Preparation of material and tools

The tabletop can be cut from transparent, frosted, textured, tinted glass or mirror cloth. Transparent glass visually expands the interior of the room. A colored countertop can be an organic addition to the decor of the room. A dark color will create a “glamorous” style. A kitchen table with black glass, complemented by white chairs, will look impressive.

If you have no experience in making furniture, it is better to make a table with your own hands with a solid tabletop and metal legs. Having mastered the technology of working with such material, in the future you will be able to figure out how to make a table from glass of a more complex type.

To make a high-quality table you will need:

- sheet of glass;

- metal legs;

- suction cups for attaching to the tabletop;

- wood glue for metal and glass;

- gloves and safety glasses;

- metal-glass glue, polishing paste.

Tools for cutting glass: 1 – square; 2 – corborundum stone; 3 – compass for cutting glass; 4 – pliers; 5, 6, 7 – glass cutters.

- diamond or roller glass cutter;

- pliers with rubber pads;

- metal ruler of suitable length;

- grinder (grinder), drill;

- grinding discs, felt wheel;

- pencil for marking.

- file (emery block).

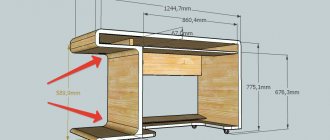

Glass should be purchased tempered, 6-12 mm thick. It must be clean and dry when cutting. On dirty material, the cut may be uneven. Having decided on the location of the homemade piece of furniture, plan its dimensions. Apply the accepted dimensions to the sketch. Mark the mounting locations for the legs.

Return to contents

Repairing a glass table is not an easy procedure. The fact is that, due to its transparency, the glass table shows all the mistakes that you may make while working. For this reason, you must act very carefully. The most popular problem among owners of such a product is getting rid of scratches. In order to avoid this, you need to properly care for the table.

Read also: The lathe apron is designed

Glass table (option 1) Glass table (option 2) Glass table (option 3) Glass table (option 4) Glass table (option 5) Glass table (option 6)

If you want to remove scratches and scuffs from glass, you can't do without valuable advice. Scratches spoil the appearance of the product, which had a neat appearance before this unpleasant incident.

1. Try toothpaste 2. Try ammonia solution 3. For deeper scratches 4. You can try jewelry polishing paste and pad

How to remove hated defects? First, prepare GOI paste. This special glue is sold in automotive stores. Pasta is sold by number. For glass products we will need the first or second number.

In order to get rid of cracks in glass, you need to grind the paste until it becomes crumbly. At the same time, it must be given homogeneity. Polish out any imperfections. In order to remove them, you need to dip a cotton swab into the crushed paste. You need to polish the scratches carefully, without pressing the stick. The procedure is repeated several times, and its duration is about ten seconds. Once polishing is complete, remove excess paste from the glass.

DIY countertop installation in the kitchen

Self-installation is only possible if you initially have some experience in installation work. The lighter the material, the easier it is to install it yourself. For example, wood or laminate countertops are much easier to install than stone, metal, or glass countertops.

If you have no experience in such work at all, then you should not undertake the installation of a countertop, even if all the instructions seem simple and understandable.

Work order during installation:

- Remove the old cover.

- They measure the dimensions of the old tabletop and, based on them, determine the dimensions of the new one, saw off unnecessary parts using a hacksaw or an electric jigsaw.

- After the excess has been cut off, it is necessary to process the edges and lubricate the ends with silicone-based sealant.

- Attach the aluminum beam.

- Make your own holes for the screws and connect the two parts.

- The baseboards are secured to the tabletop and the joints are sealed.

- Cut a hole for the sink and install it.

One of the peculiarities of installing a countertop in the kitchen yourself is that laminated table tops must be cut carefully, otherwise it will be difficult to hide the slightest inaccuracy or damage.

It is also necessary to take into account that wood, if damaged, can be easily restored by sanding and coating with a layer of varnish. Metal is recognized as one of the most durable materials, but various marks and scratches are clearly visible on it and are difficult to hide and polish. Covers made of stone (natural or artificial) are resistant to many factors: high temperature, mechanical damage, while stone products are difficult to install due to their impressive weight.

Did you manage to solve your problem using the recommendations from the article?

Yes!

51.52%

No. More answers required. I'll ask in the comments now.

27.27%

Partially. There are still questions. I'll write in the comments now.

21.21%

Voted: 33

Repairing a wobbly table

In order to repair a table leg that is wobbly, you need to understand the fasteners. The legs of the table were glued at the factory with a special glue, which may dry out over time. If the legs are secured with dowels, screws, screws, etc., they can simply be unscrewed and replaced. The legs can be glued if the tabletop is attached to them with adhesive bonds. In order to get to the damaged elements, the table is turned over in disassembled form. The screws are unscrewed from the tabletop itself. If a crack has formed on the leg under the tabletop, it can be glued. Place glue into the crack and cover it with a countertop.

If the glass tabletop is on a wooden frame

Glass table on wooden legs

We completely disassemble the base. We clean the old dowels from the old glue, apply new glue and put it in place. You can secure the loose leg with this tie. Screw the pin into the leg and tighten the tie plate into place with self-tapping screws.

You can strengthen the connections with metal elements. Give preference to the dowel. Insert one end of it into the cleaned hole, and sharpen the other so that it fits smoothly into the connection. Now you need to assemble the product. If you have never assembled it before, watch the video.

Glass table care

Taking care of a glass table

In order for the product to serve you as long as possible, it will require proper care. How to care for a glass table? First you need to figure out how to protect it from damage. If you cleaned the room, the table must be set. This will protect it from dust and possible damage. It is necessary to find a special approach to the glass table - wipe it with special compounds, protect it from exposure to direct sunlight and temperature changes.

If you have small children, a glass table could put their lives at risk. To prevent children from getting hurt or accidentally breaking the product, move the table away from children's games. It is best to install a glass table in places where it will be least exposed to household occupants. Pets are another risk to the existence of glass products. Fluffy fidgets can both break and scratch the table. For this reason, it is better to keep them away from the product. As you can see, if you properly treat a glass table, this piece of furniture can serve you for many years.

To glue glass to metal at home, you need to act very carefully and know several subtleties of the process, in particular, what exactly to glue. Glass is a delicate material, its properties affect how surfaces adhere to other matter.

When gluing, you need to pay attention not only to the use of methods for good adhesion of the glass surface and metal, but to maintaining the appearance of the product. Taking into account the product and the amount of work, they determine what can be used to glue the glass to the metal.

There are several types of glue for gluing:

- UV glue and UV lamp;

- Super glue;

- special adhesive type B 682-0, Verifix MV 750;

- epoxy adhesive;

- automobile;

- Moment;

- transparent silicone sealant.

What to use

First of all, you should decide what exactly you will use to glue these two, at first glance, non-glueable surfaces.

Before you begin, you need to prepare the necessary tools and fasteners.

There are enough options for adhesive compositions:

- Two-component epoxy adhesive. Valued for its high insulating properties, strength and electrical conductivity. Most often, this composition has a transparent color and consists of two components that need to be mixed. This glue is highly popular for its availability and ease of use.

- Heat resistant silicone. Typically this composition is used to glue glass to the oven. Basic performance qualities are indicated on the packaging, but, as a rule, after hardening, this glue is not afraid of high temperatures, fatty or oily environments. In addition, silicone can withstand low temperatures (down to -60 degrees Celsius).

- Moment-crystal. It is difficult to imagine an easier-to-use product for gluing metal and glass. The layer between the materials is elastic and resistant to various types of influences. Often used when gluing parts that will be subject to vibration loads.

- Automotive glue. Externally, the composition is very similar to rubber. Excellent for gluing glass and metal, however, due to the fact that this glue is black, it is not used very often.

Important: Whatever you choose, remember that it is important to carefully follow the recommendations on the packaging. Even if you have already “glued glass to metal a hundred times” and “the previous tube was almost the same.” The quality of repair work will depend on compliance with the instructions.

Waterproof, quick-drying mounting adhesive for mirrors and glass structures.

Using UV Glue

Often in the process of renovating an apartment, when a glass product or piece of furniture breaks, a situation arises when you need to know how to glue the metal to the glass. One way to remedy the situation when there is a large volume of work is to use an adhesive that contains a component such as methacrylic urethane resin. In addition, the work requires a special UV lamp, a degreasing compound and an industrial hair dryer.

Read also: How to cook aluminum with an inverter

In order for the parts to be glued to stick better, you need to polish and thoroughly treat the surfaces with a degreasing compound. What to replace it with? For these purposes, you can take regular alcohol. The next step is to heat the parts for gluing at the joining point a few degrees above room temperature.

Apply the adhesive and turn on the lamp for a few minutes. To apply the glue exactly to the right place, you can mark it with a marker. After hardening, the glue will become transparent and invisible at the attachment point. This must be taken into account if you need to glue not transparent glass, but frosted or colored glass.

The method of using UV glue and a lamp is considered expensive; its use is advisable if all components are present or there is a large gluing area.

What glue to use for glass and metal

To combine glass with metal, many household chemical products available in the assortment of hardware departments are suitable. But here you need to take into account that the gluing process itself is quite difficult to carry out. It is important to ensure strong adhesion of these two different materials and maintain an attractive appearance.

Cyanoacrylate

Under this difficult name lies the usual Superglue, which is easy to find in any store. It's easy to use. This is its main advantage over other adhesives. Simply squeeze the sticky mass onto the surfaces to be combined and press them briefly together. Clear glass and metal adhesive sets within 5 seconds. The result is a strong connection. The only condition is that when using a repaired item, you must not get it wet. The aqueous environment destroys the adhesive.

Bonding parts of kitchen appliances

Sometimes situations arise when you need to repair the oven or microwave door. If you decide to do this at home, the question arises: what glue should I use to glue the metal to the glass?

When choosing a connection agent, you need to pay attention to the following indicators:

- high degree of adhesion;

- elasticity;

- neutrality and exclusion of toxic emissions;

- heat resistance.

Specialized stores sell sealants for repairing kitchen appliances or glue with a silicone composition. For these purposes, you can purchase Dow Corning, but you can’t find it everywhere.

According to people who have encountered such a problem, there are other means that are no worse than imported ones, and in some ways better. Some suggest using an organosilicon compound based on rubber. This product does not emit toxic fumes, hardens without additional processing and can withstand temperature changes. It is up to the consumer to decide which product to use.

To glue glass in an oven or hob, clean the joints and dry them. Then apply glue to the metal according to the attached instructions. When repairing an oven, you have to carefully coat the metal joints, removing excess glue immediately, otherwise, after it hardens, it will be possible to remove smudges only with a special means.

Other craftsmen have found other ways to glue metal to glass:

- glue HC-1 and HC-2,

- glue BK-4,

- silicate glue,

- sealants for cars.

Auto glass

Car drivers often face the problem of replacing broken glass in their car. Of course, it is better to use the services of workshops, but every car owner should know the principle of replacement.

To glue glass to metal, treat the gluing areas with a pneumatic knife, removing fragments and old glue. Clean and degrease the body at the junction. The glass is treated with some kind of activator and automotive glue is applied.

Gluing glass to metal yourself is not difficult if you use the appropriate types of glue for the job and follow the instructions. You can repair glass tables, ovens and other items at home.

If you are tired of the old wooden tabletop, you can replace it with a glass one or make a glass table with your own hands. Many craftsmen are faced with the problem of attaching a new countertop. You will learn how to fix the glass on the table in this article.

Kitchen glass table: important nuances of choice

Tables with glass tops are no longer uncommon in the kitchen today. The range of these kitchen products is huge, but not all options are suitable for daily and long-term use. In order to choose the right glass table for the kitchen and not be disappointed in it, when purchasing this piece of furniture you need to take into account some nuances.

- The surface of a glass table top.

Transparent glass will retain all fingerprints, and since your family will gather at the dining table more than once a day, it is better to give preference to a matte table surface.

The original color of frosted glass has a greenish tint, which manufacturers today get rid of by tinting it with white. This correction allows you to use a glass table with a matte surface in a kitchen with any interior.

Tinting generally solves several problems at once:

- The color of the tabletop can be made in any shade;

- the glass surface can be decorated with an original pattern and there is no need to constantly polish the table;

- tinted frosted glass on the tabletop will hide your neighbors' legs to some extent (if this is important to you).

- Safety.

When choosing a glass top for your desk, don't hesitate to be a picky shopper: carefully inspect the glass surface to ensure its integrity. Scratches, cracks and blisters are not acceptable. In addition, the basis for such a table should be tempered glass - it is this that protects the product from scratches and deformation.

In a house where there are children, it is better to choose a glass table with streamlined smooth lines of corners, then accidental cuts are not scary for little fidgets. Pay attention to the quality of the polishing of the edges or the strength of the material framing them (most often, it is plastic or wood).

- Economical design.

Glass tables for the kitchen are usually compact - then they fit organically into the space of a small room. Don’t be upset if you have a large family: there’s enough room for everyone at the transforming table. Such products can be folded out or moved apart, turning into rectangular tables with a spacious tabletop for a pleasant time with family members.

Some manufacturers have also provided for changing the height of dining tables with glass tops: during the day, your children can study at a small, low table, and in the evening the table will rise and slide apart for a family dinner.

- Original elements.

The glass table occupies a central place in the kitchen, so use as much imagination as possible when choosing it.

A transparent table with a two-tier top will be an excellent option for any kitchen. On the lower tier you can store books, magazines, put mobile phones or a laptop there.

Much more scope for your imagination will open up if you choose a table whose tabletop is equipped with a built-in glass cabinet. Its spacious niche can be decorated with a flower arrangement, seashells and stones, or you can place a collection of souvenirs you brought from your travels there. In addition, the contents of the cabinet can be changed as often as you want.

The backlight adds even more originality to the table with a glass surface. If desired, you can make it yourself by attaching LED adhesive tape or miniature light bulbs of different colors to the edges of the table.

Depending on the type of glass tabletop, the table legs also vary. Most often they are wooden or chrome plated. Some models can be decorated with forged, wicker or plastic legs.

What is a glass table cover?

There are two types of glass top tables:

- Many people purchase glass tables with a monolithic top.

- There are also transformable tables that can increase the length of the tabletop.

Important! This option is indispensable for a large family. In addition, it is ideal for a home holiday feast.

Such coatings are made from three types of glass:

- Tinted. This option attracts more attention from visitors to the home. Using this coating, you can highlight the interior of the room in which the piece of furniture is located.

Important! It will look very original if you add black chairs to a black glass table in the kitchen.

- Matte. In this case, the glass takes on a slightly greenish color, as it is natural for such a material.

- Glass. In the interior of any room, such a design seems weightless and not as bulky as it actually is, and this adds a certain lightness and airiness to the room.

Read also: High pressure volute fan

Determining the design

Before you begin the process of making a glass table and purchasing the necessary materials, you need to carefully consider how it should look, decide where in the room it will stand, and how exactly it will be used.

You can solve this problem by making a glass table with your own hands.

According to functional characteristics, it can be:

- magazine,

- written,

- kitchen,

- and even computer.

A glass table with a properly selected base is weightless, which is especially important in small rooms.

By design they are divided into:

- mobile,

- transformers,

- sliding,

- with additional shelf.

Before you begin the process of making a glass table and purchasing the necessary materials, you need to carefully consider how it should look.

Depending on the shape of the glass tabletop, they can be:

- rectangular and square,

- round and oval,

- segmental (angular),

- non-standard.

Choosing a base (be it just legs or a finished structure with a frame for a glass surface).

When choosing a base (be it just legs or a finished structure with a frame for a glass surface), special attention should be paid to the overall interior of the room in which the table will stand:

- metal legs are ideal for high-tech style;

- forged or wooden legs paired with glass belong to the classic or loft style, and are suitable for any color scheme of the interior;

- if the main idea of the room is made in the style of minimalism, you can opt for a table made of glass or thin metal, while it is better to equip the table itself with wheels so that it can be moved to the right place at any time;

- in the case of a rustic interior, you can use rough wooden materials (logs, untreated bars), and oval or round tabletops will look best in such a pair.

Particular attention should be paid to the overall interior of the room in which the table will stand.

Pros and cons of the material

Before you move on to attaching the glass tabletop to the table, you need to understand all the advantages and disadvantages of the material you have chosen.

Let's start with the positive aspects:

- Original design. Glass tables make a very good impression and lift the mood of both residents and guests. This table looks especially great in a high-tech style interior.

- Resistance to external irritants. Many users are afraid to buy a countertop made of this material for fear that the glass may break. In fact, such a coating can be much stronger than wood.

- Moisture resistance and temperature resistance. Tempered glass is not frightened by actively changing environmental conditions.

- Easy care. Such tables are very hygienic and easy to care for, including removing coloring and greasy substances, which is a definite plus. For the same reason, ordinary wooden kitchen tables are inferior to glass-topped tables.

Before you attach the glass to the table, think about it, because this surface also has some minor disadvantages:

- There are many stains and marks left on the surface. This problem can be solved by purchasing a matte countertop.

- Even the smallest dirt is visible. You have to remove all the stains with a liquid designed for cleaning glass.

- The coating can be easily scratched.

- Creates a lot of noise when paired with kitchen utensils.

- High price.

Types of glass to create a tabletop

Several types of glass are used today in the manufacture of glass countertops. Let's list the main ones:

- Clear glass. The most popular option. The material does not cast a shadow and visually adds spaciousness to even the cramped room.

- Optical glass (optiwhite). The structure of this type of glass has a high degree of homogeneity. Optiwhite is equipped with diodes that, when turned on, illuminate the edges of the tabletop.

- Patterned colored glass. The material is not cheap, so it is not as in demand as, say, transparent glass. The product is based on laminated glass, each layer of which has an individual color. Together the layers create unique images within the glass.

- Frosted glass. Another popular product, very easy to use. The material practically does not create a shadow, easily camouflages minor scratches, does not require special care, and also hides the space under the countertop.

- Tinted glass. Most often, such countertops fit organically into the interior of a room decorated in high-tech or modern style.

- Mirror glass. A specific material that is used quite rarely for the design of countertops: the mirror surface will highlight all minor flaws in the form of scratches and water stains. At the same time, such glass has the ability to visually expand the walls in the room and will be a great idea for small rooms.

Let's move on to the attachment

Now is the time to get down to business. To do this you will have to follow this algorithm of actions:

- Make a hole at the ends of each leg.

- Attach suction cups to these holes using very strong glue.

Important! The adhesive used to attach the mirror surface will be visible through the transparent glass of the future table. In addition, such a composition takes a very long time to dry, which will be unacceptable for this work, unless, of course, there is an additional fastener on the leg.

- When the adhesive has dried, use a felt-tip pen to mark the locations of the furniture legs on the tabletop.

- Degrease the marked areas using acetone or gasoline.

- Glue the glass tabletop to the legs of the table and wait for it to fully set.

- Irradiate until the adhesive completely polymerizes.

Important! It is necessary to take into account that it will not be possible to tear off the tabletop and re-attach the glass, so it is necessary to measure everything perfectly accurately.

The glass top for the kitchen table is glued!

How to glue correctly

It turns out that you can glue it incorrectly. Only at first glance does this procedure seem so primitive. In addition to the recommendations indicated on the packaging of the adhesive composition, it is important to take into account the fact where the glued object will subsequently be used.

Despite the fact that a glass tabletop looks stylish and elegant even without the use of additional decor, it can be made even more interesting and attractive in appearance.

Among the general recommendations, it is worth noting the following:

- Never skip the point about degreasing surfaces. Often, the strength of the bond depends on the quality of the pre-treatment. After all, in this way all dirt and fatty layers that interfere with the strong adhesion of the two surfaces are removed.

- Paint, varnish and other coatings must also be removed from surfaces, since they significantly reduce the degree of adhesion.

- Warm up the glass surface before gluing. The optimal temperature is 30 degrees Celsius above zero. To achieve this figure, you will need a hair dryer. Important: remember that if there is a sharp change in temperature, the glass surface may crack, so heat gradually and with great care, fully controlling the process.

- To make the glue dry faster, use a press. The main thing is that the load is uniform, otherwise the glass will crack.

A glass tabletop is usually attached to one material, such as metal pipes.

Cyanoacrylate

The main advantages of this adhesive are its water resistance and minimal drying time.

Cyanoacrylate has many benefits.

The algorithm of actions is as follows:

- Surfaces are properly prepared. As already mentioned, you should not save time at this stage. Carry out degreasing as required by the instructions.

- The two components are mixed until a homogeneous mass is obtained. And remember, the mixture retains its plastic state for only a few minutes, then it hardens, and you will no longer be able to glue anything with it.

- The mixture is applied to the prepared surfaces and they are glued together.

- The tighter the connection you provide at the time of gluing, the more reliable the result will be.

The reliability of the result will depend on the quality of the materials.

Sealant

Sealant can also be used as an adhesive. Usually, thanks to the sealant, a high degree of joint insulation is achieved. And therefore, sealant as an adhesive is used in situations where it is required to provide not high strength, but water resistance.

Silicone sealant joints are very durable.

The algorithm of actions is almost the same as in the case of glue. The only caveat: it takes longer to dry. In addition, the strength of the connection is not as strong as after using special adhesives.

Sealant is often used for gluing furniture.

Moment crystal

Another composition that is universally popular. The moment forms a soft layer that allows you to withstand even slight displacement of the bonded surfaces. But after drying it regains its shape.

To avoid having to scrub off superglue, be as careful as possible when using it.

How to use Moment Crystal:

- Prepare the surfaces well, remove any remaining adhesive and paint. Heat the glass and metal, this will provide a more reliable connection.

- The adhesive is available in liquid or paste form. In any case, for more effective adhesion, you need to thoroughly level the adhesive over the surface.

- To enhance the effect, a high load should be placed on the surfaces to be glued, but remember, it must be uniform, otherwise the glass may burst.

- The amount of time required for drying is usually indicated in the instructions, but to be 100% sure, it is recommended to allow more time.

Glue very often does not end up where it was originally planned.

Automotive glue

Transparent car glue is available on sale. Thanks to it, you can also obtain a strong connection between surfaces made of different materials.

Automotive glue will help glue the legs to the tabletop.

The work order is as follows:

- Surfaces are prepared. All foreign substances and coatings are removed. Try to achieve maximum smoothness of the glued planes.

- For degreasing, products that do not leave a film are used.

- It is checked how tightly the surfaces are connected to each other.

- Using a construction hair dryer, the surfaces are heated to 30 degrees Celsius (not higher). Remember that both glass and metal surfaces heat up.

- The parts are arranged so that the seam is as horizontal as possible.

- While the surface is warm, the adhesive is applied and distributed evenly. If there is any excess that comes out, it should be removed immediately, as this will be difficult to do once it has hardened.

The most popular on the market are adhesives from English, Italian and German brands:

Automotive glue is offered today in a sufficient range. However, professionals recommend giving preference to products from well-known brands that have earned a serious reputation. Otherwise, you are not immune from unpleasant surprises.

Ultraviolet lamp

An ultraviolet lamp is another way to connect surfaces of different materials. It's quite simple to work with.

A UV lamp will help in gluing the table.

It is useful when, in order to attach a metal part to a glass base, you use special adhesives such as VERIFIX MV 750 or B 682-0.

UV adhesives from these manufacturers bond glass to metal and other materials.

To get a decent result, take into account the following recommendations:

- Before work, clean the surface, get rid of any small debris, as well as paint residues. Degrease the surfaces, but under no circumstances use gasoline or kerosene for this, as they leave a film behind. Special liquid degreasers are sold for glass.

- Warm up the surfaces with a construction hairdryer, and thanks to this, you will increase the level of adhesion. In this case, you need to heat it to 60 degrees.

- Apply a thin layer of glue, spread evenly over the surface and connect the parts.

- Now the ultraviolet lamp treatment begins. The surface to be bonded must be irradiated twice. After the first treatment, the strength of the connection reaches approximately 70%, and after the second we can safely talk about 100% conjugation. Remember that the duration of irradiation depends on the power of the device. And the first stage of irradiation is usually much longer than the second.

Obviously, today there are enough means available with which you can glue a glass tabletop to metal. They differ in price and method of application, but in general, most adhesives guarantee a decent result.

Carry out all work carefully.

Exploitation

A glass tabletop needs to be handled very carefully. For this reason, it is necessary to follow a number of mandatory rules for caring for the surface:

- Such a covering is wiped only with artificial suede or a microfiber cloth - these materials leave a minimal amount of stains.

- To clean the coating, household chemicals are used, namely glass and mirror surface cleaners. This should be done approximately 1-2 times a week, as there is a risk of aggressive chemical compounds getting on the food.

- You can easily get rid of scratches by sanding the surface with GOI paste, toothpaste or Polarit.

- To prevent scratches and chips, place special napkins on the table - they are quite easy to find in stores.

How to lay film on a glass table

The overlay is laid on the surface without any particular difficulties, but it requires following a special algorithm:

- Before covering the table with film, it is wiped from dirt and dust so that the stains are absolutely invisible.

- Then the “soft glass” is spread on the surface and pressed against it with both hands.

- If bubbles have formed under the cover, the “liquid glass” should be carefully lifted, spray the surface with water from a spray bottle, and press again. This method of installation will allow air to escape along with water, and the magnetic film will be leveled on the table.

Video material

A table is a key element of the interior, and it doesn’t matter whether it’s a dining table or a coffee table. Tables with glass tops look especially interesting, because the interior takes on a completely new look when such an element appears in it. From this article, you learned how to attach glass to a tabletop without glue, so that its remains do not spoil the final impression.

ATTENTION TO THOSE WHO WANT TO REGISTER ON THE FORUM. Problem activating your account? Write to (ignel(gav)mail.ru, ICQ 50389649), indicating your nickname and the address from which you registered. Don't forget to look at the forum rules. Ignorance of the rules does not exempt you from responsibility! Don't forget to look at the TB Section. Knowing the rules can save lives. Have questions about using the forum? Look for answers in the FAQ (FAQ). There's a lot of useful stuff there. Looking for interesting materials? Guide to master classes from our forum members

- Artisan »

- Our works »

- We make it ourselves (Moderator: AndyAB) »

- Topic: How to attach a glass tabletop to legs?

Author Topic: How to attach a glass tabletop to legs? (Read 89243 times)

0 Users and 1 Guest are viewing this topic.