48910

Sliding wardrobes are popular designs designed to store numerous things and other items. They come in different sizes, are usually equipped with two or three sliding doors, and can also be made from various materials. The greatest convenience of this furniture for many people is that it is equipped with sliding doors, which are comfortable and silent during use. To use them, a special mechanism is used, and the profile for sliding wardrobes is its component.

Types by place of use

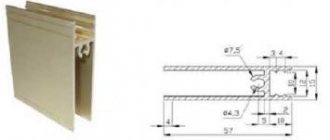

For the door system to function properly, you need a combination of several types of guides. There are 6 of them:

- Vertical profile. Frames the door on the sides and serves to connect it with other elements. Available in different configurations: straight, asymmetrical, S-, L-, H-, U-shaped. It is clearly visible on the façade and is used as a handle.

- Horizontal bottom bar. It is symmetrical, when cut it has the shape of the letter H. It serves to fix the rollers, covering them.

- Bottom guide. A profile with tracks for wheels, along which they slide when opening doors.

- Top bar. It is fixed at the top of the door leaf, connecting it to the rollers. Consists of 1-3 square or rectangular sections.

- Top guide. Symmetrical deep profile providing space for free movement of wheels.

- Connecting or intersectional profile. Used in combined decorative facades as a separating element between materials. Available in straight, zigzag, curved and wavy versions. The size of the connecting profile is smaller than the others, since it is installed on one door.

For suspended versions of the door system, the guides are swapped. The part with the rollers is attached to the top wall of the cabinet, and the supporting structure is attached to the bottom or floor. There are also universal combined guides that combine both functions. Their famous.

Types of sliding systems

The operating principle of all sliding doors is the same. Suspensions with rollers are fixed to the canvas, which move along the upper or lower rail guides. The difference lies in the materials of manufacture, the presence or absence of profiles, and the number of rail guides.

Steel

Sliding systems use high-quality steel, coated with reliable anti-rust compounds. Steel profiles are inferior to aluminum profiles in all respects: strength, reliability and ease of use. The only plus: low price.

If you choose high-quality components, the steel version will last no more than 8-10 years. Steel profiles are often deformed - the rollers move off the rails and make noise when moving.

Steel profiles are less durable than aluminum

Aluminum

Aluminum sliding options have more advantages than steel ones

This is a relatively plastic and lightweight material that allows you to produce profiles of different configurations and colors. Aluminum profiles do not spoil the aesthetic appearance of the built-in wardrobe; with a certain design idea, they only complement it.

Due to the greater thickness and closed section of the profiles, they can be used to hang doors more than 3 m high and 1.5 m wide. These are not achievable parameters for steel options. The closer, which ensures silent and smooth movement of doors, can only be installed on aluminum profiles.

The service life of aluminum systems is 15-25 years, depending on other components.

Relative disadvantage: it will cost more than similar steel options.

The soft closing closer can only be installed on an aluminum profile

Sliding systems are divided into two types:

- Frame . In these systems, doors are edged with aluminum or steel profiles, which increase the stability, reliability and smooth operation of the door leaf.

- Frameless . In this option, door edging is dispensed with; the rollers are attached directly to the door leaf. This is a less reliable and durable design, designed for low weight. During regular use, the door material becomes deformed and begins to crumble. The only plus: low price.

Sliding options for radius cabinets or other non-standard configurations are made to order. These are bent, semicircular profiles that follow the contours of the furniture.

Depending on the installation location and the number of cabinet doors, the guides are:

- top or bottom;

- single or double.

Guides are needed for smooth movement of the door when opening and closing.

The sliding system uses large rollers to support movement and small auxiliary wheels. They come in aluminum, steel, plastic, and are mostly equipped with a rubber rim.

Supplementing the rollers with bearings and shock absorbers ensures smooth and silent door movement.

Profile material

The most popular materials for making guides are aluminum and steel. They are strong enough to support doors, resistant to damage, easy to process, inexpensive - this makes mass production possible. Plastic and polymer options are less common, but they are short-lived, unreliable, and prone to breakage.

Steel

The main advantages of steel door guides are high strength, reliability, and resistance to mechanical damage. These profiles are cheaper than aluminum ones, which allowed them to gain a foothold in the Russian market.

The disadvantages of steel products include:

- it is difficult to find quality products among Russian manufacturers;

- tendency to corrosion - small cracks on the surface of the steel are enough for rust to appear, followed by slow destruction from the inside;

- design limitations - the color range of the guides is poor, they cannot be given an unusual texture.

Metal versions are produced by Russian companies, but there are exceptions - the Polish Laguna, the French Leroy Merlin. Due to their low prevalence, it is difficult to replace fittings when they break.

Aluminum

Aluminum products are more expensive than steel ones, but they do not have the inherent disadvantages of their competitors. These are durable, reliable, flexible guides of different models, dimensions, designs, and purposes. They are resistant to corrosion, moisture, temperatures, and mechanical stress, and therefore last a long time, rarely break, and are easy to repair.

Aluminum slats differ from steel slats in that they have thick walls because their structural strength is lower. But they weigh less, and therefore the door is easier to open.

Profile for sliding wardrobe doors: types and features

Sliding wardrobes come in different types, and accordingly, different profiles are used in them. By profile we mean the iron frame on which the cabinet itself is attached. The channel is located at the top and bottom of the facade, and is also used for the vertical handle. Profile for sliding wardrobe doors: we will look at its types and features in this article.

Made of metal

The use of a metal channel is practiced on budget models. It's too noisy and not very pretty. If there is high air humidity in the room, then over time this profile may become rusty. And if the wardrobe is made of ordinary chipboard, then it will not serve you for long. Many manufacturers have already abandoned the use of metal, replacing it with higher quality aluminum.

Aluminum

The most common and high-quality type is aluminum. For its manufacture I use aluminum alloy grade 6063, and the hardness class must be at least T5:

- The price of a sliding wardrobe depends on the thickness of the aluminum guide. The thicker its walls, the higher the quality. For example, a wall thickness of one millimeter is used for cheap models, but a channel with a thickness of 1.2 mm raises the price by thirty percent,

- Guides are made on the press and longitudinal strips run along its entire length. These are production costs and not every plant wants or can fight them. Those who lack qualifications or, in order to save money, leave everything as it is. But more responsible manufacturers are eliminating this defect. This is another indicator of the quality of an aluminum product,

- Next, it’s worth focusing on the geometry of the product. Aluminum is a very thin material and bends quite easily. If the calibration is done even slightly incorrectly, the profile will be very difficult to fill. To do this, you will have to make a lot of effort, and this can lead to a violation of the geometry. In order to avoid such a defect, the channel should be carefully examined from the side of the buffer pile. If there are no dents from the mallet, then the geometry is not broken. In addition, it is better to avoid assembling the cabinet yourself. If you bend a channel, no one will replace it for you, and it cannot be aligned, as shown in the photo. Therefore, it is better to entrust the assembly of the sliding wardrobe to specialists - if a defect is detected, the model can be replaced with another one,

- There is another side to the coin when the calibration is done upward. With this option, the cabinet door will slide off the profile. Alternatively, you can insert wedges or tighten a self-tapping screw, but this method is not suitable for mirrored doors and open wardrobes.

- Many buyers are afraid of Chinese channels and quite often sellers themselves come up with the country of origin. But not all Chinese products are bad; there are also high-quality models. But it’s better to beware of Chinese counterfeits of well-known brands. Therefore, the answer to the question of which profile is better for a sliding wardrobe will work longer with aluminum.

Roller system

The profile for a sliding wardrobe can also be checked using rollers. To do this, you just need to push the door lightly. With a good channel, it should silently slide into place. But if there is a poor-quality profile system, then you will have to apply force to close the door, and the closing process will be accompanied by an unpleasant rattling sound.

Previously, there was another problem - the doors came out of their grooves when closing, but at this stage of production it has been brilliantly solved. But still, you should not opt for too old models.

Most often, a frame channel is used to make facades, and the frame is made of decorative materials. But there is another option. In addition to the frame profile, solid fabric can also be used to make sliding wardrobes.

The main materials used to create door frames are aluminum, MDF, wood and thin sheets of steel. Such frames resemble a construction set; they are durable and light in weight. The most popular is aluminum, the frames of which are held on by mounting bolts. Such a frame consists of a lower channel, which is located horizontally, a vertical one, which serves as a handle, and a horizontal one, which is located at the top and serves as a connecting element.

The colors of the profiles for sliding wardrobes are selected according to the RAL scale. The most common compositions are imitation gold, bronze, silver or champagne, as shown in the photo. Wood imitation is also possible. For this purpose, lamination of the facade made of steel or aluminum is used. These options are most often used to create a classic look.

Models of radius sliding wardrobes have become increasingly popular. They look more original than regular ones and provide a wider range for design delights.

The profile for the radius cabinet is used differently than for stationary cabinets. The radius profile for sliding wardrobes can be made of aluminum or steel. And its dimensions must exceed 1.2 mm. The thicker the walls of the guide, the better the quality of the model. If you use a channel that is too thin, then over time the facade materials will begin to fall out, because they are under constant pressure, as they are located in a curved form, as can be seen in the photo.

The dimensions of the profile for the sliding wardrobe are regulated by the dimensions of the wardrobe itself. The standard height reaches 2.7 meters, and the width of the guide can be slightly less than 1 mm and significantly exceed 1.2 mm.

Let's sum it up

When choosing a sliding wardrobe, it is best to choose an aluminum profile with thick walls. A high-quality channel will ensure long-term use, and the color can be chosen according to your preferences or interior.

Characteristics

When deciding which profile to choose for a sliding wardrobe, look at the following characteristics:

- The thickness of the walls should be in the range of 1-1.6 mm - too narrow ones will bend or break, and thick ones will deform the cabinet.

- Durability. The manufacturer indicates the number of door opening-closing cycles for which the cabinet is designed. With a parameter of 60-70 thousand, the system will last 20 years.

When choosing, the reputation of the manufacturing company and user reviews of the products play an important role. Many focus on them rather than on objective quality criteria.

Types of profiles for sliding wardrobes

Lack of storage space is a problem in many modern apartments and houses. Even if the square meters allow you to create a Hollywood-style “walk-in closet,” the issue of convenient location and ease of access to things remains relevant. But it’s not enough for storage space to be structurally thought out - it also has to look good!

Traditional furniture does not always meet the objectives, and then modern storage systems and wardrobes come to the rescue. They allow you to optimize every centimeter of available space, and a huge number of design options will allow you to fit such a cabinet into any interior - both ultra-modern, minimalistic and classic.

Each wardrobe is individual, just like its owner. This furniture is designed and manufactured taking into account the most demanding requirements. From year to year, such cabinets will carefully store your things - shoes will no longer get tangled under your feet, coats will not look wrinkled, and hats, gloves and scarves will find a “summer refuge”.

Sliding wardrobes must be reliable - therefore, special attention is paid to the quality of materials and the strength of the structure itself. To manufacture sliding wardrobes, we use products from European manufacturers such as Komandor (Poland, under Canadian license), Kronopol (Poland), Raumplus, Egger (Germany).

There are also analogues of materials, their use will reduce the cost of a sliding wardrobe : for example, an analogue of Kronopol is Russian chipboard, produced under license in Nizhny Novgorod, an analogue of Raumplus is Chinese Aristo profiles. Some European manufacturers (Egger) are trying to completely move their production to “cheaper” countries - but at the same time they monitor the quality of their products with European thoroughness.

The choice of manufacturer remains with the buyer - the quality of the products differs slightly (in chipboard, in profiles the differences are more obvious), but if the brand, a well-known name is more important - then it is worth choosing “real” Europeans.

The choice of materials and components for sliding wardrobes is impressive: dozens of colors of laminated chipboard with different structures, finishing of sliding doors with artificial leather and fabric, drawings and photo printing applied to mirrors, doors made of rattan and bamboo, a variety of shelves, drawers, hooks and hangers, several types profiles...How can you find in this variety what is right for your interior?

Wardrobe system and profile - what is it and what are they?

The wardrobe system is a broader concept and includes rollers, guides (tracks) and a profile. The cabinet door is framed with a steel or aluminum frame - profile , while in the aluminum system the rollers are pressed inside the frames, and in the steel system - on the top and bottom on the inside of the door.

This does not affect the appearance of the furniture, because the rollers are not visible from the outside in any case, but hardly anyone will look at them from the inside.

All sliding wardrobe systems can be divided into groups according to the type of sliding and the material used.

Depending on the type of sliding, there are suspended and bottom sliding systems .

- In hanging systems, the door hangs on rollers and has a lock at the bottom. The cabinet door itself is made of 16-18 mm chipboard, and the mirrors are glued, so this design is heavy and more likely to fail. Nowadays, glass doors with a hanging system are common; they are mainly used as interior partitions, since the advantage of the hanging method is the absence of lower guides, i.e. "rail" on the floor.

- Bottom sliding systems are more durable. Firstly, cabinet doors are made of 8-10 mm. Chipboards are lighter and do not put extra load on the structure. Secondly, in this system, the door, using lower rollers, moves along a track-guide attached to the floor of the room or to the bottom panel of the cabinet, and the upper rollers and guide fix the door and prevent it from falling. In this case, the main load goes on the floor, and not on the rollers, which also affects the increase in the service life of such a wardrobe.

People often wonder how easy it is to clean the bottom rails from dirt? It is quite enough to go through a vacuum cleaner during normal cleaning; you can wash them with a washing vacuum cleaner or brush them with an old toothbrush.

Based on the material used, wardrobe systems are divided into aluminum and steel .

- Aluminum sliding door systems glide a little more softly and smoothly than steel ones, and the frame also doubles as a cabinet handle due to its shape. Aluminum wardrobe systems are more expensive than steel ones, they also look “more expensive”, more solid due to the larger profile width and neater joints. The Raumplus aluminum profile is available in 2 versions - symmetrical and asymmetrical, they differ in appearance, Komandor-a and Aristo have 3 options each. Colors range from gold and metallic to wood-look options, there are more than a dozen of them - there is plenty to choose from.

If you plan to install a wardrobe with a height of more than 3 meters, then the system option is only aluminum - Raumplus or Aristo, and if less than 3 meters, you can choose any profile. The width of the door when using a steel profile should be up to 70 cm, aluminum - up to 1m.10 cm.

- Komandor steel systems are made of stainless steel, a strong and durable material. In these systems, the rollers are located on the inside of the doors; they are invisible from the outside. The profile itself is thinner than aluminum, but the color range is no less varied.

Any of the wardrobe systems – both aluminum and steel – are of high quality and durable. Focus on the appearance - which one you like best, and the cost - are you willing to pay extra for an aluminum system.

Materials for sliding wardrobes: laminated chipboard (Kronopol, Kronostar, EGGER), rattan, bamboo, artificial leather, Glaverbel mirrors, glass.

Chipboard (chipboard) is a board made of compressed tarred sawdust, covered with a laminate plastic with a texture, most often a wood look. Laminated chipboards are produced by many companies; they vary in color and thickness - from 8 to 18 mm.

People have been using mirrored closet doors for many years - and this is not surprising, since mirrors can add volume and light to a room. Modern technologies make it possible to make mirrors even more diverse - you can order any design created by sandblasting or photo printing. Thus, the room will acquire an oriental flavor thanks to the image of sakura, Greek fervor - to the ornament or romance introduced by a delicate floral pattern. The combination of materials will allow you to create your own atmosphere in the house - add drama with black, red or white, use delicate pastel shades for a classic interior, unusual leather panels for a strict modernity or the warmth of oak, bamboo, rattan.

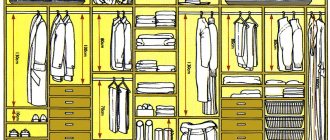

Internal filling of the wardrobe.

Custom-made furniture is good, first of all, because everything in it is made for you and for you. Your storage needs will be fully satisfied. Provide a place for hanging things: shorter for jackets, longer for coats, shelves for folding sweaters, T-shirts, drawers for underwear, mesh baskets for bedding, shoe racks and hooks. Modern storage systems will allow you to find a place for skis, a vacuum cleaner, tools - if you like to tinker. behind the chic sliding doors - while the workspaces can be of any depth, above them you can place a shelving add-on for a printer and folders with documents.

Make your choice - wardrobes and modern storage systems are an excellent company for your home for many years.

Use of the text of articles only with the permission of the author or when providing a link to this article.

Dimensions

Product parameters depend on the dimensions of the opening, door, connecting parts, and fasteners. They are calculated this way:

- the length of the horizontal guides corresponds to the distance between the side walls of the cabinet;

- between the vertical profile and the top of the compartment a gap of 2-4 mm is left for free movement of the rollers;

- the height of the guides depends on the type of model - the value ranges from 2-6 cm;

- The width of the slats is 8.5-10 cm; for triple, quadruple, and five-fold doors it increases due to the placement of additional rollers.

Profile sizes are calculated based on the door dimensions.

Standard door assembly kit with dimensions

Staining methods

Alkyd, acrylic, epoxy, and enamel paints are rarely used for processing planks. They are short-lived, easily crack, and peel due to constant movement.

The main ways to decorate profiles:

- Wrapping in PVC allows you to add different textures and shades, increases resistance to damage, and ensures silent movement of doors. Used to create wood textures.

- Anodizing is the coloring of metal with the creation of an oxide film on the surface. An anodic coating paints the surface and protects it from tarnishing, abrasion, fading, and increases the water resistance and strength of the guides. This method is chosen by the majority of leading companies, “Hephaestus”, “CityLine”, “Futurum”, “Absolute”, “Hettich”.

- Cataphoresis is a multi-stage chemical treatment that provides ideal coverage of the entire surface of the product, eliminating pores, cracks, and irregularities. Gives aluminum smoothness, uniform texture, and shine. Complemented with appliqué to simulate textures. Rarely used due to complexity.

- Brushing - thorough sanding with brushes, gives a matte finish, and cleans the product. More often it acts as an additional processing method.

- Veneering is covering a product with a thin layer of wood. Perfectly imitates the natural color and texture of different types of wood. The veneered profile is coated with transparent varnish or additionally painted to obtain the desired shade.