the entire technological process of manufacturing MDF facades begins. However, before you turn on the press, you should study several important indicators.

Characteristics of PVC film for crimping MDF facades.

· PVC film thickness. Varies from 0.2 to 0.55 mm. The maximum possible and minimum required heating temperature of the film surface depends on it. If overheated, the polyvinyl chloride base will melt, which will lead to the formation of melted holes and a violation of the vacuum seal. On some types of films, due to such “toasting”, glossy spots are formed, which negatively affects the appearance of the finished MDF product. At low heating temperatures, the film will not achieve its elasticity properties necessary for successfully fitting the bends of parts and the reaction of the adhesive. Repeated heating of the film to the required temperature reduces its quality.

· Color of PVC film. It also affects temperature indicators during the manufacturing process of MDF facades. Dark shrink films acquire their technological properties at temperatures from 45 to 60 ° C. Light and especially glossy films can heat up to 120-135 ° C.

· Adhesive for PVC film. Here you should take into account the fact that some adhesive compositions are activated only after reaching a certain temperature.

· Room temperature and temperature of the membrane-vacuum press itself. In the hot season, as a rule, the heating process occurs faster, so you should be careful about overheating the film.

Having studied all of the above factors and made the appropriate conclusions, you can proceed directly to the process of covering MDF facades with PVC film.

Crimping of MDF facades with PVC film.

After turning on the heating, the PVC film in the machine begins to “move.” At this moment, you should be wary of the formation of large folds, which may later remain on the MDF facades. However, if you see a crease at the beginning of the heating stage, do not panic. The fact is that the first sign of “readiness” of the film is its stretching. At a certain temperature, all its folds are aligned, and it is pulled “into a string” above the surface of the press table. At this point the vacuum pump needs to be started.

The second sign that the vacuum can be turned on is the appearance of a slight haze above the surface of the film. This means that the maximum possible temperature has been reached and it is time to begin the tightening process. At this time, you need to slightly open the vacuum tap and turn off the heating for 2-3 seconds, and then turn it on again. The PVC film will begin to settle on the horizontal surfaces of the MDF facades. In places where the film comes into contact with the surface of the parts, it begins to cool, so there is almost no risk of overheating here.

After the PVC film lies tightly on the surface of the MDF facade parts and begins to bend around their sides, the vacuum taps should be opened a little more.

The formation of a vacuum also has the properties of absorbing heat. Therefore, heating should continue until the PVC facing film covers all the curves of the pattern on the surface of the MDF facade and its side parts, slightly tucked under the lower edge. Then you can turn off the heat, but the vacuum pump must run a little more, in case the press is leaking air somewhere.

It is worth remembering that PVC films have maximum permissible heating temperatures, exceeding which leads to melting and burnout. You should be wary of bringing the process to such temperatures. In cases where the maximum heating temperature has been reached, and the facades are not completely covered, or folds have appeared somewhere, it is possible to repeat the cladding process again.

To do this, let the machine cool down, open the taps, turn off the vacuum, and reheat the MDF facade backfill. The non-adhesive areas of the film will stretch from the heat, after which it will be possible to turn on the vacuum again and continue the pressing process.

Also, do not forget that glue for PVC film tends to react only at a certain temperature. Therefore, if the shrinkage of the film was successful, it is not a fact that the adhesive composition has been activated, and it is necessary, without turning off the vacuum, to heat the MDF facades in the PVC film to the required temperature for 2-3 minutes.

Source: mastermdf.ru

PVC film peels off from MDF kitchen facades! What to do?

It's no secret that the kitchen is the center of any home. And our task is not only to plan it competently - in order to spend a minimum of effort and time when preparing food - but also to exploit it so that its presentation will please us and our household for many years. Most often, the consumer opts for furniture made of chipboard with MDF facades coated with PVC film. This choice is explained, first of all, by the relatively inexpensive price, as well as the availability of a wide selection of configurations and colors. That is, there is an opportunity to satisfy almost any, even very demanding, taste.

DIY MDF facade repair

What to do if you notice that the PVC film is peeling off. First of all, if the kitchen is still under warranty, report this unpleasant incident to the seller. He simply must replace the defective kitchen facades with new ones. Perhaps the defect is associated with the quality of the glue with which the film is glued, or its insufficient quantity. Simply put, the manufacturer saved money on you. However, the seller may also ask how correctly you used the furniture.

If the warranty has already expired, you can try to fix the defect yourself. Fill a medical syringe with PVA glue or “Moment” type superglue, you can also use “liquid nails” and carefully glue it under the film. However, this method can be used if the film has simply peeled off. If it “shrinks,” which most often happens as a result of overheating, then there is little that can be done. Try to disguise with matching putties. But, despite all your efforts to restore furniture in this case, I cannot guarantee you a good result. The best solution would be to order new facades, but keep in mind that they must either be ordered for the entire kitchen at once, since film facade manufacturers do not guarantee an exact color match of films from different batches; or discover the designer in you and “play” with the colors of the facades. Let's say if your kitchen is light green, then you can order the fronts for the cabinets on which they need to be replaced, yellow.

Source: hobbi-mebel.ru