Furnishing the bedroom with a non-standard bed allows the owners to make the most of the free space and get a stylish room. At the same time, it is not at all necessary to buy an original bed with 2 tiers, complemented by auxiliary compartments. You can make it yourself. For work, you can use various materials: wood, derivative raw materials, iron.

Below we told you how to make a bunk bed with your own hands easily and simply. An exact list of the necessary tools, step-by-step instructions and assembly diagrams will help you make a homemade bed for your bedroom or your child’s bedroom. If desired, the proposed drawings can be modified to assemble unique models with dimensional parameters or non-standard shapes. The main thing is to take into account the detailing of the products and monitor the reliability of the connection of individual structural elements.

Mechanisms for transforming sofas under bunk beds

The sofas of the lower tier can have various transformation mechanisms. Based on this criterion, the following options are distinguished:

- Stationary. There is no folding mechanism. Optimal if there is no need for a full-fledged sleeping place, and the sofa is planned to be used as a relaxation area. Moreover, the seat of such a sofa is often wider than the mattress of the upper tier, and therefore, if necessary, it can be used as a single bed. This sofa can be used as a single bed. Often has built-in wardrobes.

- Eurobook. A fairly popular transformation mechanism that allows you to unfold the sofa quickly and without much effort. To do this, you need to pull out the seat and lower the backrest into the resulting niche, moving it to a horizontal position. The result is a full-fledged double bed, the dimensions of which depend on the model. Such models are very easy to unfold. Ideal for small apartments.

- Sofa book. A frequently encountered mechanism that an adult can easily dismantle, but not always a child. For transformation, the seat rises up, at the same time the backrest takes a horizontal position. Next, the seat lowers down until it clicks. The book sofa can be disassembled and assembled like a book.

- Transformer. Such designs in a few movements turn from an ordinary sofa into a bunk bed with a pair of single beds. The transforming sofa easily turns into a two-tier structure.

Note! The main disadvantage of a book sofa is the presence of a noticeable connection line between the seat and backrest. To eliminate it, you can use a thin orthopedic mattress.

How to make a bunk bed: step-by-step instructions

The standard version of the berth has two tiers on a common frame - upper and lower, located one above the other, which are connected by a staircase.

Calculations and drawing creation

When calculating the material, it is important to take into account the height of the room, so that you can sit on the second tier without touching the ceiling with your head. The age of the people for whom the product is intended also matters.

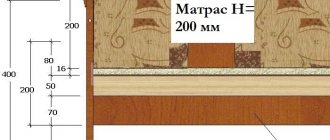

The calculations are based on the classic model of a wooden two-story bed for adults. Standard width – 80 cm. Length – 180 cm. Distance from the first level to the second – from 1 m. According to the average size, the product will cost:

- a sunbed 180 x 80 cm without a base (around the perimeter) is calculated by the formula: (180*2) + (80*2) = 520 cm, since there are 2 of them, then 520x2 = 1040 cm of boards or chipboard will be needed for two sunbeds;

- solid base for sunbeds – 180*80*2 = 288 m2;

- 4 beams for connecting the beds to each other. Taking into account the height of the sunbeds – 20 cm each + 100 cm – distance between tiers + 35 cm distance from the floor to the lower sunbed: (100+20+20+35) *4 = 700 cm;

- 4 horizontal bars 180 cm each;

- 4 end horizontal beams of 80 cm each.

The height of the bed is 175 cm, the height of the first tier is 35 cm from the floor, and the second is 135 cm from the floor. The width of the steps is 61 cm.

- calculation of bars for steps at a distance of 25 cm from each other: 135 (height of the second tier) divided by 25 (gap between steps), it turns out 135/25 = 5 steps (0.4 will leave an error). 5*61 = 305 cm of timber for the manufacture of lifting bars;

- reinforcing beams with a section of 20x20 mm for two bases: 180*80*4 = 1040 cm;

- a board made of a block with a cross-section of 30x40 mm is made on the facade of the second floor, corresponding to the length of the bed minus the staircase opening: 180 - 61 = 119 cm.

The calculation of a children's two-story bed is carried out in the same way, taking into account the size of the bed.

Metal corners and screws are used for fastenings. The structure has 8 connecting points with powerful beams. Each one uses 2 corners. For the main fastenings you need 100 g of self-tapping screws 80 mm long and 100 g 35 mm long for small fixations.

Based on the drawing, it is much easier to calculate the required amount of materials and minimize design errors. A visual diagram allows you to adjust the design according to individual parameters.

If you can’t draw up a drawing on your own, you can use furniture design and digital modeling programs. Most of them are easy to learn and have a simple and intuitive interface. They help you draw up a drawing of a bunk bed based on an individual project and build a layout according to non-standard parameters. Consider it from different angles and select colors and textures of the material.

Preparatory stage

Before making a two-level bed with your own hands, the material must be prepared for use.

- Chipboard, laminated chipboard or boards should lie in the house for 3-4 days to adapt the material to the humidity and temperature of a particular room. Treat surfaces with pest repellent.

- The wood must be sanded, leveled and treated with antiseptic agents.

- Metal workpieces must be cleaned, degreased and treated against corrosion.

Preparation of raw materials for use is carried out for the safety and durability of the finished product.

Making bed parts

To make the furniture reliable and beautiful, it is necessary to manufacture individual components in accordance with the chosen scheme or drawing.

Frame

Frames for mattress platforms are constructed from timber with a cross-section of 5*10 mm and fastened with metal staples. Angles or wood glue using the tongue-and-groove method are used as fasteners.

4 racks are made for the frame. At the height of the first and second levels, holes are made in them for the mounting screw. The same holes are made in the frames of the sun loungers.

The frame of the structure must be made of durable material and securely fastened. This part of the bed bears the main load.

Reasons

The base of the sunbeds on which the mattresses are placed can be solid or slatted. In the first case, more material will be needed, but the second option is less durable. Solid flooring is made of plywood or chipboard according to the size of the deck chair.

Plywood or transverse slats are placed and screwed onto the frames, located at an equal distance from each other.

Supports

They consist of 4 long horizontal beams in accordance with the length of the bed, 4 vertical bars with a section of 40x60 mm equal to the height of the structure. The support posts are made of thick and durable timber.

Headboards

These are two almost mirror-like elements of arbitrary shape and height. The footboard and headboard are attached to the ends of the supporting frame. These parts are made of plywood or chipboard.

Ladder

Beds with two tiers for children and adults require the creation of a ladder.

Types of stairs:

- vertical view - two planks are connected by crossbars;

- marching - a regular staircase with steps at an angle of about 70°;

- with built-in drawers - fills the free space under the stairs, making it functional.

For ease of use by children and adults, the optimal width of the staircase opening is 61 cm. The distance between steps is a minimum of 20 cm and a maximum of 25 cm. Two 4*6 cm beams are fixed to the bed frames. Install the crossbars, securing them with self-tapping screws. For the steps, boards with a section of 30x40 mm are cut.

For safety reasons, the flight of stairs is equipped with railings, and the steps are equipped with anti-slip pads.

Assembly and fastening

Try on finished parts.

After checking and making the necessary adjustments, they begin to form the structure.

- Having assembled the frame of the front and rear parts, connect the sidewalls into one structure, having previously cut off 4 end crossbars from the block. Assemble them with other parts of the bed, fasten the horizontal crossbars with corners.

- Sides and headboards are made from boards, which are attached to the edges of the frame. To do this, self-tapping screws are screwed in from the inside.

- Measure on the façade the location of the vertical post for the stairs. Cut the required number of steps. Attach them at a distance of 20-25 cm from each other. On the right, the screw is screwed into the vertical beam, and on the left through the bedpost.

- Cut the plywood the size of the bed, and secure the flooring to the supporting sections of the main beams with small self-tapping screws.

- For reliability, you can attach the structure to the wall with metal corners or screws.

Each hole for a furniture euroscrew must be drilled clearly parallel to the main surfaces, otherwise it will screw in awry and deform the part.

Decorative design

The children's sleeping bed can be painted in a color according to the gender of the child. Girls prefer bright shades: pink, yellow, purple. For boys - blue, light blue. You can decorate the fronts of the bed with drawings or decorative stickers. Cover the adult bed with matte varnish or stain. The façade looks beautiful with sides matching the color of the furniture. The edges are decorated with thermal tape or furniture edges.

Types of bunk beds and their functionality

There are many types of bunk beds, but the most common are the following:

- Traditional. The simplest option, consisting solely of two tiers and a staircase without additional elements. In this case, the tiers can either be located parallel or offset relative to each other, which can be convenient when there are significant space restrictions.

A bunk bed significantly saves space in the room. - With a sofa on the first tier. Allows you to improve both aesthetic and functional properties. A sofa looks neater than a bed and can comfortably accommodate guests, saving space without installing additional furniture. It can be used both as a sleeping place and as a relaxation area.

The lower part is a place to rest, and the upper part is a sleeping place. - With drawers. The staircase in this model consists of drawers or shelves, which, on the one hand, somewhat increases the size of the structure, and on the other hand, allows you to refuse to place a cabinet. There can also be a linen closet under the lower bed. A bunk bed with drawers is a comfortable sleeping place plus compartments in which you can easily hide clothes, bedding or toys.

- Attic. This design is designed for only one person, usually a child, although there are also angular variations that allow you to place two people on the upper tier. In it, the sleeping area is located upstairs, and the working area is downstairs. The latter includes a desktop, racks and shelves.

Bunk bed with work area below and ladder style cabinets. - Three bedroom. May have different appearances depending on requirements and space. The double bed is located either at the bottom or at the top.

Wooden triple bed with two places at the bottom and one at the top. - Transformer. Quite a popular model for one person with a lack of space. It consists of cabinets and drawers, a table and a sleeping place, and both the mattress and the table can be folded out or pulled out.

These beds come in various designs.

Important! When choosing such a model, you should pay special attention to its strength, as well as the height of the ceiling, since the lower level is quite high.

Step-by-step instructions for making a bed with your own hands

Assembling a 2-tier bed with your own hands is not a difficult task. But to obtain safe and reliable furniture, you need to carefully consider the plan for its assembly and draw up a detailed drawing of the product. Below we looked at master classes on how to independently assemble beds with two floors of different types. The proposed diagrams will help you easily make furniture without errors. When changing designs, it is recommended to maintain the proportions of the products and take into account the parameters of the materials used (if they differ from those proposed). This will eliminate the risk of assembling low-quality furniture that will not withstand the load and may be damaged during operation.

It is recommended to assemble the products in the room where they will be located. If manufacturing will take place in another room, make sure the finished furniture will fit through the bedroom doorway.

Loft bed: diagram, tools and manufacturing process

You need to make a bed with a “loft” immediately in the room where it will be used: subsequent transfer of furniture will be impossible. To work, you will need a beam with a cross-section of 10x10 cm, boards and slats with a thickness of more than 3 cm, a screwdriver, wood screws, a pencil, a level, a ruler, and a saw. To equip sleeping places, we recommend purchasing a ready-made slatted bottom with suitable dimensions. Using plywood to organize it will not allow you to obtain reliable and safe furniture. The structure should be assembled step by step according to the following scheme:

- Assembly of U-shaped sidewalls from timber. Additional fixation of the jumper from the board in the lower part (so that the “legs” of the bed are securely fastened).

- Assembling the top of the furniture: assembling a rectangle from boards turned edge up. Fastening 2 slats on the inside of the assembled plank rectangle to prepare the base for the slatted bottom.

- Attaching the U-shaped sides to the assembled top of the bed.

- Installation of the side to the base of the sleeping bed.

- Assembling a staircase from two beams and slats placed between them.

- Painting products with harmless paints, varnishing.

- Installation of slatted bottom, installation of stairs, laying of mattress.

Bunk bed with roll-out mechanism

A two-level bed with a roll-out mechanism has two sleeping beds located one above the other. But the distance from the base of the top to the base of the bottom remains minimal. Therefore, for assembly accuracy, we recommend drawing up a detailed design taking into account the optimal distance from bottom to top, at which the top one will not cling during the process of rolling out an additional stock. For work you will need: a 10x10 cm beam, a board and slats with a thickness of over 3 cm, a roll-out mechanism, 2 slatted bottoms, a screwdriver, a screwdriver, wood screws. The crib is assembled according to the following instructions:

- A small frame is assembled from timber, boards and slats (they act as the basis for the slatted bottom). The boards will determine the location of the upper sleeping bed.

- The lower sleeping bed is being assembled from boards. The slats are screwed into the assembled rectangle under the slatted bottom.

- The roll-out mechanism is being installed. Attaching the lower stock to the mechanism.

A bed with a roll-out second bed does not require a stationary ladder. It can be easily replaced by an attached model.

Solid wood duplex bed

A bed with 2 tiers made of solid wood is assembled from the following materials: timber with a section of 10x10 cm, boards and slats with a thickness of more than 3 cm, 2 slatted bottoms. The tools required for the job include a screwdriver, saw, level, pencil, and wood screws. Assembly is carried out as follows:

- Assembling the bases of sleeping boxes according to the size of the purchased slatted bottom from 4 boards (for each bed). Screwing around the perimeter of the assembled bases inside the slatted support to install the slatted bottom.

- Fastening the assembled bases to the 4 support beams. Please note that the distance between the sleeping beds must be at least 1 m (in addition, a mattress will be placed below).

- Making a side from slats and boards, attaching it to the top of the bed.

- Screwing vertical slats (vertical parts of the stairs) to the base boards.

- Screwing steps from slats to the vertical elements of the staircase.

- Painting the bed, varnishing the wood.

Bunk bed made of metal pipes and corners

An iron bed, if painted with high quality and equipped with plastic corner caps, can be used for both an adult and a teenage room. To make furniture you will need the following materials and tools: metal corners 45x50 mm, metal square pipes with a side of 25-30 mm, bed net, grinder with metal circles, welding machine, hacksaw for metal, curved U-shaped pipe (for the side) . Furniture should be made according to the following scheme:

- Welding the bases of the sleeping beds of the bed from the corners. Cutting out parts of the corners for their tight fit to the square pipes during subsequent welding of the elements.

- Welding the bases of the sleeping boxes to 4 pipes to create a strong frame.

- Welding the auxiliary legs to the lower sleeping bed.

- Welding the mesh and welding the side.

- Separately welding a ladder from square pipes and then welding it to the bed.

What materials are used for manufacturing

The choice of material is a key aspect when purchasing a bunk sofa bed. It could be as follows:

- Metal. The most durable and strong material that can last for several decades. It is difficult to damage, and therefore it will not lose its presentable appearance for a long time. Also, the metal base of the bed will not allow the mattress to sag even under significant load. However, metal is not very pleasant to the touch and does not always fit well into the interior. In addition, forged models rarely come with storage space, and their size cannot be adjusted.

Metal structures are rarely equipped with additional parts. - Tree. The most balanced option, since, on the one hand, it is durable, reliable and aesthetic, and on the other hand, it allows the structure to be equipped with a wide variety of storage spaces in any variations. However, high-quality wood is quite expensive. The most preferred species are oak, pine, beech, birch and ash.

Birch, ash, oak, pine and beech are most often used to make such beds. - Chipboard or MDF. They allow you to create a design in any style and color, and therefore are most often used for children's rooms. These materials are completely environmentally friendly and also have a more affordable price. However, they are often not strong enough. To ensure their quality, you should check the corresponding certificate when purchasing.

Bed-sofas made of MDF or chipboard are environmentally friendly and are often placed in children's rooms.

How to assemble a bunk bed: recommendations

After preparing the components, control measurements are taken, after which markings are applied. If all parts correspond to the drawing, assembly can begin. Special dowels are used as connectors. The sockets for their installation are marked with a pencil, then holes of the required diameter are drilled. After fitting, wood glue is applied to the protrusions and final assembly is carried out.

The bunk bed, the drawing of which is given below, is assembled in several stages. The glued base is fixed with clamps. After drying, it finally adheres to the screws. It is worth noting that the correct fit of parts is the key to the success of the construction of the entire structure, so disassembly and assembly can alternate many times during the process. With factory elements it is somewhat simpler, since they are adjusted in advance at the factory.

Filler for beds

The following materials can be used as fillers:

- Polyurethane foam (aka foam rubber). The most popular material, characterized by its durability and low cost. However, it has a certain rigidity, and therefore not everyone will be comfortable as the only material for sleeping.

Polyurethane foam has minimal thermal conductivity and is environmentally friendly. It is durable and easy to use. - A spring block whose springs are interconnected. This is a one-piece design, the individual springs of which work together. Most often it is used as a filler for sofas. The material is quite comfortable, but its service life is shorter than that of foam rubber, and after ten years the springs begin to lose their elasticity, which is why they burst and tear the upholstery.

A spring block whose springs are interconnected. - A spring block whose springs are free. The most advanced version of the filler, consisting of individual springs placed in a fabric cover. Under pressure, they begin to compress independently of each other, which allows them to take on the optimal shape.

In such a block, each spring is located in a separate case.

Important! When choosing, you should pay attention to the size of the springs, since as they decrease, the density of the sofa increases, and, consequently, the quality and durability.

Advantages and disadvantages of bunk beds

Double-decker beds are a fairly popular solution when decorating a room in cases where it is impossible to allocate a separate area for several people to sleep. The second tier is located at a height of 80-175 cm from the floor level, and a ladder is used to climb it.

Among the advantages of such a design as a bunk bed-sofa are a huge selection of models, a wide price range and versatility.

There are designs with built-in wardrobes, pencil cases and drawers, as well as with the replacement of the lower bed with a full-fledged workplace with a desk.

Option for a bunk bed with a desk.

The main advantage of such a bed is the rational use of space if it is limited. But other advantages can be highlighted:

- high strength, allowing the second floor to withstand loads of up to 120 kg;

- the presence of size rulers corresponding to different heights and ages;

- the ability to organize personal space for each person;

- a wide range of models allowing you to choose designs of the optimal configuration and style;

- the ability to sleep on a mattress without folds and seams that are present on folding models;

- multifunctionality, as a number of models are equipped with additional devices such as storage spaces;

- cost savings achieved by purchasing only one bed.

Note! In addition to the practical benefits, it is worth noting the sympathy of many people for the location on the second tier.

When purchasing a bunk sofa bed, pay attention to structural strength, versatility and price.

The disadvantages usually include the threat of falling from the upper level, but most models are insured against such an outcome, since they have limiting sides. Also, due to its height, the structure can significantly block sunlight, and therefore it is best to place it on the side opposite the window.

High sides near the bed on the top tier will protect your child from falling.

Use Cases

A bunk bed with a sofa is convenient for both teenagers and their parents and is the optimal solution when sharing is necessary. It allows you to ensure a full night's sleep and rest during the day. The sofa allows you to solve several problems at once:

- no need to purchase additional furniture;

- the ability not to make significant changes to the interior;

- space saving.

During the day, this design serves as a full-fledged sofa with cabinets, and at night it turns into a full-fledged sleeping place for parents and child.

Note! For especially small rooms, a transformable bunk bed with a folding sofa will be convenient, which allows you to free up additional space.

Such designs have a huge number of advantages and are very popular nowadays.

Alternative designs

In the version described above, the drawer is part of the overall frame, but often it is assembled separately. For example, the following design is possible from the same materials.

Using metal corners or glue and self-tapping screws, assemble two rectangular drawer frames, pre-attaching the support bars for the mattress to them

Just like in the previous version, you need to assemble the headboard and footboard separately. In this embodiment, the flat bars of the rack are not glued together into one, with a square cross-section, but form an angle. Two corner posts are connected by planks.

The drawer is fixed to the racks first with clamps, and then with bolts or self-tapping screws. The latter can be screwed in from the inside for invisible fastening

After installing both drawers, all the fences and stairs are attached, the slats are laid and the finishing is carried out

There is a variation of this option without slats. After assembling the drawer, with longitudinal beams, another frame is made from 60x30mm timber.

3–4 transverse struts made of the same timber are fixed in it, and the resulting bed is covered with plywood on top and bottom.

Under the mattress, take a thickness of 8 or 12 mm, and at the bottom, 4 mm is enough. For beauty, one side of the upper bed, the “ceiling” of the first tier, can be covered with fabric

This bed is placed in the drawer when the bed is fully assembled.

Children's bunk beds made of MDF can be made as a classic version, but the end parts (headboard and footboard) are made of a single sheet of material, possibly with holes. The longitudinal and side drawers are also made of MDF, but the support beam under the mattress is attached on all 4 sides of the bed, strengthening the connection of the parts.

In the manufacture of beds for adults, MDF, like laminated chipboard, is used only for decorative cladding of a frame assembled from beams. This supporting frame resembles the classic model described above, devoid of headboard, footboard and railings.

A completely alternative design is a bunk bed with hanging beds. It visually takes up much less space, but is too dangerous for small children.

In this design, the assembled drawer is screwed to the wall at several points along its entire length, and the free edge is suspended from the wall on a chain, like the top shelf in a reserved seat train car. The floating bed with illumination of the lower tier looks especially impressive.

If you are not yet ready to assemble a bunk bed, then we suggest that you familiarize yourself with a simpler version of a bed made from pallets.

Dimensions of bunk beds with a sofa below

When determining the size of the bed, you should take into account the age, height and weight of the people who will be accommodated on it. It should be borne in mind that a sleeping place for an adult should be 20-30 cm longer than his height. Also, you should not choose too narrow models, as this will negatively affect the quality of sleep.

If parents are used to sleeping separately, then this option will allow you to get three separate beds.

The dimensions of the sofa are determined by its functional purpose: if it is used as a relaxation area, it can be quite narrow, and if it is used as a sleeping place, it should be wider.

The transformable bunk bed-sofa not only looks original, but is also very versatile.

General assembly principle

Wooden elements used in the structure must be selected in size and have a smooth surface. To fix the transverse strips, side stops (drawbars) are used. During assembly, special glue is applied to them, and after installation, the boards are fixed using clamps. After the adhesive has dried, the clamps are removed and screws are screwed in flush in their place. If desired, the screw head can be masked with furniture plugs or putty. Particular attention is paid to the stability of the device. It must be designed in such a way as to withstand not only the weight of the child, but also his possible pranks or active games. In addition, if a sleeping place is being prepared for a preschooler, it should be built taking into account the fact that the child will grow.

Special requirements in arranging a bunk bed made of wood are placed on the legs on which the side panels are attached. These elements are best made from hardwood blocks. Additional stops are attached to the parts or grooves are cut out. To give the design an aesthetic appearance, patterns made of thick cardboard are used. It is advisable to make grooves using a jigsaw, which ensures the most accurate cut line. All roughness and cut areas are treated with sandpaper.

What criteria should you use to choose the bed itself and upholstery?

When choosing a bunk bed with a sofa, consider the following criteria:

- Price. Depends on the materials of manufacture, as well as the functional features of the design. It is influenced by the set of body elements, the possibilities of transforming the sofa, the composition of the filling and the upholstery.

- Material. You should pay attention to its quality and reliability.

- Transformation. The optimal solution when choosing the most ergonomic model is a two-tier transformable sofa. It is more expensive than stationary models, but more convenient to use.

- Functionality. There are many designs equipped with additional storage space in the form of niches, drawers and shelves. Before purchasing, you should decide on the need for such elements and their quantity.

- Interior style. The bed is a fairly tangible part of the room, and therefore it should fit harmoniously into the existing design, combining with other elements in texture, color, upholstery material, body and fittings.

- Stability, strength and safety. This is especially true when placing a child on the upper tier, since he will not only sleep there, but also play.

The choice of bunk beds with a sofa today is very huge.

You can choose a model based on quality, material, price and design. A bunk bed with a sofa below for parents is a functional and practical option when it is necessary to accommodate several people in conditions of limited space. Choosing a high-quality model will allow you to get a comfortable place to sleep and relax.

Dimensions and manufacturing diagrams, drawings

Before you make a bunk bed with your own hands, you need to take measurements of the room and decide on the desired size of the bed. Next, drawings are drawn up for all parts of the structure. Maintaining precision and accuracy in dimensions will allow you to get exactly the result that is needed.

You must first measure the room and determine the dimensions of the future bed.

The do-it-yourself bunk bed drawings for children indicate the following information:

- dimensions of the integral structure;

- methods of connecting nodes;

- parts assembly diagram;

- dimensions of fastening elements and parts;

- installation order of each part.